ISO/PAS 23678-2:2020

(Main)Service personnel for the maintenance, thorough examination, operational testing, overhaul and repair of lifeboats (including free-fall lifeboats) and rescue boats (including fast rescue boats), launching appliances and release gear — Part 2: Service personnel initial training

Service personnel for the maintenance, thorough examination, operational testing, overhaul and repair of lifeboats (including free-fall lifeboats) and rescue boats (including fast rescue boats), launching appliances and release gear — Part 2: Service personnel initial training

This document establishes a uniform, safe and consistent approach to training and assessment of personnel to enable them to establish and maintain the required competencies in relation to maintenance, thorough examination, operational testing, overhaul and repair of lifeboats (including free-fall lifeboats) and rescue boats (including fast rescue boats), launching appliances and release gear. It also provides the necessary information for interested parties to grant authorization, effectively evaluate and audit training, supporting the IMO Requirements, Section 3. It specifies the initial training programme for personnel certified by a manufacture or by an authorized service provider to carry out maintenance, thorough examination, operational testing, overhaul and repair of lifeboats (including free-fall lifeboats) and rescue boats (including fast rescue boats), launching appliances and release gear. This document specifies the training requirements for Initial Service Technician training only. This document is intended to be used in conjunction with ISO/PAS 23678-1, ISO/PAS 23678-3 and ISO/PAS 23678-4. This document is applicable to the following types of lifeboats (including free-fall lifeboats), rescue boats (including fast rescue boats), launching appliances and release gear. Survival craft types: a) single fall totally enclosed lifeboats with sprinkler and air systems; b) twin fall totally enclosed lifeboats with sprinkler and air systems; c) partially enclosed lifeboats; d) tender lifeboats; e) freefall lifeboats; f) open lifeboat; g) inflatable rescue boats; h) rigid rescue boats; i) semi ridged inflatable rescue boats; j) rigid fast rescue boats; k) rigid inflatable fast rescue boats. Survival craft propulsion system types: a) inboard diesel engines; b) outboard engines; c) propeller drives; d) jet drives. Davit types: a) gravity single and twin fall outrigger; b) hydraulic single pivoting/luffing; c) hydraulic multi pivot/luffing; d) telescopic; e) gravity roller track; f) gravity free fall primary; g) free fall hydraulic secondary; h) A-frame hydraulic; i) single arm slewing (manual, electric); j) davits with stored power systems. Winch types: a) twin drum; b) single drum; c) gravity lowering, electric hoisting; d) gravity lowering, hydraulic hoisting; e) hydraulic hoisting and lowering. Hook release system types: a) on-load/off load(load not over centre); b) on-load/offload (load over centre); c) off load; d) freefall hydraulic; e) automatic.

Personnel de service pour la maintenance, l'examen approfondi, les essais opérationnels, la révision et la réparation des engins de sauvetage (y compris les engins de sauvetage en chute libre) et des canots de secours (y compris les canots de secours rapides), des appareils de mise à l'eau et des dispositifs de largage — Partie 2: Formation initiale du personnel de service

General Information

Relations

Buy Standard

Standards Content (Sample)

PUBLICLY ISO/PAS

AVAILABLE 23678-2

SPECIFICATION

First edition

2020-03

Service personnel for the

maintenance, thorough examination,

operational testing, overhaul and

repair of lifeboats (including free-fall

lifeboats) and rescue boats (including

fast rescue boats), launching

appliances and release gear —

Part 2:

Service personnel initial training

Reference number

ISO/PAS 23678-2:2020(E)

©

ISO 2020

---------------------- Page: 1 ----------------------

ISO/PAS 23678-2:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/PAS 23678-2:2020(E)

