ISO/IEC TR 6371:1989

(Main)Information processing — Interchange practices and test methods for unrecorded instrumentation magnetic tape

Information processing — Interchange practices and test methods for unrecorded instrumentation magnetic tape

Describes interchange requirements for longitudinal-oriented, unrecorded magnetic tape wound on reels or hubs designed for instrumentation-recording applications. Recording and playback of the tapes shall be done on equipment according to ISO 6068 and to the application instructions of the manufacturer.

Traitement de l'information — Spécifications et méthodes d'essai pour bandes magnétiques vierges utilisées pour l'enregistrement de mesures

General Information

Standards Content (Sample)

TECHNICAL

ISOIIEC

REPORT

TR- 6371

First edition

1989-03-15

Information processing - Interchange practices

and test methods for unrecorded instrumentation

magnetic tape

-

s

= -s

=

-z

E

=

z =

=

=

f

z =

z Z

z s

-, = Reference number

-

=

s Z

-@ -

-

ISO/IEC/TR 6371 : 1989 (EI

---------------------- Page: 1 ----------------------

ISO/IEC/TR 6371 : 1989 (EI

Contents

Page

Foreword. iv

v

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1 Scope .

1

1.1 General .

1.2 Archivaltapes . 1

2 Normative references . 1

1

3 Classification of tapes. .

1

Tape type designator .

3.1

1

Basic indicator .

3.2

Magnetit coating characteristics indicator . 1

3.3

High resolution Performance class indicator . 2

3.4

Base material and thickness indicator . 2

3.5

Widthindicator . 2

3.6

3.7 Lengthindicator . 2

2

3.8 Reelindicator.‘.

2

4 Sampling .

2

5 General requirements .

2

5.1 Materials .

2

5.2 Toxiccompounds .

2

5.3 Flammable materials .

2

5.4 Tapereels .

2

Tapewind .

5.5

2

Packaging .

5.6

Environmental conditions . . . . . . . . . . . . . . . . . . . . . . s . . . . . . . . . . . . . . . . . . 2

5.7

2

V

5.8 Test environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0 ISO/IEC 1989

All rights reserved. No part of this publication may be reproduced or utilized in any form or by any

means, electronie or mechanical, including photocopying and microfilm, without Permission in

writing from the publisher.

ISO/IEC Copyright Office l Case postale 56 l CH-1211 Geneve 20 l Switzerland

Printed in Switzerland

---------------------- Page: 2 ----------------------

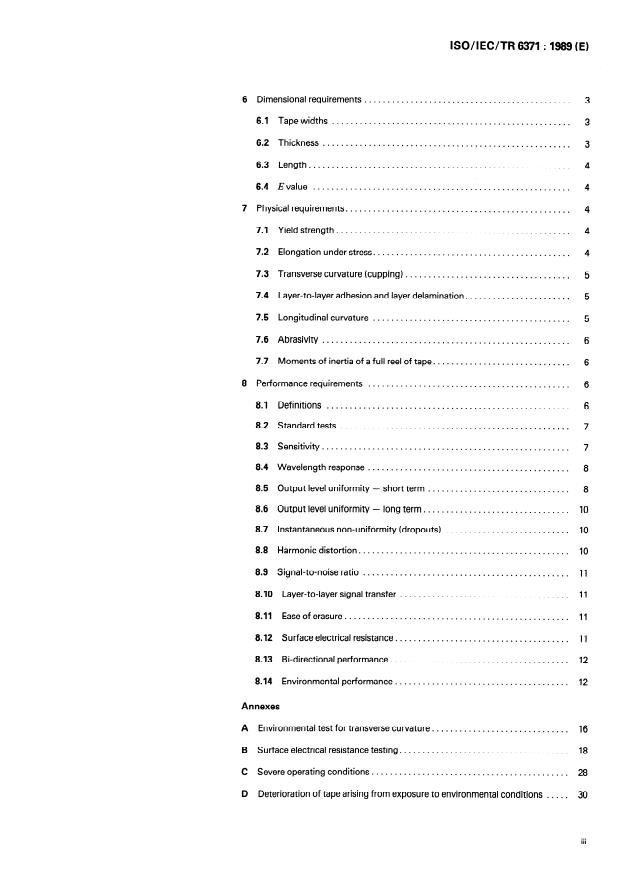

ISO/IEC/TR 6371 : 1989 (El

3

6 Dimensional requirements .

6.1 Tapewidths. . 3

6.2 Thickness . 3

......................................................... 4

6.3 Length

Evalue . 4

6.4

4

7 Physical requirements.

................................................

