ISO 7169:2014

(Main)Aerospace — Separable tube fittings for fluid systems, for 24 degree cones, for pressures up to 3 000 psi or 21 000 kPa — Procurement specification, inch/metric

Aerospace — Separable tube fittings for fluid systems, for 24 degree cones, for pressures up to 3 000 psi or 21 000 kPa — Procurement specification, inch/metric

ISO 7169:2014 specifies performance and quality requirements for the qualification and manufacture of standard 24° cone fittings and manufacture of 24° cone fittings to ensure reliable performance or equivalent inch-dimensioned fitting ends to ensure reliable performance in aircraft hydraulic systems. This International Standard specifies baseline criteria for the design and manufacture of system fittings that are qualification-tested on engines. This International Standard covers fittings of the temperature types and pressure classes specified in ISO 6771.

Aéronautique et espace — Raccordements séparables de tubes à cône de 24 degrés pour circuits de fluides jusqu'à 3 000 psi ou 21 000 kPa — Spécification d'approvisionnement, inch/métrique

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 7169

Fifth edition

2014-11-15

Aerospace — Separable tube fittings

for fluid systems, for 24° cones, for

pressures up to 3 000 psi or 21 000

kPa — Procurement specification,

inch/metric

Aéronautique et espace — Raccordements séparables de tubes à cône

de 24° pour circuits de fluides jusqu’à 3 000 psi ou 21 000 kPa —

Spécification d’approvisionnement, inch/métrique

Reference number

ISO 7169:2014(E)

©

ISO 2014

---------------------- Page: 1 ----------------------

ISO 7169:2014(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 7169:2014(E)

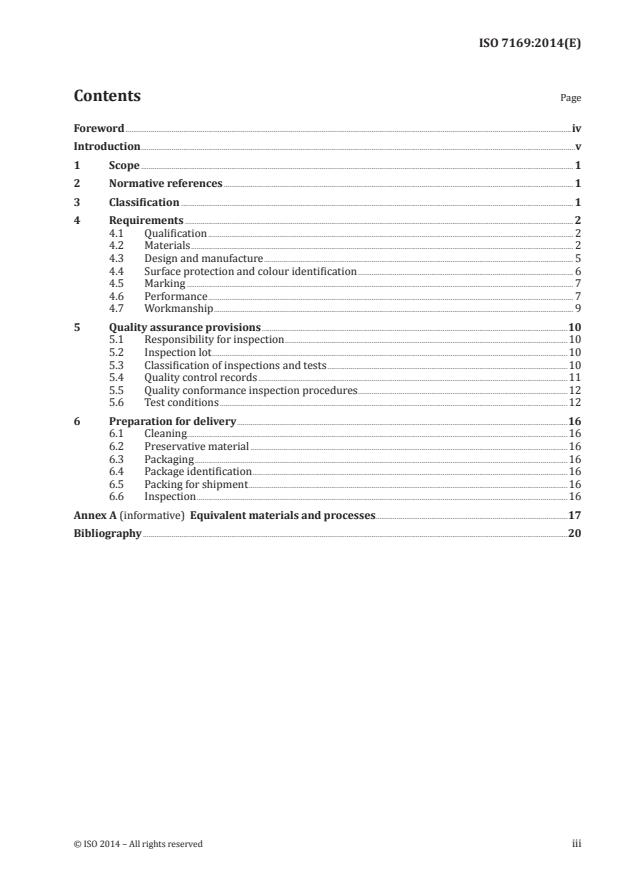

Contents Page

Foreword .iv

Introduction .v

1 Scope .1

2 Normative references .1

3 Classification .1

4 Requirements .2

4.1 Qualification . 2

4.2 Materials . 2

4.3 Design and manufacture . 5

4.4 Surface protection and colour identification . 6

4.5 Marking . 7

4.6 Performance . 7

4.7 Workmanship . 9

5 Quality assurance provisions .10

5.1 Responsibility for inspection .10

5.2 Inspection lot .10

5.3 Classification of inspections and tests .10

5.4 Quality control records .11

5.5 Quality conformance inspection procedures .12

5.6 Test conditions .12

6 Preparation for delivery .16

6.1 Cleaning .16

6.2 Preservative material .16

6.3 Packaging .16

6.4 Package identification .16

6.5 Packing for shipment .16

6.6 Inspection .16

Annex A (informative) Equivalent materials and processes.17

Bibliography .20

© ISO 2014 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 7169:2014(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 20, Aircraft and space vehicles, Subcommittee

SC 10, Aerospace fluid systems and components.

