ISO 7870-3:2020

(Main)Control charts — Part 3: Acceptance control charts

Control charts — Part 3: Acceptance control charts

This document gives guidance on the uses of acceptance control charts and establishes general procedures for determining sample sizes, action limits and decision criteria. An acceptance control chart should be used only when: a) the within subgroup variation is in-control and the variation is estimated efficiently; b) a high level of process capability has been achieved. An acceptance control chart is typically used when the process variable under study is normally distributed; however, it can be applied to a non-normal distribution. The examples provided in this document illustrate a variety of circumstances in which this technique has advantages; these examples provide details of the determination of the sample size, the action limits and the decision criteria.

Cartes de contrôle — Partie 3: Cartes de contrôle pour acceptation

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 7870-3

Second edition

2020-05

Control charts —

Part 3:

Acceptance control charts

Cartes de contrôle —

Partie 3: Cartes de contrôle pour acceptation

Reference number

ISO 7870-3:2020(E)

©

ISO 2020

---------------------- Page: 1 ----------------------

ISO 7870-3:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 7870-3:2020(E)

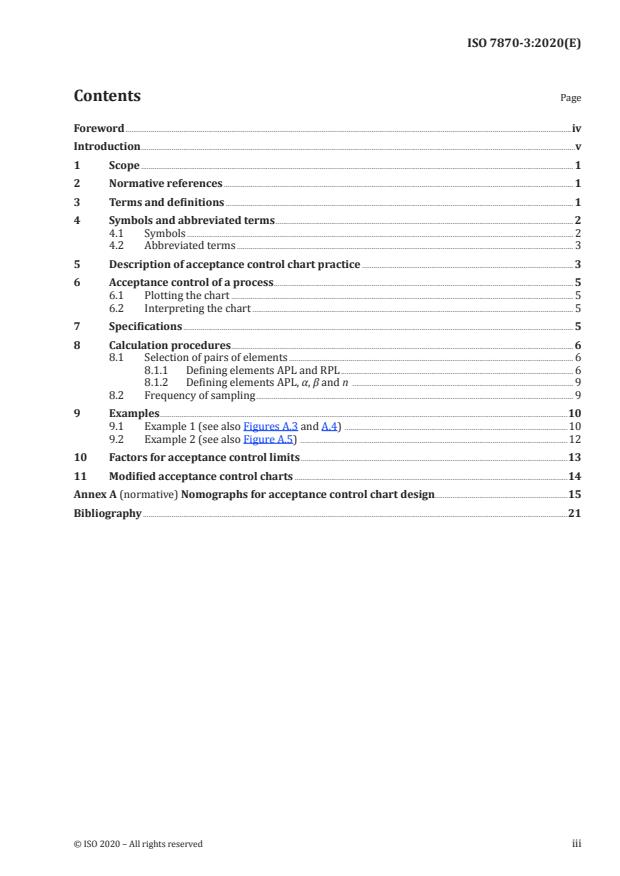

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and abbreviated terms . 2

4.1 Symbols . 2

4.2 Abbreviated terms . 3

5 Description of acceptance control chart practice . 3

6 Acceptance control of a process . 5

6.1 Plotting the chart . 5

6.2 Interpreting the chart . 5

7 Specifications . 5

8 Calculation procedures . 6

8.1 Selection of pairs of elements . 6

8.1.1 Defining elements APL and RPL . 6

8.1.2 Defining elements APL, α, β and n . 9

8.2 Frequency of sampling . 9

9 Examples .10

9.1 Example 1 (see also Figures A.3 and A.4) .10

9.2 Example 2 (see also Figure A.5) .12

10 Factors for acceptance control limits .13

11 Modified acceptance control charts .14

Annex A (normative) Nomographs for acceptance control chart design .15

Bibliography .21

© ISO 2020 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 7870-3:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 69, Applications of statistical methods,

Subcommittee SC 4, Applications of statistical methods in process management.

