ISO/TS 20458:2023

(Main)Road vehicles — Design and performance specifications for advanced Pedestrian Legform Impactor (aPLI)

Road vehicles — Design and performance specifications for advanced Pedestrian Legform Impactor (aPLI)

This document provides definitions, symbols, mechanical requirements, certification test procedure, electronic subsystem requirements and user’s manual for advanced pedestrian legform impactor (aPLI), a standardized pedestrian legform impactor with an upper mass for pedestrian subsystem testing of road vehicles. It is applicable to impact tests involving: — vehicles of category M1, except vehicles with the maximum mass above 2 500 kg and which are derived from N1 category vehicles and where the driver’s position, R-point, is either forward of the front axle or longitudinally rearwards of the front axle transverse centreline by a maximum of 1 100 mm; — vehicles of category N1, except where the driver’s position, R-point, is either forward of the front axle or longitudinally rearwards of the front axle transverse centreline by a maximum of 1 100 mm; — impacts to the bumper test area as defined by UN R127[1] and UN GTR No.9[2]; — pedestrian subsystem tests involving use of a legform for the purpose of evaluating compliance with vehicle safety standards.

Véhicules routiers — Spécifications de conception et de performance pour l'impacteur en forme de jambe de piéton (aPLI)

General Information

Buy Standard

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 20458

First edition

2023-07

Road vehicles — Design and

performance specifications for

advanced Pedestrian Legform

Impactor (aPLI)

Véhicules routiers — Spécifications de conception et de performance

pour l'impacteur en forme de jambe de piéton (aPLI)

Reference number

ISO/TS 20458:2023(E)

© ISO 2023

---------------------- Page: 1 ----------------------

ISO/TS 20458:2023(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

© ISO 2023 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TS 20458:2023(E)

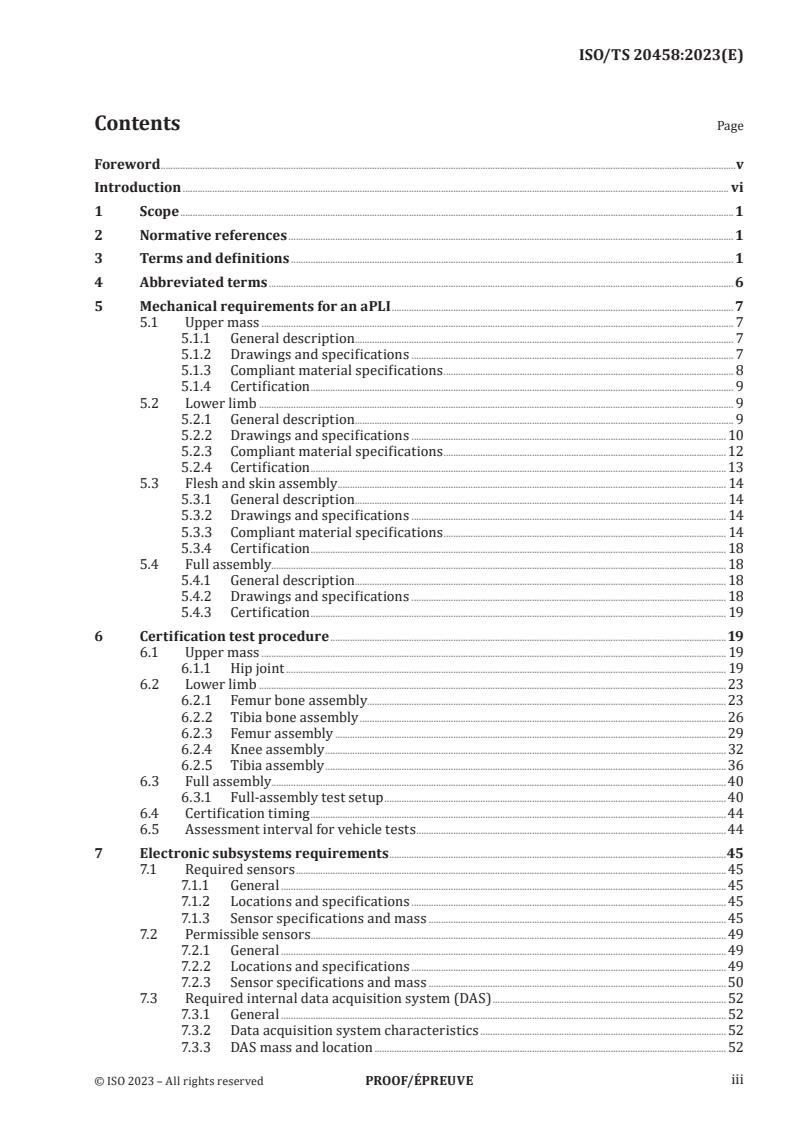

Contents Page

Foreword .v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Abbreviated terms . 6

5 Mechanical requirements for an aPLI . 7

5.1 Upper mass . 7

5.1.1 General description . 7

5.1.2 Drawings and specifications . 7

5.1.3 Compliant material specifications . 8

5.1.4 Certification . 9

5.2 Lower limb . 9

5.2.1 General description . . 9

5.2.2 Drawings and specifications . 10

5.2.3 Compliant material specifications .12

5.2.4 Certification .13

5.3 Flesh and skin assembly . 14

5.3.1 General description . 14

5.3.2 Drawings and specifications . 14

5.3.3 Compliant material specifications . 14

5.3.4 Certification . 18

5.4 Full assembly. 18

5.4.1 General description . 18

5.4.2 Drawings and specifications . 18

5.4.3 Certification . 19

6 Certification test procedure .19

6.1 Upper mass . 19

6.1.1 Hip joint . 19

6.2 Lower limb . 23

6.2.1 Femur bone assembly. 23

6.2.2 Tibia bone assembly .26

6.2.3 Femur assembly .29

6.2.4 Knee assembly . 32

6.2.5 Tibia assembly .36

6.3 Full assembly.40

6.3.1 Full-assembly test setup .40

6.4 Certification timing .44

6.5 Assessment interval for vehicle tests .44

7 Electronic subsystems requirements .45

7.1 Required sensors . 45

7.1.1 General . 45

7.1.2 Locations and specifications . 45

7.1.3 Sensor specifications and mass . 45

7.2 Permissible sensors . .49

7.2.1 General .49

7.2.2 Locations and specifications .49

7.2.3 Sensor specifications and mass .50

7.3 Required internal data acquisition system (DAS) . 52

7.3.1 General . 52

7.3.2 Data acquisition system characteristics . 52

7.3.3 DAS mass and location . 52

iii

© ISO 2023 – All rights reserved

---------------------- Page: 3 ----------------------

ISO/TS 20458:2023(E)

