ISO 12856-1:2014

(Main)Plastics — Plastic railway sleepers for railway applications (railroad ties) — Part 1: Material characteristics

Plastics — Plastic railway sleepers for railway applications (railroad ties) — Part 1: Material characteristics

ISO 12856-1:2014 specifies the characteristics of plastic and reinforced plastic materials to be used in the manufacturing of railway sleepers. It is applicable to the sleepers and parts of sleepers to be installed in tracks with or without ballast. Examples of different types of plastic and reinforced sleepers are given in an annex.

Plastiques — Traverses en plastique pour les applications ferroviaires (traverses de voie ferrée) — Partie 1: Propriétés des matériaux

General Information

Relations

Buy Standard

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 12856-1

First edition

2014-03-15

Plastics — Plastic railway sleepers for

railway applications (railroad ties) —

Part 1:

Material characteristics

Plastiques — Traverses en plastique pour les applications ferroviaires

(traverses de voie ferrée) —

Partie 1: Propriétés des matériaux

Reference number

ISO 12856-1:2014(E)

©

ISO 2014

---------------------- Page: 1 ----------------------

ISO 12856-1:2014(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 12856-1:2014(E)

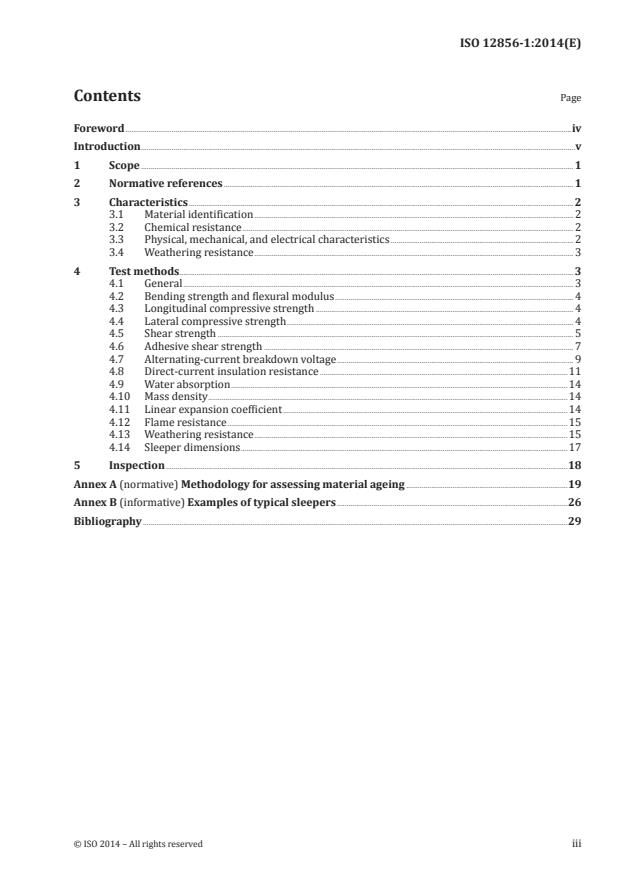

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Characteristics . 2

3.1 Material identification . 2

3.2 Chemical resistance . 2

3.3 Physical, mechanical, and electrical characteristics . 2

3.4 Weathering resistance . 3

4 Test methods . 3

4.1 General . 3

4.2 Bending strength and flexural modulus . 4

4.3 Longitudinal compressive strength . 4

4.4 Lateral compressive strength . 4

4.5 Shear strength . 5

4.6 Adhesive shear strength . 7

4.7 Alternating-current breakdown voltage . 9

4.8 Direct-current insulation resistance .11

4.9 Water absorption .14

4.10 Mass density .14

4.11 Linear expansion coefficient .14

4.12 Flame resistance .15

4.13 Weathering resistance .15

4.14 Sleeper dimensions .17

5 Inspection .18

Annex A (normative) Methodology for assessing material ageing .19

Annex B (informative) Examples of typical sleepers .26

Bibliography .29

© ISO 2014 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 12856-1:2014(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 61, Plastics, Subcommittee SC 11, Products.

