ISO 17449:2015

(Main)Road vehicles — Safety glazing materials — Test methods for properties of electrically heated glazing

Road vehicles — Safety glazing materials — Test methods for properties of electrically heated glazing

ISO 17449:2015 This provides the test methods and acceptance criteria for circuit continuity and heating power, driving visibility, electrical attachment bond performance, electrical attachment bending performance, hot spot identification and heating uniformity, defrosting efficiency, high voltage durability, low temperature performance and long term humidity durability, for all electrically heated safety glazing materials in a road vehicle. This International Standard provides test protocols for the static performance of an electrically heated glazing material; it is not representative of in-vehicle performance.

Véhicules routiers — Vitrages de sécurité — Méthodes d'essai pour les propriétés des vitrages chauffés électriquement

General Information

Buy Standard

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 17449

First edition

2015-11-15

Road vehicles — Safety glazing

materials — Test methods for

properties of electrically heated

glazing

Véhicules routiers — Vitrages de sécurité — Méthodes d’essai pour les

propriétés des vitrages chauffés électriquement

Reference number

ISO 17449:2015(E)

©

ISO 2015

---------------------- Page: 1 ----------------------

ISO 17449:2015(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 17449:2015(E)

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Specimens . 3

5 Conditioning of test specimens . 3

6 Application of test . 3

7 Requirements . 4

7.1 Circuit continuity and heating power . 4

7.1.1 Purpose of test . 4

7.1.2 Apparatus . 4

7.1.3 Procedure . 4

7.1.4 Expression of results . 4

7.2 Driving visibility . 5

7.2.1 Purpose of test . 5

7.2.2 Apparatus . 5

7.2.3 Procedure . 5

7.2.4 Expression of results . 5

7.3 Electrical attachment bond performance . 5

7.3.1 Purpose of test . 5

7.3.2 Apparatus . 5

7.3.3 Procedure . 6

7.3.4 Expression of results . 6

7.4 Electrical attachment bending performance . 6

7.4.1 Purpose of test . 6

7.4.2 Procedure . 6

7.4.3 Expression of results . 6

7.5 Hot spot and heating uniformity . 6

7.5.1 Purpose of test . 6

7.5.2 Apparatus . 7

7.5.3 Procedure . 7

7.5.4 Expression of results . 7

7.6 Defrosting efficiency . 7

7.6.1 Purpose of test . 7

7.6.2 Apparatus . 7

7.6.3 Procedure . 8

7.6.4 Expression of results . 8

7.7 High voltage durability . 8

7.7.1 Purpose of test . 8

7.7.2 Procedure . 8

7.7.3 Expression of results . 9

7.8 Low temperature performance . 9

7.8.1 Purpose of test . 9

7.8.2 Apparatus . 9

7.8.3 Procedure . 9

7.8.4 Expression of results . 9

7.9 Long term humidity durability . 9

7.9.1 Purpose of test . 9

7.9.2 Apparatus . 9

7.9.3 Procedure .10

7.9.4 Expression of results .10

8 Acceptance criteria .10

© ISO 2015 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 17449:2015(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information.

The committee responsible for this document is ISO/TC 22, Road vehicles, Subcommittee SC 35, Lighting

and visibility.

iv © ISO 2015 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 17449:2015(E)

Road vehicles — Safety glazing materials — Test methods

for properties of electrically heated glazing

1 Scope

This International Standard provides the test methods and acceptance criteria for circuit continuity and

heating power, driving visibility, electrical attachment bond performance, electrical attachment bending

performance, hot spot identification and heating uniformity, defrosting efficiency, high voltage durability,

low temperature performance and long term humidity durability, for all electrically heated safety glazing

materials in a road vehicle. This International Standard provides test protocols for the static performance

of an electrically heated glazing material; it is not representative of in-vehicle performance.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 3538, Road vehicles — Safety glazing materials — Test methods for optical properties

IEC 60051–2, Direct acting indicating analogue electrical measuring instruments and their accessories,

Part 2 — Special requirements for ammeters and voltmeters

3 Terms and definitions

For the purpose of this document, the following terms and definitions apply.

3.1

heating evaluation area

for Type 1 (3.7), represented by an area formed by outermost conductors at an extended distance of

20 mm wider than the bus bars (along the edges) and extended to 50 mm on both the top and bottom, in

the absence of specific requirements and for a glazing equipped with heating circuits formed by evenly

distanced conductive lines and bus bars near to the glass edges

Note 1 to entry: If the extended distance is over the edge of the glass, then take the glass edge as the border

of evaluation area. The size of this generated area is calculated using CAD, see Figure 1. For other specifically

designed heaters with e.g. circular shaped heater, product specification can be referenced for the heating

evaluation area.

for Type 2 (3.8) and Type 3 (3.9), shall be the same as the area of the heating elements themselves, in the

absence of special requirements

Note 2 to entry: No additional area shall be included.