8 User's manual .52

8.1 Requirements . 52

8.1.1 Disassembly and assembly . 52

Annex A (informative) Rationale regarding background and goals for aPLI .54

Annex B (informative) Rationale regarding performance of aPLI . 108

Annex C (informative) Assessment interval for vehicle tests . 121

Annex D (informative) Outer contour of the struck side of the bony structure . 135

Annex E (informative) Biofidelity and injury assessment capability evaluation data . 138

Annex F (informative) Repeatability and reproducibility data. 203

Annex G (informative) Durability assessment data . 205

Annex H (informative) Parts list . 208

Annex I (normative) Drawings and specifications, PDF and/or STP files. 213

Annex J (informative) Information regarding sensor output polarities .214

Annex K (normative) Procedures for disassembling and assembling aPLI . 218

Annex L (normative) Fastener torque values . 228

Annex M (informative) Overview of an exemplar required internal DAS . 229

Annex N (informative) Recommended aPLI general practices. 232

Annex O (informative) Assessment procedure for dynamic test equipment . 234

Annex P (informative) Validation results of aPLI models (A, C, E, F) against hardware. 236

Annex Q (informative) Exemplar of aPLI hip joint certification test rig .246

Bibliography . 247

iv

© ISO 2023 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TS 20458:2023(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had received notice

of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 36,

Safety and impact testing.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

© ISO 2023 – All rights reserved

---------------------- Page: 5 ----------------------

ISO/TS 20458:2023(E)

Introduction

This document has been prepared on the basis of the existing design, specifications and performance

of advanced pedestrian legform impactor (aPLI) standard build level B (SBL-B). The purpose of this

document is to document the design and specifications of this pedestrian legform impactor in a form

suitable and intended for worldwide harmonized use.

In 2014, aPLI development started, with the aims of defining a globally accepted next-generation

pedestrian legform impactor, with enhanced biofidelity and injury assessment capability by

implementing an upper mass to represent the influence of the upper body of a pedestrian, and

suitable for harmonized use. Participating in the development were research institutes, dummy and

instrumentation manufacturers, governments and car manufacturers from around the world. Details

are given in Annex A through Annex G and Annex P.

aPLI drawings in electronic format are available. Details are given in Annex I and Annex H.

vi

© ISO 2023 – All rights reserved

---------------------- Page: 6 ----------------------

TECHNICAL SPECIFICATION ISO/TS 20458:2023(E)

Road vehicles — Design and performance specifications

for advanced Pedestrian Legform Impactor (aPLI)

1 Scope

This document provides definitions, symbols, mechanical requirements, certification test procedure,

electronic subsystem requirements and user’s manual for advanced pedestrian legform impactor

(aPLI), a standardized pedestrian legform impactor with an upper mass for pedestrian subsystem

testing of road vehicles. It is applicable to impact tests involving:

— vehicles of category M1, except vehicles with the maximum mass above 2 500 kg and which are

derived from N1 category vehicles and where the driver’s position, R-point, is either forward of

the front axle or longitudinally rearwards of the front axle transverse centreline by a maximum of

1 100 mm;

— vehicles of category N1, except where the driver’s position, R-point, is either forward of the front

axle or longitudinally rearwards of the front axle transverse centreline by a maximum of 1 100 mm;

[1] [2]

— impacts to the bumper test area as defined by UN R127 and UN GTR No.9 ;

— pedestrian subsystem tests involving use of a legform for the purpose of evaluating compliance

with vehicle safety standards.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 6487, Road vehicles — Measurement techniques in impact tests — Instrumentation

ISO/TS 13499, Road vehicles — Multimedia data exchange format for impact tests

SAE J2570, Performance Specifications for Anthropomorphic Test Device Transducers

SAE J211-1, Instrumentation for Impact Test Part 1 — Electronic Instrumentation

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

abduction

rotation of the lower limb (3.34) relative to the upper mass (3.49) as the lower limb is rotated toward the

struck side (3.37)

1

© ISO 2023 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/TS 20458:2023(E)

3.2

adduction

rotation of the lower limb (3.34) relative to the upper mass (3.49) as the lower limb is rotated toward the

non-struck side (3.35)

3.3

adult

person who is sixteen years old or older

3.4

aPLI

advanced pedestrian legform impactor

modified pedestrian legform impactor which incorporates a mass representing the inertial effect of the

upper part of a pedestrian body to enhance biofidelity (3.8) and injury assessment capability (3.26) of

conventional pedestrian legforms

3.5

aluminium honeycomb

manufactured material comprising multi-layered bonded sheets of aluminium bent or corrugated in a

rib pattern, in which there is an internal pattern of hexagonal cylindrical spaces

Note 1 to entry: The aluminium honeycomb is used in this document as an energy-absorbing element in full

assembly certification (3.13) tests.

3.6

AAUM

angular acceleration of upper mass

angular acceleration observed at the upper mass of the advanced pedestrian legform impactor (aPLI)

(3.4) which is obtained by differentiating the angular velocity sensor (X), installed in the upper mass

(3.49) as a required sensor

Note 1 to entry: See 7.1.3.4.

