ASTM A53/A53M-24

(Specification)Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

ABSTRACT

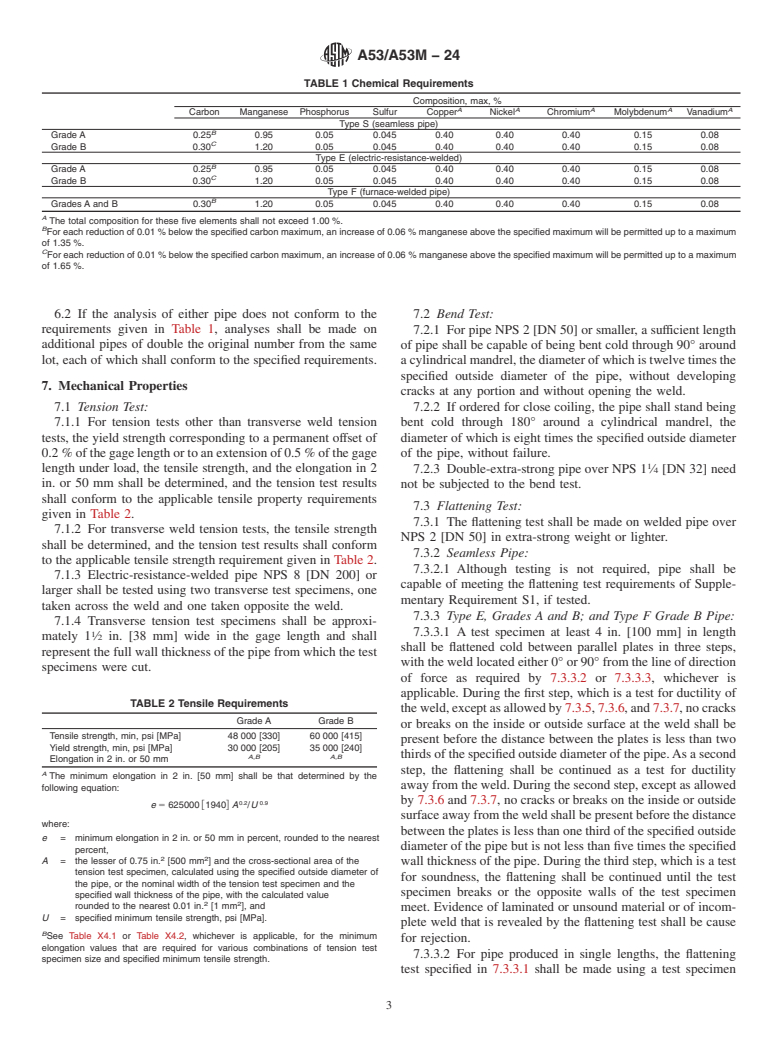

This specification covers seamless and welded black and hot-dipped galvanized steel pipe in NPS 1/8 to NPS 26. The steel categorized in this standard must be open-hearth, basic-oxygen or electric-furnace processed and must have the following chemical requirements: carbon, manganese, phosphorus, sulfur, copper, nickel, chromium, molybdenum, and vanadium. The tubing shall undergo a seamless or welding process. Tension, bend, and flattening tests shall be performed to make sure that it must adhere to the mechanical properties of the standard. The hydrostatic test shall be applied, without leakage through the weld seam or the pipe body. Nondestructive electric test shall be made to make sure that the full volume of the pipe must be in accordance with the standard. The purchaser shall have the right to perform any of the inspections and tests set forth in this specification where deemed necessary to ensure that the pipe conforms to the specified requirements.