This fifth edition cancels and replaces the fourth edition (ISO 7169:2007), of which it constitutes a

minor revision.

iv © ISO 2014 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 7169:2014(E)

Introduction

This International Standard establishes the basic performance and quality criteria for threaded tube

fitting assemblies and port connectors used in aerospace fluid systems.

The test requirements are intended to satisfy the most strenuous demands encountered in a high-

performance aircraft hydraulic system. The procurement requirements are intended to ensure that fittings,

which are procured in accordance with this specification, are of the same quality as the fittings used during

the original qualification testing. Compliance with these test and procurement requirements is necessary

for fittings that are used in control systems where a malfunction would affect the safety of flight.

© ISO 2014 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 7169:2014(E)

vi © ISO 2014 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 7169:2014(E)

Aerospace — Separable tube fittings for fluid systems, for

24° cones, for pressures up to 3 000 psi or 21 000 kPa —

Procurement specification, inch/metric

1 Scope

This International Standard specifies performance and quality requirements for the qualification

and manufacture of standard 24° cone fittings and manufacture of 24° cone fittings to ensure reliable

performance or equivalent inch-dimensioned fitting ends to ensure reliable performance in aircraft

hydraulic systems.

This International Standard specifies baseline criteria for the design and manufacture of system fittings

that are qualification-tested on engines.

This International Standard covers fittings of the temperature types and pressure classes specified in

ISO 6771.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 2859-1, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by

acceptance quality limit (AQL) for lot-by-lot inspection

ISO 3161, Aerospace — UNJ threads — General requirements and limit dimensions

ISO 5855-3, Aerospace — MJ threads — Part 3: Limit dimensions for fittings for fluid systems

ISO 6771, Aerospace — Fluid systems and components — Pressure and temperature classifications

ISO 6772, Aerospace — Fluid systems — Impulse testing of hydraulic hose, tubing and fitting assemblies

ISO 7257, Aircraft — Hydraulic tubing joints and fittings — Rotary flexure test

ISO 8574, Aerospace — Hydraulic system tubing — Qualification tests for bent tubes

ISO 9538, Aerospace — Hydraulic tubing joints and fittings — Planar flexure test

ISO 10583:1993, Aerospace fluid systems — Test methods for tube/fitting assemblies

3 Classification

Fittings furnished under this International Standard shall be classified as follows:

Type A — 3 000 psi (20 684 kPa) Pressure System

Type B — 21 000 kPa (3046 psi) Pressure System

When no classification is specified, Type B shall apply.

© ISO 2014 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO 7169:2014(E)

4 Requirements

4.1 Qualification

Fittings claiming conformity with this International Standard shall be representative of products which

have successfully met the requirements and have passed the tests in this International Standard.

4.1.1 Manufacturer qualification

Manufacturer approval shall be granted by an outside agency procedure (see Table A.2, procedure No. 1).

4.1.2 Product qualification

Product approval shall be granted by an outside agency procedure (see Table A.2, procedure No. 2).

4.2 Materials

4.2.1 Fittings

The fitting parts shall be manufactured from materials as given in Table 1 or equivalents passing

the specified tests. The various materials shall be used according to the pressure and temperature

requirements of the system, as shown in Tables 2 to 5.

4.2.2 Tubing

The tubing used with the fittings shall be in accordance with the relevant specification or equivalent

tubing passing the specified qualification tests.

Table 1 — Materials for fittings

Material

a b

Part Material Type Material code Starting stock

c

No.

d

D 1

Straight fittings and nuts Aluminium alloy I Bar, rod

W 2

d

D 3

Shape fittings Aluminium alloy I Bar and forgings

W 2

f

Carbon steel II F Bar, rod, forgings 4

I, II, III J 5

I, II, III K 7

Straight and shape fittings Corrosion-resistant steel Bar and forgings

I, II, III, IV R 6

I, II, III P 11

I, II, II, IV V 11

Titanium alloy I, II, III T Bar and forgings 8

e

Sleeves (bite type) Carbon steel II F Bar 9

I, II, II P 11

Sleeves (swaged, brazed) Corrosion-resistant steel Bar

I, II, II, IV V 11

a

Temperature types and system pressure classes are defined in ISO 6771.

b

See Table 7.

c

See Table A.1.

d

Inactive for new design, superseded by W.

e

Inactive for new design, no replacement.

f

Inactive for new design, superseded by V.

