ISO/PRF 23767

(Main)Children’s furniture -- Mattresses for cots and cribs -- Safety requirements and test methods

Children’s furniture -- Mattresses for cots and cribs -- Safety requirements and test methods

Titre manque

General Information

Standards Content (sample)

INTERNATIONAL ISO

STANDARD 23767

First edition

Children’s furniture — Mattresses for

cots and cribs — Safety requirements

and test methods

PROOF/ÉPREUVE

Reference number

ISO 23767:2021(E)

ISO 2021

---------------------- Page: 1 ----------------------

ISO 23767:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 23767:2021(E)

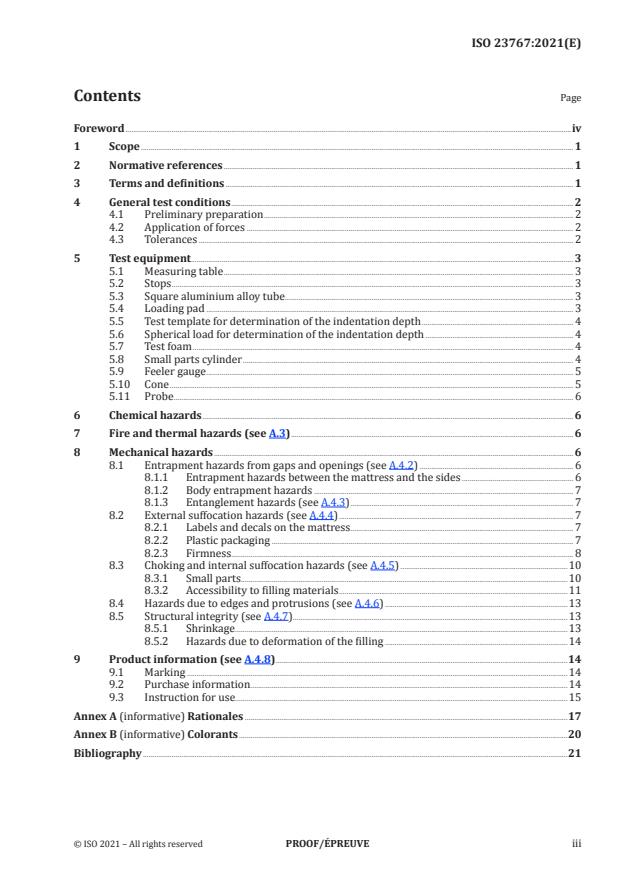

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 General test conditions .................................................................................................................................................................................. 2

4.1 Preliminary preparation ................................................................................................................................................................. 2

4.2 Application of forces .......................................................................................................................................................................... 2

4.3 Tolerances ................................................................................................................................................................................................... 2

5 Test equipment....................................................................................................................................................................................................... 3

5.1 Measuring table ...................................................................................................................................................................................... 3

5.2 Stops ................................................................................................................................................................................................................. 3

5.3 Square aluminium alloy tube ...................................................................................................................................................... 3

5.4 Loading pad ............................................................................................................................................................................................... 3

5.5 Test template for determination of the indentation depth ............................................................................... 4

5.6 Spherical load for determination of the indentation depth ............................................................................. 4

5.7 Test foam ...................................................................................................................................................................................................... 4

5.8 Small parts cylinder ............................................................................................................................................................................ 4

5.9 Feeler gauge ............................................................................................................................................................................................... 5

5.10 Cone .................................................................................................................................................................................................................. 5

5.11 Probe ................................................................................................................................................................................................................ 6

6 Chemical hazards ................................................................................................................................................................................................. 6

7 Fire and thermal hazards (see A.3) ................................................................................................................................................... 6

8 Mechanical hazards ........................................................................................................................................................................................... 6

8.1 Entrapment hazards from gaps and openings (see A.4.2) ................................................................................ 6

8.1.1 Entrapment hazards between the mattress and the sides .......................................................... 6

8.1.2 Body entrapment hazards ....................................................................................................................................... 7

8.1.3 Entanglement hazards (see A.4.3) .................................................................................................................... 7

8.2 External suffocation hazards (see A.4.4) .......................................................................................................................... 7

8.2.1 Labels and decals on the mattress .................................................................................................................... 7