7.1 Yield strength 4

...................................................

4

7.2 Elongation under stress.

..........................................

7.3 Transverse curvature (cupping) 5

....................................

5

7.4 Layer-to-layer adhesion and layer delamination .

7.5 Longitudinal curvature 5

...........................................

6

7.6 Abrasivity .

6

Moments of inertia of a full reel of tape. .

7.7

6

Performance requirements

8 .

6

8.1 Definitions

.....................................................

7

8.2 Standardtests

..................................................

7

8.3 Sensitivity

......................................................

8

8.4 Wavelength response .

8

8.5 Output level uniformity - short term .

10

8.6 Output level uniformity - long term .

10

8.7 Instantaneous non-uniformity (dropouts) .

10

8.8 Harmonie distortion. .

11

8.9 Signal-to-noise ratio .

11

8.10 Layer-to-layer Signal transfer .

................................................. 11

8.11 Easeoferasure

11

8.12 Surface electrical resistance .

12

Bi-directional Performance.

8.13 .

8.14 Environmental Performance. 12

.....................................

Annexes

16

Environmental test for transverse curvature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A

18

B Surface electrical resistance testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

C Severe operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deterioration of tape arising from exposure to environmental conditions . . . . . 30

D

. . .

Ill

---------------------- Page: 3 ----------------------

ISO/IEC/TR 6371 : 1989 (E)

Foreword

ISO (the International Organization for Standardization) and IEC (the International

Electrotechnical Commission) together form a System for worldwide standardization as

a whole. National bodies that are members of ISO or IEC participate in the develop-

ment of International Standards through technical committees established by the

respective organization to deal with particular fields of technical activity. ISO and IEC

technical committees collaborate in fields of mutual interest. Other international

organizations, governmental and non-governmental, in liaison with ISO and IEC, also

take part in the work.

In the field of information technology, ISO and IEC have established a joint technical

committee, ISOAEC JTC 1.

The main task of a technical committee is to prepare International Standards but in

exceptional circumstances, the publication of a technical report of one of the following

types may be proposed:

1, when the necessary support within the techni cal committee cannot be

- type

obtained for the publication of an International Standard, despite repeated efforts;

when the su bject is still under technical development requiring wider

- type 2,

exposure;

- type 3, when a technical committee has collected data of a different kind from

,

that which is normally published as an International Standard (“state of the art”, for

example).

Technical reports of types 1 and 2 are subject to review within three years of publica-

tion, to decide whether they tan be transformed into International Standards.

Technical reports of type 3 do not necessarily have to be reviewed until the data they

provide are considered to be no longer valid or useful.

ISO/IEC/TR 6371, which is a technical report of type 2, was prepared by

ISO/IEC JTC 1, lnformation technology.

iv

---------------------- Page: 4 ----------------------

ISO/IEC/TR 6371 : 1989 (El

Introduction

Draft international Standard ISO/DIS 6371 was distributed to ISO member bodies in

August 1982 and was approved for issue as an International Standard.

During the preparation of the final text, however, it was found necessary to replace the

existing test for surface electrical resistance and, moreover, amendments to the text

were necessitated to ensure alignment with related International Standards which at

that time were in the course of preparation.

Bearing in mind the need for this document, but also the amount of time that has

elapsed since it was approved and the extent to which the original text has been

modified, it is considered preferable to make the document available at the present

time in the form of a type 2 ISO/IEC Technical Report. lt is expected that within two to

three years, it will be further revised with a view to its issue as an International

Standard.

V

---------------------- Page: 5 ----------------------

This page intentionally lefi blank

---------------------- Page: 6 ----------------------

~~ ~

TECHNICAL REPORT ISO/IEC/TR 6371 : 1989 (E)

Information processing - Interchange practices

and test methods for unrecorded instrumentation

magnetic tape

1 Scope

ISO 6668 : 1985, lnforma tion processing - Recording

charac teris tics o f ins trumen ta tion magne tic tape (including

1 .l General

telemetry s ystems) - In terchange requiremen ts.