2 © ISO 2014 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 7169:2014(E)

Table 1 (continued)

Material

a b

Part Material Type Material code Starting stock

c

No.

Corrosion-resistant steel I, II, III, IV V 11

Sleeves (welded) Bar

Titanium alloy I, II, III, IV T 8

a

Temperature types and system pressure classes are defined in ISO 6771.

b

See Table 7.

c

See Table A.1.

d

Inactive for new design, superseded by W.

e

Inactive for new design, no replacement.

f

Inactive for new design, superseded by V.

Table 2 — Test requirements, 3 000 psi steel or titanium fittings on steel or titanium tubing

Fitting and tube

Flexure test, bending

Nominal pressure Proof pressure Burst pressure

stress 0 % to 10 %

Metric Inch

a a

Size Size kPa (psi) kPa (psi) kPa (psi) kPa (psi)

— −02

DN05 −03

DN06 −04

DN08 −05

135 000 (20 000)

DN10 −06

DN12 −08

DN14 — 20 684 (3 000) 41 368 (6 000) 82 740 (12 000)

DN16 −10

DN20 −12

DN25 −16 108 000 (16 000)

DN32 −20

DN40 −24

b b)

108 000 (16 000

— −32

a

Dash size in 1/16 in, example: −05 = 5/16 in diameter; DN size in millimetres, example: DN05: 5 mm.

b

No data available to support this value.

© ISO 2014 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO 7169:2014(E)

Table 3 — Test requirements, 21 000 kPa steel or titanium fittings on steel or titanium tubing

Fitting and tube

Flexure test, bending

Nominal pressure Proof pressure Burst pressure

stress 0 % to 10 %

Metric Inch

a

Size Size kPa (psi) kPa (psi) kPa (psi) kPa (psi)

— −02

DN05 −03

DN06 −04

DN08 −05

135 000 (20 000)

DN10 −06

DN12 −08

DN14 — 21 000 (3 046) 42 000 (6 091) 84 000 (12 183)

DN16 −10

DN20 −12

DN25 −16 108 000 (16 000)

DN32 −20

DN40 −24

b b)

108 000 (16 000

— −32

a

Dash size in 1/16 in, example: −05 = 5/16 in diameter; DN size in millimetres, example: DN05: 5 mm.

b

No data available to support this value.

Table 4 — Test requirements, return line aluminium fittings, up to 1 500 psi, on aluminium

Fitting and tube

Flexure test, bending

Nominal pressure Proof pressure Burst pressure

stress 0 % to 10 %

Metric Inch

a a

Size Size kPa (psi) kPa (psi) kPa (psi) kPa (psi)

— −02

DN05 −03

DN06 −04 41 368 (6 000)

DN08 −05 10 342 (1 500) 20 684 (3 000) 41 368 (6 000)

DN10 −06

DN12 −08

DN14 — 37 922 (5 500)

DN16 −10 6 845 (1 000) 13 790 (2 000) 27 579 (4 000)

DN20 −12 34 474 (5 000)

6 206 (900) 12 411 (1 800) 24 824 (3 600)

DN25 −16

27 579 (4 000)

DN32 −20

DN40 −24 4 137 (600) 8 274 (1 200) 16 548 (2 400)

b b)

27 579 (4 000

— −32

a

Dash size in 1/16 in, example: −05 = 5/16 in diameter; DN size in millimetres, example: DN05: 5 mm.

b

No data available to support this value.

4 © ISO 2014 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 7169:2014(E)

Table 5 — Test requirements, return line aluminium fittings, 10 500 kPa, on aluminium tubing

Fitting and tube

Flexure test, bending

Nominal pressure Proof pressure Burst pressure

stress 0 % to 10 %

Metric Inch

a a

Size Size kPa (psi) kPa (psi) kPa (psi) kPa (psi)

— −02

DN05 −03

DN06 −04 41 368 (6 000)

DN08 −05

DN10 −06

DN12 −08

DN14 — 10 500 (1 522) 21 000 (3 046) 42 000 (6 091) 37 922 (5 500)

DN16 −10

DN20 −12 34 474 (5 000)

DN25 −16

27 579 (4 000)

DN32 −20

DN40 −24

b b)

27 579 (4 000

— −32

a

Dash size in 1/16 in, example: −05 = 5/16 in diameter; DN size in millimetres, example: DN05: 5 mm.

b

No data available to support this value.