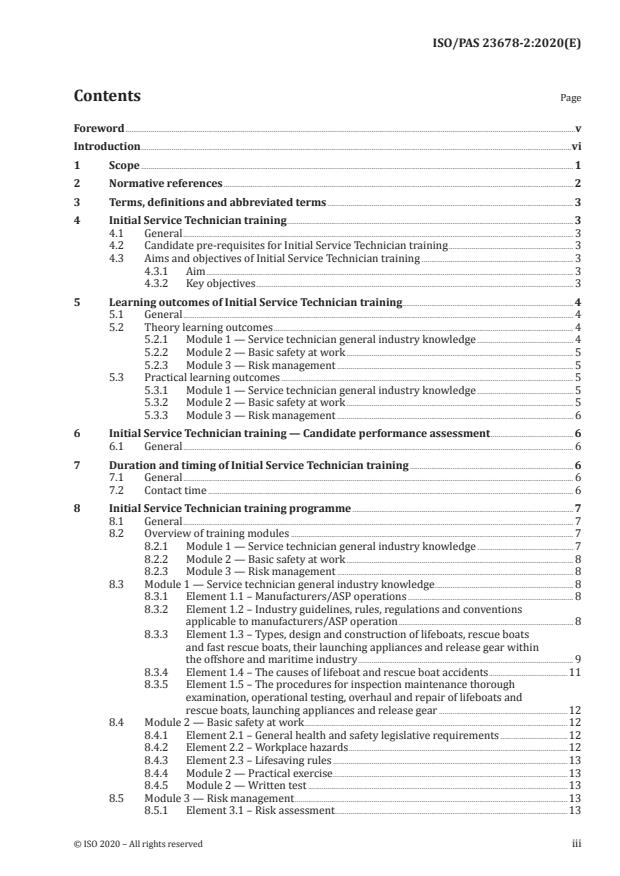

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 2

3 Terms, definitions and abbreviated terms . 3

4 Initial Service Technician training . 3

4.1 General . 3

4.2 Candidate pre-requisites for Initial Service Technician training . 3

4.3 Aims and objectives of Initial Service Technician training . 3

4.3.1 Aim . 3

4.3.2 Key objectives . 3

5 Learning outcomes of Initial Service Technician training . 4

5.1 General . 4

5.2 Theory learning outcomes . 4

5.2.1 Module 1 — Service technician general industry knowledge . 4

5.2.2 Module 2 — Basic safety at work . 5

5.2.3 Module 3 — Risk management . 5

5.3 Practical learning outcomes . 5

5.3.1 Module 1 — Service technician general industry knowledge . 5

5.3.2 Module 2 — Basic safety at work . 5

5.3.3 Module 3 — Risk management . 6

6 Initial Service Technician training — Candidate performance assessment .6

6.1 General . 6

7 Duration and timing of Initial Service Technician training . 6

7.1 General . 6

7.2 Contact time . 6

8 Initial Service Technician training programme . 7

8.1 General . 7

8.2 Overview of training modules . 7

8.2.1 Module 1 — Service technician general industry knowledge . 7

8.2.2 Module 2 — Basic safety at work . 8

8.2.3 Module 3 — Risk management . 8

8.3 Module 1 — Service technician general industry knowledge . 8

8.3.1 Element 1.1 – Manufacturers/ASP operations . 8

8.3.2 Element 1.2 – Industry guidelines, rules, regulations and conventions

applicable to manufacturers/ASP operation . 8

8.3.3 Element 1.3 – Types, design and construction of lifeboats, rescue boats

and fast rescue boats, their launching appliances and release gear within

the offshore and maritime industry . 9

8.3.4 Element 1.4 – The causes of lifeboat and rescue boat accidents .11

8.3.5 Element 1.5 – The procedures for inspection maintenance thorough

examination, operational testing, overhaul and repair of lifeboats and

rescue boats, launching appliances and release gear .12

8.4 Module 2 — Basic safety at work .12

8.4.1 Element 2.1 – General health and safety legislative requirements .12

8.4.2 Element 2.2 – Workplace hazards .12

8.4.3 Element 2.3 – Lifesaving rules .13

8.4.4 Module 2 — Practical exercise .13

8.4.5 Module 2 — Written test .13

8.5 Module 3 — Risk management .13

8.5.1 Element 3.1 – Risk assessment .13

© ISO 2020 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/PAS 23678-2:2020(E)