3.7

Belleville washer

type of spring which can be loaded along its axis, with its frusto-conical shape giving the spring

characteristics

3.8

biofidelity

aspect of an advanced pedestrian legform impactor (aPLI) (3.4) capability to represent impact responses

of human subjects

3.9

bone core

beam with a rectangular cross-section made of glass fibre reinforced plastic installed in the centre of

the femur (3.14) and the tibia (3.40) that provides human-like bending stiffness

3.10

bumper angle

acute angle formed by the vertical plane tangential to the surface of a car bumper and the vertical

transverse plane relative to the car

3.11

bumper system

component installed at the hip joint (3.24) inside the upper mass (3.49) composed of the bumper, the

bumper mount and the compression surface, designed to apply a force on the upper part of the femur

(3.14) in adduction (3.2) to enhance injury assessment capability (3.26) of the advanced pedestrian

legform impactor (aPLI) (3.4)

2

© ISO 2023 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/TS 20458:2023(E)

3.12

capacity

maximum value of a physical quantity which can be measured by a sensor without causing sensor

damage

3.13

certification

process by which the relevant advanced pedestrian legform impactor (aPLI) (3.4) component or full

assembly is verified and documented to meet the specifications

3.14

femur

portion of the lower limb (3.34) between the femur top (3.15) and the upper knee block (3.29), excluding

the flesh (3.22) and the skin (3.36)

3.15

femur top

aluminium part that forms the hip joint (3.24) and the junction between the upper mass (3.49) and the

femur (3.14)

3.16

femur-1

measurement location of the femur (3.14) bending moment (137 mm vertically up from the flat surface

of the knee meniscus) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

3.17

femur-2

measurement location of the femur (3.14) bending moment (217 mm vertically up from the flat surface

of the knee meniscus) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

3.18

femur-3

measurement location of the femur (3.14) bending moment (297 mm vertically up from the flat surface

of the knee meniscus) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

3.19

femur-LO

measurement location of the femur (3.14) bending moment which is equal to the measurement location

of femur-1 (3.16) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

Note 1 to entry: For the femur-LO, the femur's bending moment is specified in ISO/TS 13499.

3.20

femur-MID

measurement location of the femur (3.14) bending moment which is equal to the measurement location

of femur-2 (3.17) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

Note 1 to entry: For the femur-MID, the femur bending moment is specified in ISO/TS 13499.

3.21

femur-UP

measurement location of the femur (3.14) bending moment which is equal to the measurement location

of femur-3 (3.18) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

Note 1 to entry: For the femur-UP, the femur bending moment is specified in ISO/TS 13499.

3

© ISO 2023 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/TS 20458:2023(E)

3.22

flesh

moulded soft part constituting the outer layer of the lower limb (3.34) positioned inside the skin (3.36)

3.23

high-bumper car

car with a lower bumper reference line height (3.33) of 425 mm or more

3.24

hip joint

uniaxial joint that allows abduction (3.1) and adduction (3.2) and connects the upper mass (3.49) with

the lower limb (3.34)

3.25

impact carriage

moving part of the full assembly certification (3.13) test fixture comprising the impact surface with an

aluminium honeycomb (3.5) and a linearly guided rigid mass

3.26

injury assessment capability

aspect of an advanced pedestrian legform impactor (aPLI) (3.4) capability to produce peak injury values

that correlate with those obtained from human body model impact simulations

3.27

ISO metric

objective rating metric used in this document to verify time histories of sensor output against

experimentally or computationally produced target time histories

Note 1 to entry: For more information on the ISO metric, refer to ISO/TS 18571.

3.28

knee

middle part of the lower limb (3.34) that involves the knee joint, comprises the upper and lower knee

blocks (3.29) and provides a junction between the femur (3.14) and the tibia (3.40)

3.29

knee block

aluminium block that forms either the upper part of the knee joint with condyles, or the lower part of

the knee joint with the meniscus attached, accommodating knee ligaments, Belleville washers (3.7) that

represent stiffness of the knee ligaments and sensors to measure elongation of the knee ligaments and

linear acceleration and angular rate of the knee (3.28)

3.30

lateral

direction from the struck side (3.37) to the the non-struck side (3.35)

3.31

leg

portion of the lower limb (3.34) below the lower knee block (3.29), including the flesh (3.22) and the skin

(3.36)

3.32

low-bumper car

car with a lower bumper reference line height (3.33) less than 425 mm

3.33

lower bumper reference line height

LBRL height

height of the geometric trace of the lowermost points of contact between a straight edge and the

bumper, measured from the ground

4

© ISO 2023 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/TS 20458:2023(E)

3.34

lower limb

lower part of the advanced pedestrian legform impactor (aPLI) (3.4) attached to the upper mass (3.49)

via a hip joint (3.24), representing the thigh (3.39), knee (3.28) and leg (3.31) of a human in a standing

position

3.35

non-struck side

opposite side of the struck side (3.37)

3.36

skin

sheet of polychloroprene with fabric surface that covers the flesh (3.22), forming the outermost layer of

the lower limb (3.34)

3.37

struck side

side facing a car in car tests, representing the outer side of the lower limb (3.34) of a pedestrian

3.38

subsystem test

test to evaluate safety performance of cars where subsystem impactors representing individual

body regions of a pedestrian are propelled into a front-end collision with a stationary car, in impact

[1]

conditions representing specific load cases in car-pedestrian accidents, as described in UN R127 and

[2]

UN GTR No.9

3.39

thigh

portion of the lower limb (3.34) between the femur top (3.15) and the upper knee block (3.29), including

the flesh (3.22) and the skin (3.36)

3.40

tibia

portion of the lower limb (3.34) below the lower knee block (3.29), excluding the flesh (3.22) and the skin

(3.36)

3.41

tibia-1

measurement location of the tibia (3.40) bending moment (134 mm vertically down from the flat

surface of tibia plateau) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

3.42

tibia-2

measurement location of the tibia (3.40) bending moment (214 mm vertically down from the flat

surface of tibia plateau) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

3.43

tibia-3

measurement location of the tibia (3.40) bending moment (294 mm vertically down from the flat

surface of tibia plateau) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

3.44

tibia-4

measurement location of the tibia (3.40) bending moment (374 mm vertically down from the flat

surface of tibia plateau) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

5

© ISO 2023 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/TS 20458:2023(E)

3.45

tibia-LO

measurement location of the tibia (3.40) bending moment which is equal to the measurement location

of tibia-4 (3.44) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

Note 1 to entry: For the tibia-LO, the tibia bending moment is specified in ISO/TS 13499.

3.46

tibia-MID-LO

measurement location of t

...

© ISO #### – All rights reserved

ISO/TS 20458:202#(2023(E)

ISO TC 22/SC 36/WG 5

Secretariat: XXXX

Date: 2023-03-18

Road vehicles - Design and performance specifications for advanced pedestrian legform

impactor (aPLI) –

TS stage

Warning for WDs and CDs

This document is not an ISO International Standard. It is distributed for review and comment. It is subject to

change without notice and may not be referred to as an International Standard.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of

which they are aware and to provide supporting documentation.