4.3 Design and manufacture

4.3.1 Threads

All threads shall be in accordance with ISO 3161 for inch-size tube fittings, and with ISO 5855-3 for SI-

metric tube fittings.

Threads can be cut, rolled, or, except for titanium, ground. The external threads of fittings should be rolled

and, if machined, shall have an arithmetical mean deviation, R , of the profile of 3,2 µm (0,125 µin) or smoother.

a

Rolled threads shall be free of laps, cracks, surface irregularities, and seams on any part of the pressure

thread flank, in the thread-root, or on the non-pressure thread flank. Laps and seams whose depths

are within the limits of Table 6 are acceptable on the crest and the non-pressure thread flank above the

pitch diameter.

Table 6 — Maximum depth of laps, seams and surface irregularities in rolled threads

Fitting size

Depth

Metric Inch

a

Size Size mm (in)

— −02 0,15 (0,006)

DN05 −03 0,15 (0,006)

DN06 −04 0,18 (0,007)

DN08 −05 0,18 (0,007)

DN10 −06 0,20 (0,008)

DN12 −08 0,22 (0,009)

DN14 — 0,25 (0,01)

a

Dash size in 1/16 in, example: −05 = 5/16 in diameter; DN size in millimetres, example:

DN05 = 5 mm.

© ISO 2014 – All rights reserved 5

---------------------- Page: 11 ----------------------

ISO 7169:2014(E)

Table 6 (continued)

Fitting size

Depth

Metric Inch

a

Size Size mm (in)

DN16 −10 0,25 (0,01)

DN20 −12 0,25 (0,01)

DN25 −20 0,25 (0,01)

DN32 −16 0,25 (0,01)

DN40 −24 0,25 (0,01)

— −32 0,25 (0,01)

a

Dash size in 1/16 in, example: −05 = 5/16 in diameter; DN size in millimetres, example:

DN05 = 5 mm.

4.3.2 Fluid passages

On fittings where the fluid passage is drilled from each end, the offset between the drilled holes at the

meeting point shall not exceed 0,4 mm (0,015 in). It shall be possible to pass through the fitting passage

a ball whose diameter is 0,5 mm (0,020 in) less than the minimum diameter specified for the passage.

4.4 Surface protection and colour identification

4.4.1 Surface protection

The surfaces of fitting parts shall be protected in the following manner:

a) Aluminium alloy fittings: by sulfuric acid anodizing, then dyeing and dichromate or nickel acetate

sealing (process No. 18 in Table A.1);

b) Carbon steel fittings and sleeves: by cadmium plating 0,007 mm to 0,012 mm (0,000 30 in to

0,000 50 in) thick, followed by a chromate post-plate treatment (process No. 19 in Table A.1);

Note Cadmium plating is not to be used in new designs.

c) Corrosion-resistant steel fittings: by passivation treatment (process No. 12 in Table A.1). Sleeves

can be cadmium plated (process No. 19 in Table A.1);

d) Titanium fittings: by a fluoride conversion coating or anodizing (process No. 20 or No. 21 in Table A.1).

4.4.2 Colour identification

As a reference, the material of the finished fitting can be distinguished by the colours as shown in Table 7.

6 © ISO 2014 – All rights reserved

---------------------- Page: 12 ----------------------

ISO 7169:2014(E)

Table 7 — Material codes and colours

Material Code Colour

a

Aluminium D Green

Aluminium W Brown

a

Carbon steel F Gold brown

Corrosion-resistant steel J Bright metallic

Corrosion- and acid-resistant steel K Bright metallic

Corrosion-resistant stabilized steel R Bright metallic

a,b

Heat-treatable corrosion-resistant steel P Gold brown

Heat-treatable corrosion-resistant steel V Metallic

Titanium T Dull gray

a

Inactive for new design.

b

P designatives V material, cadmium plated.

4.5 Marking

Unless otherwise specified, parts shall be permanently identified with the complete part number and the

manufacturer’s trademark. The method of marking shall be laser marking, impression stamping or electro-

etching, in that order of preference. When the complete part number cannot be used in the DN10 (−06) size

and under because of the size of the part, the marking can be limited to the basic part number, without a

size designation. The marking shall not be in a location detrimental to the part of its surface protection,

and should preferably be visible when the part is assembled. When material code letters are used, the code

letter (see Table 7) shall also be laser marked, electro-etched, or impression stamped on the part.