This Technical Report specifies the interchange requirements

In case of conflicts between reference documents and this

for longitudinally-orientated, unrecorded magnetic tape wound

Technical Report, the Technical Report should prevail.

on reels or hubs designed for use in instrumentation-recording

applications. Tapes for interchange shall be recorded and

played back on equipment conforming to ISO 6668 and to the

3 Classification of tapes

applicable instructions furnished by the equipment manufac-

turer.

3.1 Tape type designator

1.2 Archival tapes

Tape types covered by this Technical Report may be

designated in the following form:

lt is recognized that archival interchange tapes, or those pro-

duced by Systems in use Prior to the publication of this

TIT-El-HTI-127(500)-760(2500)-GI

Technical Report, may not meet the stringent requirements

that follow. Users requiring exchange of Standard tapes should

TIT E 1

verify that the planned interchange of data will be accom-

Basic Magnetit coating Performance

plished according to the following Standards for tapes, reels,

indicator characteristic

class indicator

and recorderlreproducers : ISO 1858, ISO 1860, ISO 3802,

(sec 3.2) indicator (E magnetic coating

ISO 6668, and this Technical Report.

(see 3.3) only) (see 3.4)

HTI 127WO) 760(2500) GI

Base material Width Length

Ree1

2 Normative references

and thickness indicator

indicator indicator

indicator (sec 3.6) (see 3.7) (sec 3.8)

(sec 3.5)

The following Standards contain provisions which, through

reference in this text, constitute provisions of this Technical

Report. At the time of publication, the editions indicated were

3.2 Basic indicator

valid. All Standards are subject to revision, and Parties to

agreements based on this Technical Report are encouraged to

The basic indicator defines the general application for a par-

investigate the possibility of applying the most recent editions

ticular class of tape as specified herein. The basic indicator is

of the Standards listed below. Members of IEC and ISO main-

“TIT” for tape, instrumentation type.

tain registers of currently valid International Standards.

ISO 1184 : 1983, Plastics - Determination of tensife properties

3.3 Magnetit coating characteristics indicator

of films.

The magnetic coating characteristics indicator defines a

ISO 1858 : 1977, Information processing - General purpose

coating in terms of its short wavelength recording capabilities:

hubs and reels, with 76 mm (3 in) centrehole, for magnetic

tape used in in terchange ins trumen ta tion applica tions.

a) indicator ‘IB” (intermediate resolution) denotes tape in-

ISO 1860 : 1986, Information processing - Precision reels for tended for use on low-band and intermediate-band

recorder/ reproducers [ having a recorded wavelength not

magne tic tape used for in terchange ins trumen ta tion appli-

ca tions. less than 6,1 Pm (240 Pin)] ;

ISO 3802 : 1980, Information processing - General purpose b) indicator ‘IE” (high resolution) denotes tape intended

for use on wideband recorder/reproducers [having a re-

reels with 8 mm (5116 in) centre hole for magnetic tape for

in terchange ins trumen ta tion applica tions. corded wavelength down to 1,5 Pm (60 Pin)].

1

---------------------- Page: 7 ----------------------

ISO/IEC/TR 6371 : 1989 (EI

See ISO 6068 for further information on the types of 5 General requirements

recorderlreproducers.

5.1 Materials

3.4 High resolution Performance class indicator

The tape shall consist of a layer of ferromagnetic material on a

High resolution tape (see 3.3) is subclassified as either El or E2

suitable continuous and splice-free, flexible base material and

depending on its output level uniformity (see 8.5 and 8.6) and

shall have the physical, magnetic and other characteristics as

dropout Performance (see 8.7).

specified herein.

3.5 Base material and thickness indicator

5.2 Toxic compounds

The base material and thickness indicator combines two letters

Tape or reel components which may Cause bodily harm by con-

and a number as an indicator. The number indicates whether

tact, inhalation or ingestion shall not be used.

the back side of the base material has been treated; untreated

tape is defined by the number “1” and treated tape is defined

by the number “2”. The first letter identifies the type of base

5.3 Flammable materials

material, and the second letter indicates the nominal thickness

of the base material. The base material is indicated by the letter

Flammable materials which will ignite from a match flame, and

“H” for polyethylene terephthalate (polyester). Base material of

when so ignited continue to burn in a still carbon dioxide at-

nominal thickness 38,l Pm (0,001 5 in) is defined by the letter

mosphere, shall not be part of the magnetic tape.

