ISO/TR 14187:2011

(Main)Surface chemical analysis — Characterization of nanostructured materials

Surface chemical analysis — Characterization of nanostructured materials

ISO/TR 14187 provides an introduction to (and some examples of) the types of information that can be obtained about nanostructured materials using surface-analysis tools. Of equal importance, both general issues or challenges associated with characterising nanostructured materials and the specific opportunities or challenges associated with individual methods are identified. As the size of objects or components of materials approaches a few nanometres, the distinctions among "bulk", "surface" and "particle" analysis blur. Although some general issues relevant to characterisation of nanostructured materials are identified, this Technical Report focuses on issues specifically relevant to surface chemical analysis of nanostructured materials. A variety of analytical and characterisation methods will be mentioned, but this report focuses on methods that are in the domain of ISO/TC 201 including auger electron spectroscopy, X-ray photoelectron spectroscopy, secondary ion mass spectrometry, and scanning probe microscopy. Some types of measurements of nanoparticle surface properties such as surface potential that are often made in a solution are not discussed in this Report. Although they have many similar aspects, characterisation of nanometre-thick films or a uniform collection of nanometre-sized particles present different characterisation challenges. Examples of methods applicable to both thin films and to particles or nano-sized objects are presented. Properties that can be determined include: the presence of contamination, the thickness of coatings, and the chemical nature of the surface before and after processing. In addition to identifying the types of information that can be obtained, the Technical Report summarises general and technique-specific Issues that must be considered before or during analysis. These include: identification of needed information, stability and probe effects, environmental effects, specimen-handling issues, and data interpretation. This introduction to information available about nanomaterials using a specific set of surface-analysis methods cannot by its very nature be fully complete. However, important opportunities, concepts and issues have been identified and many references provided to allow the topics to be examined in greater depth as required.

Analyse chimique des surfaces - Caractérisation des matériaux nanostructurés

General Information

Relations

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 14187

First edition

2011-08-15

Surface chemical analysis —

Characterization of nanostructured

materials

Analyse chimique des surfaces — Caractérisation des matériaux

nanostructurés

Reference number

ISO/TR 14187:2011(E)

©

ISO 2011

---------------------- Page: 1 ----------------------

ISO/TR 14187:2011(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2011

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2011 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TR 14187:2011(E)

