ISO/TS 22583:2019

(Main)Guidance for supervisors and operators of point-of-care testing (POCT) devices

Guidance for supervisors and operators of point-of-care testing (POCT) devices

This document gives guidance for supervisors and operators of point-of-care testing (POCT) services where POCT is performed without medical laboratory training, supervision or support. It includes the key components that should be considered to provide safe and reliable POCT results. Self-testing is excluded from this document.

Titre manque

General Information

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 22583

First edition

2019-11

Guidance for supervisors and

operators of point-of-care testing

(POCT) devices

Reference number

ISO/TS 22583:2019(E)

©

ISO 2019

---------------------- Page: 1 ----------------------

ISO/TS 22583:2019(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2019

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2019 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TS 22583:2019(E)

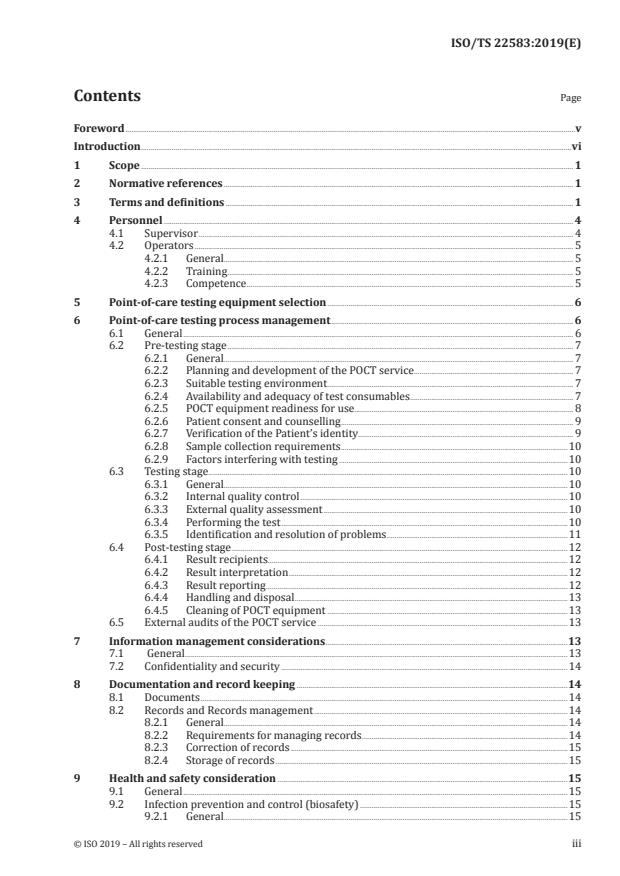

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Personnel . 4

4.1 Supervisor . 4

4.2 Operators . 5

4.2.1 General. 5

4.2.2 Training . 5

4.2.3 Competence . 5

5 Point-of-care testing equipment selection . 6

6 Point-of-care testing process management . 6

6.1 General . 6

6.2 Pre-testing stage . 7

6.2.1 General. 7

6.2.2 Planning and development of the POCT service . . 7

6.2.3 Suitable testing environment . 7

6.2.4 Availability and adequacy of test consumables . 7

6.2.5 POCT equipment readiness for use. 8

6.2.6 Patient consent and counselling . 9

6.2.7 Verification of the Patient’s identity. 9

6.2.8 Sample collection requirements .10

6.2.9 Factors interfering with testing .10

6.3 Testing stage .10

6.3.1 General.10

6.3.2 Internal quality control .10

6.3.3 External quality assessment .10

6.3.4 Performing the test .10

6.3.5 Identification and resolution of problems .11

6.4 Post-testing stage .12

6.4.1 Result recipients.12

6.4.2 Result interpretation .12

6.4.3 Result reporting .12

6.4.4 Handling and disposal .13

6.4.5 Cleaning of POCT equipment .13

6.5 External audits of the POCT service .13

7 Information management considerations .13

7.1 General .13

7.2 Confidentiality and security .14

8 Documentation and record keeping .14

8.1 Documents .14

8.2 Records and Records management .14

8.2.1 General.14

8.2.2 Requirements for managing records .14

8.2.3 Correction of records .15

8.2.4 Storage of records .15

9 Health and safety consideration .15

9.1 General .15

9.2 Infection prevention and control (biosafety) .15

9.2.1 General.15

© ISO 2019 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TS 22583:2019(E)