“R” and base material of nominal thickness 25,4 Pm (0,001 in)

is defined by the letter “T”.

5.4 Tape reels

3.6 Width indicator

Tape reels shall conform to the requirements of ISO 1860 or

The width indicator is the nominal width of the tape in tenths of ISO 1858 or ISO 3802.

a millimetre followed in parentheses by its equivalent in

thousandths of an inch. For example, tape with a nominal

5.5 Tape wind

width of 12,7 mm (0,5 in) has the width indicator 127 (500)

(sec 6.1).

The tape shall be wound with the magnetic coated surface

facing the surface of the hub.

3.7 Length indicator

The length indicator is the nominal length, in metres (feet), of a

5.6 Packaging

tape wound on a reel (see 6.3).

lt is recommended that each reel of magnetic tape should be

enclosed, as a minimum, by an individually sealed polyethylene

3.8 Ree1 indicator

wrapper packaged in an appropriate Container which provides

This Symbol identif ies the type of reel on which the tape is support of the enclosed reel at the hub.

wound, as follows

5.7 Environmental conditions

Table 1 - Ree1 indicator

NOTE - Recent research results as reported in annex D suggest that

Definition

Designator

certain Points of the following specification may result in an

undesirable operating condition. A future revision in this area may be

General purpose reels conforming to ISO 1858

GI

issued.

G2 General purpose reels conforming to ISO 3802

P Precision reels conforming to ISO 1860

5.7.1 Standard operating conditions

Temperature range : 10°Cto400C(500Fto1040F)

4 Sampling (sec note 1)

Relative humidity range: 40 % to 60 %

Sampli schemes and AQL (acceptable quality level) criteria

w

(sec note 2)

for

Barometric pressure : 50 kPa to 106 kPa

a) dimensional requirements;

5.7.2 Extended operating conditions (see note 3)

b) physical requirements;

Performance requirements;

Cl Temperature range : 0 OC to 55 OC (32 OF to 131 OF)

(see note 1)

shall be separately agreed between interchange Parties. Esch

Relative humidity range: 25 % to 95 %

Sample tape shall be tested against the above requirements in

(see notes 2 and 4)

Order to determine compliance or non-compliance of the

sampled batch. 5 kPa to 106 kPa

Barometric pressure :

2

---------------------- Page: 8 ----------------------

ISO/IEC/TR 6371 : 1989 (El

5.7.3 Severe operating conditions (sec note 4) 5.8 Test environment

Annex C provides guidelines for instrumentation tape use in 5.8.1 Preliminary conditioning

severe conditions, for example, airborne recording.

Individual test clauses may require preliminary conditioning of

each reel of tape Prior to testing to relieve Stresses and establish

uniformity. Reels of tape shall be wound and rewound with a

5.7.4 Standard shipping and short-term storage

tensile forte of 0,131 N/mm If: 0,033 N/mm (12 ozf/in + 3 ozf/in)

tape width. The tape shall then be conditioned at 23 OC & 3 OC

Temperature range : 10 OC to 40 OC (59 OF to 77 OF)

(73 OF * 5 OF), 40 % RH to 60 % RH for a minimum of 24 h,

Relative humidity range: 10 % to 40 %

and stored under the same environmental conditions until re-

(sec note 3)

quired for testing.

Barometric pressure : 5 kPa to 106 kPa

5.8.2 Standard test environment

During testing, unless otherwise specified, the testing environ-

5.7.5 Extended shipping and short-term storage

ment shall be

(see note 3)

Temperature : 23 OC + 3 OC (73 OF + 5 OF)

Temperature range : - 60 OC to + 60 OC

Relative humidity : 45 % to 55 %

(- 76 OF + 140 OF)

Barometric pressure : 80 kPa to 106 kPa

Relative humidity range: 0 % to 95 %

(see notes 2 and 4)

Barometric pressure : 5 kPa to 106 kPa 6 Dimensional requirements

6.1 Tape widths

5.7.6 Recommended long-term storage

The Standard tape widths shall be as listed in table 2.

