ISO 20152-1:2010

(Main)Timber structures — Bond performance of adhesives — Part 1: Basic requirements

Timber structures — Bond performance of adhesives — Part 1: Basic requirements

ISO 20152-1:2010 specifies the basic performance requirements for adhesives used to bond structural timber components. These requirements depend upon the service conditions according to Service Classes 1, 2 and 3, defined therein.

Structures en bois — Performance d'adhérence des adhésifs — Partie 1: Exigences de base

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 20152-1

First edition

2010-08-01

Timber structures — Bond performance

of adhesives —

Part 1:

Basic requirements

Structures en bois — Performance d'adhérence des adhésifs —

Partie 1: Exigences de base

Reference number

ISO 20152-1:2010(E)

©

ISO 2010

---------------------- Page: 1 ----------------------

ISO 20152-1:2010(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2010

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2010 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 20152-1:2010(E)

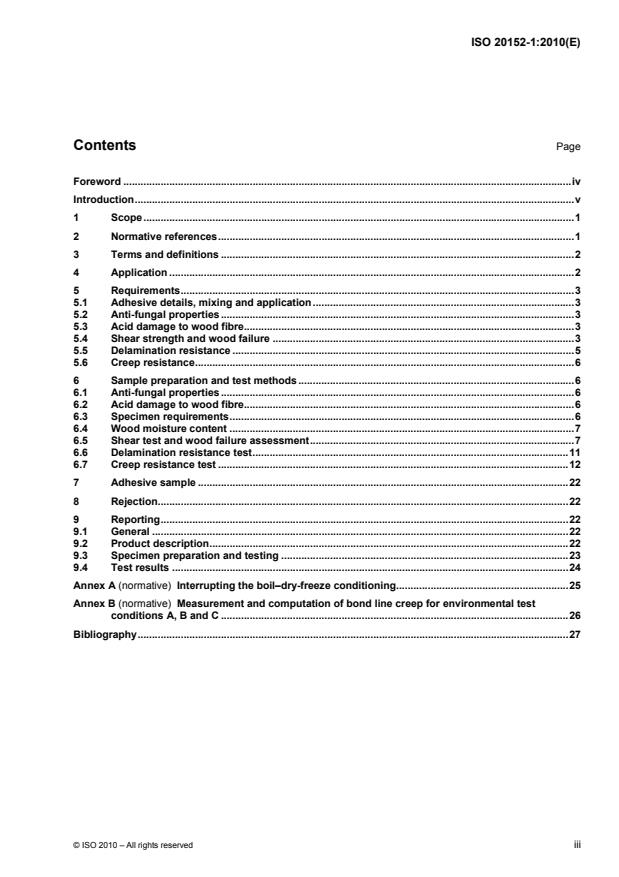

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Normative references.1

3 Terms and definitions .2

4 Application .2

5 Requirements.3

5.1 Adhesive details, mixing and application.3

5.2 Anti-fungal properties .3

5.3 Acid damage to wood fibre.3

5.4 Shear strength and wood failure .3

5.5 Delamination resistance .5

5.6 Creep resistance.6

6 Sample preparation and test methods .6

6.1 Anti-fungal properties .6

6.2 Acid damage to wood fibre.6

6.3 Specimen requirements.6

6.4 Wood moisture content .7

6.5 Shear test and wood failure assessment.7

6.6 Delamination resistance test.11

6.7 Creep resistance test .12

7 Adhesive sample .22

8 Rejection.22

9 Reporting.22

9.1 General .22

9.2 Product description.22

9.3 Specimen preparation and testing .23

9.4 Test results .24

Annex A (normative) Interrupting the boil–dry-freeze conditioning.25

Annex B (normative) Measurement and computation of bond line creep for environmental test

conditions A, B and C .26

Bibliography.27

© ISO 2010 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 20152-1:2010(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through

ISO technical committees. Each member body interested in a subject for which a technical committee has

been established has the right to be represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 20152-1 was prepared by Technical Committee ISO/TC 165, Timber structures.

ISO 20152 consists of the following parts, under the general title Timber structures — Bond performance of

adhesives:

⎯ Part 1: Basic requirements

⎯ Part 2: Additional requirements

iv © ISO 2010 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 20152-1:2010(E)

Introduction

ISO 20152 has been developed by ISO/TC 165 to provide performance requirements for adhesive bond lines

formed in structural wood products. It is largely based on the Canadian Standards Association's

[1] [2]

CSA O112.9 and CSA O112.10 . These CSA-based tests for resistance to shear in the dry and wet states,

resistance to delamination during exposure to wetting and drying, and resistance to creep static shear loading

during exposure to high humidity, heat and combined heat and moisture are designated as Method A. An

alternative “pathway” to the provisions has been provided by equivalent provisions of CEN (European

Committee for Standardization) standards, designated as Method B. Both the CSA and CEN standards

evaluate adhesive bonds against standardized wood species having tightly prescribed specific gravities.