9.2.2 Use of sharps .16

9.2.3 Personal protection .16

9.2.4 Disposal of waste .16

9.2.5 Hazard analysis .16

9.3 Other health and safety considerations .16

Annex A (normative) Training and competence of operators .17

Annex B (normative) POCT Equipment and selecting the most appropriate test .20

Annex C (informative) Documents and Records .26

Annex D (normative) Internal Quality Control and External Quality Assessment .28

Annex E (informative) Infection prevention and control (Biosafety) .32

Bibliography .35

iv © ISO 2019 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TS 22583:2019(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 212, Clinical laboratory testing and in

vitro diagnostic test systems.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

© ISO 2019 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/TS 22583:2019(E)

Introduction

Due to the ease of use and rapidness of point-of-care-testing (POCT), POCT equipment is widely used as

a tool for making decisions related to the health, management or care needs of patients. Such decisions

can include admission to hospital, evacuation to more appropriate care environments and directed

patient management. There can also be significant civil and/or legal implications that arise from POCT

such as cessation or termination of employment, family court rulings or revocation of bail or parole.

The availability of simple-to-use point of care equipment has led to continuous development in POCT,

examples include testing for diabetes management, blood clotting factors, infectious disease markers,

haemoglobin, white blood cell counts, pregnancy tests, cardiac markers, illicit drug use and performance

enhancing chemical testing.

Whilst examinations of a patient’s body fluids, excreta and tissues have been performed traditionally in

the controlled and regulated environment of a medical laboratory, globally, POCT is increasingly being

performed outside of a traditional laboratory setting and by operators without medical laboratory

support.

Circumstances where POCT testing can occur include but are not limited to hospitals, medical practices,

pharmacies, paramedics, long-term care facilities, outreach clinics in remote and rural settings, in

emergency and natural disasters and community settings such as law enforcement, workplace health

and safety, sporting facilities, academia, the military and public areas such as shopping centres.

As POCT results can be used to make important decisions about patients, it is vital that the equipment

works properly to yield the correct results and that the operators are trained and competent. This

requires that a quality testing structure is provided by supervisors and made available to the operators.

Testing should be of benefit to the patient being tested, if the testing is not performed within a defined

quality testing structure then incorrect results can have a negative effect on the patient in terms of

health outcomes or punitive action taken.

This document has been written in easy to understand language. Its purpose is to provide supervisors

and operators of POCT services guidance for assessing the appropriateness of proposed POCT, test and

equipment selection, as well as skill requirements for technical performance and result interpretation

that will ensure that the reliability, quality and interpretation of the results produced is of a quality

appropriate to the intended use.

It is recommended that manufacturers and their distributors draw this this document to the attention

of purchasers of POCT equipment and encourage them to follow this document.

NOTE 1 The Annexes provide detailed information and add context that is not included in the main body of

this document. Therefore, to appreciate this document fully the reader is encouraged to ensure the relevant

annexes are read in conjunction with main body of this document.

NOTE 2 It is presupposed that procedures are developed in accordance with statutory and regulatory

requirements.

NOTE 3 In some sections readers of this document are referred to medical laboratory professionals. Medical

laboratory professionals with the required competence to offer advice can be found in laboratories adhering to

international standards including ISO 15189, Medical laboratories — Requirements for Quality and Competence

and ISO 22870, Point-of-care testing (POCT) — Requirements for quality and competence.

vi © ISO 2019 – All rights reserved

---------------------- Page: 6 ----------------------

TECHNICAL SPECIFICATION ISO/TS 22583:2019(E)

Guidance for supervisors and operators of point-of-care

testing (POCT) devices

1 Scope

This document gives guidance for supervisors and operators of point-of-care testing (POCT) services

where POCT is performed without medical laboratory training, supervision or support. It includes the

key components that should be considered to provide safe and reliable POCT results.

Self-testing is excluded from this document.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

analyte

item that is being measured, tested or calculated

EXAMPLE Glucose, troponin, concaine, HIV antibodies.