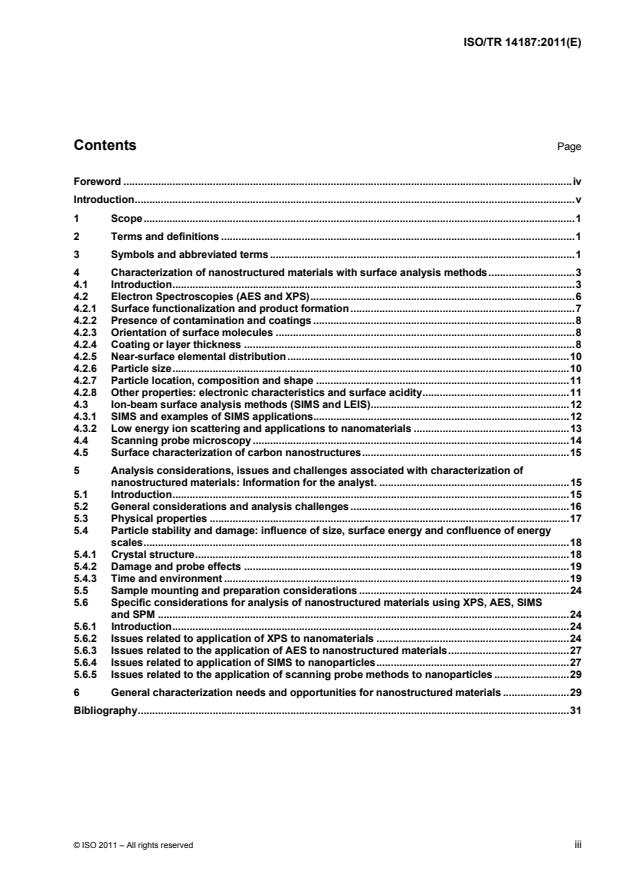

Contents Page

Foreword . iv

Introduction . v

1 Scope . 1

2 Terms and definitions . 1

3 Symbols and abbreviated terms . 1

4 Characterization of nanostructured materials with surface analysis methods . 3

4.1 Introduction . 3

4.2 Electron Spectroscopies (AES and XPS) . 6

4.2.1 Surface functionalization and product formation . 7

4.2.2 Presence of contamination and coatings . 8

4.2.3 Orientation of surface molecules . 8

4.2.4 Coating or layer thickness . 8

4.2.5 Near-surface elemental distribution . 10

4.2.6 Particle size . 10

4.2.7 Particle location, composition and shape . 11

4.2.8 Other properties: electronic characteristics and surface acidity . 11

4.3 Ion-beam surface analysis methods (SIMS and LEIS) . 12

4.3.1 SIMS and examples of SIMS applications . 12

4.3.2 Low energy ion scattering and applications to nanomaterials . 13

4.4 Scanning probe microscopy . 14

4.5 Surface characterization of carbon nanostructures . 15

5 Analysis considerations, issues and challenges associated with characterization of

nanostructured materials: Information for the analyst. . 15

5.1 Introduction . 15

5.2 General considerations and analysis challenges . 16

5.3 Physical properties . 17

5.4 Particle stability and damage: influence of size, surface energy and confluence of energy

scales . 18

5.4.1 Crystal structure . 18

5.4.2 Damage and probe effects . 19

5.4.3 Time and environment . 19

5.5 Sample mounting and preparation considerations . 24

5.6 Specific considerations for analysis of nanostructured materials using XPS, AES, SIMS

and SPM . 24

5.6.1 Introduction . 24

5.6.2 Issues related to application of XPS to nanomaterials . 24

5.6.3 Issues related to the application of AES to nanostructured materials . 27

5.6.4 Issues related to application of SIMS to nanoparticles . 27

5.6.5 Issues related to the application of scanning probe methods to nanoparticles . 29

6 General characterization needs and opportunities for nanostructured materials . 29

Bibliography . 31

© ISO 2011 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TR 14187:2011(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In exceptional circumstances, when a technical committee has collected data of a different kind from that

which is normally published as an International Standard (“state of the art”, for example), it may decide by a

simple majority vote of its participating members to publish a Technical Report. A Technical Report is entirely

informative in nature and does not have to be reviewed until the data it provides are considered to be no

longer valid or useful.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TR 14187 was prepared by Technical Committee ISO/TC 201, Surface chemical analysis, Subcommittee

SC 5, Auger electron spectroscopy.

iv © ISO 2011 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TR 14187:2011(E)

Introduction

As engineered nanomaterials of many types play an increasing role in many different technologies [1],

international organizations (including ISO, ASTM, the International Bureau of Weights of Measures (BIPM),

Consultative Committee for Amount of Substance: Metrology in Chemistry (CCQM) and the Organization for

Economic Cooperation and Development (OECD))[1] are working to identify critical properties [2] and

measurements that must be understood to adequately define the nature of the materials being used. An

inherent property of any nanostructured material, whether a particle, fibre or other object, is that a large

percentage of the material is associated with a surface or interface. Therefore, surface composition and

chemistry have been identified as being part of a minimum set of chemical parameters need to characterize

nanomaterials and it would naturally seem that the wide range of tools developed for surface characterization

could or should be routinely applied to these materials. Two different issues, however, have limited the impact

of traditional surface analysis tools in some areas of nanoscience and nanotechnology. First, many of the

tools do not have sufficient spatial resolution in three dimensions needed to analyse individual nanostructured

materials (or, equivalently, variations of composition within that material). For this reason, some researchers

do not consider application of the tools even though they can often provide very important information. Second,

surface analytical (and other) tools are often applied to nanostructured materials without appropriately

considering several analytical challenges or issues that these materials present. Such challenges include

environmentally altered behaviours of nanoparticles (including effects of making measurements in vacuum),

time-dependent characteristics of nanostructured materials, the influence of particle shape on analysis results,

and the increased possibility of altering the structure or composition of the nanomaterial by the incident

radiation (typically electrons, X-rays, or ions) during the analysis. This Technical Report gives information on

these important issues. The report first describes the types of information that can be obtained about

nanostructured materials, sometimes using analytical approaches beyond those in standard applications.

Second, the report examines the technical challenges generally faced when applying surface analysis tools

(and often other tools) for characterization of nanostructured materials as well as those specific to each

technique.

Because of the expanding use of nanostructured materials in research, development, and commercial

applications as well as their natural presence in air and ground water, there is an increasing need to

understand the properties and behaviours of nanostructured materials as they are synthesized or as they

evolve in a particular environment. The novel and unusual properties of nanostructured materials excite

scientists, technologists and the general public. However, the sometimes surprising properties of many of

these materials raise analysis or characterization issues that sometimes are unexpected by analysts,

scientists, and production engineers [3-5].

Potential health and environmental concerns related to materials with unusual or unique properties increase

the need to understand the chemical, physical and biological properties of these materials throughout their life

cycle. It is now recognized that some early reports on the properties of nanoparticles and other nanostructured

materials, including their toxicity and environmental stability, were based on inadequate characterizations [6].