8.2.2 Plastic packaging ............................................................................................................................................................. 7

8.2.3 Firmness .................. .................................................... ............................................................................................................ 8

8.3 Choking and internal suffocation hazards (see A.4.5) .......................................................................................10

8.3.1 Small parts..........................................................................................................................................................................10

8.3.2 Accessibility to filling materials .......................................................................................................................11

8.4 Hazards due to edges and protrusions (see A.4.6) ...............................................................................................13

8.5 Structural integrity (see A.4.7) ...............................................................................................................................................13

8.5.1 Shrinkage .............................................................................................................................................................................13

8.5.2 Hazards due to deformation of the filling ...............................................................................................14

9 Product information (see A.4.8) ........................................................................................................................................................14

9.1 Marking ......................................................................................................................................................................................................14

9.2 Purchase information .....................................................................................................................................................................14

9.3 Instruction for use .............................................................................................................................................................................15

Annex A (informative) Rationales ........................................................................................................................................................................17

Annex B (informative) Colorants ...........................................................................................................................................................................20

Bibliography .............................................................................................................................................................................................................................21

© ISO 2021 – All rights reserved PROOF/ÉPREUVE iii---------------------- Page: 3 ----------------------

ISO 23767:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 136, Furniture.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 23767:2021(E)

Children’s furniture — Mattresses for cots and cribs —

Safety requirements and test methods

1 Scope

This document specifies safety requirements and test methods for mattresses, including mattress

bases and mattress toppers, used in children's cots, cribs and suspended baby beds, for domestic and

non-domestic use.This document does not apply to mattresses for carry cots and pram bodies, inflatable mattresses,

water mattresses and mattresses used for medical purposes.2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2439, Flexible cellular polymeric materials — Determination of hardness (indentation technique)

ISO 8124-1, Safety of toys — Part 1: Safety aspects related to mechanical and physical properties

ISO 8124-2:2014, Safety of toys — Part 2: FlammabilityEN 71-3:2019, Safety of toys — Part 3: Migration of certain elements

ISO 13936-2, Textiles — Determination of the slippage resistance of yarns at a seam in woven fabrics —

Part 2: Fixed load methodEN 597-1, Furniture - Assessment of the ignitability of mattresses and upholstered bed bases — Part 1:

Ignition source smouldering cigaretteEN 1334:1996, Domestic furniture - Beds and mattresses - Methods of measurement and recommended

tolerancesEN 1730:2012, Furniture – Tables – Test methods for the determination of stability, strength and durability

3 Terms and definitionsFor the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at http:// www .electropedia .org/

3.1

mattress topper

thin product that comprises a cover and filling(s) designed to be used on top of a mattress

3.2mattress base

cot base and mattress combined in one component

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 1

---------------------- Page: 5 ----------------------

ISO 23767:2021(E)

3.3

woven fabric

fabric produced by interlacing (by weaving on a loom or weaving machine) a set of warp threads and a

set of weft threads normally at right angles to each other[SOURCE: ISO 3572:1976, 2.1]

3.4

nonwoven fabric

engineered fibrous assembly, primarily planar, which has been given a designed level of structural

integrity by physical and/or chemical means, excluding weaving, knitting or papermaking

[SOURCE: ISO 9092:2019, 3.1.1]3.5

knitted fabric

fabric in which at least one system of threads is formed into knitted loops and the knitted loops are

intermeshed into stitches[SOURCE: ISO 8388:1998, 3.0.1]

4 General test conditions

4.1 Preliminary preparation

The mattress shall be tested as delivered.

Unless otherwise specified, the tests shall be carried out on the same sample.

Unless otherwise specified by the manufacturer, the mattress shall be stored in indoor ambient

conditions for at least 24 h immediately prior to testing.The tests shall be carried out at indoor ambient conditions. However, if during a test the temperature is

outside the range 15 °C to 25 °C, the maximum and/or minimum temperature shall be recorded in the

test report.4.2 Application of forces

The test forces in durability and static load tests shall be applied sufficiently slowly to ensure that

negligible dynamic load is applied. The forces in durability tests shall be applied sufficiently slowly to

ensure that kinetic heating does not occur.Unless otherwise stated, static forces shall be maintained for (10 ± 2) s and durability forces shall be

maintained for (2 ± 1) s.The forces may be replaced by masses. The relationship 10 N = 1 kg shall be used.