To help you, this guide on writing standards was produced by the ISO/TMB and is available at

A model manuscript of a draft International Standard (known as “The Rice Model”) is available at

---------------------- Page: 1 ----------------------

© ISO 202#,

---------------------- Page: 2 ----------------------

ISO/TS 20458:202# 2023(E)

© ISO 2023, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or

utilized otherwise in any form or by any means, electronic or mechanical, including photocopying,

or posting on the internet or an intranet, without prior written permission. Permission can be

requested from either ISO at the address below or ISO’s member body in the country of the

requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

copyright@iso.org

www.iso.org

www.iso.org

© ISO 202# – All rights reserved

ii © ISO 2023 – All rights reserved

---------------------- Page: 3 ----------------------

ISO/TS 20458:202#(2023(E)

Contents

Foreword . v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Abbreviated terms. 7

5 Mechanical requirements for an aPLI . 8

5.1 Upper mass . 8

5.1.1 General description . 8

5.1.2 Drawings and specifications . 8

5.1.3 Compliant material specifications . 10

5.1.4 Certification . 12

5.2 Lower limb . 12

5.2.1 General description . 12

5.2.2 Drawings and specifications . 12

5.2.3 Compliant material specifications . 16

5.2.4 Certification . 18

5.3 Flesh and skin assembly . 18

5.3.1 General description . 18

5.3.2 Drawings and specifications . 18

5.3.3 Compliant material specifications . 19

5.3.4 Certification . 27

5.4 Full assembly . 27

5.4.1 General description . 27

5.4.2 Drawings and specifications . 28

5.4.3 Certification . 29

6 Certification test procedure . 29

6.1 Upper mass . 30

6.1.1 Hip joint . 30

6.2 Lower limb . 37

6.2.1 Femur bone assembly. 37

6.2.2 Tibia bone assembly . 41

6.2.3 Femur assembly . 45

6.2.4 Knee assembly . 49

6.2.5 Tibia assembly . 58

6.3 Full assembly . 62

6.3.1 Full-assembly test setup . 63

6.4 Certification timing . 68

6.5 Assessment interval for vehicle tests . 69

7 Electronic subsystems requirements. 69

7.1 Required sensors . 69

7.1.1 General . 69

© ISO 202# – All rights reserved © ISO 2023 – All rights iii

reserved

---------------------- Page: 4 ----------------------

ISO/TS 20458:202# 2023(E)

7.1.2 Locations and specifications . 69

7.1.3 Sensor specifications and mass . 70

7.2 Permissible sensors . 75

7.2.1 General . 75

7.2.2 Locations and specifications . 75

7.2.3 Sensor specifications and mass . 76

7.3 Required internal data acquisition system (DAS) . 80

7.3.1 General . 80

7.3.2 Data acquisition system characteristics . 80

7.3.3 DAS mass and location . 80

8 User's manual . 81

8.1 Requirements . 81

8.1.1 Disassembly and assembly . 81

Annex A (informative) Rationale regarding background and goals for aPLI . 82

Annex B (informative) Rationale regarding performance of aPLI . 167

Annex C (informative) Assessment interval for vehicle tests . 184

Annex D (informative) Outer contour of the struck side of the bony structure . 208

Annex E (informative) Biofidelity and injury assessment capability evaluation data . 212

Annex F (informative) Repeatability and reproducibility data . 406

Annex G (informative) Durability assessment data . 409

Annex H (informative) Parts list . 413

Annex I (normative) Drawings and specifications, PDF and/or STP files . 419

Annex J (informative) Information regarding sensor output polarities . 420

Annex K (normative) Procedures for disassembling and assembling aPLI . 428

Annex L (normative) Fastener torque values . 443

Annex M (informative) Overview of an exemplar required internal DAS . 445

Annex N (informative) Recommended aPLI general practices . 448

Annex O (informative) Assessment procedure for dynamic test equipment . 451

Annex P (informative) Validation results of aPLI models (A, C, E, F) against hardware . 454

Annex Q (informative) An exemplar of aPLI hip joint certification test rig . 478

Bibliography . 480

© ISO 202# – All rights reserved

iv © ISO 2023 – All rights reserved

---------------------- Page: 5 ----------------------

ISO/TS 20458:202#(2023(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national

standards bodies (ISO member bodies). The work of preparing International Standards is normally

carried out through ISO technical committees. Each member body interested in a subject for which a

technical committee has been established has the right to be represented on that committee.

International organizations, governmental and non-governmental, in liaison with ISO, also take part in

the work. ISO collaborates closely with the International Electrotechnical Commission (IEC) on all

matters of electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documentsdocument should be noted. This document was drafted in accordance

with the editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawnISO draws attention to the possibility that some of the elementsimplementation of

this document may beinvolve the subjectuse of (a) patent(s). ISO takes no position concerning the

evidence, validity or applicability of any claimed patent rights in respect thereof. As of the date of

publication of this document, ISO had received notice of (a) patent(s) which may be required to

implement this document. However, implementers are cautioned that this may not represent the latest

information, which may be obtained from the patent database available at www.iso.org/patents. ISO

shall not be held responsible for identifying any or all such patent rights. Details of any patent rights

identified during the development of the document will be in the Introduction and/or on the ISO list of

patent declarations received (see ).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 36,

Safety and impact testing.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

© ISO 202# – All rights reserved © ISO 2023 – All rights v

reserved

---------------------- Page: 6 ----------------------

ISO/TS 20458:202# 2023(E)

Introduction

This document has been prepared on the basis of the existing design, specifications and performance of

advanced pedestrian legform impactor (aPLI) standard build level B (SBL-B). The purpose of this

document is to document the design and specifications of this pedestrian legform impactor in a form

suitable and intended for worldwide harmonized use.

In 2014, aPLI development started, with the aims of defining a globally accepted next-generation

pedestrian legform impactor, with enhanced biofidelity and injury assessment capability by

implementing an upper mass to represent the influence of the upper body of a pedestrian, and suitable

for harmonized use. Participating in the development were research institutes, dummy and

instrumentation manufacturers, governments and car manufacturers from around the world. Details

are given in Annex A through Annex G and .Annex P.

aPLI drawings in electronic format are available. Details are given in Annex I and .Annex H.

The International Organization for Standardization (ISO) draws attention to the fact that it is claimed

that compliance with this document may involve the use of a patent.

ISO takes no position concerning the evidence, validity and scope of this patent right.

