ISO 19904-1:2019

(Main)Petroleum and natural gas industries — Floating offshore structures — Part 1: Ship-shaped, semi-submersible, spar and shallow-draught cylindrical structures

Petroleum and natural gas industries — Floating offshore structures — Part 1: Ship-shaped, semi-submersible, spar and shallow-draught cylindrical structures

This document provides requirements and guidance for the structural design and/or assessment of floating offshore platforms used by the petroleum and natural gas industries to support the following functions: — production; — storage and/or offloading; — drilling and production; — production, storage and offloading; — drilling, production, storage and offloading. NOTE 1 Floating offshore platforms are often referred to using a variety of abbreviations, e.g. FPS, FSU, FPSO (see Clauses 3 and 4), in accordance with their intended mission. NOTE 2 In this document, the term "floating structure", sometimes shortened to "structure", is used as a generic term to indicate the structural systems of any member of the classes of platforms defined above. NOTE 3 In some cases, floating platforms are designated as "early production platforms". This term relates merely to an asset development strategy. For the purposes of this document, the term "production" includes "early production". This document is not applicable to the structural systems of mobile offshore units (MOUs). These include, among others, the following: — floating structures intended primarily to perform drilling and/or well intervention operations (often referred to as MODUs), even when used for extended well test operations; — floating structures used for offshore construction operations (e.g. crane barges or pipelay barges), for temporary or permanent offshore living quarters (floatels), or for transport of equipment or products (e.g. transportation barges, cargo barges), for which structures reference is made to relevant recognized classification society (RCS) rules. This document is applicable to all possible life-cycle stages of the structures defined above, such as: — design, construction and installation of new structures, including requirements for inspection, integrity management and future removal, — structural integrity management covering inspection and assessment of structures in-service, and — conversion of structures for different use (e.g. a tanker converted to a production platform) or re‑use at different locations. The following types of floating structure are explicitly considered within the context of this document: a) ship-shaped structures and barges; b) semi-submersibles; c) spars; d) shallow-draught cylindrical structures. In addition to the structural types listed above, this document covers other floating platforms intended to perform the above functions, consisting of partially submerged buoyant hulls made up of any combination of plated and space frame components. These other structures can have a great range of variability in geometry and structural forms (e.g. tension leg platforms) and, therefore, can be only partly covered by the requirements of this document. In other cases, specific requirements stated in this document can be found not to apply to all or part of a structure under consideration. NOTE 4 Requirements for topsides structures are presented in ISO 19901-3. In the above cases, conformity with this document requires the design to be based upon its underpinning principles and to achieve a level of safety equivalent, or superior, to the level implicit in it. NOTE 5 The speed of evolution of offshore technology often far exceeds the pace at which the industry achieves substantial agreement on innovation in structural concepts, structural shapes or forms, structural components and associated analysis and design practices, which are continuously refined and enhanced. On the other hand, International Standards can only capture explicit industry consensus, which requires maturation and acceptance of new ideas. Consequently, advanced structural concepts can, in some cases, only be partly covered by the requirements of this document. This document is applicable to steel floating structures. The principles documented herein are, however, considered to be generally applicable to structures fabricated in materials other

Industries du pétrole et du gaz naturel — Structures en mer flottantes — Partie 1: Unités monocoques, unités semi-submersibles et unités spars

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 19904-1

Second edition

2019-05

Petroleum and natural gas

industries — Floating offshore

structures —

Part 1:

Ship-shaped, semi-submersible,

spar and shallow-draught cylindrical

structures

Industries du pétrole et du gaz naturel — Structures en mer

flottantes —

Partie 1: Unités monocoques, unités semi-submersibles et unités spars

Reference number

ISO 19904-1:2019(E)

©

ISO 2019

---------------------- Page: 1 ----------------------

ISO 19904-1:2019(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2019

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2019 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 19904-1:2019(E)