4.3 TolerancesUnless otherwise stated, the following tolerances shall apply:

— Forces: ±5 % of the nominal force;

— Masses: ±0,5 % of the nominal mass;

— Dimensions: ±1 mm of the nominal dimension;

— Positioning of loading pads: ±5 mm;

2 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 23767:2021(E)

NOTE For the purposes of uncertainty measurement, test results are not considered to be adversely affected

when the above tolerances are met.5 Test equipment

5.1 Measuring table

The measuring table shall be a horizontal, flat and smooth surface with dimensions sufficient to fully

support the mattress in any measuring position. The maximum deflection shall not exceed 1 mm when

a force of 1 000 N is applied to the table when tested in accordance with EN 1730:2012, 6.3.

5.2 StopsStops shall be used to prevent the mattress from sliding by a mean that does not affect the test result.

5.3 Square aluminium alloy tubeThe aluminium alloy tube shall be 40 mm in width × 40 mm in height × 2 mm in thickness, approximately

2 m long, with a mass of (1,65 ± 0,0125) kg.5.4 Loading pad

The loading pad shall be a rigid circular object 200 mm in diameter, the face of which has a convex

spherical curvature with a radius of 300 mm with a 12 mm edge radius (see Figure 1).

Dimensions in millimetresKey

R radius

Figure 1 — Loading pad

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 3

---------------------- Page: 7 ----------------------

ISO 23767:2021(E)

5.5 Test template for determination of the indentation depth

The test template shall be made from hard smooth material with the dimensions shown in Figure 2. It

shall have a total mass of (0,26 ± 0,01) kg. The edges of the template shall be rounded with a radius of

(2 ± 0,5) mm and it shall have a hole in its centre with a diameter of (111 ± 0,5) mm, see Figure 2.

Dimensions in millimetresKey

intersection view

top view

side view

R radius

Figure 2 — Test template for determination of firmness

5.6 Spherical load for determination of the indentation depth

+05,

The spherical load shall have a diameter of 115 mm and a mass of (2,5 ± 0,0125) kg.

5.7 Test foamThe text foam shall be a layer of flexible PU foam, corresponding to the dimensions of the mattress

topper to be tested, having a thickness of 100 mm, a density of (25 ± 2,5) kg/m and a hardness of

(120 ± 12) N in accordance with Method A (A ) in ISO 2439.(40 %/30 s)

5.8 Small parts cylinder

The cylinder shall have the dimensions as shown in Figure 3.

4 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 23767:2021(E)

Dimensions in millimetres

Figure 3 — Small parts cylinder

5.9 Feeler gauge

The feeler gauge shall have the dimensions shown in Figure 4.

Dimensions in millimetres

Key

side view

top view

R radius

Figure 4 — Feeler gauge

5.10 Cone

+01,

The cone shall have an angle of 30° ± 0,5° with a diameter of 60 mm with conical ends, see Figure 5.

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 5---------------------- Page: 9 ----------------------

ISO 23767:2021(E)

Dimensions in millimetres

Figure 5 — Examples of cones

5.11 Probe

+01,

The cylindrical probe shall have a diameter of 12 mm, see Figure 6.

Dimensions in millimetres

Figure 6 — Cylindrical Probe

6 Chemical hazards

Verification shall be provided that the migration of heavy metals from materials on the cover of the

sleeping surface does not exceed the limits (Category III) in EN 71-3:2019, Table 2.

The migration shall be determined using the methods specified in EN 71-3.Suggestions on colour fastness test methods are given in Annex B.

7 Fire and thermal hazards (see A.3)

A separate sample can be used.

When tested in accordance with ISO 8124-2:2014, 5.4, there shall be no surface flash, and the rate of

spread of flame of textiles, coated textiles or plastic coverings shall not exceed 50 mm/s.

When tested in accordance with EN 597-1, there shall be no progressive smouldering ignition or flaming

ignition.NOTE In certain cases, national regulations can apply.

8 Mechanical hazards

8.1 Entrapment hazards from gaps and openings (see A.4.2)

8.1.1 Entrapment hazards between the mattress and the sides

This measurement shall be carried out before the whole test procedure.

