ASTM C1775-22

(Specification)Standard Specification for Laminate Protective Jacket and Tape for Use over Thermal Insulation for Outdoor Applications

Standard Specification for Laminate Protective Jacket and Tape for Use over Thermal Insulation for Outdoor Applications

SCOPE

1.1 This specification addresses the minimum performance for flexible laminate protective jacket and a pressure sensitive adhesive tape for use over thermal insulation on pipes, duct, and equipment operating at both above and below ambient temperatures and installed outdoors, above ground. It does not include the following: protective metal jacket, homogenous plastic film jacket materials, modified asphalt jacket materials, and butyl rubber membranes.

1.2 This type of material shall consist of multiple layers of polymer film and aluminum foil laminated to one another with layer(s) of reinforcement as an option.

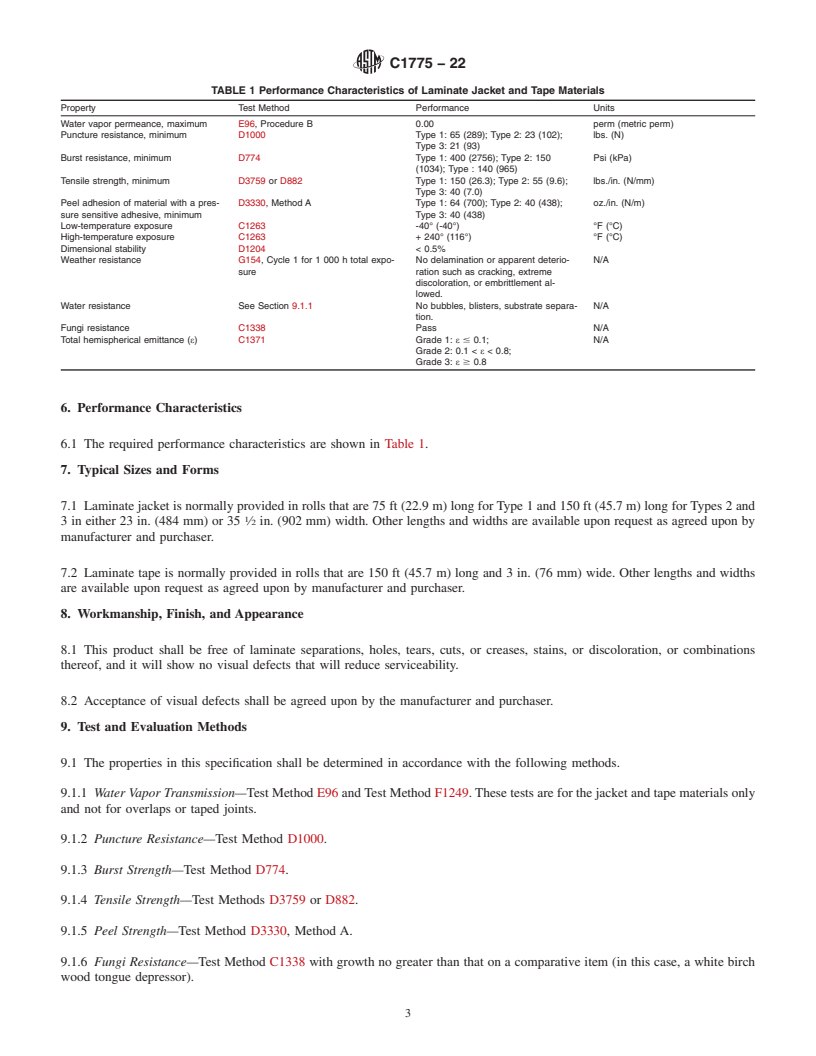

1.3 Jacket and tape materials covered by this specification shall have low water vapor permeance values; however, they are not necessarily always used as vapor retarders. The water vapor transmission tests address the jacket and tape materials only and do not address overlaps or taped joints. All materials shall be weather resistant and intended to have sufficient strength to provide protection for mechanical insulation.

1.4 Materials covered under this specification shall have a high, medium, or low surface emittance.

1.5 The top layer shall be on of the following: aluminum foil, a polymer film, or a polymer coating.

1.6 This specification includes jacket materials both with and without factory applied, pressure sensitive adhesives. The tape materials covered by this specification always have a factory applied, pressure sensitive adhesive.

1.7 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:C1775 −22

Standard Specification for

Laminate Protective Jacket and Tape for Use over Thermal

1

Insulation for Outdoor Applications

This standard is issued under the fixed designation C1775; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.1 This specification addresses the minimum performance

mine the applicability of regulatory limitations prior to use.

for flexible laminate protective jacket and a pressure sensitive

1.9 This international standard was developed in accor-

adhesive tape for use over thermal insulation on pipes, duct,

dance with internationally recognized principles on standard-

and equipment operating at both above and below ambient

ization established in the Decision on Principles for the

temperatures and installed outdoors, above ground. It does not

Development of International Standards, Guides and Recom-

include the following: protective metal jacket, homogenous

mendations issued by the World Trade Organization Technical

plastic film jacket materials, modified asphalt jacket materials,

Barriers to Trade (TBT) Committee.

and butyl rubber membranes.

