ISO/TS 20175:2018

(Main)Vacuum technology — Vacuum gauges — Characterization of quadrupole mass spectrometers for partial pressure measurement

Vacuum technology — Vacuum gauges — Characterization of quadrupole mass spectrometers for partial pressure measurement

This document describes procedures to characterize quadrupole mass spectrometers (QMSs) with an ion source of electron impact ionization and which are designed for the measurement of atomic mass-to-charge ratios m/z This document is not applicable to QMSs with other ion sources, such as chemical ionization, photo-ionization or field ionization sources and for the measurements of higher m/z, which are mainly used to specify organic materials. It is well known from published investigations on the metrological characteristics of quadrupole mass spectrometers that their indications of partial pressures depend significantly on the settings of the instrument, the total pressure, and the composition of the gas mixture. For this reason, it is not possible to calibrate a quadrupole mass spectrometer for all possible kinds of use. The characterization procedures described in this document cover the applications of continuous leak monitoring of a vacuum system, leak rate measurement with tracer gas, residual gas analysis and outgassing rate measurements. The user can select that characterization procedure that best suits his or her needs. These characterization procedures can also be useful for other applications. It is also well known that the stability of several parameters of quadrupole mass spectrometers, in particular sensitivity, are rather poor. Therefore, when a parameter has been calibrated, it needs frequent recalibration when accuracy is required. For practical reasons this can only be accomplished by in situ calibrations. To this end, this document not only describes how a quadrupole mass spectrometer can be calibrated by a calibration laboratory or a National Metrological Institute with direct traceability to the System International (SI), but also how calibrated parameters can be frequently checked and maintained in situ. By their physical principle, quadrupole mass spectrometers need high vacuum within the instrument. By reducing dimensions or by special ion sources combined with differential pumping the operational range can be extended to higher pressures, up to atmospheric pressure. This document, however, does not include quadrupole mass spectrometers with differential pumping technology. Therefore, it does not cover pressures exceeding 1 Pa on the inlet flange of the quadrupole mass spectrometer. This document does not describe how the initial adjustment of a quadrupole mass spectrometer by the manufacturer or by a service given order by the manufacturer should be made. The purpose of such an initial adjustment is mainly to provide a correct m/z scale, constant mass resolution or constant transmission, and is very specific to the instrument. Instead, it is assumed for this document that a manufacturer's readjustment procedure exists which can be carried on-site by a user. This procedure is intended to ensure that the quadrupole mass spectrometer is in a well-defined condition for the characterization. It is the intention of this document that the user gets the best possible metrological quality from his quadrupole mass spectrometer. From investigations it is known that in most cases this can be achieved in the so called "scan mode". The bar graph may also be of an adequate quality depending on the software used for evaluation of the data taken by the quadrupole mass spectrometer. The trend mode, however, often involves the additional uncertainty that a shift of the peak value position on the mass scale causes a shift in ion current. For this reason, the scan mode is preferable for most of the measurement procedures of this document. It is not the intent of this document that all the parameters described be determined for each quadrupole mass spectrometer. However, it is intended that the value of a parameter addressed in this document be determined according to the procedure described in this document if it is given or measured (e.g. for an inspection test). It is assumed for this document that the applicant

Technique du vide — Manomètres à vide — Description des spectromètres de masse quadripolaires pour mesurage de la pression partielle

General Information

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 20175

First edition

2018-04

Vacuum technology — Vacuum gauges

— Characterization of quadrupole

mass spectrometers for partial

pressure measurement

Technique du vide — Manomètres à vide — Description des

spectromètres de masse quadripolaires pour mesurage de la pression

partielle

Reference number

ISO/TS 20175:2018(E)

©

ISO 2018

---------------------- Page: 1 ----------------------

ISO/TS 20175:2018(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TS 20175:2018(E)