In some cases, important characterizations appear not to have been attempted or reported [7, 8]. A

March 2006 article in Small Times magazine described a workshop designed to identify roadblocks to

nanobiotech commercialization [6] at which several experts reported that many of the important physical

characteristics needed to understand the physical and chemical properties of nanoparticles were not reported

and apparently often unmeasured, especially in assessments of particle toxicity. The article further notes that

the changes that these particles undergo when exposed to the environment where they are stored or used are

especially important and usually unknown. In many cases, nanoparticles are coated with surfactants or

contaminants, and these are often not well characterized and sometimes not adequately identified. As a result,

the validity of the conclusions may be questionable. Inadequate characterization of the surface chemistry of

nanoparticles has been identified as one of the areas where appropriate characterization is often lacking [4, 8].

One of the definitions of a nanostructured material is that, in at last one dimension, the size of the object or

structure must be 100 nm or less. Considerable attention is being given to the characterization of nanosized-

objects (particles, rods or other shapes) that might be released into the environment and a set of minimum

characterization requirements for nanoparticles for use in toxicity studies has been identified [2]. However, the

needs for nanomaterials characterization include the wide variety of nanostructured materials that are used in

© ISO 2011 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/TR 14187:2011(E)

computers, as sensors, in batteries or fuel cells and many other types of applications. Nonetheless, the

minimum characterization requirements for nanoparticles can be generalized to a wider range of materials and

potential applications as shown in Table 1.

Surface-analysis methods of various forms (described later) can provide information that relates to many

elements in Table 1 including those that appear obvious (such as surface composition and chemistry) but also

includes particle or component size, presence of surface impurities, nature of surface functionality (including

acidity), surface structure/morphology, near-surface variation of composition (both laterally and with depth,

coating/film thickness, and electronic properties of nanostructures/films.

Surface characterization is only a subset of several nanomaterials analysis needs that are being examined by

ISO/TC 229. This report on surface chemical analysis methods prepared by ISO/TC 201/SC 5 has been

prepared in coordination with the overall characterization needs identified by experts in TC 201 and TC 229 as

well as awareness of the objectives being addressed by ISO/TC 229. This Technical Report describes the

information that can be obtained (and by which techniques), and examines some of the issues and challenges

faced when performing such analyses.

Table 1. Physical and chemical properties for characterization of nanostructured materials

Items in bold font are properties for which surface chemical analysis can provide useful information, as

described in this Technical Report.

____________________________________________________________________________________

What does the material look like?

Particle/grain/film/structural unit size(s) /size distribution

Grain, particle, film morphology (shape, layered, roughness, topography)

Agglomeration state/aggregation (e.g., do particles stick together)

What is the material made of?

Bulk composition (including chemical composition and crystal structure)

Bulk purity (including levels of impurities)

Elemental, chemical and/or phase distribution (including surface composition and surface

impurities)

What factors affect how a material interacts with its surroundings?

Surface area

Surface chemistry, including reactivity, hydrophobicity

Surface charge

Overarching considerations to take into account when characterizing engineered nanomaterials (for toxicity

studies and other applications):

Stability—how do material properties (especially the surface composition, particle agglomeration,

etc.) change with time (dynamic stability), storage, handling, preparation, delivery, etc.? Include

solubility and the rate of material release through dissolution

Context/media—how do material properties change in different media or during processing

(environmental effects); i.e., from the bulk material to dispersions to material in various biological

matrices? (“as administered” characterization is considered to be particularly important)

Where possible, materials should be characterized sufficiently to interpret functional behaviours. For

toxicology studies, information is required on the response to the amount of material against a range

of potentially relevant dose metrics, including mass, surface area, and number concentration

_______________________________________________________________________________________

This table is adapted from [2]. The recommendations in the initial table were developed at a workshop on

ensuring appropriate material characterization in nanotoxicology studies, held at the Woodrow Wilson

International Center for Scholars in Washington, DC, USA, between 28 October and 29 October, 2008;

http://www.characterizationmatters.org.

vi © ISO 2011 – All rights reserved

---------------------- Page: 6 ----------------------

TECHNICAL REPORT ISO/TR 14187:2011(E)

Surface chemical analysis — Characterization of

nanostructured materials

1 Scope

This Technical Report provides an introduction to (and some examples of) the types of information that can be

obtained about nanostructured materials using surface-analysis tools (Section 4). Of equal importance, both

general issues or challenges associated with characterizing nanostructured materials and the specific

opportunities or challenges associated with individual methods are identified (Section 5). As the size of objects

or components of materials approaches a few nanometres, the distinctions among “bulk”, “surface” and

“particle” analysis blur. Although some general issues relevant to characterization of nanostructured materials

are identified, this Technical Report focuses on issues specifically relevant to surface chemical analysis of

nanostructured materials. A variety of analytical and characterization methods will be mentioned, but this

report focuses on methods that are in the domain of ISO/TC 201 including Auger Electron Spectroscopy,

X-ray photoelectron spectroscopy, secondary ion mass spectrometry, and scanning probe microscopy. Some

types of measurements of nanoparticle surface properties such as surface potential that are often made in a

solution are not discussed in this Report.