1.2 This type of material shall consist of multiple layers of

2. Referenced Documents

polymer film and aluminum foil laminated to one another with 2

2.1 ASTM Standards:

layer(s) of reinforcement as an option.

C168 Terminology Relating to Thermal Insulation

1.3 Jacket and tape materials covered by this specification C1263 Test Method for Thermal Integrity of Flexible Water

shall have low water vapor permeance values; however, they

Vapor Retarders

are not necessarily always used as vapor retarders. The water C1338 Test Method for Determining Fungi Resistance of

vapor transmission tests address the jacket and tape materials

Insulation Materials and Facings

only and do not address overlaps or taped joints. All materials C1371 Test Method for Determination of Emittance of

shall be weather resistant and intended to have sufficient

Materials Near Room Temperature Using Portable Emis-

strength to provide protection for mechanical insulation. someters

D774 Test Method for Bursting Strength of Paper

1.4 Materials covered under this specification shall have a

D882 Test Method for Tensile Properties of Thin Plastic

high, medium, or low surface emittance.

Sheeting

1.5 The top layer shall be on of the following: aluminum

D1000 Test Methods for Pressure-Sensitive Adhesive-

foil, a polymer film, or a polymer coating.

Coated Tapes Used for Electrical and Electronic Applica-

1.6 This specification includes jacket materials both with tions

and without factory applied, pressure sensitive adhesives. The D1204 Test Method for Linear Dimensional Changes of

tape materials covered by this specification always have a Nonrigid Thermoplastic Sheeting or Film at Elevated

factory applied, pressure sensitive adhesive. Temperature

D3330 Test Method for PeelAdhesion of Pressure-Sensitive

1.7 The values stated in inch-pound units are to be regarded

Tape

as standard. The values given in parentheses are mathematical

D3759 Test Method for Breaking Strength and Elongation of

conversions to SI units that are provided for information only

Pressure-Sensitive Tape

and are not considered standard.

E96 Test Methods for Gravimetric Determination of Water

1.8 This standard does not purport to address all of the

Vapor Transmission Rate of Materials

safety concerns, if any, associated with its use. It is the

F1249 Test Method for Water Vapor Transmission Rate

Through Plastic Film and Sheeting Using a Modulated

Infrared Sensor

1

This specification is under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.40 on

2

Insulation Systems. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2022. Published March 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2013. Last previous edition approved in 2014 as C1775 – 14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1775-22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1775−22

G154 Practice

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1775 − 14 C1775 − 22

Standard Specification for

Laminate Protective Jacket and Tape for Use over Thermal

1

Insulation for Outdoor Applications

This standard is issued under the fixed designation C1775; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification addresses the minimum performance for flexible laminate protective jacket and a pressure sensitive adhesive

tape for use over thermal insulation on pipes, duct, and equipment operating at both above and below ambient temperatures and

installed outdoors, above ground. It does not include the following: protective metal jacket, homogenous plastic film jacket

materials, modified asphalt jacket materials, and butyl rubber membranes.

1.2 This type of material shall consist of multiple layers of polymer film and aluminum foil laminated to one another with layer(s)

of reinforcement as an option.

1.3 Jacket and tape materials covered by this specification shall have low water vapor permeance values; however, they are not

necessarily always used as vapor retarders. The water vapor transmission tests address the jacket and tape materials only and do

not address overlaps or taped joints. All materials shall be weather resistant and intended to have sufficient strength to provide

protection for mechanical insulation.

1.4 Materials covered under this specification shall have a high, medium, or low surface emittance.

1.5 The top layer shall be on of the following: aluminum foil, a polymer film, or a polymer coating.

1.6 This specification includes jacket materials both with and without factory applied, pressure sensitive adhesives. The tape

materials covered by this specification always have a factory applied, pressure sensitive adhesive.

1.7 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.40 on Insulation

Systems.

Current edition approved Oct. 15, 2014March 1, 2022. Published November 2014March 2022. Originally approved in 2013. Last previous edition approved in 20132014

as C1775 – 13.14. DOI: 10.1520/C1775-14.10.1520/C1775-22.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1775 − 22

2. Referenced Documents

2

2.1 ASTM Standards:

C168 Terminology Relating to Thermal Insulation

C1136 Specification for Flexible, Low Permeance Vapor Retarders for Thermal Insulation

C1263 Test Method for Thermal Integrity of Flexible Water Vapor Retarders

C1338 Test Method for Determining Fungi Resistance of Insulation Materials and Facings

C1371 Test Method for Determination of Emittance of Materials Near Room Temperature Using Portable Emissometers

D774 Test Method for Bursting Strength of Paper

D882 Test Method for Tensile Properties of Thin Plastic Sheeting

D1000 Test Methods for Pressure-Sensitive Adhesive-Coated Tapes Used for Electrical and Electronic Applications

D1204 Test Method for Linear Dimensional Changes of Nonrigid Thermoplastic Sheeting or Film at Elevated Temperature

D3330 Test Method for Peel Adhesion of Pressure-Sensitive Tape

D3759 Test Method for Breaking Strength and Elongation of Pressure-Sensitive Tape

E96 Test Methods for Gravimetric Determination of Water Vapor Transmission Rate of Materials

F1249 Test Method for Water Vapor Transmission Rate Through Plastic Film and Sheeting Using a Modulated Inf

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.