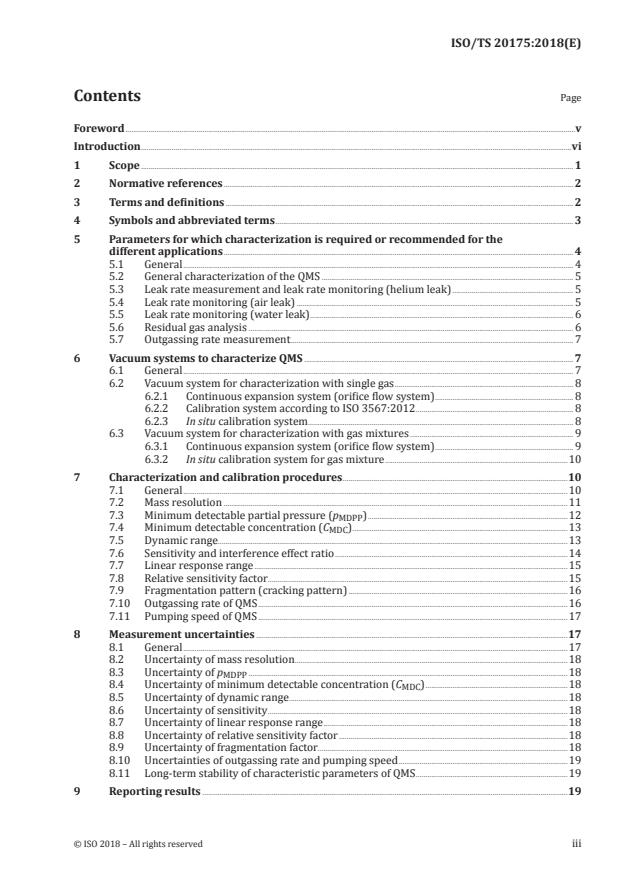

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 2

4 Symbols and abbreviated terms . 3

5 Parameters for which characterization is required or recommended for the

different applications . 4

5.1 General . 4

5.2 General characterization of the QMS . 5

5.3 Leak rate measurement and leak rate monitoring (helium leak) . 5

5.4 Leak rate monitoring (air leak) . 5

5.5 Leak rate monitoring (water leak) . 6

5.6 Residual gas analysis . 6

5.7 Outgassing rate measurement . 7

6 Vacuum systems to characterize QMS . 7

6.1 General . 7

6.2 Vacuum system for characterization with single gas . 8

6.2.1 Continuous expansion system (orifice flow system) . 8

6.2.2 Calibration system according to ISO 3567:2012 . 8

6.2.3 In situ calibration system . 8

6.3 Vacuum system for characterization with gas mixtures . 9

6.3.1 Continuous expansion system (orifice flow system) . 9

6.3.2 In situ calibration system for gas mixture .10

7 Characterization and calibration procedures .10

7.1 General .10

7.2 Mass resolution .11

7.3 Minimum detectable partial pressure (p ) .12

MDPP

7.4 Minimum detectable concentration (C ) .13

MDC

7.5 Dynamic range.13

7.6 Sensitivity and interference effect ratio .14

7.7 Linear response range .15

7.8 Relative sensitivity factor .15

7.9 Fragmentation pattern (cracking pattern) .16

7.10 Outgassing rate of QMS .16

7.11 Pumping speed of QMS .17

8 Measurement uncertainties .17

8.1 General .17

8.2 Uncertainty of mass resolution .18

8.3 Uncertainty of p .18

MDPP

8.4 Uncertainty of minimum detectable concentration (C ) .18

MDC

8.5 Uncertainty of dynamic range . .18

8.6 Uncertainty of sensitivity .18

8.7 Uncertainty of linear response range .18

8.8 Uncertainty of relative sensitivity factor .18

8.9 Uncertainty of fragmentation factor.18

8.10 Uncertainties of outgassing rate and pumping speed .19

8.11 Long-term stability of characteristic parameters of QMS .19

9 Reporting results .19

© ISO 2018 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TS 20175:2018(E)

Annex A (informative) Estimate of gas composition in the measurement chamber from

known gas composition in the reservoir in front of a leak element under different

flow conditions .21

Bibliography .23

iv © ISO 2018 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TS 20175:2018(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 112, Vacuum technology.

© ISO 2018 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/TS 20175:2018(E)

Introduction

Quadrupole mass spectrometers (QMSs) are nowadays used not only in vacuum technology for leak

detection and residual gas analysis but also in the process industry as an instrument to provide

quantitative analysis in processes and to control processes such as physical and chemical vapour

deposition, and etch processes. They are also used for quantitative outgassing rate measurements

which are important to characterize vacuum components for critical applications like in the EUV

lithography, semiconductor industry or medical instruments.

Total pressure, composition of the gas mixture, settings and the operational history of QMSs, to name

a few, have a significant influence on the measured signal, its uncertainty and interpretation. For this

reason, it is not possible to calibrate QMS for all its possible applications. Instead, it has either to be

calibrated for the special conditions at use or for a standardized condition. It is the purpose of this

document to establish such conditions.