SCOPE

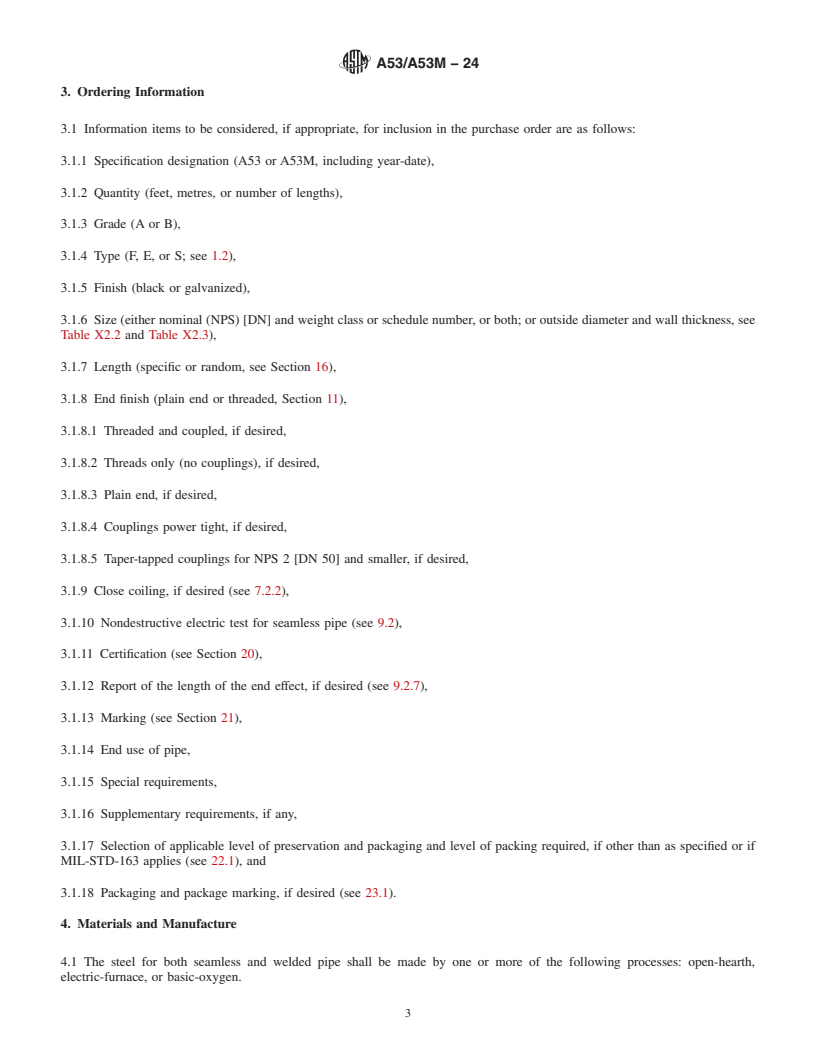

1.1 This specification2 covers seamless and welded black and hot-dipped galvanized steel pipe in NPS 1/8 to NPS 26 [DN 6 to DN 650] (Note 1), inclusive, with nominal wall thickness (Note 2) as given in Table X2.2 and Table X2.3. It shall be permissible to furnish pipe having other dimensions provided that such pipe complies with all other requirements of this specification. Supplementary requirements of an optional nature are provided and shall apply only when specified by the purchaser.

Note 1: The dimensionless designators NPS (nominal pipe size) [DN (diameter nominal)] have been substituted in this specification for such traditional terms as “nominal diameter,” “size,” and “nominal size.”

Note 2: The term nominal wall thickness has been assigned for the purpose of convenient designation, existing in name only, and is used to distinguish it from the actual wall thickness, which may vary over or under the nominal wall thickness.

1.2 This specification covers the following types and grades:

1.2.1 Type F—Furnace-butt-welded, continuous welded Grades A and B,

1.2.2 Type E—Electric-resistance-welded, Grades A and B, and

1.2.3 Type S—Seamless, Grades A and B.

Note 3: See Appendix X1 for definitions of types of pipe.

1.3 Pipe ordered under this specification is intended for mechanical and pressure applications and is also acceptable for ordinary uses in steam, water, gas, and air lines. It is suitable for welding, and suitable for forming operations involving coiling, bending, and flanging, subject to the following qualifications:

1.3.1 Type F is not intended for flanging.

1.3.2 When pipe is required for close coiling or cold bending, Grade A is the preferred grade; however, this is not intended to prohibit the cold bending of Grade B pipe.

1.3.3 Type E is furnished either nonexpanded or cold expanded at the option of the manufacturer.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 The following precautionary caveat pertains only to the test method portion, Sections 7, 8, 9, 13, 14, and 15 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory requirements prior to use.

1.6 The text of this specification contains notes or footnotes, or both, that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization ...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A53/A53M − 24

Standard Specification for

Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and

1

Seamless

This standard is issued under the fixed designation A53/A53M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.3.2 When pipe is required for close coiling or cold

2 bending, Grade A is the preferred grade; however, this is not

1.1 This specification covers seamless and welded black

intended to prohibit the cold bending of Grade B pipe.

1

and hot-dipped galvanized steel pipe in NPS ⁄8 to NPS 26 [DN

1.3.3 Type E is furnished either nonexpanded or cold

6 to DN 650] (Note 1), inclusive, with nominal wall thickness

expanded at the option of the manufacturer.

(Note 2) as given in Table X2.2 and Table X2.3. It shall be

permissible to furnish pipe having other dimensions provided 1.4 The values stated in either SI units or inch-pound units

that such pipe complies with all other requirements of this are to be regarded separately as standard. The values stated in

specification. Supplementary requirements of an optional na- each system may not be exact equivalents; therefore, each

ture are provided and shall apply only when specified by the system shall be used independently of the other. Combining

purchaser. values from the two systems may result in non-conformance

with the standard.

