ASTM E3286-21

(Practice)Standard Practice for Preparation Of Cell Monolayers on Glass Surfaces for Evaluation of Microbicidal Properties of Non-Chemical Based Antimicrobial Treatment Technologies

Standard Practice for Preparation Of Cell Monolayers on Glass Surfaces for Evaluation of Microbicidal Properties of Non-Chemical Based Antimicrobial Treatment Technologies

SIGNIFICANCE AND USE

5.1 There are no reproducible standardized protocols for preparing specimens used to evaluate the microbicidal efficacy of non-chemical treatments such as ultraviolet (UV), highenergy electron beam, or other forms of non-chemical antimicrobial technologies.

5.2 Conventional protocols for applying bioburdens to carriers (see Test Method E2197) cause cells to stack upon one another, thereby creating multiple cell layers in which cells in layers closer to the carrier are masked by cells in overlying layers, which makes relative comparison of different non-chemical antimicrobial treatments more difficult.

5.3 Steel and other metal carriers have asperities that can shield a percentage of the applied cells from direct exposure to electromagnetic irradiation.

5.4 The combined effects of 5.2 and 5.3 confound determination of the microbicidal effect of electromagnetic irradiation on test specimens.

5.5 The practice addresses these two confounding factors by:

5.5.1 Using glass microscope slides – the surfaces of which are asperity-free – as carriers.

5.5.2 Reliably depositing bacterial cells onto the carrier as a monolayer.

5.6 The resulting specimen ensures that all microbes deposited onto the carrier are exposed equally to the irradiation source thereby ensuring that the only variables are the controlled ones – starting inoculum concentration, wavelength (λ – in nm), exposure time(s), and resulting energy dose (J).

SCOPE

1.1 This practice provides a protocol for creating bacterial cell monolayers on a flat surface.

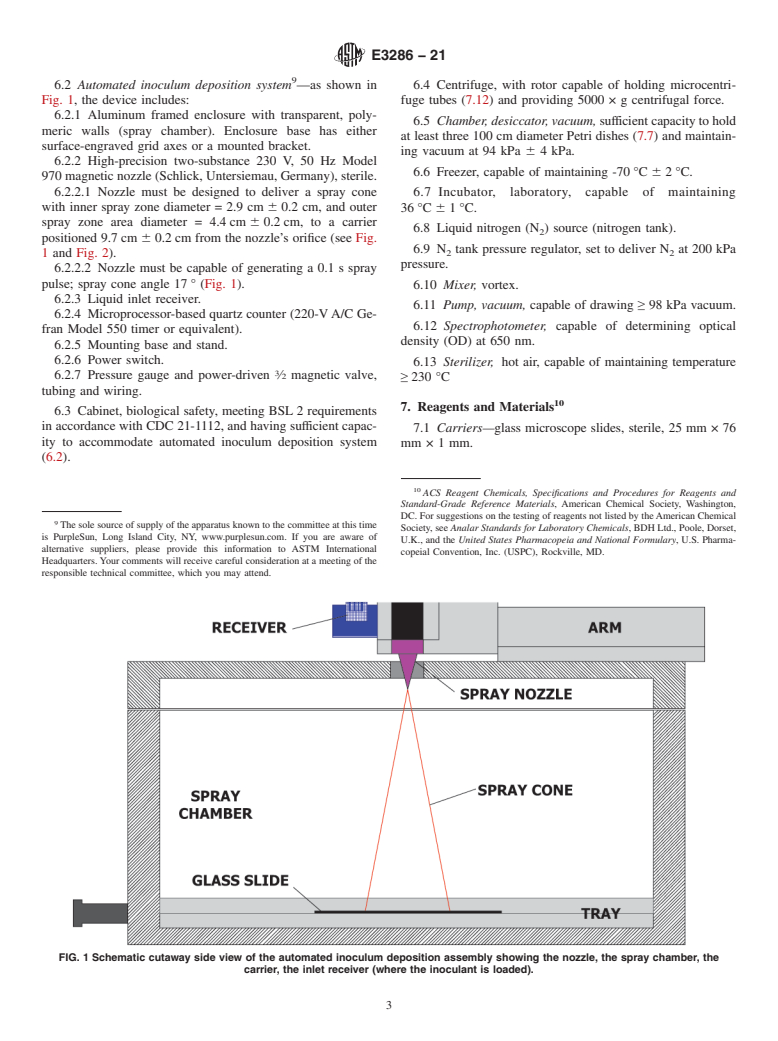

1.2 The cultures used and culture preparation steps in this Practice are similar to AOAC Method 961.02 and US EPA MB-06. However, test bacteria are applied to the carrier using an automated deposition device (6.2) rather than as a suspension droplet.

1.3 The carrier inspection protocol is similar to US EPA MB-03 except that carrier surfaces are inspected microscopically rather than visually, unaided.

1.4 A monolayer of cells eliminates the confounding effect caused by the shadowing effect of outer layers of bacteria stacked upon other bacteria on test specimens – thereby attenuating directed energy beams (that is, ultraviolet light, high-energy electron beams) before they can reach underlying cells.