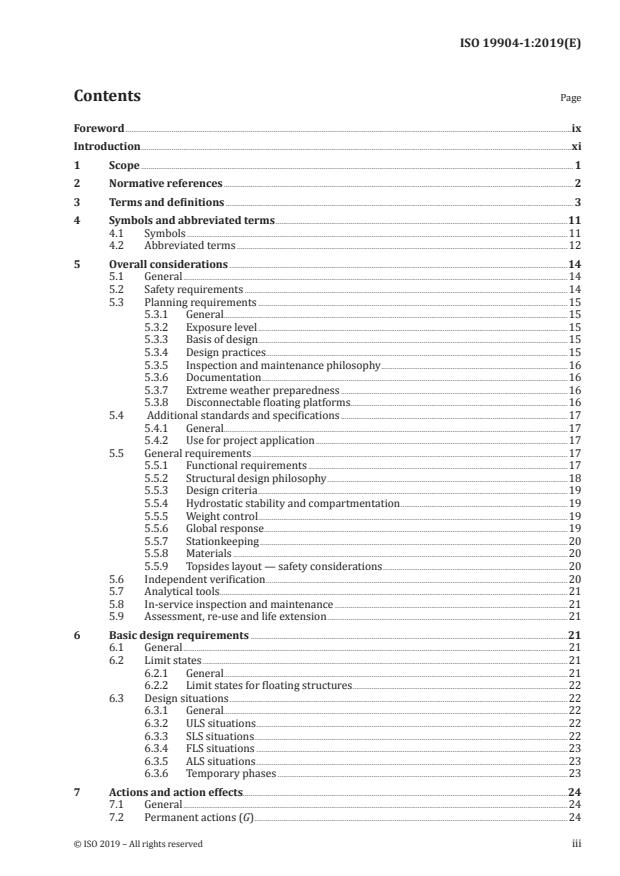

Contents Page

Foreword .ix

Introduction .xi

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 3

4 Symbols and abbreviated terms .11

4.1 Symbols .11

4.2 Abbreviated terms .12

5 Overall considerations .14

5.1 General .14

5.2 Safety requirements .14

5.3 Planning requirements .15

5.3.1 General.15

5.3.2 Exposure level .15

5.3.3 Basis of design . .15

5.3.4 Design practices . . .15

5.3.5 Inspection and maintenance philosophy .16

5.3.6 Documentation .16

5.3.7 Extreme weather preparedness .16

5.3.8 Disconnectable floating platforms.16

5.4 Additional standards and specifications .17

5.4.1 General.17

5.4.2 Use for project application .17

5.5 General requirements .17

5.5.1 Functional requirements .17

5.5.2 Structural design philosophy .18

5.5.3 Design criteria .19

5.5.4 Hydrostatic stability and compartmentation .19

5.5.5 Weight control .19

5.5.6 Global response.19

5.5.7 Stationkeeping .20

5.5.8 Materials .20

5.5.9 Topsides layout — safety considerations .20

5.6 Independent verification .20

5.7 Analytical tools .21

5.8 In-service inspection and maintenance .21

5.9 Assessment, re-use and life extension .21

6 Basic design requirements .21

6.1 General .21

6.2 Limit states .21

6.2.1 General.21

6.2.2 Limit states for floating structures .22

6.3 Design situations .22

6.3.1 General.22

6.3.2 ULS situations .22

6.3.3 SLS situations .22

6.3.4 FLS situations .23

6.3.5 ALS situations .23

6.3.6 Temporary phases .23

7 Actions and action effects.24

7.1 General .24

7.2 Permanent actions (G) .24

© ISO 2019 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 19904-1:2019(E)

7.3 Variable actions (Q) .24

7.4 Environmental actions (E ) .25

e

7.4.1 General.25

7.4.2 Environmental site-specific data .25

7.4.3 Wind actions .26

7.4.4 Current actions .28

7.4.5 Wave actions .28

7.4.6 Vortex-induced vibrations and motions .31

7.4.7 Direct ice action .32

7.4.8 Temperature effects .32

7.4.9 Tidal effects .33

7.4.10 Geotechnical hazards .33

7.5 Accidental actions (A) .33

7.5.1 General.33

7.5.2 Collision .33

7.5.3 Dropped objects .34

7.5.4 Fire and blast.34

7.6 Other actions.34

7.6.1 Stationkeeping actions .34

7.6.2 Sloshing actions .34

7.7 Repetitive actions .35

7.8 Action combinations .35

8 Global analysis .35

8.1 General .35

8.2 Static and mean response analyses .35

8.2.1 General.35

8.2.2 Static equilibrium in still-water condition .36

8.2.3 Mean response analysis .36

8.3 Global dynamic behaviour .36

8.3.1 General.36

8.3.2 Analysis models .37

8.3.3 Mass .37

8.3.4 Damping .38

8.3.5 Stiffness .38

8.3.6 Action classification .38

8.3.7 Turret moored systems .38

8.4 Frequency domain analysis .38

8.5 Time domain analysis .39

8.6 Uncoupled analysis .39

8.7 Coupled analysis .39

8.8 Resonant excitation and response .39

8.9 Platform offset .40

8.10 Air gap and wave crest assessment .40

8.10.1 Air gap .40

8.10.2 Wave crest effects .40

8.11 Platform motions and accelerations.41

8.12 Model tests.41

8.13 Structural analysis .42

8.13.1 General.42

8.13.2 Short-term response analysis .42

8.13.3 Long-term response analysis .42

8.13.4 Design wave analysis .42

9 Structural modelling, analysis and design.42

9.1 General .42

9.2 Representative values of actions .43

9.2.1 General.43

9.2.2 Representative values of actions for operating phases .43

iv © ISO 2019 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 19904-1:2019(E)

9.2.3 Representative values of actions for temporary phases .43

9.2.4 Actions at interfaces . . .44

9.3 Scantlings .44

9.4 Modelling .45

9.4.1 General.45

9.4.2 Global models .45

9.4.3 Local models .45

9.4.4 Response evaluation .46

9.4.5 Model verification .46

9.5 Structural analysis .47

9.5.1 General principles .47

9.5.2 Linear analysis .47

9.5.3 Non-linear analysis .48

9.5.4 Vibration analysis . .48

9.6 Structural strength .49

9.6.1 Representative strength values .49

9.6.2 Yield strength . . .49

9.6.3 Buckling strength .49

9.7 Design verification .49

9.7.1 General.49

9.7.2 SLS deflection limits .50

9.7.3 Partial factor design format .50

9.7.4 Working stress design format.52

9.7.5 Reliability-based methods .53

9.8 Special design issues .53

9.8.1 General.53

9.8.2 Slamming .54

9.8.3 Green water .54

9.8.4 Sloshing .54

9.8.5 Wave impact on deck.54

9.8.6 Local structure and components .54

9.9 Materials .55

9.9.1 General.55

9.9.2 Material selection .56

9.9.3 Through-thickness tension .56

9.9.4 Aluminium substructures .57

9.9.5 Cement grout .57

9.9.6 Elastomeric material .57

9.10 Corrosion protection of steel .57

9.10.1 General.57

9.10.2 Electrical bonding and isolation .58

9.11 Fabrication and construction .58

9.11.1 General.58

9.11.2 Inspection and testing during fabrication and construction .58

9.11.3 Fabrication details .

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.