The holder of this patent right has assured ISO that he/she is willing to negotiate licences under

reasonable and non-discriminatory terms and conditions with applicants throughout the world. In this

respect, the statement of the holder of this patent right is registered with ISO. Information may be

obtained from the patent database available at .

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights other than those in the patent database. ISO shall not be held responsible for identifying

any or all such patent rights.

© ISO 202# – All rights reserved

vi © ISO 2023 – All rights reserved

---------------------- Page: 7 ----------------------

TECHNICAL SPECIFICATION ISO/TS 20458:2023(E)

Road vehicles - Design and performance specifications for

advanced pedestrian legform impactor (aPLI) -

1 Scope

This document provides definitions, symbols, mechanical requirements, certification test procedure,

electronic subsystem requirements and user’s manual for advanced pedestrian legform impactor

(aPLI), a standardized pedestrian legform impactor with an upper mass for pedestrian subsystem

testing of road vehicles. It is applicable to impact tests involving:

— vehicles of category M1, except vehicles with the maximum mass above 2 500 kg and which are

derived from N1 category vehicles and where the driver’s position, R-point, is either forward of the

front axle or longitudinally rearwards of the front axle transverse centreline by a maximum of

1 100 mm;

— vehicles of category N1, except where the driver’s position, R-point, is either forward of the front

axle or longitudinally rearwards of the front axle transverse centreline by a maximum of 1

100mm 100 mm;

[1] [2]

— impacts to the bumper test area as defined by UN R127 and UN GTR No.9; ;

— pedestrian subsystem tests involving use of a legform for the purpose of evaluating compliance

with vehicle safety standards.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 6487, Road vehicles — Measurement techniques in impact tests — Instrumentation

ISO/TS 13499, Road vehicles — Multimedia data exchange format for impact tests

SAE J2570, Performance Specifications for Anthropomorphic Test Device Transducers

SAE J211-1, Instrumentation for impact test –Impact Test Part 1: — Electronic

instrumentationInstrumentation

ISO 6487, Measurement techniques in impact tests — Instrumentation

ISO/TS 13499, Road vehicles – Multimedia data exchange format for impact tests

© ISO 2023 – All rights reserved 1

---------------------- Page: 8 ----------------------

ISO/TS 20458:2023(E)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

abduction

rotation of the lower limb (3.34) relative to the upper mass (3.49) as the lower limb is rotated toward

the struck side (3.37)

3.2

adduction

rotation of the lower limb (3.34) relative to the upper mass (3.49) as the lower limb is rotated toward

the non-struck side (3.35)

3.3

adult

person who is sixteen years old or older

3.4

aPLI

advanced pedestrian legform impactor

aPLI

modified pedestrian legform impactor which incorporates a mass representing the inertial effect of the

upper part of a pedestrian body to enhance biofidelity (3.8) and injury assessment capability (3.26) of

conventional pedestrian legforms

3.5

aluminium honeycomb

manufactured material comprising multi-layered bonded sheets of aluminium bent or corrugated in a

rib pattern, in which there is an internal pattern of hexagonal cylindrical spaces

Note 1 to entry: The aluminium honeycomb used in this document as an energy-absorbing element in full

assembly certification (3.13) tests.

3.6

AAUM

angular acceleration of upper mass

AAUMangular acceleration observed at the upper mass of the advanced pedestrian legform impactor

(aPLI) (3.4) which is obtained by differentiating the angular velocity sensor (X), installed in the upper

mass (3.49) as a required sensor

Note 1 to entry: See .7.1.3.4.

3.7

Belleville washer

type of spring which can be loaded along its axis, with its frusto-conical shape giving the spring

characteristics

© ISO #### – All rights reserved

2 © ISO 2023 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/TS 20458:2023(E)

3.8

biofidelity

aspect of an advanced pedestrian legform impactor (aPLI) (3.4) capability to represent impact responses

of human subjects

3.9

bone core

beam with a rectangular cross-section made of glass fibre reinforced plastic installed in the centre of

the femur (3.14) and the tibia (3.40) that provides human-like bending stiffness

3.10

bumper angle

acute angle formed by the vertical plane tangential to the surface of a car bumper and the vertical

transverse plane relative to the car

3.11

bumper system

component installed at the hip joint (3.24) inside the upper mass (3.49) composed of the bumper, the

bumper mount and the compression surface, designed to apply a force on the upper part of the femur

(3.14) in adduction (3.2) to enhance injury assessment capability (3.26) of an advanced pedestrian

legform impactor (aPLI) (3.4)

3.12

capacity

maximum value of a physical quantity which can be measured by a sensor without causing sensor

damage

3.13

certification

process by which the relevant advanced pedestrian legform impactor (aPLI) (3.4) component or full

assembly is verified and documented to meet the specifications

3.14

femur

portion of the lower limb (3.34) between the femur top (3.15) and the upper knee block (3.29), excluding

the flesh (3.22) and the skin (3.36)

3.15

femur top

aluminium part that forms the hip joint (3.24) and the junction between the upper mass (3.49) and the

femur (3.14)

3.16

femur-1

ameasurementmeasurement location of the femur's (3.14) bending moment (137 mm vertically up from

the flat surface of the knee meniscus) used in the development and evaluation phase of the advanced

pedestrian legform impactor (aPLI) (3.4)

3.17

femur-2

measurement location of the femur's (3.14) bending moment (217 mm vertically up from the flat

surface of the knee meniscus) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

© ISO #### – All rights reserved © ISO 2023 – All rights 3

reserved

---------------------- Page: 10 ----------------------

ISO/TS 20458:2023(E)

3.18

femur-2

measurement location of the femur's (3.14) bending moment (217 mm vertically up from the flat

surface of the knee meniscus) used in the development and evaluation phase of the advanced

pedestrian legform impactor (aPLI) (3.4) femur-3

measurement location of the femur's (3.14) bending moment (297 mm vertically up from the flat

surface of the knee meniscus) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

3.19

femur-LO

measurement location of the femur's (3.14) bending moment which is equal to the measurement

location of femur-1 (3.16) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

Note 1 to entry: For the femur-LO, the femur's bending moment is specified in ISO/TS 13499.

3.20

femur-MID

measurement location of the femur's (3.14) bending moment which is equal to the measurement

location of femur-2 (3.17) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

Note 1 to entry: For the femur-MID, the femur's bending moment is specified in ISO/TS 13499.