Temperature range : 15 OC to 25 OC (59 OF to 77 OF)

Table 2 - Standard tape widths

Relative humidity range: IO % to 20 % .

Standard tape widths

(see note 2)

mm in

Barometric pressure : 50 kPa to 106 kPa

6,30 0,248

-x,o6 - 8,00* 5

NOTES

12,70 -g 1.

0,500 -;,m

I

1,000

2540 -;,,.

1 These temperatures apply to the air in the immediate vicinity of the

-0,004

tape within the tape transport.

2,000

50,80 -:,,o

-&xM

2 Relative humidity values shall be maintained under non-

condensing conditions.

This Technical Report does not at present define Performance

requirements (see clause 8) for tape widths of 6,30 mm

3 Extended environments may require component qualification for

(0,248 in) or 50,80 mm (2,000 in).

tape and transport.

6.2 Thickness

4 The deterioration of tape under adverse conditions is progressive

(see annex D for further information). Tapes subjected to such condi-

tions for long periods may need additional restrictions (see recom- Maximum total thickness is a function of Standard reel dimen-

mended long-term storage conditions in 5.7.6).

sions, length, coating thickness and E value (sec 6.4.1).

For reels with 76 mm (3 in) centre hole

- Tape length by reel diameters

Table 3a)

(Reels to ISO 1860 or ISO 1858)

Ree1 diameters

1

I I

356 mm (14 in) 381 mm (15 in) 406 mm (16 in)

’ 266 mm (IO,5 in) 318 mm (12,5 in)

203 mm (8 in)

Nominal Tape

Nom-

base perf. Nom- Minimum Nom- Minimum Nom- Minimum Nom- Minimum Minimum Nom- Minimum

class inal actual inal actual inal actual inal actual inal actual

thickness actual inal

length”“) length”) length”“) length”) length”“) length”) length”“) length”) length”“)

length” 1 length”“) length”)

m m ft

ft m m ft m m ft m m ft m m ft

mm in m m

-

+) +) +) 1520 1531 5025 - - - - -

0,038 0,001 5 B 365 366 1200 760 768 2520

2200 2204 7230 - - - - - -

0,025 0,001 0 B 525 527 1730 1100 1105 3625 +) +) +)

3303 10795 3800 3792 12440

0,025 0,001 0 El or 670 673 2210 1400 1410 4625 2190 2204 7230 2800 2815 9235 3290

E2

IThese nominal lengths are metric conversions, rounded for convenience of description, of original values in feet.

*)

I I

1 **) IThese lengths apply for an E value as specified in 6.4.2.

I

+ ) BI / B2 tape not normally available on 318 mm reel.

3

---------------------- Page: 9 ----------------------

ISO/lEC/TR 6371 : 1989 (EI

Table 3b) - Tape length by reel diameters for reels with 8 mm (0,312 5 in) centre hole

(Reels to ISO 3862)

Ree1 diameters

102 mm (4 in) 127 mm 146 mm 178 mm

Nominal

(5 in) (5,75 in) (7 in)

Metal Plastic

base Type perf.

thickness

class

Tape lengths

min. min. min. min. min.

m ft m ft m ft m ft m ft

B 100 330 112 365 180 590 242 795 371 1220

B 146 4430 161 530 256 840 347 1140 535 1 755

El or E2 186 610 205 675 274 900 445 1460 683 2240

7.1.2 Test procedure

6.3 Length

Tape shall be supplied in the minimum lengths given in table 3.