In order to prevent entrapment hazards from gaps and openings, the tolerances on dimensions of the

mattress shall be the nominal value of width and length (+25/-0) mm.This shall be measured in accordance with EN 1334:1996, 6.1.

6 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 23767:2021(E)

8.1.2 Body entrapment hazards

8.1.2.1 Requirements

To avoid entrapment of the body, there shall be no gap between components of the mattress. This

requirement is fulfilled if the 60 mm cone (5.10) does not pass through the components when tested in

accordance with 8.1.2.2.8.1.2.2 Test method

Push the 60 mm cone (5.10) between components of the mattress with a 30 N force.

8.1.3 Entanglement hazards (see A.4.3)

8.1.3.1 Requirements

The restraint system is excluded from the following requirements.

Cords, ribbons and similar parts shall have a maximum free length of 220 mm when tested in accordance

with 8.1.3.2.Where cords, ribbons and similar parts are attached to the mattress together or within 80 mm of each

other, all single cords shall have a maximum free length of 220 mm and the combined length from one

loose end to the end of another loose end shall be maximum of 360 mm.Loops shall have a maximum peripheral dimension of 360 mm when tested in accordance with 8.1.3.2.

8.1.3.2 Test methodThe length of a cord, ribbon or similar part shall be measured from the fixing point on the mattress to

the free end of the cord, ribbon or similar part under a 25 N tensile force.The peripheral dimension of a loop shall be measured from the fixing point on the mattress of one end

to the fixing point of the other end under a 25 N tensile force.8.2 External suffocation hazards (see A.4.4)

8.2.1 Labels and decals on the mattress

8.2.1.1 Requirements

When tested in according to 8.2.1.2, labels and decals shall not become detached or be loosened from

the product.8.2.1.2 Test method

Using a force of (25 ± 2) N, insert the feeler gauge (5.9) between the label or decal and the mattress at

any angle between 0° and 10° from the mattress surface.Repeat for a further 29 times at the same position so that the feeler gauge is pushed between the label

or decal and the mattress for a total of 30 times.8.2.2 Plastic packaging

Plastic bags and plastic sheeting used for packaging shall conform to one of the following requirements:

a) bags made of flexible plastics with an opening perimeter greater than 360 mm used for external or

internal packaging or plastic sheeting used for packaging shall have an average sheet thickness of

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 7---------------------- Page: 11 ----------------------

ISO 23767:2021(E)

0,038 mm or more when measured in accordance with ISO 8124-1 and shall not have a drawstring

or cord as a means of closing;b) bags made of perforated sheets or perforated plastic sheeting with an average thickness of less

than 0,038 mm when measured in accordance with ISO 8124-1 and of an area greater than 100 mm

by 100 mm shall be perforated with defined holes so that a minimum of 1 % of the area has been

removed over any area of 30 mm by 30 mm;c) any plastic covering used as packaging that does not fulfil the previous requirements shall be

conspicuously marked in the official language(s) of the country where the mattress is sold with

a statement indicating that any plastic cover should be removed, destroyed or kept away from

children to avoid suffocation hazard.8.2.3 Firmness

8.2.3.1 Requirement

This requirement applies to all mattress toppers, to mattresses that are more than 30 mm in thickness

as well as to mattress bases with a soft filling thickness of more than 30 mm.When tested in accordance with 8.2.3.2, the spherical load (5.6) shall not be in complete contact with

the inner edge of the template (5.5).8.2.3.2 Test method

8.2.3.2.1 Conditioning

Unpack the mattress and keep it flat and unloaded in an environment of (23 ± 2) °C and a relative

humidity of (50 ± 5) % for a minimum of 72 h prior to testing.When repeating the firmness test after the test of deformation of the filling (8.5.2), the sample shall be

conditioned at least for 5 h prior to testing.8.2.3.2.2 Procedure

Mattresses supplied with a product shall be tested using that product.

Mattresses that are supplied to consumers as stand-alone or generic replacement products shall be

placed on a horizontal, plane, rigid structure for testing.Mattress toppers shall be placed on the test foam specified in (5.7).