NOTE 1—The dimensionless designators NPS (nominal pipe size) [DN

(diameter nominal)] have been substituted in this specification for such 1.5 The following precautionary caveat pertains only to the

traditional terms as “nominal diameter,” “size,” and “nominal size.”

test method portion, Sections 7, 8, 9, 13, 14, and 15 of this

NOTE 2—The term nominal wall thickness has been assigned for the

specification: This standard does not purport to address all of

purpose of convenient designation, existing in name only, and is used to

the safety concerns, if any, associated with its use. It is the

distinguish it from the actual wall thickness, which may vary over or

responsibility of the user of this standard to establish appro-

under the nominal wall thickness.

priate safety, health, and environmental practices and deter-

1.2 This specification covers the following types and

mine the applicability of regulatory requirements prior to use.

grades:

1.6 The text of this specification contains notes or footnotes,

1.2.1 Type F—Furnace-butt-welded, continuous welded

or both, that provide explanatory material. Such notes and

Grades A and B,

footnotes, excluding those in tables and figures, do not contain

1.2.2 Type E—Electric-resistance-welded, Grades A and B,

any mandatory requirements.

and

1.7 This international standard was developed in accor-

1.2.3 Type S—Seamless, Grades A and B.

dance with internationally recognized principles on standard-

NOTE 3—See Appendix X1 for definitions of types of pipe.

ization established in the Decision on Principles for the

1.3 Pipe ordered under this specification is intended for

Development of International Standards, Guides and Recom-

mechanical and pressure applications and is also acceptable for

mendations issued by the World Trade Organization Technical

ordinary uses in steam, water, gas, and air lines. It is suitable

Barriers to Trade (TBT) Committee.

for welding, and suitable for forming operations involving

coiling, bending, and flanging, subject to the following quali-

2. Referenced Documents

fications: 3

2.1 ASTM Standards:

1.3.1 Type F is not intended for flanging.

A90/A90M Test Method for Weight [Mass] of Coating on

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

A370 Test Methods and Definitions for Mechanical Testing

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, of Steel Products

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.09 on Carbon Steel Tubular Products.

Current edition approved March 1, 2024. Published March 2024. Originally

3

approved in 1915. Last previous edition approved in 2022 as A53/A53M – 22. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/A0053_A0053M-24. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

For ASME Boiler and Pressure Vessel Code applications, see related Specifi- Standards volume information, refer to the standard’s Document Summary page on

cation SA-53 in Section

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A53/A53M − 22 A53/A53M − 24

Standard Specification for

Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and

1

Seamless

This standard is issued under the fixed designation A53/A53M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

2

1

1.1 This specification covers seamless and welded black and hot-dipped galvanized steel pipe in NPS ⁄8 to NPS 26 [DN 6 to DN

650] (Note 1), inclusive, with nominal wall thickness (Note 2) as given in Table X2.2 and Table X2.3. It shall be permissible to

furnish pipe having other dimensions provided that such pipe complies with all other requirements of this specification.

Supplementary requirements of an optional nature are provided and shall apply only when specified by the purchaser.

NOTE 1—The dimensionless designators NPS (nominal pipe size) [DN (diameter nominal)] have been substituted in this specification for such traditional

terms as “nominal diameter,” “size,” and “nominal size.”

NOTE 2—The term nominal wall thickness has been assigned for the purpose of convenient designation, existing in name only, and is used to distinguish

it from the actual wall thickness, which may vary over or under the nominal wall thickness.

1.2 This specification covers the following types and grades:

1.2.1 Type F—Furnace-butt-welded, continuous welded Grades A and B,

1.2.2 Type E—Electric-resistance-welded, Grades A and B, and

1.2.3 Type S—Seamless, Grades A and B.

NOTE 3—See Appendix X1 for definitions of types of pipe.

1.3 Pipe ordered under this specification is intended for mechanical and pressure applications and is also acceptable for ordinary

uses in steam, water, gas, and air lines. It is suitable for welding, and suitable for forming operations involving coiling, bending,

and flanging, subject to the following qualifications:

1.3.1 Type F is not intended for flanging.

1.3.2 When pipe is required for close coiling or cold bending, Grade A is the preferred grade; however, this is not intended to

prohibit the cold bending of Grade B pipe.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.09

on Carbon Steel Tubular Products.

Current edition approved July 1, 2022March 1, 2024. Published August 2022March 2024. Originally approved in 1915. Last previous edition approved in 20202022 as

A53/A53M – 20.A53/A53M – 22. DOI: 10.1520/A0053_A0053M-22.10.1520/A0053_A0053M-24.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA-53 in Section II of that code.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A53/A53M − 24

1.3.3 Type E is furnished either nonexpanded or cold expanded at the option of the manufacturer.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.5 The following precautionary caveat pertains only to the test method portion, Sections 7, 8, 9, 13, 14, and 15 of this

specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the

applicability of regulatory requirements prior to use.

1.6 The text of this specification contains notes or footnotes, or both, that provide explanatory material. Such notes and footnotes,

excluding those in tables and figures, do not contain any mandatory requirements.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.