The Sample tape shall undergo the preliminary conditioning

specified in 5.8. A Strip of tape, minimum length 200 mm (8 in),

6.4 E value shall be clamped in the grips set for an initial Separation of

100 mm (4 in). The test specimen shall be clamped in the

6.4.1 Definition >

testing machine taking care to align the long axis of the

specimen with an imaginary line joining the Points of attach-

E value: The radical distance by which the reel flanges extend

ment of the grips to the machine. The grips shall be tightened

beyond the outermost layer of tape wound on a reel.

evenly and firmly to the degree necessary to prevent slipping

of the specimen during the test. The rate of grip Separation

6.4.2 Requirement

shall be 0,8 mm/s (2 in/min). Not less than five specimens of a

particular type of tape shall be tested. A forte-strain diagram

The minimum E value shall be 254 mm (0,100 in) for reels

shall be obtained. Means shall be provided for calibration of the

having a diameter up to and including 203 mm (8 in), and shall

strain axis. The forte corresponding to 1 % offset yield shall

be 3,18 mm (0,125 in) for reels having a diameter greater than

equal or exceed the value listed in the table. For a more com-

203 mm (8 in).

plete description of Standard test procedures, see ISO 1184.

6.4.3 Test condition

In the event that the breakage of a particular tape occurs Prior

to reaching the 1 % offset yield Point, the load at break shall

The tape pack shall be wound on a reel of a type listed in table 1

equal or exceed the value listed in table 4.

under a tensile forte of 0,131 N/mm + 0,033 N/mm

(12 ozf/in & 3 ozf/in) of tape width.

NOTE - ISO 1184 describes the determination of tensile properties of

films and does not refer specifically to magnetic tape.

NOTE - lt is current practice in some countries to use a Standard ten-

sile forte of 0,175 N/mm (16 ozf/in) tape width. Interchange Parties

should exercise caution when defining tests involving this parameter-.

7.2 Elongation under stress

7.2.1 Definition

7 Physical requirements

7.1 Yield strength Elongation under stress is defined as the differente between an

initially measured unstressed tape length and the final stressed

7.1.1 Requirement

tape length expressed as a percentage of the unstressed tape

length.

The tensile forte at break and/or the 1 % offset yield Point

(defined in ISO 1184) shall not be less than the value specified

7.2.2 Requirement

in table 4.

The elongation shall not exceed the value specified in table 4.

Table 4 - Physical requirements

Base material and

7.2.3 Test procedure

thickness indicator

4.5) Units

Characteristics (see

The Sample tape shall undergo the preliminary conditioning

HR HT

specified in 5.8. Samples at least 600 mm (24 in) long shall be

Yield strength or N/mm (Ibf/in)

clamped so as to hang in the test area in a Standard test en-

tape width

breaking forte

vironment, for at least 24 h under no externally applied stress

%

Elongation

before tests are begun. Before any weight is hung on the

u nder stress

samples, a mark shall be made approximately 500 mm (20 in)

---------------------- Page: 10 ----------------------

ISO/IEC/TR 6371 : 1989 (El

imately 100 mm (4 in) in length with a non-oozing adhesive

from the Point of clamping to serve as a reference Point for

length measurement before and after stress. The distance be- material. The tube shall be made of a non-oxidizing metal such

as brass or corrosion resisting steel and shall have a mass of not

tween the mark and clamping Point shall be measured ac-

curately to the nearest 0,25 mm (0,Ol in). A weight shall be less than 15 g (0,5 oz) nor more than 30 g (1,O oz). The tube

shall be mounted in bearings so that it may be rotated freely

attached which applies a tensile forte of 0,5 N (2 ozf). The

distance shall be taken as the base distance for calculation of around its central axis and easily removed from the bearings.

residual elongation. When measurement of the base distance

Weights shall be attached to the free end of the tape so as to

has been made, the test shall begin. A weight, which applies a

apply a stress of 40 MPa (5 700 Ibf/in*). A small Strip of double

tensile forte of 1,75 N/mm (IO Ibf/in) of tape width, shall be

coated adhesive tape shall be affixed to the magnetic side of

attached to the tape below the mark at zero time and allowed to

the tape about 25 mm (1 in) above the weight. The tube shall

hang undisturbed for 180 min I!I 30 s, at which time the

then be slowly and uniformly rotated so that the tape, held in

weight shall be removed from the tape. The tape shall be

tension by the weight, Winds uniformly around the tube into a

allowed to hang under its own weight for an additional

compact and even roll. The double-coated tape when wound

180 min &30 s. The distance between the mark and the Point

into the test roll acts to secure the roll and prevent its un-

of clamping shall then be measured to the nearest 0,25 mm

winding when the weight is removed.