ISO/TC 165 is nevertheless aware that North American and European species are not readily available in

many other countries. Future revisions of ISO 20152 are expected to include evaluations of bond line

performance made against other species having alternative specific gravities, provided evidence is produced

to show that such evaluations produce equivalent results.

ISO 20152 consists of two parts: this part gives minimum requirements for adhesive bonds in all jurisdictions;

ISO 20152-2 gives requirements that are specified by building regulatory authorities (high temperature

performance at or above 180 °C) in other jurisdictions or for specific applications (gap-filling performance).

In the above-mentioned Canadian standards, normative reference is made to a number of other documents,

which means that they (and a standard based on them) could not be used independently of those documents.

Such references have been replaced wherever possible in this part of ISO 20152 without unduly lengthening

the text. Because International Standards in the wood products area are not extensive, this has not been

practicable in all instances, and normative reference to CEN and ASTM (American Society for Testing and

Materials) standards has been retained. The ASTM references, for example, apply only to adhesive bond

requirements that are less likely to be specified or are rather lengthy.

The Method A provisions for adhesives provide assessments based on using tightly specified hardwood

and/or softwood substrates; the Method B provisions, on the other hand, are confined to the use of beech

substrates. The tests and provisions herein represent only a first stage of adhesive evaluation when

manufacturing an adhesively bonded structural wood product. It is anticipated that product standards will

specify qualification procedures that verify the capacity of the adhesive to produce effective wood bonds,

given the specific species and manufacturing processes involved. Within an international context, there are

many variations in species and manufacturing practices that cannot be taken into account in an adhesive

standard and thus case-by-case evaluations are essential.

Creep performance criteria and tests under elevated temperatures (180 °C) contained within CSA O112.9

have been removed. The matter was discussed within ISO/TC 165 and it was agreed that high temperature

performance (greater than 180 °C) is not a requirement in all jurisdictions. A number of countries do not

require the bond line itself to have a fire rating. Where a wood product (either protected or unprotected) is

required to have a fire rating for specific classes of building construction, the view is taken that it is the

structural assembly that must be evaluated by a national fire testing standard for assessment against national

building code requirements.

© ISO 2010 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 20152-1:2010(E)

Timber structures — Bond performance of adhesives —

Part 1:

Basic requirements

1 Scope

This part of ISO 20152 specifies the basic performance requirements for adhesives used to bond structural

timber components. These requirements depend upon the service conditions according to Service Classes 1,

2 and 3, as defined herein.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 3130, Wood — Determination of moisture content for physical and mechanical tests

EN 301, Adhesives, phenolic and aminoplastic, for load-bearing timber structures — Classification and

performance requirements

EN 302-1, Adhesives for load-bearing timber structures — Test methods — Part 1: Determination of bond

strength in longitudinal tensile shear strength

EN 302-2, Adhesives for load-bearing timber structures — Test methods — Part 2: Determination of

resistance to delamination

EN 302-3, Adhesives for load-bearing timber structures — Test methods — Part 3: Determination of the effect

of acid damage to wood fibres by temperature and humidity cycling on the transverse tensile strength

EN 15416-2, Adhesives for load bearing timber structures other than phenolic and aminoplastic — Test

methods — Part 2: Static load test of multiple bondline specimens in compression shear

EN 15425, Adhesives — One component polyurethane, for load bearing timber structures — Classification

and performance requirements

ASTM D1583, Standard Test Method for Hydrogen Ion Concentration of Dry Adhesive Films

ASTM D3535, Standard Test Method for Resistance to Creep Under Static Loading for Structural Wood

Laminating Adhesives Used Under Exterior Exposure Conditions

ASTM D4300, Standard Test Methods for Ability of Adhesive Films to Support or Resist the Growth of Fungi

© ISO 2010 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 20152-1:2010(E)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

Service Class 1

service class characterized by a moisture content in the materials corresponding to a temperature of 20 °C

and a relative humidity of the surrounding air exceeding 65 % for a few weeks per year

NOTE In Service Class 1, the average equilibrium moisture content of most softwoods does not exceed 12 %.