3.21

femur-UP

measurement location of the femur's (3.14) bending moment which is equal to the measurement

location of femur-3 (3.18) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

Note 1 to entry: For the femur-UP, the femur's bending moment is specified in ISO/TS 13499.

3.22

flesh

moulded soft part constituting the outer layer of the lower limb (3.34) positioned inside the skin (3.36)

3.23

high-bumper car

car with a lower bumper reference line height (3.33) of 425 mm or more

3.24

hip joint

uniaxial joint that allows abduction (3.1) and adduction (3.2) and connects the upper mass (3.49) with

the lower limb (3.34)

3.25

impact carriage

moving part of the full assembly certification (3.13) test fixture comprising the impact surface with an

aluminium honeycomb (3.5) and a linearly guided rigid mass

3.26

© ISO #### – All rights reserved

4 © ISO 2023 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/TS 20458:2023(E)

injury assessment capability

aspect of an advanced pedestrian legform impactor (aPLI) (3.4) capability to produce peak injury values

that correlate with those obtained from human body model impact simulations

3.27

ISO metric

objective rating metric used in this document to verify time histories of sensor output against

experimentally or computationally produced target time histories

Note 1 to entry: For more information on the ISO metric, refer to ISO/TS 18571.

3.28

knee

middle part of the lower limb (3.34) that involves the knee joint, comprises the upper and lower knee

blocks (3.29) and provides a junction between the femur (3.14) and the tibia (3.40)

3.29

knee block

aluminium block that forms either the upper part of the knee joint with condyles, or the lower part of

the knee joint with the meniscus attached, accommodating knee ligaments, Belleville washers (3.7) that

represent stiffness of the knee ligaments and sensors to measure elongation of the knee ligaments and

linear acceleration and angular rate of the knee (3.28)

3.30

lateral

direction from the struck side (3.37) to the the non-struck side (3.35)

3.31

leg

portion of the lower limb (3.34) below the lower knee block (3.29), including the flesh (3.22) and the skin

(3.36)

3.32

low-bumper car

car with a lower bumper reference line height (3.33) less than 425 mm

3.33

lower bumper reference line height

LBRL height

height of the geometric trace of the lowermost points of contact between a straight edge and the

bumper, measured from the ground, as defined in UN R127 and UN GTR No.9

3.34

lower limb

lower part of the advanced pedestrian legform impactor (aPLI) (3.4) attached to the upper mass (3.49)

via a hip joint (3.24), representing the thigh (3.39), knee (3.28) and leg (3.31) of a human in a standing

position

3.35

non-struck side

opposite side of the struck side (3.37)

3.36

© ISO #### – All rights reserved © ISO 2023 – All rights 5

reserved

---------------------- Page: 12 ----------------------

ISO/TS 20458:2023(E)

skin

sheet of polychloroprene with fabric surface that covers the flesh (3.22), forming the outermost layer of

the lower limb (3.34)

3.37

struck side

side facing a car in car tests, representing the outer side of the lower limb (3.34) of a pedestrian

3.38

subsystem test

test to evaluate safety performance of cars where subsystem impactors representing individual body

regions of a pedestrian are propelled into a front-end collision with a stationary car, in impact

[1]

conditions representing specific load cases in car-pedestrian accidents, as described in UN R127 and

[2]

UN GTR No.9

3.39

thigh

portion of the lower limb (3.34) between the femur top (3.15) and the upper knee block (3.29), including

the flesh (3.22) and the skin (3.36)

3.40

tibia

portion of the lower limb (3.34) below the lower knee block (3.29), excluding the flesh (3.22) and the

skin (3.36)

3.41

tibia-1

measurement location of the tibia's (3.40) bending moment (134 mm vertically down from the flat

surface of tibia plateau) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

3.42

tibia-2

measurement location of the tibia's (3.40) bending moment (214 mm vertically down from the flat

surface of tibia plateau) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

3.43

tibia-3

measurement location of the tibia's (3.40) bending moment (294 mm vertically down from the flat

surface of tibia plateau) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

3.44

tibia-4

measurement location of the tibia's (3.40) bending moment (374 mm vertically down from the flat

surface of tibia plateau) used in the development and evalu

...

TECHNICAL ISO/TS

SPECIFICATION 20458

First edition

Road vehicles — Design and

performance specifications for

advanced Pedestrian Legform

Impactor (aPLI)

Véhicules routiers — Spécifications de conception et de performance

pour l'impacteur en forme de jambe de piéton (aPLI)

PROOF/ÉPREUVE

Reference number

ISO/TS 20458:2023(E)

© ISO 2023

---------------------- Page: 1 ----------------------

ISO/TS 20458:2023(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

PROOF/ÉPREUVE © ISO 2023 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TS 20458:2023(E)

Contents Page

Foreword .v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Abbreviated terms . 6

5 Mechanical requirements for an aPLI . 7

5.1 Upper mass . 7

5.1.1 General description . 7

5.1.2 Drawings and specifications . 7

5.1.3 Compliant material specifications . 8

5.1.4 Certification . 9

5.2 Lower limb . 9

5.2.1 General description . . 9

5.2.2 Drawings and specifications . 10

5.2.3 Compliant material specifications .12

5.2.4 Certification .13

5.3 Flesh and skin assembly . 14

5.3.1 General description . 14

5.3.2 Drawings and specifications . 14

5.3.3 Compliant material specifications . 14

5.3.4 Certification . 18

5.4 Full assembly. 18

5.4.1 General description . 18

5.4.2 Drawings and specifications . 18

5.4.3 Certification . 19

6 Certification test procedure .19

6.1 Upper mass . 19

6.1.1 Hip joint . 19

6.2 Lower limb . 23

6.2.1 Femur bone assembly. 23

6.2.2 Tibia bone assembly .26

6.2.3 Femur assembly .29

6.2.4 Knee assembly . 32

6.2.5 Tibia assembly .36

6.3 Full assembly.40

6.3.1 Full-assembly test setup .40

6.4 Certification timing .44

6.5 Assessment interval for vehicle tests .44

7 Electronic subsystems requirements .45

7.1 Required sensors . 45

7.1.1 General . 45

7.1.2 Locations and specifications . 45

7.1.3 Sensor specifications and mass . 45

7.2 Permissible sensors . .49

7.2.1 General .49

7.2.2 Locations and specifications .49

7.2.3 Sensor specifications and mass .50

7.3 Required internal data acquisition system (DAS) . 52

7.3.1 General . 52

7.3.2 Data acquisition system characteristics . 52

7.3.3 DAS mass and location . 52

iii

© ISO 2023 – All rights reserved PROOF/ÉPREUVE

---------------------- Page: 3 ----------------------

ISO/TS 20458:2023(E)