This second edition cancels and replaces the first edition (ISO 7870-3:2012), of which it constitutes a

minor revision with the following changes:

— typo corrections in 9.1, example 1;

— editorial updates.

A list of all parts in the ISO 7870 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

iv © ISO 2020 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 7870-3:2020(E)

Introduction

An acceptance control chart combines consideration of control implications with elements of acceptance

sampling. It is an appropriate tool for helping to make decisions with respect to process acceptance.

The bases for the decisions may be defined in terms of

a) whether or not a designated percentage of units of a product or service derived from that process

will satisfy specification requirements;

b) whether or not a process has shifted beyond some allowable zone of process level locations.

A difference from most acceptance sampling approaches is the emphasis on process acceptability rather

than on product disposition decisions.

A difference from usual control chart approaches is that the concept of process acceptance is introduced

in the process control. The process usually does not need to be in control about a single standard

process level; as long as the within-subgroup variability remains in control and is much smaller than

the tolerance spread, it can (for the purpose of acceptance) run at any level or levels within a zone of

process levels which would be acceptable in terms of tolerance requirements. Thus, it is assumed that

some assignable causes will create shifts in the process levels which are small enough in relation to

requirements that it would be uneconomical to attempt to control them too tightly for the purpose of

mere acceptance.

The use of an acceptance control chart does not, however, rule out the possibility of identifying and

removing assignable causes for the purpose of continuing process improvement.

A check on the inherent stability of the process is required. Therefore, variables are monitored using

Shewhart-type range or sample standard deviation control charts to confirm that the variability

inherent within rational subgroups remains in a steady state. Supplementary examinations of the

distribution of the encountered process levels form an additional source of control information. A

preliminary Shewhart control chart study should be conducted to verify the validity of using an

acceptance control chart.

© ISO 2020 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 7870-3:2020(E)

Control charts —

Part 3:

Acceptance control charts

1 Scope

This document gives guidance on the uses of acceptance control charts and establishes general

procedures for determining sample sizes, action limits and decision criteria. An acceptance control

chart should be used only when:

a) the within subgroup variation is in-control and the variation is estimated efficiently;

b) a high level of process capability has been achieved.

An acceptance control chart is typically used when the process variable under study is normally

distributed; however, it can be applied to a non-normal distribution. The examples provided in this

document illustrate a variety of circumstances in which this technique has advantages; these examples

provide details of the determination of the sample size, the action limits and the decision criteria.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3534-1, Statistics — Vocabulary and symbols — Part 1: General statistical terms and terms used in

probability

ISO 3534-2, Statistics — Vocabulary and symbols — Part 2: Applied statistics

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 3534-1, ISO 3534-2 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

acceptable process

process which is represented by a Shewhart control chart with a central line within the acceptable

process zone

Note 1 to entry: Ideally, the average value X of such a control chart would be at the target value.

Note 2 to entry: The acceptable process zone is shown in Figure 1. Information on the Stewhart control chart can

be found in ISO 7870-2.

© ISO 2020 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 7870-3:2020(E)

Key

1 rejectable processes

2 indifference zone

3 acceptable processes

4 target level

upper RPL line

R

PL

U

upper APL line

A

PL

U

lower APL line

A

PL

L

lower RPL line

R

PL

L

Figure 1 — Two-sided specification limits: Upper and lower APL and RPL lines in relation to

processes of acceptable, rejectable, and indifference (borderline) quality

4 Symbols and abbreviated terms

NOTE The ISO/IEC Directives makes it necessary to depart from common SPC usage in respect to the

differentiation between abbreviated terms and symbols. An abbreviated term and its symbol can differ in

appearance in two ways: by font and by layout. To distinguish between abbreviated terms and symbols,

abbreviated terms are given in Arial upright and symbols in Times New Roman or Greek italics, as applicable.

Whereas abbreviated terms can contain multiple letters, symbols consist only of a single letter. For example, the

conventional abbreviation of acceptable process limit, APL, is valid but its symbol in equations becomes A . The

PL

reason for this is to avoid misinterpretation of compound letters as an indication of multiplication.