3.2

Service Class 2

service class characterized by a moisture content in the materials corresponding to a temperature of 20 °C

and a relative humidity of the surrounding air exceeding 85 % for a few weeks per year

NOTE In Service Class 2, the average equilibrium moisture content of most softwoods does not exceed 20 %. Such

conditions include resistance to the effects of moisture on structural performance due to construction delays or other

conditions of similar severity.

3.3

Service Class 3

service class characterized by climatic conditions leading to higher moisture content than Service Class 2

such as occurs when a member is fully exposed to the weather

3.4

specific gravity

ratio of the oven-dry mass of a specimen to the mass of a volume of water equal to the volume of the

specimen at the specified moisture content

3.5

oven-dry specific gravity

expression of the specific gravity based on oven-dry mass of wood and its oven-dry volume after drying to

constant mass in a ventilated oven at a temperature between 100 °C and 105 °C

3.6

flat-sawn timber

back-sawn timber

timber whose growth rings make an angle of less than 45° with its wider face

3.7

wood failure percentage

percentage of wood fibre ruptured during the separation of an adhesive/adherend interface and used to

evaluate the effectiveness of adhesive bonding

4 Application

The adhesive bond requirements given in this part of ISO 20152 are based on the performance of the

adhesive as measured by the following properties:

a) resistance to biological degradation (see 5.2);

b) acid damage to wood fibre (see 5.3);

c) resistance to shear in the dry and wet states (see 5.4);

d) resistance to delamination during exposure to wetting and drying (see 5.5);

e) resistance to creep under static shear loading during exposure to high humidity, heat and combined heat

and moisture (see 5.6).

2 © ISO 2010 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 20152-1:2010(E)

[1]

In the cases of c), d) and e), two alternative test methods are presented. Method A is based on CSA O112.9

and Method B on equivalent European test methods. Adhesive suppliers shall choose to test according to

either Method A or Method B for resistance to shear, resistance to delamination and resistance to creep.

There shall be no mixing of Methods A and B (for example, Method A for shear resistance and Method B for

delamination) nor shall retesting of the same adhesive be permitted once the choice of the test method family

(A or B) is made.

5 Requirements

5.1 Adhesive details, mixing and application

The adhesive shall be mixed and applied to the wood substrate in accordance with the adhesive

manufacturer's specification. The adhesive mix evaluated shall contain all ingredients, including fillers,

catalysts, hardeners, accelerators, modifiers, inhibitors and other additives necessary for the

⎯ setting or curing of the mix,

⎯ provision of specific properties to the liquid (appropriate viscosity, open and closed assembly times, etc.),

and

⎯ development of relevant properties in the final cured state such as minimum strength levels and creep

resistance.

The type and amount of fillers and/or extenders used in the adhesive shall comply with the adhesive

manufacturer's specification. Where the adhesive supplier specifies that adhesive and hardener are spread

separately, all test specimens shall be prepared in that manner and not as a glue mix.

5.2 Anti-fungal properties

If the adhesive contains amylaceous and/or protein-based components, the adhesive, when tested in

accordance with 6.1, shall possess sufficient anti-fungal properties to inhibit the growth of selected fungal

species to a grading of OC, OM or NG as defined in ASTM D4300.

5.3 Acid damage to wood fibre

If, when tested in accordance with 6.2, the pH of the adhesive mix or, in the case of separately spread

adhesive and hardener, one of its components, is less than 3, then the adhesive shall be tested in accordance

with EN 302-3 and shall meet the requirements of EN 301.

5.4 Shear strength and wood failure

5.4.1 General

Depending on whether Method A or B is used, shear strength and wood failure results (if any) shall meet or

exceed either the requirements of 5.4.2 or 5.4.3 respectively.

5.4.2 Method A (block shear)

5.4.2.1 General

When tested in accordance with 6.5, the block shear results shall meet or exceed the shear strength

requirements given in 5.4.2.2 and the percentage wood failure requirements given in 5.4.2.3.

© ISO 2010 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 20152-1:2010(E)

5.4.2.2 Shear strength requirements

The median shear strength requirements of samples following the treatments specified in 6.5.1.3.2 to 6.5.1.3.6

inclusive shall meet or exceed the requirements given in Table 1.

Table 1 — Median shear strength requirements (MPa)

Service Class 3 Service Classes 1 and 2

Treatment and condition at test

a b

Hardwood Softwood Softwood only

6.5.1.3.2 — Dry 19 10 10

6.5.1.3.3 — Wet (Vacuum-pressure test) 11 5,6 6,5

6.5.1.3.5 — Wet (Boil–dry-freeze test) 6,9 3,5 3,7

a

Oven-dry specific gravity shall not be less than 0,65.

b

Oven-dry specific gravity shall not be less than 0,49.