There is also a need for standardization in order to enable the users of QMSs to compare the devices of

different manufactures and to use the QMS properly.

This document provides standardized calibration procedures for QMSs for some important applications.

These have been selected from the results of a survey of the international project EMRP (European

Metrological Research Programme) IND12 which was conducted in 2013. This survey included

manufacturers, distributors and users of quadrupole mass spectrometers.

vi © ISO 2018 – All rights reserved

---------------------- Page: 6 ----------------------

TECHNICAL SPECIFICATION ISO/TS 20175:2018(E)

Vacuum technology — Vacuum gauges — Characterization

of quadrupole mass spectrometers for partial pressure

measurement

1 Scope

This document describes procedures to characterize quadrupole mass spectrometers (QMSs) with an

ion source of electron impact ionization and which are designed for the measurement of atomic mass-

to-charge ratios m/z < 300.

This document is not applicable to QMSs with other ion sources, such as chemical ionization, photo-

ionization or field ionization sources and for the measurements of higher m/z, which are mainly used to

specify organic materials.

It is well known from published investigations on the metrological characteristics of quadrupole

mass spectrometers that their indications of partial pressures depend significantly on the settings of

the instrument, the total pressure, and the composition of the gas mixture. For this reason, it is not

possible to calibrate a quadrupole mass spectrometer for all possible kinds of use. The characterization

procedures described in this document cover the applications of continuous leak monitoring of a

vacuum system, leak rate measurement with tracer gas, residual gas analysis and outgassing rate

measurements. The user can select that characterization procedure that best suits his or her needs.

These characterization procedures can also be useful for other applications.

It is also well known that the stability of several parameters of quadrupole mass spectrometers,

in particular sensitivity, are rather poor. Therefore, when a parameter has been calibrated, it needs

frequent recalibration when accuracy is required. For practical reasons this can only be accomplished by

in situ calibrations. To this end, this document not only describes how a quadrupole mass spectrometer

can be calibrated by a calibration laboratory or a National Metrological Institute with direct traceability

to the System International (SI), but also how calibrated parameters can be frequently checked and

maintained in situ.

By their physical principle, quadrupole mass spectrometers need high vacuum within the instrument.

By reducing dimensions or by special ion sources combined with differential pumping the operational

range can be extended to higher pressures, up to atmospheric pressure. This document, however, does

not include quadrupole mass spectrometers with differential pumping technology. Therefore, it does

not cover pressures exceeding 1 Pa on the inlet flange of the quadrupole mass spectrometer.

This document does not describe how the initial adjustment of a quadrupole mass spectrometer by the

manufacturer or by a service given order by the manufacturer should be made. The purpose of such

an initial adjustment is mainly to provide a correct m/z scale, constant mass resolution or constant

transmission, and is very specific to the instrument. Instead, it is assumed for this document that a

manufacturer’s readjustment procedure exists which can be carried on-site by a user. This procedure

is intended to ensure that the quadrupole mass spectrometer is in a well-defined condition for the

characterization.

It is the intention of this document that the user gets the best possible metrological quality from

his quadrupole mass spectrometer. From investigations it is known that in most cases this can be

achieved in the so called “scan mode”. The bar graph may also be of an adequate quality depending on

the software used for evaluation of the data taken by the quadrupole mass spectrometer. The trend

mode, however, often involves the additional uncertainty that a shift of the peak value position on the

mass scale causes a shift in ion current. For this reason, the scan mode is preferable for most of the

measurement procedures of this document.

© ISO 2018 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO/TS 20175:2018(E)

It is not the intent of this document that all the parameters described be determined for each quadrupole

mass spectrometer. However, it is intended that the value of a parameter addressed in this document be

determined according to the procedure described in this document if it is given or measured (e.g. for an

inspection test).

It is assumed for this document that the applicant is familiar with both the operation of quadrupole

mass spectrometers and high and ultra-high vacuum technology.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3567:2011, Vacuum technology — Vacuum gauges — Calibration by direct comparison with a

reference gauge

ISO 14291, Vacuum technology — Vacuum gauges — Definitions and specifications for quadrupole mass

spectrometer

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 14291 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

matrix gas

gas or gas mixture that makes the major contribution to the total pressure

3.2

equivalent nitrogen pressure

pressure of nitrogen which would produce the same gauge reading as the pressure of gas acting on a

vacuum gauge

[SOURCE: ISO 3529-3:2014, 2.3.5, modified.]