Although they have many similar aspects, characterization of nanometre-thick films or a uniform collection of

nanometre-sized particles present different characterization challenges. Examples of methods applicable to

both thin films and to particles or nano-sized objects are presented. Properties that can be determined

include: the presence of contamination, the thickness of coatings, and the chemical nature of the surface

before and after processing. In addition to identifying the types of information that can be obtained, the

Technical Report summarizes general and technique-specific Issues that must be considered before or during

analysis. These include: identification of needed information, stability and probe effects, environmental effects,

specimen-handling issues, and data interpretation.

Surface characterization is an important subset of several analysis needs for nanostructured materials. The

broader characterization needs for nanomaterials are within the scope of ISO/TC 229 and this report has been

coordinated with experts of TC 229 Joint Working Group (JWG) 3.

This introduction to information available about nanomaterials using a specific set of surface-analysis methods

cannot by its very nature be fully complete. However, important opportunities, concepts and issues have been

identified and many references provided to allow the topics to be examined in greater depth as required.

2 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 18115 parts 1 and 2 apply.

3 Symbols and abbreviated terms

AES Auger electron spectroscopy

APT atom probe tomography

AFM atomic force microscopy

ARXPS angle resolved X-ray photoelectron spectroscopy

CNT carbon nanotube

CVD chemical vapour deposition

© ISO 2011 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO/TR 14187:2011(E)

dSIMS dynamic secondary ion mass spectrometry

EI-MS electron ionization mass spectrometry

EPMA electron probe micro-analysis

ESCA electron spectroscopy for chemical analysis (same as XPS)

G-SIMS gentle secondary ion mass spectrometry (a variant of SIMS to extract information about

molecular groups)

HRLEIS high resolution - low energy ion scattering

ICP-MS inductively coupled plasma mass spectrometry

IMFP inelastic mean free path

IRS Infrared Spectroscopy

ISS ion scattering spectroscopy

LED light emitting diode

LEIS low energy ion scattering

LRS laser Raman spectroscopy

MultiQuant a spectrum evaluation program for quantitative evaluation of XPS data

MWCNT multi-walled carbon nanotube

NRA nuclear reaction analysis

PECVD plasma enhanced chemical vapour deposition

PEM fuel cell polymer electrolyte membrane fuel cell

PMMA poly(methyl methacrylate),

PPV poly(diakloxy-p-phenylene vinylene)

PVB poly(vinyl butyral)

QUASES quantitative analysis of surfaces by electron spectroscopy (computer program for

quantitative evaluation of XPS and Auger spectra)

RBS Rutherford backscattering spectroscopy

SEM scanning electron microscopy

SESSA simulation of electron spectra for surface analysis (computer program for quantitative

evaluation of XPS and AES spectra)

SHG/SFG second harmonic generation/sum frequency generation

SI secondary ion

SIMS secondary ion mass spectrometry

SNOM scanning near-field optical microscopy

SPM scanning probe microscopy (a generic term covering STM, AFM and other scanning tip

based microscopies)

sSIMS static secondary ion mass spectrometry

STM scanning tunnelling microscopy

SWCNT single walled carbon nanotube

2 © ISO 2011 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/TR 14187:2011(E)

TEM-PEELS transmission electron microscopy - parallel electron energy loss spectroscopy

TCNQ tetracyanoquinodimethane

TOF-SIMS time of flight – secondary ion mass spectrometry

WPMN-OECD Working Party on Manufactured Nanomaterials – Organization for Economic Co-operation

and Development

XPS X-ray photoelectron spectroscopy

TA microthermal anlaysis

4 Characterization of nanostructured materials with surface analysis methods

4.1 Introduction

Surfaces and interfaces can strongly influence many properties of materials and material systems. Surfaces

control chemical reactivity, influence adhesion, and are associated with heat and electron transfer. In many

circumstances, the surface composition may differ from the bulk composition due to surface contamination or

to segregation (enrichment) of one component. Interfaces between grains of one material or of differing

materials are critical to the performance of electronic materials and the strength of structural materials.

