ASTM C167-22

(Test Method)Standard Test Methods for Thickness and Density of Blanket or Batt Thermal Insulations

Standard Test Methods for Thickness and Density of Blanket or Batt Thermal Insulations

SIGNIFICANCE AND USE

4.1 Proper measurements of thickness and density of blanket or batt insulations are essential for determining thermal insulation properties. For a particular batt or blanket product, thickness and density are usually directly related to thermal insulating value.

4.2 These test methods are of significant value in manufacturing quality control, to ensure that claimed insulation values of products are maintained.

SCOPE

1.1 These test methods cover the determination of thickness and density of flexible, felted, or woven thermal insulating blankets, rolls, or batts composed of fibrous materials, with or without surface covering or reinforcement.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C167 − 22

Standard Test Methods for

Thickness and Density of Blanket or Batt Thermal

1

Insulations

This standard is issued under the fixed designation C167; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 package—an individually wrapped group or bag of

1.1 These test methods cover the determination of thickness

batts or a single roll of thermal insulation material.

and density of flexible, felted, or woven thermal insulating

blankets, rolls, or batts composed of fibrous materials, with or

4. Significance and Use

without surface covering or reinforcement.

4.1 Proper measurements of thickness and density of blan-

1.2 The values stated in inch-pound units are to be regarded

ket or batt insulations are essential for determining thermal

as standard. The values given in parentheses are mathematical

insulation properties. For a particular batt or blanket product,

conversions to SI units that are provided for information only

thickness and density are usually directly related to thermal

and are not considered standard.

insulating value.