Note 1 to entry: Nitrogen equivalent depends on the type of gauge, since the relative sensitivity factor is different

for different types. For this reason, the term should be used with the type of vacuum gauge.

3.3

transmission probability

ratio of ion current of a certain mass-to-charge ratio exiting a quadrupole filter of a QMS to the current

of ions of the same mass-to-charge ratio entering it

3.4

scan speed

speed as u (Δm/z=1) per time with a defined number of signal points per u (Δm/z=1)

3.5

linear response range

partial pressure range over which the non-linearity is within a specified limit

Note 1 to entry: For the purpose of this document the limit is ± 10 % from the mean value.

2 © ISO 2018 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/TS 20175:2018(E)

Note 2 to entry: The linear response range can also depend on the conversion of the output current signal to a

digital value. Sometimes a single digital bit does not quantise the same amount of current at the lower and upper

end of the range.

[SOURCE: ISO 14291:2012, 2.2.18, modified – Notes to entry have been added.]

3.6

leak rate measurement

quantitative measurement of a tracer gas through a leak

3.7

leak rate monitoring

continuous monitoring of one or several selected gas species with respect to the normal background in

a vacuum system in order to detect a change caused by a leak

EXAMPLE 1 In an accelerator tube, argon is monitored to detect a leak from air.

EXAMPLE 2 In a fusion reactor, water peaks are monitored to detect a leak from the cooling system.

3.8

fragmentation pattern

pattern (i.e. kinds and relative amounts) of ions produced by a given pure gas in a given mass

spectrometer under given conditions

Note 1 to entry: This definition does include the isotopic and isomeric distribution of the species.

[SOURCE: ISO 14291:2012, modified – Notes to entry replaced.]

3.9

interference effect ratio

ratio S ´ / S where

i i

S ´ is the sensitivity of a specified gas species i of partial pressure p present in an interference gas

i i

or interference gas mixture;

S is the sensitivity at the same value of p when only species i is present.

i i

3.10

interference gas

gas species added to a pure gas that may cause an interference effect

3.11

interference gas mixture

mixture of several gas species added to a pure gas that may cause an interference effect

3.12

dynamic range

ratio of the largest signal to the smallest signal within a spectrum

Note 1 to entry: The difference between minimum detectable concentration (C ) as defined in ISO 14291 and

MDC

dynamic range is that for the C it is acceptable to optimize the signal to noise ratio for the minor constituent,

MDC

while this is not possible for the dynamic range.

4 Symbols and abbreviated terms

Symbol Designation Unit

3

effective conductance of a duct, effective m /s or

C

eff

pumping speed L/s

R dynamic range 1

dyn

f fragmentation factor 1

© ISO 2018 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO/TS 20175:2018(E)

Symbol Designation Unit

I ion current at partial pressure p A

I ion current at residual pressure p A

0 0

m molecular mass in atomic mass units u

M molecular mass kg

C minimum detectable concentration 1

MDC

p minimum detectable partial pressure Pa

MDPP

p pressure or partial pressure Pa

residual pressure or residual partial

p Pa

0

pressure

relative sensitivity for a specified gas

r species “x” divided by sensitivity S for 1

x N2

nitrogen

3

volume flow rate of species i into a vacuum m /s or

q

V,i

pump (pumping speed) L/s

−1

universal gas constant J mol

R

−1

K

S sensitivity (coefficient) A/Pa

SI System International

S sensitivity for nitrogen A/Pa

N2

T temperature K

T transmission probability 1

P

z the ionization state of a molecule 1

Δm mass resolution as defined in ISO 14291 u

CEM continuous dynode electron multiplier

MCP micro-channel plate

QMS quadrupole mass spectrometer

SEM secondary electron multiplier

NOTE The symbol m characterizes the mass of a molecule in u, while m/z characterizes at which position

the molecule with mass m appears on the mass scale indicated by the QMS. This is proportional to the mass-to-

charge ratio and therefore also to m/z.

5 Parameters for which characterization is required or recommended for the

different applications

5.1 General

ISO 14291 requires a certain number of parameters to be stated by a manufacturer for general

characterization. This is covered in 5.1. It is also recommended that the general characterization is

applied as characterization of an individual QMS and its performance monitored over its lifetime. It

is recommended that the parameters described in the following sections are determined to improve

accuracy and reliability of the QMS for the specific application mentioned in the section title.