4.1 Symbols

A acceptance control limits

CL

A acceptable process level

PL

L lower specification limit

n subgroup sample size

p acceptable proportion nonconforming items

0

p rejectable proportion nonconforming items

1

P probability of acceptance

a

2 © ISO 2020 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 7870-3:2020(E)

R rejectable process level or non-acceptable process zone

PL

T target value, i.e. the optimum value of the characteristic

U upper specification limit

average value of the variable X plotted on a control chart

X

z variable that has a normal distribution with zero mean and unit standard deviation

z ′ normal deviate that is exceeded by 100p′ % of the deviate in a specified direction (similarly for

p

z , z , etc.)

α β

α risk of not accepting a process centred at the APL

β risk of not rejecting a process centred at the RPL

μ process mean

σ within-subgroup standard deviation corresponding to the inherent process variability

w

σ standard deviation of the subgroup average corresponding to the inherent process varia-

X

bility: σσ= / n

w

X

4.2 Abbreviated terms

ACL acceptance control limits

APL acceptable process level

L lower specification limit (used as a subscript)

OC operating characteristic

RPL rejectable process level or non-acceptable process zone

U upper specification limit (used as a subscript)

5 Description of acceptance control chart practice

In the pursuit of an acceptable product or service, there often is room for some latitude in the ability

to centre a process around its target level. The contribution to overall variation of such location

factors is additional to the inherent random variability of individual elements around a given process

level. In most cases, some shifts in process level must be expected and can be tolerated. These shifts

usually result from an assignable cause that cannot be eliminated because of engineering or economic

considerations. They often enter the system at infrequent or irregular intervals, but can rarely be

treated as random components of variance.

There are several seemingly different approaches to treating these location factors contributing

variation beyond that of inherent variability. At one extreme is the approach in which all variability

that results in deviations from the target value must be minimized. Supporters of such an approach

seek to improve the capability to maintain a process within tighter tolerance limits so that there is

greater potential for process or product quality improvement.

At the other extreme is the approach that if a high level of process capability has been achieved, it is

not only uneconomic and wasteful of resources, but it can also be counterproductive to try to improve

the capability of the process. This often is the result of the introduction of pressures which encourage

“tampering” with the process (over-control) by people qualified to work on control aspects but not

product or process quality improvement programmes.

© ISO 2020 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 7870-3:2020(E)

The acceptance control chart is a useful tool for covering this wide range of approaches in a logical

and simple manner. It distinguishes between the inherent variability components randomly occurring

throughout the process and the additional location factors which contribute at less frequent intervals.

When shifts appear, the process may then stabilize at a new level until the next such event occurs.

Between such disturbances, the process runs in control with respect to inherent variability.

An illustration of this situation is a process using large uniform batches of raw material. The within-

batch variability could be considered to be the inherent variability. When a new batch of material is

introduced, its deviation from the target may differ from that of the previous batch. The between-batch

variation component enters the system at discrete intervals.

An example of this within- and between-batch variation can very well occur in a situation where a

blanking die is blanking a machine part. The purpose of the chart is to determine when the die has worn

to a point where it must be repaired or reworked. The rate of wear is dependent upon the hardness of

the successive batches of material and is therefore not readily predictable. It will be seen that the use of

an acceptance control chart makes it possible to judge the appropriate time to service the blanking die.

The acceptance control chart is based on the Shewhart control chart (i.e. X – R chart or X – s chart)

but is set up so that the process mean can shift outside of control limits of the Shewhart control chart if

the specifications are sufficiently wide, or be confined to narrower limits if the inherent variability of

the process is comparatively large or a large fraction of the total tolerance spread.

What is required is protection against a process that has shifted so far from the target value that it will

yield some predetermined undesirable percentage of items falling outside the specification limits, or

exhibits an excessive degree of process level shift.