1.3 This standard does not purport to address all of the

4.2 These test methods are of significant value in manufac-

safety concerns, if any, associated with its use. It is the

turing quality control, to ensure that claimed insulation values

responsibility of the user of this standard to establish appro-

of products are maintained.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

5. Apparatus

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

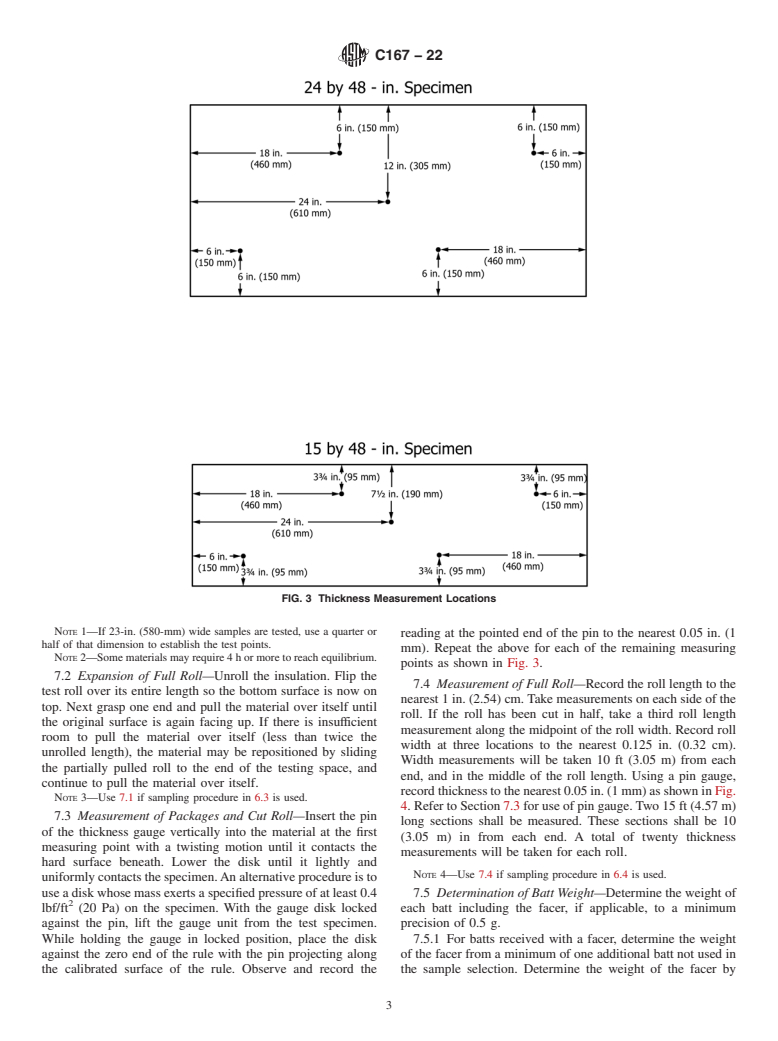

5.1 Depth Gauge,ofthetypeshowninFig.1.Thediskshall

ization established in the Decision on Principles for the

be fabricated of a suitable plastic material. The disk shall have

Development of International Standards, Guides and Recom-

a mass of 9.3 6 0.3 grams and shall exert a pressure of 0.4

2

mendations issued by the World Trade Organization Technical

lbf/ft (20 Pa). The disk shall be 3-in. 6 0.08-in. (76 mm 6

Barriers to Trade (TBT) Committee.

2mm) in diameter. The disk shall be perpendicular to the pin at

all times and shall have a friction device or thumb grip to

2. Referenced Documents

secure the pin unless purposely moved. The pin shall be made

2

1

at a maximum ⁄8-in. (3 mm) diameter. The pin shall be of

2.1 ASTM Standards:

sufficient length for the material to be measured.

C168 Terminology Relating to Thermal Insulation

E2935 Practice for Evaluating Equivalence of Two Testing

5.2 Steel rule, graduated in 0.05-in. or 1-mm intervals.

Processes

5.3 Scales, of sufficient capacity and sensitivity to weigh the

test specimen to an accuracy of 60.5 %.

3. Terminology

5.4 An alternative thickness measurement technique is con-

3.1 Definitions—Terminology C168 shall be considered as

sidered acceptable if the alternative method and depth gauge

applicable to the terms used in these test methods.

presented in 5.1 meet the means equivalency analysis as

directed in Section 7 of Practice E2935. The equivalence limit

of 0.2 in., a confidence level of 95 %, and minimum sample

1

These test methods are under the jurisdiction of ASTM Committee C16 on

size of 50 shall be used in the equivalency analysis. The

Thermal Insulation and are the direct responsibility of Subcommittee C16.32 on

Mechanical Properties.

equivalence analysis must cover the range of thickness for

Current edition approved Nov. 1, 2022. Published December 2022. Originally

which it will be used.

approved in 1941. Last previous edition approved in 2018 as C167 – 18. DOI:

10.1520/C0167-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 6. Sampling

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1 A test sample shall consist of one representative roll or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. package of insulation.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C167 − 22