The extent of such characterizations has to be adapted to the application and can usually not be

accomplished by a manufacturer for economical reasons.

4 © ISO 2018 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/TS 20175:2018(E)

5.2 General characterization of the QMS

It is required by ISO 14291 that the following parameters are given by the manufacturer for a general

characterization:

a) linear response range for pure nitrogen;

b) sensitivity for pure nitrogen in the linear response range as a result of measurement a);

c) minimum detectable partial pressure for helium and nitrogen;

d) dynamic range.

It is recommended that, in addition, the following parameters are given as part of the specification of

the QMS:

e) minimum detectable concentration for helium in nitrogen (nitrogen partial pressure at around

−3

10 % of the maximum operational pressure or around 10 Pa, whatever is lower);

f) mass resolution at m/z = 4 and optionally also m/z = 28 and 136(Xenon).

−4

NOTE The upper limit of linear response range of conventional QMSs is typically below 10 Pa except for

−2

QMSs designed for pressures higher than 10 Pa.

5.3 Leak rate measurement and leak rate monitoring (helium leak)

a) linear response range for pure helium;

b) sensitivity for pure helium in the linear response range as a result of measurement a);

c) interference effect of helium within the linear response range for pure helium by introducing

−3

nitrogen of partial pressure of 10 Pa or the typical operational pressure in the application;

d) linear response range for helium in nitrogen as a result of measurement c);

e) minimum detectable partial pressure for helium;

−3

f) minimum detectable concentration for helium in nitrogen (nitrogen partial pressure around 10 Pa);

g) dynamic range.

5.4 Leak rate monitoring (air leak)

This type of characterization depends on the specific need of application. In particular, it is important

whether a clean UHV system as a high energy accelerator or a system at high vacuum with many

constituents (e.g. fusion or plasma reactor) is monitored.

For a clean UHV system it is recommended that the following is measured:

a) linear response range for nitrogen, oxygen, and argon, each as pure gas;

b) sensitivity for nitrogen, oxygen and argon in linear response range as a result of measurement a);

c) fragmentation pattern for nitrogen and oxygen as a result of measurement a);

d) relative sensitivity factors for oxygen and argon as a result of measurement a);

e) dynamic range.

© ISO 2018 – All rights reserved 5

---------------------- Page: 11 ----------------------

ISO/TS 20175:2018(E)

For other systems with background in the high vacuum range with a major gas constituent m (e.g.

argon), it is recommended that the following is measured:

1) sensitivity for the gas to be monitored as air constituent (nitrogen, oxygen, or argon, whichever

applies), in the major gas constituent m at its maximum operational pressure (equivalent nitrogen

−7

pressure) between partial pressure of 10 Pa and maximum operational pressure (equivalent

nitrogen pressure);

2) relative sensitivity factors for the monitoring gas as a result of measurement a);

3) fragmentation pattern for the monitoring gas as a result of measurement a);

4) minimum detectable concentration for the monitoring gas in the major gas constituent;

5) dynamic range.

5.5 Leak rate monitoring (water leak)

−5

a) Sensitivity for pure water vapour near 10 Pa;

b) fragmentation pattern for water vapour as a result of measurement a);

−5

c) interference effect of water vapour at 10 Pa by introducing nitrogen or the major constituent of

−3

the residual gas in the application at 10 Pa pressure or the operational pressure in the application;

d) linear response range for water vapour in nitrogen or the major constituent of the residual gas as a

result of measurement c);

e) fragmentation pattern for water vapour as a result of measurement c);

f) minimum detectable concentration for water vapour in nitrogen or the major constituent of

−3

the residual gas (partial pressure preferably near 10 Pa or the operational pressure in the

application).

NOTE 1 When the residual gas is water vapour, there is no need to characterize the interference effect.

NOTE 2 Depending on the surface area, the time to reach equilibrium could be many hours.

5.6 Residual gas analysis

a) Total outgassing rate of the QMS in equivalent nitrogen pressure under residual pressure conditions

after a bake-out and optionally outgassing rate for individual gas species of interest;

−5

b) sensitivity for hydrogen, methane, nitrogen and carbon dioxide at a total pressure of 10 Pa

(equivalent nitrogen pressure) in a mixture of 70 % hydrogen, 5 % methane, 20 % nitrogen, 5 %

carbon dioxide;

−5

c) fragmentation pattern for methane, nitrogen, carbon dioxide in pure gas,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.