ISO 23114:2020

(Main)Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for determining bonding strength of ceramic coatings

Fine ceramics (advanced ceramics, advanced technical ceramics) — Test method for determining bonding strength of ceramic coatings

This document specifies the testing method for the determination of the bonding strength of ceramic coatings at ambient temperature by the compression tests on the cross-joined test pieces. Methods for test piece preparation, test mode and rate, data collection and reporting procedures are addressed. This document applies primarily to any ceramic coatings, thick or thin, bonded onto substrates of various materials. The test method described can be used for materials research, quality control, characterization and design data generation purposes.

Titre manque

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 23114

First edition

2020-01

Fine ceramics (advanced ceramics,

advanced technical ceramics) — Test

method for determining bonding

strength of ceramic coatings

Reference number

ISO 23114:2020(E)

©

ISO 2020

---------------------- Page: 1 ----------------------

ISO 23114:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 23114:2020(E)

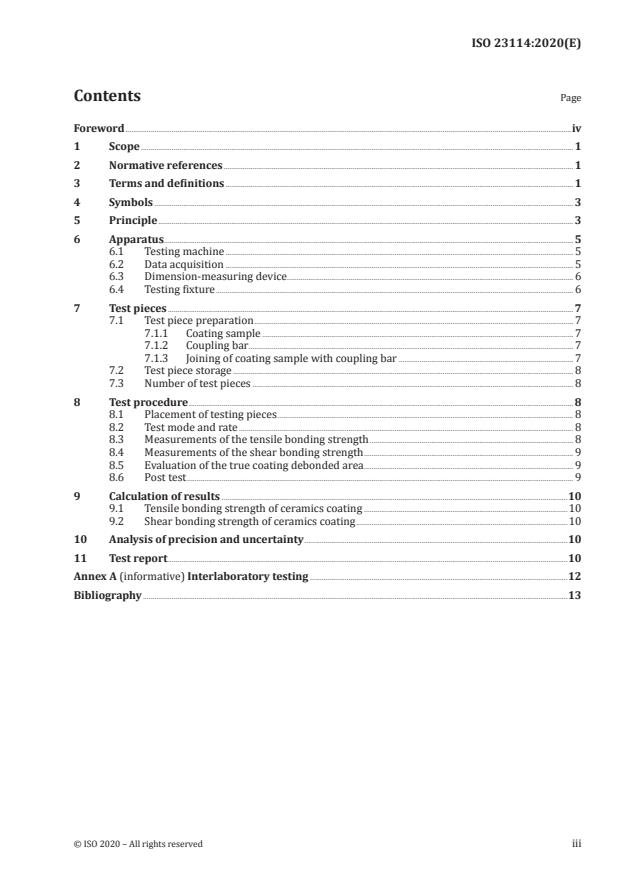

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols . 3

5 Principle . 3

6 Apparatus . 5

6.1 Testing machine . 5

6.2 Data acquisition . 5

6.3 Dimension-measuring device. 6

6.4 Testing fixture . 6

7 Test pieces . 7

7.1 Test piece preparation . 7

7.1.1 Coating sample . 7

7.1.2 Coupling bar . . 7

7.1.3 Joining of coating sample with coupling bar . 7

7.2 Test piece storage . 8

7.3 Number of test pieces . 8

8 Test procedure . 8

8.1 Placement of testing pieces . 8

8.2 Test mode and rate . 8

8.3 Measurements of the tensile bonding strength . 8

8.4 Measurements of the shear bonding strength . 9

8.5 E valuation of the true coating debonded area . 9

8.6 Post test . 9

9 Calculation of results .10

9.1 Tensile bonding strength of ceramics coating .10

9.2 Shear bonding strength of ceramics coating .10

10 Analysis of precision and uncertainty .10

11 Test report .10

Annex A (informative) Interlaboratory testing .12

Bibliography .13

© ISO 2020 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 23114:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 206, Fine ceramics.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

iv © ISO 2020 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 23114:2020(E)

Fine ceramics (advanced ceramics, advanced technical

ceramics) — Test method for determining bonding

strength of ceramic coatings

1 Scope

This document specifies the testing method for the determination of the bonding strength of ceramic

coatings at ambient temperature by the compression tests on the cross-joined test pieces. Methods for

test piece preparation, test mode and rate, data collection and reporting procedures are addressed.