5.4.2.3 Wood failure

Only block shear specimens that are used in the strength analysis in connection with the requirements of

5.4.2.2 shall determine whether the percentage wood failure requirements of this section are met. The

percentage wood failure in the block shear specimens for each of the treatments shall meet or exceed the

values specified in Table 2.

Table 2 — Wood failure (%) requirements

Service Class 3 Service Classes 1 and 2

a b

Test condition

Hardwood Softwood Softwood only

Lower quartile Median Lower quartile Median Lower quartile Median

Dry 15 60 75 85 75 85

Wet 35 80 75 85 75 85

a

Oven-dry specific gravity shall not be less than 0,65.

b

Oven-dry specific gravity shall not be less than 0,49.

5.4.2.4 Interpretation of results

5.4.2.4.1 If a specimen fails with shear strength less than the median value specified in Table 1, but the

wood failure exceeds that specified in Table 3, it is permissible to disregard that specimen when determining

the median and lower quartile shear strength. If more than one-third of the specimens for any test condition

are discarded for this reason, the test shall be repeated for that condition.

5.4.2.4.2 If the shear strengths for all test conditions meet the requirements of Table 1, but the wood failure

of each sample fails to meet the requirements of Table 2, the percentage wood failure of the shear specimens

may be re-evaluated, provided that the percent wood failure of the 30 specimens evaluated under each test

condition meets the requirements of Table 4. The re-evaluation procedure shall be as follows.

Not more than three additional independent laboratories or agencies shall be identified for re-evaluating the

wood failure values. These laboratories or agencies shall be noted in the test report. All block shear

specimens from the tests shall be sent to the alternative laboratories or agencies to determine the median and

lower-quartile wood failure in accordance with this part of ISO 20152. The findings of the additional

laboratories or agencies and the procedures used shall be documented and appended to the test report.

If the requirements of Table 2 are met, the adhesive is considered to have passed the wood failure

requirements of this part of ISO 20152.

4 © ISO 2010 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 20152-1:2010(E)

Table 3 — Threshold wood failure (%) rates for discarding block shear test specimens

Test condition Hardwood Softwood

Dry 60 85

Wet 80 85

Table 4 — Minimum percent wood failure requirements for re-evaluation

Hardwood Softwood

Test condition

Lower quartile Median Lower quartile Median

Dry 10 50 65 75

Wet 50 70 65 75

5.4.3 Method B (tension shear)

When Method B is used, the tension shear test specified in EN 302-1, together with the requirements given in

EN 301, shall be applied.

5.5 Delamination resistance

5.5.1 General

Delamination tests shall be carried out using either Method A or Method B and shall be in accordance with

5.5.2 or 5.5.3 respectively.

5.5.2 Method A

5.5.2.1 Requirements for hardwoods

5.5.2.1.1 Service Class 3

For adhesives intended for use in Service Class 3, the total delamination within any one bond line shall not

exceed 1,6 % of the total length of the bond line in the assembly when tested in accordance with 6.6.1. In

order for the adhesive to be approved, three of the four assemblies tested according to 6.6.1 shall meet these

requirements.

5.5.2.1.2 Service Classes 1 and 2

There are no requirements for Service Classes 1 and 2 for hardwoods.

5.5.2.2 Requirements for softwoods — Service Classes 1, 2 and 3

For adhesives intended for use in Service Class 1, 2 or 3, the total delamination within any one bond line shall

not exceed 1 % of the total length of the bond line in the assembly when tested in accordance with 6.6.1. In

order for the adhesive to be approved, three of the four assemblies tested according to 6.6.1 shall meet these

requirements.

5.5.3 Method B

When Method B is used, the delamination test specified in EN 302-2, together with the requirements given in

EN 301, shall be applied.

© ISO 2010 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 20152-1:2010(E)

5.6 Creep resistance

5.6.1 General

Creep resistance tests for all three service classes shall be carried out using either Method A or Method B and

shall meet the requirements given in 5.6.2 or 5.6.3 respectively.