1.5 An asperity-free surface eliminates the shadowing effect of specimen surface topology that can block direct exposure of target bacteria to non-chemical antimicrobial treatments.

1.6 This practice provides a reproducible target microbe and surface specimen to minimize specimen variability within and between testing facilities. This facilitates direct data comparisons among various non-chemical antimicrobial technologies.

1.6.1 Antimicrobial pesticides used in clinical and industrial applications are expected to overcome shadowing effects. However, this practice meets a need for a protocol that facilitates relative comparisons among non-chemical antimicrobial treatments.

1.6.2 This practice is not intended to satisfy or replace existing test requirements for liquid chemical antimicrobial treatments (for example Test Methods E1153 and E2197) or established regulatory agency performance standards such as US EPA MB-06.

1.7 This practice was validated using Staphylococcus aureus (ATCC 6538) and Pseudomonas aeruginosa (ATCC 15442) using a protocol based on AOAC Method 961.02. If other cultures are used, the suitability of this practice must be confirmed by inspecting prepared surfaces, by using scanning electron microscopy (SEM) or comparable high-resolution microscopy.

1.8 The specimens prepared in accordance with this practice are not meant to simulate end-use conditions.

1.8.1 Non-chemical technologies are only to be used on visibly clean, non-porous surfaces. Consequently, a soil load is not used.

1.9 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.10 Th...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E3286 − 21

Standard Practice for

Preparation Of Cell Monolayers on Glass Surfaces for

Evaluation of Microbicidal Properties of Non-Chemical

1

Based Antimicrobial Treatment Technologies

This standard is issued under the fixed designation E3286; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This practice was validated using Staphylococcus au-

reus (ATCC 6538) and Pseudomonas aeruginosa (ATCC

1.1 This practice provides a protocol for creating bacterial

15442) using a protocol based on AOAC Method 961.02. If

cell monolayers on a flat surface.

other cultures are used, the suitability of this practice must be

1.2 The cultures used and culture preparation steps in this

confirmed by inspecting prepared surfaces, by using scanning

Practice are similar to AOAC Method 961.02 and US EPA

electron microscopy (SEM) or comparable high-resolution

MB-06. However, test bacteria are applied to the carrier using

microscopy.

an automated deposition device (6.2) rather than as a suspen-

1.8 Thespecimenspreparedinaccordancewiththispractice

sion droplet.

are not meant to simulate end-use conditions.

1.3 The carrier inspection protocol is similar to US EPA

1.8.1 Non-chemical technologies are only to be used on

MB-03 except that carrier surfaces are inspected microscopi-

visiblyclean,non-poroussurfaces.Consequently,asoilloadis

cally rather than visually, unaided.

not used.

1.4 A monolayer of cells eliminates the confounding effect

1.9 Units—The values stated in SI units are to be regarded

caused by the shadowing effect of outer layers of bacteria

asstandard.Nootherunitsofmeasurementareincludedinthis

stacked upon other bacteria on test specimens – thereby

standard.

attenuating directed energy beams (that is, ultraviolet light,

1.10 This standard does not purport to address all of the

high-energy electron beams) before they can reach underlying

safety concerns, if any, associated with its use. It is the

cells.

responsibility of the user of this standard to establish appro-

1.5 Anasperity-freesurfaceeliminatestheshadowingeffect

priate safety, health, and environmental practices and deter-

ofspecimensurfacetopologythatcanblockdirectexposureof

mine the applicability of regulatory limitations prior to use.

target bacteria to non-chemical antimicrobial treatments.

1.11 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.6 Thispracticeprovidesareproducibletargetmicrobeand

ization established in the Decision on Principles for the

surface specimen to minimize specimen variability within and

Development of International Standards, Guides and Recom-

between testing facilities. This facilitates direct data compari-

mendations issued by the World Trade Organization Technical

sons among various non-chemical antimicrobial technologies.

Barriers to Trade (TBT) Committee.

1.6.1 Antimicrobialpesticidesusedinclinicalandindustrial

applications are expected to overcome shadowing effects.

2. Referenced Documents

However, this practice meets a need for a protocol that

2

2.1 ASTM Standards:

facilitates relative comparisons among non-chemical antimi-

D5465Practices for Determining Microbial Colony Counts

crobial treatments.

from Waters Analyzed by Plating Methods

1.6.2 This practice is not intended to satisfy or replace

E1153TestMethodforEfficacyofSanitizersRecommended

existing test requirements for liquid chemical antimicrobial

for Inanimate, Hard, Nonporous Non-Food Contact Sur-

treatments (for example Test Methods E1153 and E2197)or

faces

established regulatory agency performance standards such as

E2197Quantitative Disk Carrier Test Method for Determin-

US EPA MB-06.

ing Bactericidal, Virucidal, Fungicidal, Mycobactericidal,

1

This practice is under the jurisdiction ofASTM Committee E35 on Pesticides,

2

Antimicrobials, and Alternative Control Agents and is the direct responsibility of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Subcommittee E35.15 on Antimicrobial Agents. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Oct. 1, 2021. Published November 2021. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E3286–21 the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.