Laser marking shall not be used on weld-ends of titanium weld fittings.

4.6 Performance

The tubing/fitting assembly shall be capable of meeting the performance requirements specified in

4.6.1 to 4.6.7.

4.6.1 Proof pressure

When testing in accordance with ISO 10583:1993, 5.1, the test assembly shall withstand pressure equal

to twice the nominal pressure in conformity with ISO 8574 without leakage, evidence of permanent

deformation or other malfunction that might affect the ability to disconnect or connect using the

specified range of torque values. All specimens, except tensile specimens, shall be proof tested.

4.6.2 Gaseous pressure

When tested in accordance with ISO 10583:1993, 5.2, assemblies shall pass the gaseous pressure test to

the specified nominal pressure without leakage or other failure. Six specimens shall be tested.

4.6.3 Hydraulic impulse resistance

When tested in accordance with ISO 6772 and ISO 10583:1993, 5.3, the test assembly shall withstand

200 000 impulse pressure cycles without leakage. Six specimens shall be tested.

4.6.4 Minimum burst pressure

When tested in accordance with ISO 10583:1993, 5.4, there shall be no leakage or burst at less than the

specified minimum burst pressure. Tubing expansion is permissible. Six specimens shall be tested to failure.

© ISO 2014 – All rights reserved 7

---------------------- Page: 13 ----------------------

ISO 7169:2014(E)

4.6.5 Flexure fatigue resistance

4.6.5.1 Standard rotary flexure text, temperature type II, pressure class D

When tested in accordance with ISO 7257 and ISO 10583:1993, 5.5, the test assemblies shall not fail. Six

specimens with straight unions shall be tested. Bulkhead-tee fitting connections shall match the flexure

fatigue life of straight unions. Two specimens with bulkhead tees shall be tested.

4.6.5.1.1 Basic qualification requirement for flexure testing to 10Text 7 cycles

a) Steel 24° cone fittings shall be used with ISO 6771 type II, class D, 304 1/8 hard cold-worked

corrosion-resistant steel tubing (material No. 14 in Table A.1). Inch sizes shall be flexure fatigue

tested to 135 MPa (20 000 psi) bending stress in sizes −10 and under, and 108 MPa (16 000 psi) in

0

sizes −12 and over to a relative tolerance of %.

−10

Metric sizes shall be flexure fatigue tested to 135 MPa (20 000 psi) bending stress in sizes DN16 and

0

under, and 108 MPa (16 000 psi) in sizes DN20 and over, to a relative tolerance of %.

−10

b) For use with type II, class D, 21-6-9 cold-worked tubing (Material No. 15 in Table A.1), inch size steel

24° cone fittings shall be flexure fatigue tested to 135 MPa (20 000 psi) bending stress in sizes −10

0

and under, and 108 MPa (16 000 psi) in sizes −12 and over, to a relative tolerance of %.

−10

Metric sizes shall be flexure fatigue tested to 135 MPa (20 000 psi) bending stress in sizes DN16 and

0

under, and 108 MPa (16 000 psi) in sizes DN20 and over, to a relative tolerance of %.

−10

c) Titanium 24° cone fittings shall be flexure fatigue tested with type II, class D, 3Al-2,5V cold-worked

and stress-relieved tubing (material No. 17 in Table A.1). Inch sizes shall be flexure fatigue tested to

135 MPa (20 000 psi) bending stress in sizes −10 and under, and 108 MPa (16 000 psi) in sizes −12

0

and over, to a relative tolerance of %.

−10

Metric sizes shall be flexure fatigue tested to 135 MPa (20 000 psi) bending stress in sizes DN16 and

0

under, and 108 MPa (16 000 psi) in sizes DN20 and over, to a relative tolerance of %.

−10

4.6.5.1.2 Alternative qualification test requirements

Modifications of 24° cone fittings, other fitting designs, new tubing materials or other attachment

methods are to be qualified by comparing their fatigue life against that of the basic 24° cone fitting by

7

testing to 10 cycles, to the same fatigue life measured in deflection as the basic fitting. The performance

of such other designs, materials or joining methods shall meet or exceed that of the standard 24° cone

type II, class D fitting and cold-worked corrosion-resistant steel tubing (material No. Fourteen in

7

Table A.1); that is, all six specimens shall withstand 10 flexure cycles without failure.