Because of the importance of surfaces and interfaces, special tools have been developed to determine their

compositions and to assess how these affect the properties of natural and engineered materials. Significant

groupings of surface analysis tools include those based on electron spectroscopy (Auger electron

spectroscopy (AES) and x-ray photoelectron spectroscopy (XPS)), those involving incident ion beams

(secondary ion mass spectrometry (SIMS) and low-energy ion scattering (LEIS), and those based on scanning

probe microscopy (SPM) including atomic force microscopy (AFM) and scanning tunnelling microscopy (STM).

These tools are widely applied to characterize natural and engineered surfaces in relation to fundamental

studies, for material and product development, and for analysing product reliability and performance in service

environments. These analysis methods have provided significant value in many technologies including

pharmacology, health, microelectronics, chemical, power, transport and aerospace, and the advanced

materials used in many technologies.

Although other surface-analysis techniques are used and will be mentioned in this report, the focus will be on

AES, LEIS, SIMS, SPM, and XPS and the application of these techniques to the characterization of

nanostructured materials; it is noted that there are subcommittees for all of these methods except LEIS within

ISO/TC 201. Detailed discussions of these methods are available from many sources [9, 10]. Information on

the typical spatial resolutions of AES, SIMS, SPM, and XPS is summarized in Figure 1. In all cases, the

techniques have nanometre resolution in at least one dimension.

© ISO 2011 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO/TR 14187:2011(E)

Figure 1. Schematic overview of probing and detected species for surface analysis by AES, SIMS,

SPM, and XPS. Also indicated are the typical spatial resolutions available with these surface-analysis

methods.

In addition to having differences in spatial resolution, different surface analysis techniques can provide

different types of information. The UK National Physical Laboratory [11] has created a drawing that

summarizes the types of information that can be provided by many different analysis methods, as shown in

Figure 2. The types of information that can be obtained include topography, elemental composition, molecular

and chemical state, and structural information. Useful or potentially useful methods not included in Fig. 2

include LEIS, laser Raman spectroscopy, and nonlinear optical methods such as second harmonic generation

(SHG) and sum frequency generation (SFG). LEIS has also been known as Ion Scattering Spectrometry (ISS)

and is a well-established method. However, in modern instruments it can be particularly useful because of the

high sensitivity to the very outermost atomic layers of a sample [12]. A few examples of LEIS will be included

in the examples provided in later sections. TOF-SIMS is often applied in the static mode and is indicated by

Static SIMS in Figure 2. Full chemical structure would include information about the molecular structure of the

elements and molecules present in the sample or on the sample surface. Several methods provide some, but

not comprehensive, information about molecular structure.

4 © ISO 2011 – All rights reserved

---------------------- Page: 10 ----------------------

ISO/TR 14187:2011(E)

Figure 2. Diagram providing overview of spatial resolution and types of information that can be

ordained by a range of tools important for the analysis of nanostructured materials.

After reference [11].

It has already been noted that nanostructured materials inherently involve a high percentage of atoms located

on or near surfaces or interfaces, and that the material properties are significantly impacted by the nature and

properties of these surfaces and interfaces in addition to any fundamental changes in materials properties due

to their overall small size. Among the materials properties that must be known to understand behaviour are

characteristics related to surface chemistry and surface charge. Specific knowledge is often required on the

presence and properties of surface layers and surface contamination, the chemical state or enrichment of

species on the surface or at interfaces, and information about surface functionality. Examples of the types of

information needs and techniques by which they can be addressed are shown in Table 2. Table 2 includes

commonly used tools beyond those shown in Figure 1, but is not intended to be comprehensive.

Although many analysis tools can be useful for characterizing nanostructured materials, it is important to

recognize that there are many challenges and unmet analysis needs for such applications. Some challenges

are associated with limitations of the current tools [5, 13] or with challenges in using (or having access to) all

of the needed tool set [3, 4], Issues associated with environmentally induced changes, damage or sample

handling issues [3, 14], will be discussed in Section 5.

© ISO 2011 – All rights reserved 5

---------------------- Page: 11 ----------------------

ISO/TR 14187:2011(E)

Table 2 - Information needs and relevant tools for nanostructured material surfaces

Type of Film or Comments or range of

Information nanoparticle Possible Techniques applicability

Surface

composition

Nanometre films XPS, AES Outer 10 nm

(including

surface

functionalization)

LEIS

Outer < 1nm

SIMS

Outer 1 nm

Nanoparticles XPS, AES, SIMS, LEIS As above

Outer 10 nm

Depth distribution Nanometre films XPS nondestructively

RBS, NR

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.