5.6.2 Method A

When tested in accordance with 6.7.1 and under environmental test conditions A, B and C (see Tables 5 and

6), the overall average creep displacement (see Figure 6 and Annex B) across all bonded cross-sections and

within any of the six specimens (full length or full length cut into partial lengths) shall not exceed 0,05 mm; the

maximum average creep displacement at any single bonded cross-section shall not exceed 0,25 mm after the

prescribed load period. In order for the adhesive to be approved, a minimum of two of the three full-length

specimens, or seven partial-length specimens taken from two full-length specimens, tested under each set of

environmental test conditions in accordance with 6.7.1, shall meet these requirements. If any bonded section

of the specimen breaks during the test or if the creep displacement requirement is not met, a retest is

permitted, provided the percentage wood failure of the bonded section for that specimen is 95 % or more.

Table 5 — Environmental test conditions applicable to adhesives

for use in Service Classes 1, 2 and 3

Service Class Environmental test conditions for adhesives

3 A, B, C

1 and 2 A, B

5.6.3 Method B

When Method B is used, the compression shear tests specified in EN 15416-2, together with the requirements

given in EN 15425, shall be applied.

6 Sample preparation and test methods

6.1 Anti-fungal properties

This test shall be performed in accordance with ASTM D4300.

6.2 Acid damage to wood fibre

The pH of the adhesive mix shall be determined in accordance with ASTM D1583. If required in accordance

with 5.3, the test for acid damage to wood fibre shall be undertaken according to EN 302-3.

6.3 Specimen requirements

6.3.1 Evaluation on hardwoods

When adhesives for hardwoods are tested in accordance with 6.5 to 6.7, the tests shall be performed on hard

maple (acer saccharum or acer nigrum) or the species specified in the relevant CEN standard.

6 © ISO 2010 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 20152-1:2010(E)

6.3.2 Evaluation on softwoods

When adhesives for softwoods are tested in accordance with 6.5 to 6.7, the tests shall be performed on one of

the following species, depending on the method chosen.

a) Method A

1) Lodgepole pine (pinus contorta var. latifolia)

2) Black spruce (picea mariana)

3) Douglas fir (psuedotsuga menziesii)

b) Method B

Species specified in the relevant CEN standard.

NOTE The addition of further test species will be considered if additional test data become available in the future.

6.3.3 Wood-specific gravity

6.3.3.1 A 25-mm-long full cross-section shall be cut at least 150 mm from the end of each board used to

provide wood samples for the tests specified in 6.5 to 6.7.

6.3.3.2 The oven-dry specific gravity shall be

a) not less than 0,65 for hardwoods,

b) not less than 0,49 for softwoods.

6.4 Wood moisture content

6.4.1 The moisture content shall be determined in accordance with ISO 3130.

6.4.2 The moisture content of the wood samples at the time of assembly shall be as specified by the

adhesive manufacturer.

6.4.3 When the adhesive sample is designated as suitable for bonding green timber, the moisture content

of each piece being bonded shall be greater than 30 % at the time of bonding.

6.5 Shear test and wood failure assessment

6.5.1 Method A — Block shear

6.5.1.1 Preparation of test assemblies

6.5.1.1.1 Six separate test assemblies for each of the tests indicated in 6.5.1.3.2 to 6.5.1.3.6 shall be

prepared: three for each of the minimum and maximum assembly times recommended by the adhesive

manufacturer. A total of 18 test assemblies are required to complete all tests in this section.

6.5.1.1.2 Laminations approximately 20 mm thick × 65 mm wide × 350 mm along the grain shall be

prepared from timber of length suitable for planing. The timber shall be of sufficient thickness so that the entire

surface to be bonded can be planed. Surfaces to be bonded shall not be sanded and shall be free of

contaminants.

© ISO 2010 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO 20152-1:2010(E)

6.5.1.1.3 The slope of grain of the laminations on the wide or narrow face shall not be greater than 1 in 15.

The laminations shall be free from knots larger than 3 mm in diameter. They shall also be free from defects

such as decay, pith, pitch pockets/streaks, unusual discolouration within the shearing area, machining defects

(chipped grain, feed roll polish, coarse knife marks and feed roll compression), and any drying defects (case

hardening, collapse, splits and checks). Only flat-sawn (also known as back-sawn) wood shall be used.

6.5.1.1.4 The timber shall be cut to the lamination length specified above. The laminations shall be

weighed and assembled in two piles so that laminations of approximately the same weight are bonded to each

other. The direction of the growth rings shall be oriented, when viewed on the end of the laminations in the

assembly, so that they are concave away from the bond line.

6.5.1.1.5 Bonding shall be performed within 24 h after the timber is planed. The assemblies shall be

prepared under ambient conditions such that the specified minimum and maximum assembl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.