8 User's manual .52

8.1 Requirements . 52

8.1.1 Disassembly and assembly . 52

Annex A (informative) Rationale regarding background and goals for aPLI .54

Annex B (informative) Rationale regarding performance of aPLI . 108

Annex C (informative) Assessment interval for vehicle tests . 121

Annex D (informative) Outer contour of the struck side of the bony structure .134

Annex E (informative) Biofidelity and injury assessment capability evaluation data . 137

Annex F (informative) Repeatability and reproducibility data. 202

Annex G (informative) Durability assessment data .204

Annex H (informative) Parts list . 207

Annex I (normative) Drawings and specifications, PDF and/or STP files. 212

Annex J (informative) Information regarding sensor output polarities . 213

Annex K (normative) Procedures for disassembling and assembling aPLI .217

Annex L (normative) Fastener torque values . 227

Annex M (informative) Overview of an exemplar required internal DAS . 228

Annex N (informative) Recommended aPLI general practices. 231

Annex O (informative) Assessment procedure for dynamic test equipment . 233

Annex P (informative) Validation results of aPLI models (A, C, E, F) against hardware. 235

Annex Q (informative) An exemplar of aPLI hip joint certification test rig . 245

Bibliography .246

iv

PROOF/ÉPREUVE © ISO 2023 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TS 20458:2023(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had received notice

of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee SC 36,

Safety and impact testing.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

© ISO 2023 – All rights reserved PROOF/ÉPREUVE

---------------------- Page: 5 ----------------------

ISO/TS 20458:2023(E)

Introduction

This document has been prepared on the basis of the existing design, specifications and performance

of advanced pedestrian legform impactor (aPLI) standard build level B (SBL-B). The purpose of this

document is to document the design and specifications of this pedestrian legform impactor in a form

suitable and intended for worldwide harmonized use.

In 2014, aPLI development started, with the aims of defining a globally accepted next-generation

pedestrian legform impactor, with enhanced biofidelity and injury assessment capability by

implementing an upper mass to represent the influence of the upper body of a pedestrian, and

suitable for harmonized use. Participating in the development were research institutes, dummy and

instrumentation manufacturers, governments and car manufacturers from around the world. Details

are given in Annex A through Annex G and Annex P.

aPLI drawings in electronic format are available. Details are given in Annex I and Annex H.

vi

PROOF/ÉPREUVE © ISO 2023 – All rights reserved

---------------------- Page: 6 ----------------------

TECHNICAL SPECIFICATION ISO/TS 20458:2023(E)

Road vehicles — Design and performance specifications

for advanced Pedestrian Legform Impactor (aPLI)

1 Scope

This document provides definitions, symbols, mechanical requirements, certification test procedure,

electronic subsystem requirements and user’s manual for advanced pedestrian legform impactor

(aPLI), a standardized pedestrian legform impactor with an upper mass for pedestrian subsystem

testing of road vehicles. It is applicable to impact tests involving:

— vehicles of category M1, except vehicles with the maximum mass above 2 500 kg and which are

derived from N1 category vehicles and where the driver’s position, R-point, is either forward of

the front axle or longitudinally rearwards of the front axle transverse centreline by a maximum of

1 100 mm;

— vehicles of category N1, except where the driver’s position, R-point, is either forward of the front

axle or longitudinally rearwards of the front axle transverse centreline by a maximum of 1 100 mm;

[1] [2]

— impacts to the bumper test area as defined by UN R127 and UN GTR No.9 ;

— pedestrian subsystem tests involving use of a legform for the purpose of evaluating compliance

with vehicle safety standards.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 6487, Road vehicles — Measurement techniques in impact tests — Instrumentation

ISO/TS 13499, Road vehicles — Multimedia data exchange format for impact tests

SAE J2570, Performance Specifications for Anthropomorphic Test Device Transducers

SAE J211-1, Instrumentation for Impact Test Part 1 — Electronic Instrumentation

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

abduction

rotation of the lower limb (3.34) relative to the upper mass (3.49) as the lower limb is rotated toward the

struck side (3.37)

1

© ISO 2023 – All rights reserved PROOF/ÉPREUVE

---------------------- Page: 7 ----------------------

ISO/TS 20458:2023(E)

3.2

adduction

rotation of the lower limb (3.34) relative to the upper mass (3.49) as the lower limb is rotated toward the

non-struck side (3.35)

3.3

adult

person who is sixteen years old or older

3.4

aPLI

advanced pedestrian legform impactor

modified pedestrian legform impactor which incorporates a mass representing the inertial effect of the

upper part of a pedestrian body to enhance biofidelity (3.8) and injury assessment capability (3.26) of

conventional pedestrian legforms

3.5

aluminium honeycomb

manufactured material comprising multi-layered bonded sheets of aluminium bent or corrugated in a

rib pattern, in which there is an internal pattern of hexagonal cylindrical spaces

Note 1 to entry: The aluminium honeycomb used in this document as an energy-absorbing element in full

assembly certification (3.13) tests.

3.6

AAUM

angular acceleration of upper mass

angular acceleration observed at the upper mass of the advanced pedestrian legform impactor (aPLI)

(3.4) which is obtained by differentiating the angular velocity sensor (X), installed in the upper mass

(3.49) as a required sensor

Note 1 to entry: See 7.1.3.4.