3.2

biological reference interval

reference range

normal range

normal value

specified interval of the distribution of values taken from a biological reference population

Note 1 to entry: A reference interval is composed of the values or range for an analyte (3.1) that are expected for

a “healthy person”. They are sometimes called "normal" values. Whilst “normal” ranges can give an indication

about the wellbeing of a patient (3.10), things which should be considered are that a result within the “normal”

range does not necessarily mean the patient (3.10) is healthy, or a result outside of the “normal” range does not

necessarily mean the patient (3.10) is unhealthy. It is also important to note that “normal ranges” can differ from

equipment (3.6) to equipment (3.6) and population to population.

Note 2 to entry: In some cases, such as drugs of abuse testing the normal value should be negative or not detected.

[SOURCE: ISO 15189:2012, 3.4, modified — NOTE 1 to NOTE 4 have been deleted and Note 1 to entry

has been added.]

© ISO 2019 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO/TS 22583:2019(E)

3.3

clinical handover

patient handover

handover

transfer of professional responsibility and accountability for some or all aspects of care for a patient

(3.10) to another person or professional group on a temporary or permanent basis

Note 1 to entry: Transferring all or part of a patient’s (3.10) care between healthcare providers or locations is a

high-risk situation and a failure in clinical handover is a major source in preventable patient (3.10) harm.

Note 2 to entry: Effective clinical handover, which is structured and standardised, can reduce communication

errors and improve patient (3.10) safety.

Note 3 to entry: A simple example of clinical handover is ensuring critical result notification to an appropriate

person is performed in a timely manner to minimise harm to the patient (3.10).

3.4

competence

demonstrated ability to apply knowledge and skills to produce an accurate POCT result

[SOURCE: ISO 15189:2012, 3.5, modified — “to produce an accurate POCT result” has been added and

“NOTE” has been deleted.]

3.5

critical results

results outside defined limits which may indicate a life-threatening situation and require immediate

notification of the referring doctor

3.6

equipment

any device or apparatus which can be used to perform a POCT (3.11)

Note 1 to entry: Examples include simple colour changing urine test strips for glucose to more complex electronic

hand held or bench top analysers such as glucometers, lipid analysers and alcoholmeters.

Note 2 to entry: For the purposes of this document equipment includes any reagents or consumables required to

perform the test.

3.7

external quality assessment (EQA)

proficiency testing (PT)

process where samples (3.13) of known values are tested periodically and the results are not known to

the operator at the time of testing

Note 1 to entry: The results obtained are then compared against others testing the same sample (3.13) with

the same POCT (3.11) equipment (3.6) type giving the participant the ability to evaluate their performance

against others.

Note 2 to entry: Commercially available EQA programmes are recommended but are not always available. Where

these are not available manufacturers and/or laboratories may be able to offer assistance with sample (3.13)

exchange programs.

3.8

interference factors

a substance or process which falsely alters a test result

Note 1 to entry: Interference can be significant.

Note 2 to entry: Interfering substances can be endogenous (substances found naturally in the patient (3.10)

sample (3.13) such as lipids, proteins, antibodies) or exogenous (substances not naturally found in the patient’s

sample such as drugs, poisons or medications).

2 © ISO 2019 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/TS 22583:2019(E)

Note 3 to entry: The most common interfering factors are haemolysis (the rupturing of red blood cells and the

release of their contents into surrounding fluid (e.g. blood plasma/serum), hyperbilirubinemia (a yellow or green

pigmentation of the blood plasma/serum due to high bilirubin) and lipaemia (an abnormally high concentration

of lipids in the blood, characteristically the blood plasma can appear white or milky in colour due to the presence

of fat).

Note 4 to entry: The type of collection tube can also cause test interference as these often contain additive

components.

3.9

internal quality control (IQC)

quality control (QC)

internal procedure which monitors the testing process to decide if the system is working correctly and

gives confidence that the results are reliable enough to be released

Note 1 to entry: IQC samples (3.13) have known quantities of the analyte (3.1) being tested. The result obtained is

expected to be close to the known value and within an acceptable range. Where results fall outside the acceptable

range action to rectify the issue needs to occur before patients (3.10) are tested.