4.6.5.1.3 Alternative qualification test requirement using S-N curve

The S-N method of testing eight specimens given in ISO 7257 can be used as an alternative to the method

7

of testing six specimens to 10 cycles at a specified bending or stress level (4.6.5.1.1).

NOTE This alternative method requires testing of at least eight specimens, two each at four stress levels, to

produce an S-N curve. Such a curve shows cycles to failure for three sets of two specimens tested to different high

stress levels, and one set of two specimens at one low stress level which lasts 10Text 7 cycles without failure.

4.6.5.2 Rotary flexure test for other temperature types and pressure classes

Fitting assemblies of temperature types and pressure classes other than those in ISO 6771 shall be

qualified by testing to the same deflection levels as obtained for testing in accordance with 4.6.5.1. The

performance shall meet or exceed that of the ISO 6771 type II, class D fitting.

8 © ISO 2014 – All rights reserved

---------------------- Page: 14 ----------------------

ISO 7169:2014(E)

4.6.6 Re-use capability

Three samples shall be tested in accordance with ISO 10583:1993, 5.7, there shall be none of the

following defects:

a) leakage during any of the proof pressure tests;

b) inability to assemble the fitting to the interface point by hand;

c) nut deformation preventing engagement of the nut hexagon with an open-end wrench; and

d) gaseous leakage following final assembly, when tested in accordance with 4.6.2.

4.6.7 Tensile load capability

When tested in accordance with ISO 10583:1993, 5.8, steel fitting assemblies of temperature type II, and

pressure class D, shall withstand the axial loads specified in Table 8 without rupture. Two specimens

shall be tested.

4.7 Workmanship

Fitting parts shall conform with the requirements specified on the drawing and in this International

Standard and shall be free of burrs and slivers. Sealing surfaces shall be machined smooth to a finish

with an R value of 1,6 μm (0,06 µin). All other machined surfaces shall have a roughness value, R , of

a a

3,2 μm (0,125 µin). Unmachined surfaces of forgings or bar stock flats shall be of uniform quality and

condition. They shall be free of cracks, folds, fissures, pits, or defects, as visible to the unaided eye or

by magnetic or dye-penetrant inspection. Defects that can be removed so that they do not reappear

on re-etching, and where the required section thickness can be maintained, shall not be considered as

grounds for rejection.

Table 8 — Minimum joint strength, steel 24° cone fitting on steel and titanium tubing

Fitting size Tube wall thickness Tensile strength

Metric part Inch part

Metric part Inch part

Equivalent tube outside diameter

a

Size Size mm (in) mm (in) (in) mm kN (lbs)

— −02 3,175 0 (0,125 0) 0,3 (0,012) (0,012) 0,30 1,78 (400)

DN05 −03 4,762 5 (0,187 5) 0,4 (0,016) (0,016) 0,41 3,56 (800)

DN06 −04 6,350 0 (0,250 0) 0,5 (0,020) (0,020) 0,51 4,60 (1 300)

DN08 −05 7,937 5 (0,312 5) 0,5 (0,020) (0,020) 0,51 7,50 (1 800)

DN10 −06 9,525 0 (0,375 0) 0,7 (0,028) (0,028) 0,71 11,0 (2 500)

DN12 −08 12,700 0 (0,500 0) 0,9 (0,035) (0,035) 0,89 19,0 (4 200)

b b b b b b b b

DN14 —

DN16 −10 15,875 0 (0,625 0) 1,1 (0,043) (0,042) 1,07 31,0 (6 200)

DN20 −12 19,050 0 (0,750 0) 1,5 (0,060) (0,058) 1,47 40,0 (8 800)

DN25 −16 25,400 0 (1,000 0) 1,6 (0,063) (0,065) 1,65 44,0 (10 000)

DN32 −20 31,750 0 (1,250 0) 1,2 (0,047) (0,049) 1,24 42,2 (9 500)

b b b b b b

DN40 −24 38,100 0 (1,500 0)

b b b b b b

— −32 50,800 0 (2,000 0)

a

Dash size in 1/16 in, example: −05 = 5/16 in diameter.

b

These values will be added when available.

© ISO 2014 – All

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.