When a chart of the average value of data sets from a process is plotted, in sequence of the production,

one notices a continual variation in average values. In a central zone (acceptable process, Figure 1),

there is a product that is indisputably acceptable. Data in the outer zones (Figure 1) represent a process

that is producing product that is indisputably not acceptable.

Between the inner and the outer zones are zones where the product is acceptable but there is an

indication that the process should be watched and, as the outer zone is approached, corrective action

may be taken. These criteria are the basic concepts for the acceptance control chart. The description in

this document is designed to provide practices for the establishment of appropriate action lines for one-

and two-sided specification situations.

Since it is impossible to have a single dividing line that can sharply distinguish a good from an

unsatisfactory quality level, one must define a process level that represents a process that should be

accepted almost always (1 − α). This is called the acceptable process level (APL), and it marks the outer

boundary of the acceptable process zone located about the target value (see Figure 1).

Any process centred closer to the target value than the APL will have a risk smaller than α of not being

accepted. So the closer the process is to the target, the smaller the likelihood that a satisfactory process

will not be accepted.

It is also necessary to define the process level that represents processes that should almost never be

accepted (1 − β). This undesirable process level is labelled the rejectable process level (RPL). Any process

located further away from the target value than the RPL will have a risk of acceptance smaller than β.

The process levels lying between the APL and RPL would yield a product of borderline quality. That

is, process levels falling between the APL and RPL would represent quality which is not so good that it

would be a waste of time, or represent over-control, if the process were adjusted, and not so bad that

the product could not be used if no shift in level were made. This region is often called the “indifference

zone”. The width of this zone is a function of the requirements for a particular process and the risks one

is willing to take in connection with it. The narrower the zone, i.e. the closer the APL and RPL are to

each other, the larger the sample size will have to be. This approach will permit a realistic appraisal of

the effectiveness of any acceptance control system, and will provide a descriptive method for showing

just what any given control system is intended to do.

4 © ISO 2020 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 7870-3:2020(E)

As with any acceptance sampling system, the four elements required for the definition of an acceptance

control chart are:

a) an acceptable process level (APL) associated with a one-sided α-risk;

b) a rejectable process level (RPL) associated with a one-sided β-risk;

c) an action criterion or acceptance control limit (ACL);

d) the sample size (n).

NOTE Generally, the defined risks are one-sided in this document. In the case of two-sided specifications,

the risks are either a 5 % risk to go above an upper limit or a 5 % risk to go below a lower limit. This results in a

5 % (not 10 %) total risk.

Simplicity of operation is of critical importance to the use of a procedure such as an acceptance control

chart. Only the acceptance control limits and the sampling instructions (such as sample size, frequency,

or method of selection) need to be known to the operator who uses the chart, although training him to

understand the derivation is not difficult and can be helpful. It is thus no more complicated to use than

the Shewhart chart. The supervisor, quality expert, or trained operator will derive these limits without

much effort from the above considerations and will obtain a more meaningful insight into the process

acceptance procedure, and a better understanding of the control implications.

6 Acceptance control of a process

6.1 Plotting the chart

The sample average value of the quality characteristic is plotted on acceptance control charts in the

following way. A point is plotted on the chart for each sample with an identification number (numerical

order, time order, etc.) on the horizontal scale, and the corresponding sample average on the vertical scale.

6.2 Interpreting the chart

When the plotted point falls above the upper acceptance control limit ACL or below the lower

U

acceptance control limit ACL , the process shall be considered non-acceptable.

L

If a plotted point is close to the control line, the numerical values shall be used to make the decision.

7 Specifications

Theoretically, the specification of the values of any two of the defining elements APL (with α−risk), RPL

(with β−risk), acceptance control limit (ACL) or sample size (n) of an acceptance control chart system

determines the remaining two values; however, in practice, it is essential that APL (with α-risk) be

defined first. In addition, the within-rational subgroup value of σ must be known or have been

w

estimated by the usual control chart techniques such as using σˆ =Rd/ or sc/ . It is essential that

4

w 2

the inherent random variability be in a state of statistical control in order for the risk computations to

be meaningful. This can be monitored through the use of a Shewhart-type control chart for ranges or

standard deviations (see ISO 7870-2).