3.7

Belleville washer

type of spring which can be loaded along its axis, with its frusto-conical shape giving the spring

characteristics

3.8

biofidelity

aspect of an advanced pedestrian legform impactor (aPLI) (3.4) capability to represent impact responses

of human subjects

3.9

bone core

beam with a rectangular cross-section made of glass fibre reinforced plastic installed in the centre of

the femur (3.14) and the tibia (3.40) that provides human-like bending stiffness

3.10

bumper angle

acute angle formed by the vertical plane tangential to the surface of a car bumper and the vertical

transverse plane relative to the car

3.11

bumper system

component installed at the hip joint (3.24) inside the upper mass (3.49) composed of the bumper, the

bumper mount and the compression surface, designed to apply a force on the upper part of the femur

(3.14) in adduction (3.2) to enhance injury assessment capability (3.26) of an advanced pedestrian legform

impactor (aPLI) (3.4)

2

PROOF/ÉPREUVE © ISO 2023 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/TS 20458:2023(E)

3.12

capacity

maximum value of a physical quantity which can be measured by a sensor without causing sensor

damage

3.13

certification

process by which the relevant advanced pedestrian legform impactor (aPLI) (3.4) component or full

assembly is verified and documented to meet the specifications

3.14

femur

portion of the lower limb (3.34) between the femur top (3.15) and the upper knee block (3.29), excluding

the flesh (3.22) and the skin (3.36)

3.15

femur top

aluminium part that forms the hip joint (3.24) and the junction between the upper mass (3.49) and the

femur (3.14)

3.16

femur-1

measurement location of the femur's (3.14) bending moment (137 mm vertically up from the flat surface

of the knee meniscus) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

3.17

femur-2

measurement location of the femur's (3.14) bending moment (217 mm vertically up from the flat surface

of the knee meniscus) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

3.18

femur-3

measurement location of the femur's (3.14) bending moment (297 mm vertically up from the flat surface

of the knee meniscus) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

3.19

femur-LO

measurement location of the femur's (3.14) bending moment which is equal to the measurement location

of femur-1 (3.16) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

Note 1 to entry: For the femur-LO, the femur's bending moment is specified in ISO/TS 13499.

3.20

femur-MID

measurement location of the femur's (3.14) bending moment which is equal to the measurement location

of femur-2 (3.17) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

Note 1 to entry: For the femur-MID, the femur's bending moment is specified in ISO/TS 13499.

3.21

femur-UP

measurement location of the femur's (3.14) bending moment which is equal to the measurement location

of femur-3 (3.18) used in the development and evaluation phase of the advanced pedestrian legform

impactor (aPLI) (3.4)

Note 1 to entry: For the femur-UP, the femur's bending moment is specified in ISO/TS 13499.

3

© ISO 2023 – All rights reserved PROOF/ÉPREUVE

---------------------- Page: 9 ----------------------

ISO/TS 20458:2023(E)

3.22

flesh

moulded soft part constituting the outer layer of the lower limb (3.34) positioned inside the skin (3.36)

3.23

high-bumper car

car with a lower bumper reference line height (3.33) of 425 mm or more

3.24

hip joint

uniaxial joint that allows abduction (3.1) and adduction (3.2) and connects the upper mass (3.49) with

the lower limb (3.34)

3.25

impact carriage

moving part of the full assembly certification (3.13) test fixture comprising the impact surface with an

aluminium honeycomb (3.5) and a linearly guided rigid mass

3.26

injury assessment capability

aspect of an advanced pedestrian legform impactor (aPLI) (3.4) capability to produce peak injury values

that correlate with those obtained from human body model impact simulations

3.27

ISO metric

objective rating metric used in this document to verify time histories of sensor output against

experimentally or computationally produced target time histories

Note 1 to entry: For more information on the ISO metric, refer to ISO/TS 18571.

3.28

knee

middle part of the lower limb (3.34) that involves the knee joint, comprises the upper and lower knee

blocks (3.29) and provides a junction between the femur (3.14) and the tibia (3.40)

3.29

knee block

aluminium block that forms either the upper part of the knee joint with condyles, or the lower part of

the knee joint with the meniscus attached, accommodating knee ligaments, Belleville washers (3.7) that

represent stiffness of the knee ligaments and sensors to measure elongation of the knee ligaments and

linear acceleration and angular rate of the knee (3.28)

3.30

lateral

direction from the struck side (3.37) to the the non-struck side (3.35)

3.31

leg

portion of the lower limb (3.34) below the lower knee block (3.29), including the flesh (3.22) and the skin

(3.36)

3.32

low-bumper car

car with a lower bumper reference line height (3.33) less than 425 mm

3.33

lower bumper reference line height

LBRL height

height of the geometric trace of the lowermost points of contact between a straight edge and the

bumper, measured from the ground

4

PROOF/ÉPREUVE © ISO 2023 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/TS 20458:2023(E)

3.34

lower limb

lower part of the advanced pedestrian legform impactor (aPLI) (3.4) attached to the upper mass (3.49)

via a hip joint (3.24), representing the thigh (3.39), knee (3.28) and leg (3.31) of a human in a standing

position

3.35

non-struck side

opposite side of the struck side (3.37)

3.36

skin

sheet of polychloroprene with fabric surface that covers the flesh (3.22), forming the outermost layer of

the lower limb (3.34)

3.37

struck side

side facing a car in car tests, representing the outer side of the lower limb (3.34) of a pedestrian

3.38

subsystem test

test to evaluate safety performance of cars where subsystem impactors representing individual

body regions of a pedestrian are propelled into a front-end collision with a stationary car, in impact

[1]

conditions representing specific load cases in car-pedestrian accidents, as described in UN R127 and

[2]

UN GTR No.9

3.39

thigh

portion of the lower limb (3.34) between the femur top (3.15) and the upper knee block (3.29), including

the flesh (3.22) and the skin (3.36)

3.40

tibia

portion of the lower limb (3.34) below the lower knee block (3.29), excluding the flesh (3.22) and the skin

(3.36)

3.41

tibia-1

measurement location of the tibia's (3.40) bending moment (134 mm vertically down from the flat

surface of tibia plateau) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

3.42

tibia-2

measurement location of the tibia's (3.40) bending moment (214 mm vertically down from the flat

surface of tibia plateau) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

3.43

tibia-3

measurement location of the tibia's (3.40) bending moment (294 mm vertically down from the flat

surface of tibia plateau) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

3.44

tibia-4

measurement location of the tibia's (3.40) bending moment (374 mm vertically down from the flat

surface of tibia plateau) used in the development and evaluation phase of the advanced pedestrian

legform impactor (aPLI) (3.4)

5

© ISO 2023 – All rights reserved PROOF/ÉPREUVE

---------------------- Page: 11 ----------------------

ISO/TS 20458:2023(E)

3.45

tibia-LO

measurement location of the tibia's (3.40) bending moment which is equal to the measurement location

of tibia-4 (3.44) used in the development and evaluation phase of the advanced pedestrian legform

impa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.