8.5.2 Element 3.2 – Risk intervention systems .14

8.5.3 Module 3 — Practical exercises .14

8.5.4 Module 3 — Written test .15

9 Initial Service Technician refresher training .15

9.1 General .15

9.2 Candidate pre-requisites for initial refresher training .15

9.3 Aims and objectives of Initial Service Technician refresher training.15

9.3.1 Aim of Initial Service Technician refresher training .15

9.3.2 Objectives of Initial Service Technician refresher training .15

9.4 Learning outcomes of Initial Service Technician refresher training .15

9.4.1 General.15

9.4.2 Theory — Learning outcomes . .15

9.5 Initial Service Technician refresher training — Candidate assessment .16

9.6 Duration and timing of Initial ASP Service Technician refresher training .16

10 Initial Service Technician refresher training programme .16

10.1 General .16

10.2 Module 4 — Service technician general industry knowledge .17

10.2.1 Element 4.1 – Legislative framework, industry guidelines, rules,

regulations, and conventions applicable to manufacturers and ASP's.17

10.2.2 Element 4.2 – The procedures for thorough examination, operational

testing, overhaul and repair of lifeboats and rescue boats, launching

appliances and release gear .17

10.3 Module 5 — Basic safety at work .17

Annex A (informative) Assessors checklists .18

Bibliography .24

iv © ISO 2020 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/PAS 23678-2:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 8, Ships and marine technology,

Subcommittee SC 1, Maritime safety.

A list of all parts in the ISO/PAS 23678 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

© ISO 2020 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/PAS 23678-2:2020(E)

Introduction

The industry recognises that a major objective is to prevent accidents and incidents from occurring. A

global network of competent personnel employed by authorized service providers is vital for lifesaving

appliances to remain fit for purpose, sustaining crew confidence and contributing to the prevention of

incidents and accidents.

It has been recognized from the new requirements in IMO Resolution MSC.402 (96) for maintenance,

thorough examination, operational testing, overhaul and repair of lifeboats (including free-fall

lifeboats) and rescue boats (including fast rescue boats), launching appliances, and release gear

(henceforth referred to as the "IMO Requirements" ) adopted 19th May 2016 and entering into force 1st

January 2020, that it is necessary to develop an International Standard. This necessity is based on the

IMO Requirements, paragraph 7.1.1:

"Employment and documentation of personnel certified in accordance with a recognized national,

international or industry standard as applicable, or a manufacturer's established certification programme.

In either case, the certification programme shall comply with section 8 for each make and type of equipment

for which service is to be provided;"

This document and associated ISO/PAS 23678-1, ISO/PAS 23678-3 and ISO/PAS 23678-4 have been

developed to achieve three key objectives.

1. The first objective was to develop training documents that would support the IMO Requirements,

section 7, paragraph 7.1.1.

2. The second objective was to develop training documents that would provide a consistent, reliable,

and standardised approach to training and provide a clear auditable trail for interested parties to

grant authorisation supporting the IMO Requirements, section 3, to approved service providers.

3. The third objective was to develop training documents that would enable personnel certified by

authorized service providers to develop and maintain competencies identified by industry experts

to a level that enables them to competently work unsupervised on equipment covered by this

document.

This document has been developed by identifying common design features in relation to survival craft,

davits, winches and release gear makes and types for which service is to be provided. This has been

achieved by conducting professional discussions with disciplined experts, to obtain the appropriate

information to develop a training programme that is fit for purpose. Successfully completing the service

technician training in ISO/PAS 23678-2, ISO/PAS 23678-3 and ISO/PAS 23678-4 enables personnel

certified by an authorized service provider to meet the IMO requirements, section 7, paragraph 7.1.1,

and section 8.

The ISO/PAS 23678-series on service technician training consist of:

— Part 1 Guidance to Training Providers; describes the competence route of the candidate and the

resources that the training provider needs to deliver the training.

— Part 2 Initial training; describes the training programme for initial familiarisation and induction

training that is classroom education. The training programme focuses on introducing individuals

to the complex terminology, rules and regulations, organisations, health and safety that a service

technician needs to understand in order to carry out their role.

— Part 3, Level 1 training; describes the controlled environment education and training delivered

at a training school. The training programme focuses on the technical training for type-specific

lifesaving appliances.

— Part 4, Level 2 in-field competence; describes the requirements for initial infield and ongoing

competence assessments.

vi © ISO 2020 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/PAS 23678-2:2020(E)

NOTE ISO/PAS 23678-1, ISO/PAS 23678-2 and ISO/PAS 23678-3 are referencing typical in-house/training

school training programmes. ISO/PAS 23678-4 is typical in-field performance of the personnel trained and

recording of their competence.