© ISO 2015 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO 17449:2015(E)

1

2

3

4

5

Heating evaluation area

Key

1 glass

2 heating circuits

3 electrical attachment

4 bus bar

5 outmost conductor

Figure 1 — Heating evaluation area of Type 1

3.2

electrical attachment

components used for connecting to the vehicle power supply

3.3

defrosting

elimination of frost from the exterior of the glazing by heating at specified voltage

3.4

melted area

area of the outer glazed surface of the sample having a dry surface or covered with melted frost

Note 1 to entry: Partially melted area is excluded. The melted area shall be determined visually.

3.5

defrosting efficiency

ratio of the melted area to the heating evaluation area after supplying specified voltage for the specified

period of time at specified ambient condition

3.6

hot spot

any area on outer surface of the whole part that exceeds the maximum temperature defined in the

product specification after the part is supplied with specified voltage for the specified heating time

period at the specified ambient condition

3.7

Type 1

heater circuit consisting of conductors applied to the inside surface of a tempered or laminated safety

glass or a plastic safety glazing parts by means of a screen print, ink jet, or other method

2 © ISO 2015 – All rights reserved

20 mm

50 mm

50 mm

---------------------- Page: 6 ---------------

...

DRAFT INTERNATIONAL STANDARD

ISO/DIS 17449

ISO/TC 22/SC 11 Secretariat: ANSI

Voting begins on: Voting terminates on:

2014-08-25 2014-11-25

Road vehicles — Safety glazing materials — Test methods

for properties of electrically heated glazing

Véhicules routiers — Vitrages de sécurité — Méthodes d’essai pour les propriétés des vitrages chauffés

électriquement

ICS: 43.040.65

THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 17449:2014(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

©

PROVIDE SUPPORTING DOCUMENTATION. ISO 2014

---------------------- Page: 1 ----------------------

ISO/DIS 17449:2014(E)

Copyright notice

This ISO document is a Draft International Standard and is copyright-protected by ISO. Except as

permitted under the applicable laws of the user’s country, neither this ISO draft nor any extract

from it may be reproduced, stored in a retrieval system or transmitted in any form or by any means,

electronic, photocopying, recording or otherwise, without prior written permission being secured.

Requests for permission to reproduce should be addressed to either ISO at the address below or ISO’s

member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii © ISO 2014 – All rights reserved

---------------------- Page: 2 ----------------------

Road vehicles—Safety glazing materials –Test methods for performance of

electrically heated glazing

1. Scope

This International Standard provides the test methods for circuit continuity and heating power, driving

visibility, electrical attachment bond performance, electrical attachment bending performance, hot spot

identification and heating uniformity, defrosting efficiency, high voltage durability, low temperature

performance and long term humidity durability, for all electrically heated safety glazing materials in a

road vehicle. This standard provides test protocols for the static performance of an electrically heated

glazing material, it is not representative of in-vehicle performance.

2. Normative references

The following normative documents contain provisions which, through reference in this text, constitute

provisions of this International Standard. For dated references, subsequent amendments to, or revisions

of, any of these publications do not apply. However, parties to agreements based on this International

Standard are encouraged to investigate the possibility of applying the most recent editions of the

normative documents indicated below. For undated references, the latest edition of the normative

document referred to applies. Members of ISO and IEC maintain registers of currently valid International

Standards.

IEC 51-2 Direct acting indicating analogue electrical measuring instruments and their accessories

Parts 2 - Special requirements for ammeters and voltmeters

ISO 3538 Road vehicles —Safety glazing materials —Test methods for optical properties.

ISO 15082 Road vehicles —Tests for rigid plastic safety glazing materials

ECE R125 Uniform provisions concerning approval of motor vehicle with regards to the forwards

field of vision of the motor vehicle driver

3. Terms and definitions

For the purpose of this International Standard, the following definitions apply.

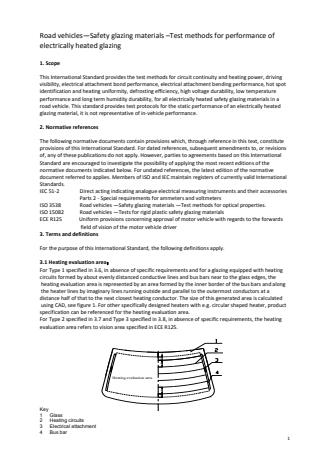

3.1 Heating evaluation area:

For Type 1 specified in 3.6, in absence of specific requirements and for a glazing equipped with heating

circuits formed by about evenly distanced conductive lines and bus bars near to the glass edges, the

heating evaluation area is represented by an area formed by the inner border of the bus bars and along

the heater lines by imaginary lines running outside and parallel to the outermost conductors at a

distance half of that to the next closest heating conductor. The size of this generated area is calculated

using CAD, see figure 1. For other specifically designed heaters with e.g. circular shaped heater, product

specification can be referenced for the heating evaluation area.