(0,Ol in) with an applied tensile forte of 0,5 N (2 ozf). The dif-

ference between the base distance and the final distance shall

The tube supporting the rolled tape shall be removed from the

be expressed as a percentage of the base distance to determine

winding set-up and subjected to a heat and humidity cycle of

compliance with table 4.

16 h to 18 h at 55 OC * 3 OC (130 OF Ir: 5 OF) and 80 % RH to

90 % RH, followed by 4 h at 55 OC k 3 OC (130 OF & 5 OF)

7.3 Transverse curvature kupping)

dry heat (less than 5 % RH). During the humidification and dry

heat Phase, Provision shall be made so that the air surrounding

7.3.1 Definitions

the tube is constantly circulated to assure uniformity of condi-

tions throughout the test area. At the end of the dry heat cycle,

7.3.1.1 transverse curvature (cupping) : The angle formed

the rod shall be removed from the conditioned area and allowed

by the conjunction of lines constructed perpendicular to the

to come to equilibrium in a Standard test environment (sec 5.8).

edges of the tape when viewed end on.

To evaluate the tape for layer-to-layer adhesion, the end of the

roll on the rod shall be carefully opened and the double-coated

7.3.1 .2 initial cupping : The transverse cupping measured

tape shall be removed. The rod shall then be held between the

Prior to testing under humidifying or desiccating conditions.

thumb and fingers and the untabbed tape shall be observed to

note if the first two or three layers loosen up of their own

7.3.1.3 differential cupping : The arithmetic differente be-

accord; if this occurs, there is no adhesion and the tape has

tween the transverse curvatures measured on the humidified

passed the test. If no loosening, or very little loosening of the

tape and the desiccated tape.

outermost layer is observed, the free end of the tape shall be

unwound slowly until250 mm (IO in) has been unwound. The

7.3.2 Requirement

free end shall then be allowed to hang and the tape shall be

observed to see if it will loosen by itself. If it will not unwind

This test is not needed for Standard interchange of Polyester

unaided, the tube with the tape hanging freely shall be slowly

tapes. If needed by the User, the test procedure and recom-

rotated in the direction of tape unwind. If the tape adheres to

manded Performance levels appear in annex A.

itself and refuses to begin to unwind after the rod has been

rotated through one-fourth revolution or 7c/2 rad (900), it shall

7.4 Layer-to- layer adhesion and layer

be considered to have failed the test. After the rotation test has

dela mination

been made, the free end of the tape shall be held and the rod

allowed to fall, thereby unwinding the tape. The unwound tape

7.4.1 Definition

shall be checked for evidente of coating delamination and in

this way the severity of adhesion is established. Any tape which

Layer-to-layer adhesion is defined as the tendency for one layer

will not self-unwind after rotating the rod through 71/2 rad (9OO)

of tape to adhere to an adjacent layer of tape in the same pack.

or which Shows any delamination except in the 50 mm (2 in)

nearest the rod shall be considered as having failed this test.

7.4.2 Requirement

7.5 Longitudinal curvature

A Sample of tape when conditioned according to the procedure

described in 7.4.3, shall exhibit no sticking or layer-to-layer

7.5.1 Definition

adhesion.

longitudinal CU : The deviation of each tape edge from

a straight line.

7.4.3 Test procedure

7.5.2 Requirement

The Sample tape shall undergo the preliminary conditioning

specified in 5.8. Samples of 900 mm (36 in) in length shall be

The longitudinal curvature of a tape shall not exceed 3,8 mm

allowed to hang without bends or kinks in a Standard test

when measured along a 1 m straight edge. (Alternatively, in

environment (see 5.8) for at least 24 h under no externally

inch dimensions, the curvature shall not exceed 0,125 in when

applied stress, before tests are begun.

measured along a 36 in straight edge.)

The Sample length shall be fastened at one end, magnetic side

NOTE - The longitudinal curvature measu rement has a resolu

tion of

down, to a 12,7 mm (0,5 in) diameter hollow tube, approx-

about 0,4 mm (0,031 25 in).

5

---------------------- Page: 11 ----------------------

ISO/IEC/TR 6371 : 1989 (El

Table 5 - Maximum moments of inertia for full reels

Nominal reel diameter

Nominal tape

318 mm (12,5 in) 355 mm (14 in) 381 mm (15 in) 406 m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.