© ISO 2020 – All rights reserved vii

---------------------- Page: 7 ----------------------

PUBLICLY AVAILABLE SPECIFICATION ISO/PAS 23678-2:2020(E)

Service personnel for the maintenance, thorough

examination, operational testing, overhaul and repair of

lifeboats (including free-fall lifeboats) and rescue boats

(including fast rescue boats), launching appliances and

release gear —

Part 2:

Service personnel initial training

1 Scope

This document establishes a uniform, safe and consistent approach to training and assessment

of personnel to enable them to establish and maintain the required competencies in relation to

maintenance, thorough examination, operational testing, overhaul and repair of lifeboats (including

free-fall lifeboats) and rescue boats (including fast rescue boats), launching appliances and release gear.

It also provides the necessary information for interested parties to grant authorization, effectively

evaluate and audit training, supporting the IMO Requirements, Section 3.

It specifies the initial training programme for personnel certified by a manufacture or by an authorized

service provider to carry out maintenance, thorough examination, operational testing, overhaul

and repair of lifeboats (including free-fall lifeboats) and rescue boats (including fast rescue boats),

launching appliances and release gear. This document specifies the training requirements for Initial

Service Technician training only.

This document is intended to be used in conjunction with ISO/PAS 23678-1, ISO/PAS 23678-3 and

ISO/PAS 23678-4.

This document is applicable to the following types of lifeboats (including free-fall lifeboats), rescue

boats (including fast rescue boats), launching appliances and release gear.

Survival craft types:

a) single fall totally enclosed lifeboats with sprinkler and air systems;

b) twin fall totally enclosed lifeboats with sprinkler and air systems;

c) partially enclosed lifeboats;

d) tender lifeboats;

e) freefall lifeboats;

f) open lifeboat;

g) inflatable rescue boats;

h) rigid rescue boats;

i) semi ridged inflatable rescue boats;

j) rigid fast rescue boats;

k) rigid inflatable fast rescue boats.

© ISO 2020 – All rights reserved 1

---------------------- Page: 8 ----------------------

ISO/PAS 23678-2:2020(E)

Survival craft propulsion system types:

a) inboard diesel engines;

b) outboard engines;

c) propeller drives;

d) jet drives.

Davit types:

a) gravity single and twin fall outrigger;

b) hydraulic single pivoting/luffing;

c) hydraulic multi pivot/luffing;

d) telescopic;

e) gravity roller track;

f) gravity free fall primary;

g) free fall hydraulic secondary;

h) A-frame hydraulic;

i) single arm slewing (manual, electric);

j) davits with stored power systems.

Winch types:

a) twin drum;

b) single drum;

c) gravity lowering, electric hoisting;

d) gravity lowering, hydraulic hoisting;

e) hydraulic hoisting and lowering.

Hook release system types:

a) on-load/off load(load not over centre);

b) on-load/offload (load over centre);

c) off load;

d) freefall hydraulic;

e) automatic.

2 Normative references

There are no normative references in this document.

2 © ISO 2020 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/PAS 23678-2:2020(E)

3 Terms, definitions and abbreviated terms

For the purposes of this document, the terms, definitions and abbreviated terms given in

ISO/PAS 23678-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

4 Initial Service Technician training

4.1 General

This programme is designed to meet the initial training and assessment requirements for all prospective

service technicians. The Initial Service Technician training explains how competence shall be assessed

and certified.

4.2 Candidate pre-requisites for Initial Service Technician training

To hold or be working towards a nationally recognised qualification in engineering or mechanics, but

not unduly excluding similar qualifications.

4.3 Aims and objectives of Initial Service Technician training

4.3.1 Aim

The aim of this programme is to give individuals who have little or no experience as a service technician

the theoretical and practical knowledge of manufacturer’s/ASP operations at an entry level that enables

them to progress through the Level 1 and Level 2 service technician training.

