ASTM F72-24

(Specification)Standard Specification for Gold Wire for Semiconductor Lead Bonding

Standard Specification for Gold Wire for Semiconductor Lead Bonding

ABSTRACT

This specification covers round drawn/extruded gold wires for internal semiconductor device electrical connections. The wires are available in four classifications, namely: copper-modified wire, beryllium-modified wire, high-strength wire, and special purpose wire. Aptly sampled wires shall be examined by test methods suggested herein, and each class shall conform correspondingly to specified requirements for chemical composition, mechanical properties (breaking load and elongation), dimension (diameter and weight), and workmanship and finish. The wires shall also undergo wire curl, wire axial twist, and wire roundness tests.

SCOPE

1.1 This specification covers round drawn/extruded gold wire for internal semiconductor device electrical connections. Four classifications of wire are distinguished, (1) copper-modified wire, (2) beryllium-modified wire, (3) high-strength wire, and (4) special purpose wire.

Note 1: Trace metallic elements have a significant effect upon the mechanical properties and thermal stability of high-purity gold wire. It is customary in manufacturing to add controlled amounts of selected impurities to gold to modify or stabilize bonding wire properties, or both. This practice is known variously as “modifying,” “stabilizing,” or “doping.” The first two wire classifications denoted in this specification refer to wire made with either of two particular modifiers, copper or beryllium, in general use. In the third and fourth wire classifications, “high-strength” and “special purpose” wire, the identity of modifying additives is not restricted.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3 The following hazard caveat pertains only to the test method portion, Section 9, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F72 − 24

Standard Specification for

1

Gold Wire for Semiconductor Lead Bonding

This standard is issued under the fixed designation F72; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F16 Test Methods for Measuring Diameter or Thickness of

Wire and Ribbon for Electronic Devices and Lamps

1.1 This specification covers round drawn/extruded gold

3

(Withdrawn 2023)

wire for internal semiconductor device electrical connections.

F205 Test Method for Measuring Diameter of Fine Wire by

Four classifications of wire are distinguished, (1) copper-

3

Weighing (Withdrawn 2023)

modified wire, (2) beryllium-modified wire, (3) high-strength

F219 Test Methods of Testing Fine Round and Flat Wire for

wire, and (4) special purpose wire.

3

Electron Devices and Lamps (Withdrawn 2023)

NOTE 1—Trace metallic elements have a significant effect upon the

F584 Practice for Visual Inspection of Semiconductor Lead-

mechanical properties and thermal stability of high-purity gold wire. It is

3

Bonding Wire (Withdrawn 2015)

customary in manufacturing to add controlled amounts of selected

impurities to gold to modify or stabilize bonding wire properties, or both.

This practice is known variously as “modifying,” “stabilizing,” or

3. Ordering Information

“doping.” The first two wire classifications denoted in this specification

refer to wire made with either of two particular modifiers, copper or

3.1 Orders for material under this specification shall include

beryllium, in general use. In the third and fourth wire classifications,

the following information:

“high-strength” and “special purpose” wire, the identity of modifying

additives is not restricted. 3.1.1 Classification: copper-modified, beryllium-modified,

high strength, or special purpose,

1.2 The values stated in SI units are to be regarded as

standard. The values given in parentheses after SI units are 3.1.2 Quantity,

provided for information only and are not considered standard.

3.1.3 Purity (Section 4),

1.3 The following hazard caveat pertains only to the test

3.1.4 Type, hard, stress relieved, or annealed (Section 5),

method portion, Section 9, of this specification. This standard

3.1.5 Breaking load and percentage elongation range (Sec-

does not purport to address all of the safety concerns, if any,

tion 5),

associated with its use. It is the responsibility of the user of this

3.1.6 Wire diameter (Section 6),

standard to establish appropriate safety, health, and environ-

3.1.7 Spool type, length of wire per spool, and type of wind

mental practices and determine the applicability of regulatory

(Section 11),

limitations prior to use.

1.4 This international standard was developed in accor-

3.1.8 Despooling, left-handed unwind or right-handed un-

dance with internationally recognized principles on standard-

wind (Section 11), and,

ization established in the Decision on Principles for the

3.1.9 Packaging and marking (Section 12).

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4. Chemical Composition

Barriers to Trade (TBT) Committee.

4.1 Beryllium-modified material shall conform to the

2. Referenced Documents

chemical requirements specified in Table 1.

2

2.1 ASTM Standards:

4.2 High-strength material shall conform to the chemical

requirements specified in Table 2.

1

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

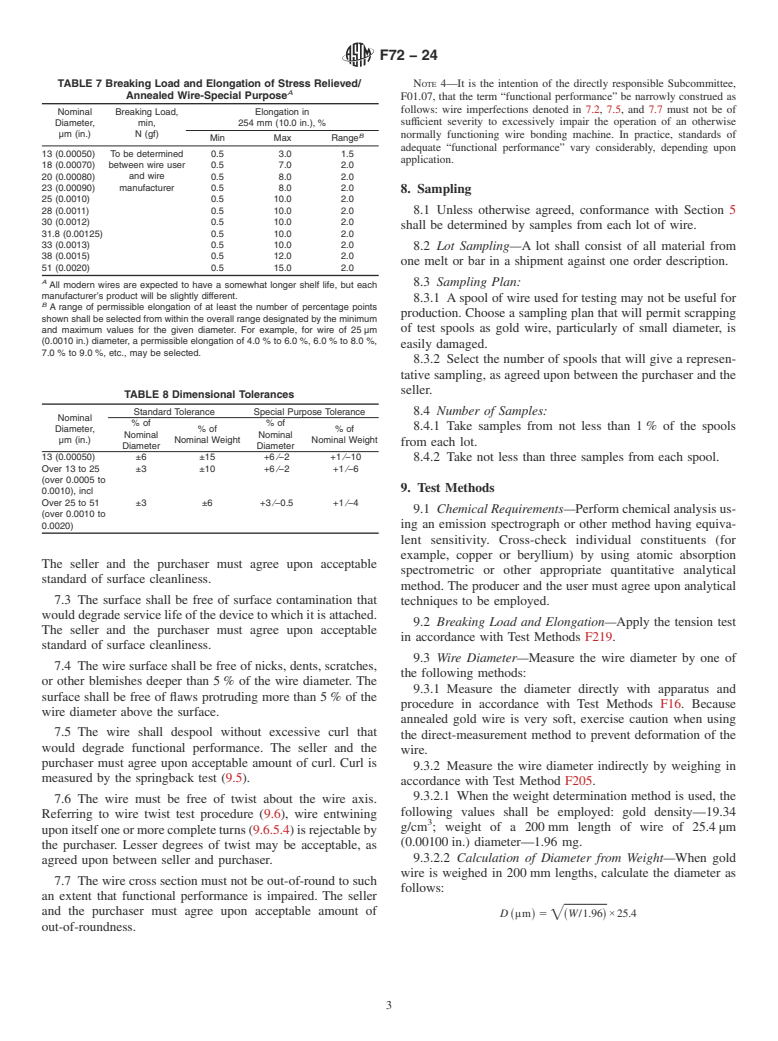

4.3 Special purpose material shall be in accordance with

B02.05 on Precious Metals and Electrical Contact Materials and Test Methods.

Table 3.

Current edition approved April 1, 2024. Published April 2024. Originally

approved in 1966. Last previous edition approved in 2021 as F72 – 21 which was

withdrawn January 2024 and reinstated in April 2024. DOI: 10.1520/F0072-24.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F72 − 24

TABLE 1 Chemical Requirements, Beryllium-Modified Gold TABLE 5 Breaking

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.