FIG. 1 Depth Gauge for Thickness Measurements

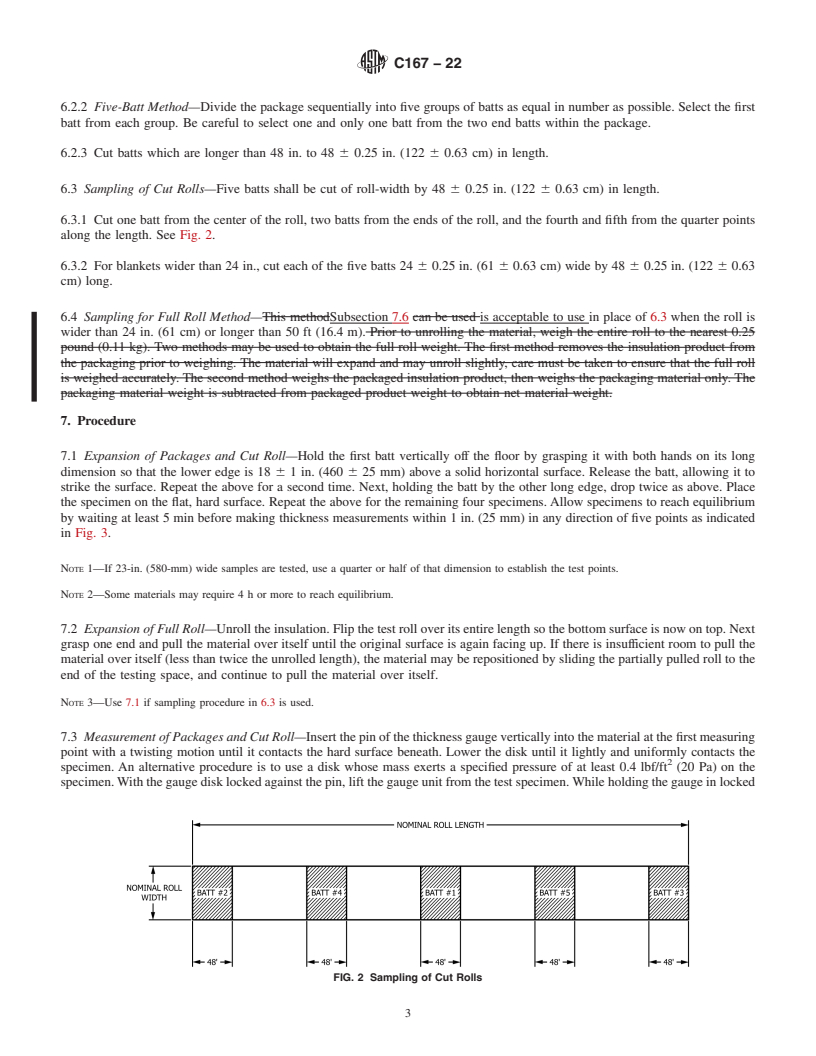

6.2 Sampling of Packages—For packages which contain 20 6.3.2 For blankets wider than

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C167 − 18 C167 − 22

Standard Test Methods for

Thickness and Density of Blanket or Batt Thermal

1

Insulations

This standard is issued under the fixed designation C167; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods cover the determination of thickness and density of flexible, felted, or woven thermal insulating blankets,

rolls, or batts composed of fibrous materials, with or without surface covering or reinforcement.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C168 Terminology Relating to Thermal Insulation

E2935 Practice for Evaluating Equivalence of Two Testing Processes

3. Terminology

3.1 Definitions—Terminology C168 shall be considered as applicable to the terms used in these test methods.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 package—an individually wrapped group or bag of batts or a single roll of thermal insulation material.

4. Significance and Use

4.1 Proper measurements of thickness and density of blanket or batt insulations are essential for determining thermal insulation

properties. For a particular batt or blanket product, thickness and density are usually directly related to thermal insulating value.

1

These test methods are under the jurisdiction of ASTM Committee C16 on Thermal Insulation and are the direct responsibility of Subcommittee C16.32 on Mechanical

Properties.

Current edition approved Nov. 1, 2018Nov. 1, 2022. Published November 2018December 2022. Originally approved in 1941. Last previous edition approved in 20152018

as C167 – 15.C167 – 18. DOI: 10.1520/C0167-18.10.1520/C0167-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C167 − 22

4.2 These test methods are of significant value in manufacturing quality control, to ensure that claimed insulation values of

products are maintained.

5. Apparatus

5.1 Depth Gauge, of the type shown in Fig. 1. The disk shall be fabricated of a suitable plastic material. The disk shall have a

2

mass of 9.3 6 0.3 grams and shall exert a pressure of 0.4 lbf/ft (20 Pa). The disk shall be 3-in. 6 0.08-in. (76 mm 6 2mm) in

diameter. The disk shall be perpendicular to the pin at all times and shall have a friction device or thumb grip to secure the pin

1

unless purposely moved. The pin shall be made at a maximum ⁄8-in. (3 mm) diameter. The pin shall be of sufficient length for

the material to be measured.

5.2 Steel rule, graduated in 0.05-in. or 1-mm intervals.

5.3 Scales, of sufficient capacity and sensitivity to weigh the test specimen to an accuracy of 60.5 %.

5.4 An alternative thickness measurement technique is considered acceptable if the alternative method and depth gauge presented

in 5.1 meet the means equivalency analysis as directed in Section 7 of Practice E2935. The equivalence limit of 0.2 in., a

confidence level of 95 %, and minimum sample size of 50 shall be used in the equivalency analysis. The equivalence analysis must

cover the range of thickness for which it will be used.

6. Sampling

6.1 A test sample shall consist of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.