For Type 2 specified in 3.7 and Type 3 specified in 3.8, in absence of specific requirements, the heating

evaluation area refers to vision area specified in ECE R125.

Heating evaluation area

Key

1 Glass

2 Heating circuits

3 Electrical attachment

4 Bus bar

1

a/2 a b b/2

---------------------- Page: 3 ----------------------

Fig. 1, Heating evaluation area of Type 1

3.2 Electrical attachment:The components used for connecting to the vehicle power supply.

3.3 Defrosting: Elimination of frost or ice from the exterior of the glazing by heating at specified voltage.

3.4 Defrosting efficiency: A ratio of the melted area to the heating evaluation area after supplying

specified voltage for the specified period of time at specified ambient condition.

3.5 Hot spot: Any area on outer surface of the whole part that exceeds the maximum temperature

defined in the product specification after the part is supplied with specified voltage for the specified

heating time period at the specified ambient condition.

3.6 Type 1:Heater circuit consisting of conductors applied to the inside surface of a tempered or

laminated safety glass or a plastic safety glazing parts by means of a screen print, ink jet or other

method.

3.7 Type 2: Heater circuit consisting of discrete conductor lines applied to the inside of a laminated safety

glazing by incorporation of metal wires or any other suitable method.

3.8 Type 3: Heater circuit utilizing a transparent conductive film applied to one of the inner surfaces of a

laminated safety glazing.

4. Conditioning of test parts

Unless otherwise specified, parts to be tested shall be conditioned prior to testing under the following

conditions and for at least 4 hours:

— Ambient temperature: 23℃ ± 2℃

—Atmospheric pressure: 86 kPa to 106 kPa (860 mbar to 1 060 mbar)

— Ambient relative humidity: (50±20)%

5. Specimens

Test specimens shall be production parts.

6. Application of test

For certain types of safety glazing material, it is not necessary to carry out all the tests specified in this

International Standard. Test items for a certain type of electrically heating glazing are suggested in Table

1.

2

---------------------- Page: 4 ----------------------

Table 1

Type

No. Test item Paragraph

1 2 3

Circuit continuity and heating

1 7.1 × × ×

power

2 Driving visibility 7.2 × × ×

Electrical attachment bond

3 7.3 × × ×

performance

Electrical attachment Bending

4 7.4 × - -

performance

Hot spot identification and

5 7.5

× × ×

heating uniformity

6 Defrosting efficiency 7.6

× × ×

High voltage durability

7 7.7 × × ×

Low temperature performance

8 7.8 × × ×

Long term humidity durability

9 7.9 - × ×

× Test required.

- Test needs not be carried out.

7. Requirements

7.1 Circuit continuity and heating power

7.1.1 Purpose of test

The purpose of this test is to determine whether the heating system circuit has the correct continuity

between elements and heating power conforms to the product specification.

7.1.2 Apparatus

a) Variable direct current (DC) power supply, rated at a minimum of 1.5 times the voltage and 1.5 times

the current specified for the parts to be tested.

b) Voltage meter, conforming to IEC 51-2, with an Accuracy Class of 1.

c) Ampere meter, conforming to IEC 51-2, with an Accuracy Class of 1.

d) Heat sensitive paper.

e ) Projector conforms to ISO 3538.

f) Thermal camera, with range 0 to 100°C, accuracy +/-0.5°C, can measure and record the tested area

with a spatial resolution of 2 mm.

7.1.3 Procedure

7.1.3.1 Circuit continuity

For Type 1 parts, supply the voltage defined in product specification to the electrical attachments of the

part. Lay heat sensitive paper across the heating wires. Optionally, use a thermal camera to check the

part after power is supplied.

For Type 2 parts, supply the voltage defined in product specification to the electrical attachments of the

part. Set the part vertically between the projector and a display screen. Light is projected through the

part to the display screen. Wires with light shadow on the screen are broken wires.

For Type 3 parts, supply the voltage defined in product specification to the electrical attachments of the

part, record value of ampere meter.

7.1.3.2 Heating power

In absence of special requirements, heating the part for 30 minutes, and read the electrical current value

shown on the ampere meter.

7.1.4 Expression of results

7.1.4.1 Circuit continuity

3

---------------------- Page: 5 ----------------------

For Type 1 parts, check the colour change in the paper or in thermal camera due to heat. Make

record of broken heating wires.

For Type 2 parts, check the shadow of the part on the screen. Make record of broken wire position on the

part.

For Type 3 parts, calculate the resistance according to the voltage measured at the attachments and the

corresponding current as measured in 7.1.3.2, and determine the continuity.

7.1.4.2 Heating power

Calculate the heating power according to the voltage measu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.