Two selections of pairs of defining elements may be chosen.

a) Definition of the APL and RPL along with their respective α- and β-risks, and determination of the

sample size (n) and the acceptance control limit (ACL).

Often, α = 0,05 is chosen in acceptance control chart applications since there are few instances

where a process continuously runs at the APL. This means that the risk of rejection on each side of

the target value, T, should always be smaller than α.

This option is generally used when

© ISO 2020 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 7870-3:2020(E)

1) acceptable processes are defined either for economic or other practical reasons in terms of

process capabilities that include allowance for small discrete shifts in process level in addition

to inherent random variation, or in terms of an acceptable quality level described by the

percentage of items exceeding specification limits, and

2) when rejectable processes are defined either for practical reasons in terms of unnecessarily

large shifts in process level, or in terms of a process level yielding an unsatisfactory percentage

of items exceeding specification limits.

b) Definition of the APL (with α) and the sample size n, and determination of the RPL for a given β-risk

and the ACL.

This option is used when acceptable processes are defined as in 1) above, and when there is a restriction

determining the allowable sample size. The option a) is preferable in most cases.

The examples in this document deal with variables data and are described in terms of two-sided

specifications with limits and levels defined both above and below the target value. However, the

method is equally valid for one-sided specification limits. In addition, there is no requirement that the

values selected above and below the target value be symmetrical should more latitude be desired on

either side. If different values are selected above and below the target, the sample size required for the

more stringent situation (i.e. smaller distance between the APL and RPL) shall be used (see 8.1.1).

8 Calculation procedures

8.1 Selection of pairs of elements

8.1.1 Defining elements APL and RPL

In the case of variables ( X ), the APL may be selected in several ways. If the specification limits are

known, as well as the underlying distribution of the individual population items, the APL may be defined

in terms of an acceptable proportion (or percentage) p of nonconforming items which would occur

0

when the process is centred at the APL (see Figure 2). If the underlying distribution is normal (Gaussian),

a one-tailed table of standard normal deviate z values can be used where,

∞

2

1 x

p=−expdx .

∫

2

2π

z

p

6 © ISO 2020 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 7870-3:2020(E)

Figure 2 — Limits and defining elements of acceptance control charts

For samples of four or more, the assumption of a normal distribution for control purposes is generally

valid for X charting. However, the interpretation of the proportion (percentage) of nonconforming

items associated with the APL and RPL levels is dependent on the underlying distribution. Thus, for

other distributions, appropriate tables should be followed and the standard normal deviate values z

p

t

replaced accordingly. The advantage of the z approach in this application is that the limits and defining

elements fall above and below the centre, so that it is convenient to have identical α and β values on

both sides of the target rather than having to deal with α and 1 − α or β and 1 − β, depending on which

side of the centre is involved. This also aids in a geometric interpretation such as

zzσσ+=RA−

αβ PL PL

XX

UpperAPL AU=−z σ

()

PL pw

U 0

LowerAPL AL=+z σ

()

PL p w

L 00

See example 1 in 9.1 where X charts with the APL and RPL are defined in terms of the percentage of

nonconforming items. A flowchart for the calculation procedure is shown in Figure 3.

© ISO 2020 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO 7870-3:2020(E)

Figure 3 — Flowchart for calculation procedure (defining elements APL and RPL)

In some cases, the selection of an APL value may not be directly related to the specification limits,

but may be chosen on an arbitrary basis. Experience may show that the “uneconomic” or “not readily

adjustable” causes for shifts in process level correspond to a narrow band. The edge of this band may be

arbitrarily designated as the APL (see example 2 in 9.2). In this case, the normal distribution assumption

is not invoked since the APL is not directly related to the specification limits.

In a similar fashion, the RPL may be selected in several ways. It can be related to the specification limits

by defi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.