4.3.2 Key objectives

The key objectives are:

a) introduce and familiarise candidates to the terminology and equipment;

b) ensure candidates have an awareness of the functions and roles of the various organisations within

the maritime and offshore industry, in relation to manufacturers/ASP operations;

c) ensure candidates can identify the types, components, role, function, design and construction

requirements for lifeboats (including free-fall lifeboats), rescue boats and fast rescue boats,

including on-load release gear and launching appliances;

d) ensure candidates can identify and explain the key causes of lifeboat and rescue boat accidents;

e) ensure candidates understand the roles and responsibilities of a manufacturer/ASP service

technician;

f) ensure candidates can identify, interpret and apply to their role key legislation, industry guidelines,

rules, regulations and conventions applicable to ASP/manufacturer’s operations;

g) ensure candidates can identify the procedures for maintenance thorough examination, operational

testing, repair and overhaul of lifeboat (including free-fall lifeboats), rescue boats and fast rescue

boats, launching appliances and on-load release gear, as applicable;

h) ensure candidates can identify the requirements for reports and records;

© ISO 2020 – All rights reserved 3

---------------------- Page: 10 ----------------------

ISO/PAS 23678-2:2020(E)

i) ensure candidates understand and can demonstrate in their working environment basic safety and

awareness.

5 Learning outcomes of Initial Service Technician training

5.1 General

The learning outcomes for Initial Service Technician training are specified in 5.2 and 5.3. During

the training programme, candidates shall be required to demonstrate they have the skills and

understanding required to be deemed competent in relation to the learning outcomes.

5.2 Theory learning outcomes

5.2.1 Module 1 — Service technician general industry knowledge

To successfully complete the Initial Service Technician training programme, candidates shall be able to:

a) identify the organisations and regulatory bodies associated with the maritime and oil and gas

industry, and their roles and functions;

b) understand the legislative framework and industry guidelines applicable to manufacturers and ASPs;

c) identify and interpret the relevant rules and regulations, including international conventions

related to the maintenance, thorough examination, operational testing, overhaul and repair of

lifeboats and rescue boats, launching appliances and release gear;

d) explain the key roles and responsibilities of a service technician;

e) identify the different types of lifeboats, rescue boats, fast rescue boats and davit-launched liferafts,

and explain their key roles and functions;

f) identify and interpret the design and construction requirements for lifeboats (including free-fall

lifeboats), rescue boats and fast rescue boats and davit-launched liferafts;

g) identify the various types of launching appliances for lifeboats, rescue boats and davit-launched

liferafts;

h) identify the individual components that make the various types of launching appliances for

lifeboats, rescue boats, fast rescue boats and davit-launched liferaft, and explain their role and how

they function;

i) identify the characteristics of mechanical restraints, and explain their function;

j) identify the various types of on-load release gear, and interpret their design and construction

requirements;

k) identify the common causes of lifeboat and rescue boat accidents, and the measures to mitigate

risks and to stop accidents from occurring;

l) identify and interpret procedures for the inspection, maintenance, thorough examination,

operational testing, overhaul and repair of lifeboats, rescue boats, launching appliances and release

gear; and

m) identify and interpret procedures for issuing a report of service and statement of fitness for

purpose.

4 © ISO 2020 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/PAS 23678-2:2020(E)

5.2.2 Module 2 — Basic safety at work

To successfully complete the Initial Service Technician training programme, candidates shall be able to:

a) identify and explain health and safety legislation in the work environment, including specific

requirements whilst conducting activities on-board;

b) identify diverse types and uses of PPE;

c) explain the basic principles of manual handling techniques;

d) explain the requirements of COSHH and its application in the workplace;

e) identify typical workplace hazards, including pressure systems in lifeboats;

f) explain procedures to follow and identify the equipment required for working at height;

g) identify and explain relevant lifesaving rules associated with the typical workplace hazards;

h) identify and explain company specific lifesaving/golden rules; and

i) explain basic lifesaving appliance safety.

5.2.3 Module 3 — Risk management

To successfully complete the Initial Service Technician training programme, candidates shall be able to:

a) explain the difference between hazard, risk and control;

b) explain the concepts of risk assessment and techniques used;

c) explain the risk assessment process and the use of a risk matrix;

d) explain how to apply control to bring the risk down to ALARP;

e) identify the need for dynamic risk assessment; and

f) explain the function of a risk intervention system and how to carry out an intervention.

5.3 Practical learning outcomes

5.3.1 Module 1 — Service technician general industry knowledge

To successfully complete the Initial ASP Service Technician training programme, candidates shall be

able to de

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.