3.10

patient

individual undergoing POCT (3.11)

Note 1 to entry: For this document the term patient has been used for consistency.

Note 2 to entry: It should be noted that an individual who undergoes POCT (3.11) may not have an ongoing

disease and therefore may not be a patient as such. They can be clients or employees being tested for reasons

other than to receive medical care, such as community screening, pre-employment testing or assessing the use of

performance-enhancing drugs or chemicals.

3.11

point-of-care testing

POCT

near-patient testing

testing that is performed near or at the site of a patient (3.10)

3.12

point of care testing service provider

POCT service provider

individual or organisation responsible for providing POCT (3.11)

3.13

sample

primary sample

specimen

discrete portion of a body fluid (e.g. blood, urine, saliva), breath, hair or tissue taken from the human

body for POCT (3.11) which is assumed to represent the whole patient

Note 1 to entry: In some countries, the terms “specimen” or “primary sample’ are used instead of sample. For

the purpose of this document the terms “sample”, “primary sample” and “specimen” should be considered

interchangeable

Note 2 to entry: The source of blood samples (whether arterial, venous or capillary) is another important

consideration as POCT results for capillary specimens may differ from arterial, venous values for certain tests

and in certain circumstances.

3.14

urgent results

results needed for the care management of a patient within a minimal time period

© ISO 2019 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO/TS 22583:2019(E)

3.15

validation

process of establishing the performance characteristics and limitations of POCT (3.11) equipment (3.6)

and the identification of the influences which can change these characteristics and to what extent

Note 1 to entry: Which analytes (3.1) it can measure and in which sample (3.13) type (blood arterial, venous or

capillary), plasma, urine) in the presence of which interferences (3.8) are important considerations.

Note 2 to entry: The process for confirming that a method is fit for purpose (is appropriate for its intended use).

3.16

verification

process of demonstrating the performance criteria to which the method has been validated have been

met by the POCT Service provider (3.12) prior to introducing into routine use

4 Personnel

4.1 Supervisor

There shall be an appointed person(s) (supervisor) who has the authority and takes responsibility for,

the quality of the service and is competent to supervise the testing provided.

The supervisor is responsible for the quality, timeliness, accuracy and safe delivery of the POCT which

includes hazard analysis (See 9.2.5).

The supervisor shall define the roles and responsibilities of POCT operators.

The supervisor shall ensure implementation of the following:

— selection of appropriate tests in consultation with a medical professional, when indicated;

— maintaining privacy, safety and confidentiality of personal information and test results of patients

undergoing testing;

— availability of appropriate result interpretation;

— access to advisory services;

— confirmatory testing and/or referral for appropriate or necessary additional testing;

— selection of suitable testing equipment;

— identification and adherence to applicable guidelines;

— performance and review of quality control with corrective actions;

— establishment and maintenance of internal instructions or processes;

— operator training and competency assessment;

— appropriate environment for testing;

— inventory control management processes;

— appropriate and effective clinical handover; and

— appropriate biosafety and infection control procedures.

The supervisor shall ensure procedures are in place and appropriate for the POCT service provided and

that operators adhere to all instructions and procedures relating to POCT.

4 © ISO 2019 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/TS 22583:2019(E)

The supervisor should ensure there is access to medical experts and medical laboratory professionals

to provide consultation as needed.

4.2 Operators

4.2.1 General

There shall be an appointed person(s) (operator) who has been trained and has demonstrated the

competence required to perform testing. A supervisor may also be an operator.

4.2.2 Training

An operator training program shall be implemented that

— describes the key aspects of the testing process including:

— the intent of the testing process;

— its essential steps; and

— the significance of each step;

— ensures the operators can produce reliable results;

— describes the requirements for use of internal quality control and external quality assessment

programs and ensure they are used (if available); and

— states the importance of following policies, procedures and instructions for use.

All operators are required to have successfully completed the training program.

The training program shall be updated when changes to the testing service occur (e.g. new equipment

or procedure is introduced) and operators shall be trained to the new processes.

The training program shall be evaluated periodically for effectiveness.

NOTE Aspects of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.