Unless one side of the mattress is clearly not suitable as a sleep surface, both sides of the mattress shall

be tested if they are of different construction.The procedure for testing shall be as follows:

a) When applicable, compress the sleep surface by agitating or shaking it so as to achieve its maximum

aerated state and an even distribution of any filling material.b) If the sleep surface has been separated from other product components, return the sleep surface to

its normal secured position in the product, ensuring it is well supported in a horizontal orientation.

c) Allow the sleep surface to settle for at least five minutes.d) Mark the point to be tested as follows:

Point B shall be located in the centre of the mattress.

Point C shall be located as close as possible to the edges of the mattress but the template shall be

totally in contact with the mattress.8 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 12 ----------------------

ISO 23767:2021(E)

Point A shall be located on a position, which represents a subjective ‘worst case’ scenario, where an

infant’s head might lay in a particularly soft spot, or an infant’s nose/mouth might contact a fold or

undulation protruding above or below the average plane of the sleep surface.e) The test template (5.5) shall be positioned on each testing point defined in d) as shown in Figure 7.

Keytest template for determination of the indentation depth, see 5.5

Figure 7 — Test location

The spherical load (5.6) shall be placed in the centre of the test template. Check after 5 min if the

spherical load is in complete contact with the template (see Figures 8 and 9).Key

1 test template

2 spherical load

3 mattress

4 test surface

Figure 8 — Test passed – The spherical load is not in complete contact with the template

© ISO 2021 – All rights reserved PROOF/ÉPREUVE 9---------------------- Page: 13 ----------------------

ISO 23767:2021(E)

Key

1 test template

2 spherical load

3 mattress

4 test surface

Figure 9 — Test failed – The spherical load is in complete contact with the template

8.3 Choking and internal suffocation hazards (see A.4.5)8.3.1 Small parts

8.3.1.1 Requirements

The requirements do not apply to paper, fabric, and yarn. When tested in accordance with 8.3.1.2, no

part that can be detached shall fit wholly within the small parts cylinder (5.8).

8.3.1.2 Test method8.3.1.2.1 General

The tests are applicable only to small parts that are considered grippable by a child and that can fit

wholly within the small parts cylinder (5.8).A part is considered to be grippable by a child if the child can grip the part between their thumb and

forefinger or between their teeth.The tension test (see 8.3.1.2.3) shall be carried out after the torque test (see 8.3.1.2.2) and on the same

part as used for the torque test.8.3.1.2.2 Torque test

Apply a torque gradually to the part within a period of approximately 5 s in a clockwise direction until

either— rotation of 180° from the original position has been attained, or

— torque of 0,34 Nm is reached.

The maximum rotation or required torque shall be applied for (10 ± 2) s.

The part shall then be allowed to return to a relaxed condition and the procedure repeated in an

anticlockwise direction.10 PROOF/ÉPREUVE © ISO 2021 – All rights reserved

---------------------- Page: 14 ----------------------

ISO 23767:2021(E)

Where projections, parts or assemblies are rigidly mounted on a rod or shaft designed to rotate together

with the projections, parts or assemblies, the rod or shaft shall be clamped to prevent rotation during

the test.8.3.1.2.3 Tension test

Apply a tensile force gradually over approximately 5 s and maintain the force for (10 ± 2) s to the part

through a clamp or other suitable means. Apply a force of— 50 N where the largest dimension is ≤6 mm, or

— 90 N where the largest dimension is >6 mm.

If the part becomes detached, check whether the part fits wholly within the small parts cylinder (5.8).

8.3.2 Accessibility to filling materials8.3.2.1 General

The tests may be carried out on a separate sample.

8.3.2.2 Requirements

8.3.2.2.1 Mattress cover made of woven fabrics

When tested in accordance with 8.3.2.3.1, the maximum slippage of thread shall be 7 mm.

8.3.2.2.2 Mattress covers made of other materialsWhen tested in accordance with 8.3.2.3.2, the force of rupture shall be greater than 60 N.

8.3.2.2.3 Removable mattress coversThe means to close/attach removable covers shall not allow a child to have access to filling materials.

This requirement is met if one of the following conditions is fulfilled:— a minimum force of 50 N is required to open the closing system;

— two actions (e.g. push and twist) are necessary to open the closing system, the first of which shall be

maintained while the second is carried out;— two independent actions are necessary to open the closing system that shall be operated

simultaneously;— the use of a tool is required to open the closing system;

— a non-removable in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.