This document applies primarily to any ceramic coatings, thick or thin, bonded onto substrates of

various materials. The test method described can be used for materials research, quality control,

characterization and design data generation purposes.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3611, Geometrical product specifications (GPS) — Dimensional measuring equipment: Micrometers for

external measurements — Design and metrological characteristics

ISO 7500-1, Metallic materials — Calibration and verification of static uniaxial testing machines — Part 1:

Tension/compression testing machines — Calibration and verification of the force-measuring system

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

ceramic coating

coating of ceramics onto a substrate, via a physical or chemical technique, which creates an interface or

boundary between the coating and the substrate

3.2

interface

smooth or rough boundary generated between coating and substrate that results from one or several

bonding mechanisms, for example mechanical anchorage, interatomic or intermolecular bonds

3.3

cross-joined test piece

test piece prepared by joining coating sample (see Figure 1 and 7.1.1) and coupling bar (see Figure 2

and 7.2.2) perpendicularly to each other at middle, by means of high-strength adhesive, as shown in

Figure 3

© ISO 2020 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO 23114:2020(E)

Key

1 notch

2 coating

3 substrate

Figure 1 — Schematic of the coating sample

a)

b)

Key

1 groove

2 sloped end

Figure 2 — Schematic of the coupling bar

Figure 3 — Schematic of the cross-joined test piece

2 © ISO 2020 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 23114:2020(E)

3.4

tensile failure load

maximum load applied to the horizontally placed cross-joined test piece during a test by subjecting load

normal to interface between coating and substrate

3.5

tensile bonding strength

tensile stress calculated from the tensile failure load and the cross-joined area

3.6

shear failure load

maximum load applied to the vertically placed cross-joined test piece during a test by subjecting load

parallel to interface between coating and substrate

3.7

shear bonding strength

shear stress calculated by using the shear failure load and the cross-joined area

4 Symbols

Symbol Designation Unit References

2 2

A Cross-joined area (=b ) mm Formulae (1) and (2)

0

2

A True coating debonded area mm 8.5

c

b Test piece width mm Table 1

b Groove width of sample holder mm Figure 6 b)

1

b Sample holder width mm Figure 6 b)

2

b Pressure head width (=b) mm Figure 6 a)

3

c Pressure head length (

1 2

c Slot span of pressure head (>b) mm Figure 6 a)

2

d Space of two notches (=b) mm Table 1

h Test piece thickness mm Table 1

h Sample holder height mm Figure 6 b)

1

h Pressure head height mm Figure 6 a)

2

h Slot depth of pressure head (>b) mm Figure 6 a)

3

l Test piece length mm Table 1

l Sample holder length mm Figure 6 b)

1

l Groove length of sample holder (>c ) mm Figure 6 a)

2 1

P Failure load to debonding N Formulae (1) and (2)

c

σ Tensile bonding strength by calculation MPa Formula (1)

t

σ Tensile bonding strength of ceramics coating MPa 9.1

ct

τ Shear bonding strength by calculation MPa Formula (2)

τ Shear bonding strength of ceramics coating MPa 9.2

c

5 Principle

A cross-joined test piece is subjected to an increasing compression load giving a tensile or shear stress

on the area that is joined until the coating is debonded. Two different forms of mounting the cross-joined

test piece in a fixture are conducted to measure the tensile and shear bond strength, respectively. In the

case of the tensile test, a uniaxial tensile stress is generated when the cross-joined test piece is subjected

to compressive load, as shown in Figure 4. The tensile strength of the coating–substrate interface, or

the cohesive strength of the ceramic coating, will be obtained. In the case of the shear strength test, a

cross-joined test piece is loaded in compression to induce failure by shear at the interface, as shown in

© ISO 2020 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.