ISO 18487-1:2017

(Main)Aerospace series — Titanium tube for 35 MPa operating pressure — Part 1: Inch series

Aerospace series — Titanium tube for 35 MPa operating pressure — Part 1: Inch series

ISO 18487-1:2017 is applicable to seamless tubing of circular cross-section made from titanium alloy and intended for use primarily in systems with system operating pressure of 35 MPa (5 080 psi) (Pressure Class J), but usage is not limited to such applications.

Série aérospatiale — Tubes en titane — Pression de service : 35 MPa — Partie 1: Série en inches

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 18487-1

First edition

2017-04

Aerospace series — Titanium tube for

35 MPa operating pressure —

Part 1:

Inch series

Série aérospatiale — Tubes en titane — Pression de service : 35 MPa —

Partie 1: Série en inches

Reference number

ISO 18487-1:2017(E)

©

ISO 2017

---------------------- Page: 1 ----------------------

ISO 18487-1:2017(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 18487-1:2017(E)

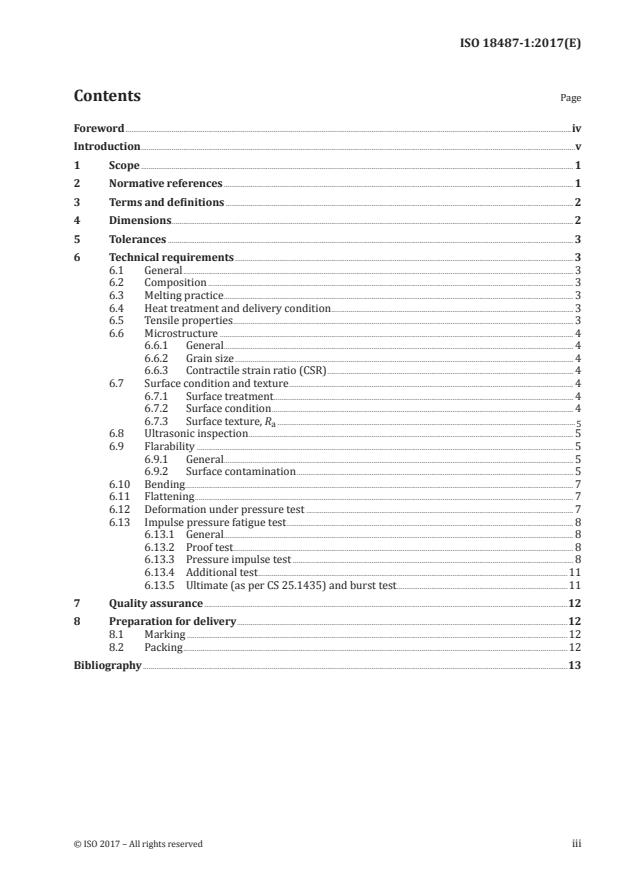

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Dimensions . 2

5 Tolerances . 3

6 Technical requirements . 3

6.1 General . 3

6.2 Composition . 3

6.3 Melting practice . 3

6.4 Heat treatment and delivery condition . 3

6.5 Tensile properties . 3

6.6 Microstructure . 4

6.6.1 General. 4

6.6.2 Grain size . 4

6.6.3 Contractile strain ratio (CSR) . 4

6.7 Surface condition and texture . 4

6.7.1 Surface treatment. 4

6.7.2 Surface condition . 4

6.7.3 Surface texture, R .

a 5

6.8 Ultrasonic inspection . 5

6.9 Flarability . 5

6.9.1 General. 5

6.9.2 Surface contamination . 5

6.10 Bending . 7

6.11 Flattening . 7

6.12 Deformation under pressure test . 7

6.13 Impulse pressure fatigue test . 8

6.13.1 General. 8

6.13.2 Proof test. 8

6.13.3 Pressure impulse test . 8

6.13.4 Additional test .11

6.13.5 Ultimate (as per CS 25.1435) and burst test.11

7 Quality assurance .12

8 Preparation for delivery .12

8.1 Marking .12

8.2 Packing .12

Bibliography .13

© ISO 2017 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 18487-1:2017(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO’s adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: w w w . i s o .org/ iso/ foreword .html

This document was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicles,

Subcommittee SC 10, Aerospace fluid systems and components.

A list of all the parts in the ISO 18487 series can be found on the ISO website.

iv © ISO 2017 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 18487-1:2017(E)

Introduction

This document is intended to harmonize the technical requirements for titanium tubes used in

aerospace with design operating pressure of 35 MPa.

It is noted that, while ISO standards should normally refer only to SI units, large segments of the

aerospace industry refer to other measurement systems as a matter of common working practice. The

mention of “inch series” in the title of this document reflects this. It recognizes the fact that the nominal

sizes referred to in the document, which are in common use in the aerospace industry, were originally

defined in terms of fractional inches.

Although the tube sizes were originally defined, and are frequently referred to, in terms of non-SI units,

all dimensions used in this document are in SI units with inch units given in addition for the convenience

of those users more familiar with these.

It is further noted that the standard ISO decimal symbol “,” (comma) is not used as common working

practice for inch dimensions. A decimal point is used in the inch dimensions in this document as in

many other aerospace standards.

NOTE The use of non-SI units and the decimal point in this document does not constitute general acceptance

of measurement systems other than SI within International Standards.

© ISO 2017 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 18487-1:2017(E)

Aerospace series — Titanium tube for 35 MPa operating

pressure —

Part 1:

Inch series

1 Scope

This document is applicable to seamless tubing of circular cross-section made from titanium alloy and

intended for use primarily in systems with system operating pressure of 35 MPa (5 080 psi) (Pressure

Class J), but usage is not limited to such applications.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 4287, Geometrical Product Specifications (GPS) — Surface texture: Profile method — Terms, definitions

and surface texture parameters

ISO 6772, Aerospace — Fluid systems — Impulse testing of hydraulic hose, tubing and fitting assemblies

ISO 8492, Metallic materials — Tube — Flattening test

ISO 8575:2016, Aerospace — Fluid systems — Hydraulic system tubing

ISO 10583, Aerospace fluid systems — Test methods for tube/fitting assemblies

ISO 12573, Aircraft — Tubing tolerances — Inch series

EN 2003-010, Aerospace series — Titanium and titanium alloys — Test methods — Part 010: Sampling for

determination of hydrogen content

EN 3718, Aerospace series — Test method for metallic materials — Ultrasonic inspection of tubes

AS 4076, Contractile strain ratio testing of titanium hydraulic tubing

AMS 2634, Ultrasonic inspection, thin wall metal tubing superseding

ASTM E112, Standard test methods for determining average grain size

ASTM E1409, Standard test method for determination of oxygen and nitrogen in titanium and titanium

alloys by inert gas fusion

ASTM E1941, Standard test method for determination of carbon in refractory and reactive metals and their

alloys by combustion analysis

ASTM E1447, Standard test method for determination of hydrogen in titanium and titanium alloys by the

inert gas fusion thermal conductivity/infrared detection method

ASTM E2371, Standard test method for analysis of titanium and titanium alloys by direct current plasma

and inductively coupled plasma atomic emission spectrometry (Performance-based test methodology)

© ISO 2017 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 18487-1:2017(E)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http:// www .electroped

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.