ISO 12856 consists of the following parts, under the general title Plastics — Plastic railway sleepers for

railway applications (railroad ties):

— Part 1: Material characteristics

The following parts are planned:

— Part 2: Products

iv © ISO 2014 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 12856-1:2014(E)

Introduction

Railway sleepers are manufactured mainly of pre-stressed concrete, wood, or steel. However, based on

the development of plastic materials, some plastic sleepers have been installed in recent years.

In view of the facts that the types of plastics and manufacturing processes can have various effects on

the in-service performance, this part of ISO 12856 covers the general characteristics of materials which

plastic/composite sleepers are made from, in order to specify their performance.

This part of ISO 12856 will be used in conjunction with ISO 12856-2 to be developed in the foreseeable

future.

This part of ISO 12856 applies to sleepers made from plastic materials, including reinforced plastic

materials.

© ISO 2014 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 12856-1:2014(E)

Plastics — Plastic railway sleepers for railway applications

(railroad ties) —

Part 1:

Material characteristics

1 Scope

This part of ISO 12856 specifies the characteristics of plastic and reinforced plastic materials to be used

in the manufacturing of railway sleepers.

It is applicable to the sleepers and parts of sleepers to be installed in tracks with or without ballast.

Examples of different types of plastic and reinforced sleepers are given in Annex B.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 62, Plastics — Determination of water absorption

ISO 75 (all parts), Plastics — Determination of temperature of deflection under load

ISO 178, Plastics — Determination of flexural properties

ISO 291, Plastics — Standard atmospheres for conditioning and testing

ISO 306, Plastics — Thermoplastic materials — Determination of Vicat softening temperature (VST)

ISO 527-2, Plastics — Determination of tensile properties — Part 2: Test conditions for moulding and

extrusion plastics

ISO 527-4, Plastics — Determination of tensile properties — Part 4: Test conditions for isotropic and

orthotropic fibre-reinforced plastic composites

ISO 604, Plastics — Determination of compressive properties

ISO 877-1:2009, Plastics — Methods of exposure to solar radiation — Part 1: General guidance

ISO 877-2:2009, Plastics — Methods of exposure to solar radiation — Part 2: Direct weathering and exposure

behind window glass

ISO 1183-1, Plastics — Methods for determining the density of non-cellular plastics — Part 1: Immersion

method, liquid pyknometer method and titration method

ISO 2578, Plastics — Determination of time-temperature limits after prolonged exposure to heat

ISO 3611, Geometrical product specifications (GPS) — Dimensional measuring equipment: Micrometers for

external measurements — Design and metrological characteristics

ISO 4892-2, Plastics — Methods of exposure to laboratory light sources — Part 2: Xenon-arc lamps

ISO 4892-4, Plastics — Methods of exposure to laboratory light sources — Part 4: Open-flame carbon-arc

lamps

© ISO 2014 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 12856-1:2014(E)

ISO 8256, Plastics — Determination of tensile-impact strength

ISO 10640, Plastics — Methodology for assessing polymer photoageing by FTIR and UV/visible spectroscopy

ISO 11357-2, Plastics — Differential scanning calorimetry (DSC) — Part 2: Determination of glass transition

temperature and glass transition step height

ISO 11357-6, Plastics — Differential scanning calorimetry (DSC) — Part 6: Determination of oxidation

induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT)

ISO 11359-2, Plastics — Thermomechanical analysis (TMA) — Part 2: Determination of coefficient of linear

thermal expansion and glass transition temperature

ISO 13385-1, Geometrical product specifications (GPS) — Dimensional measuring equipment — Part 1:

Callipers; Design and metrological characteristics

ISO 13385-2, Geometrical product specifications (GPS) — Dimensional measuring equipment — Part 2:

Calliper depth gauges; Design and metrological characteristics

ISO 14125, Fibre-reinforced plastic composites — Determination of flexural properties

ISO/TR 19032, Plastics — Use of polyethylene reference specimens (PERS) for monitoring laboratory and

outdoor weathering conditions

IEC 60695-11-20:2003, Fire hazard testing — Part 11-20: Test flames — 500 W flame test methods

3 Characteristics

3.1 Material identification

The manufacturer shall declare the following information:

a) type of polymer(s), e.g. thermoplastic or thermosetting, including the main additives and the

materials constituting composite matrix, if any;

b) type, form, structure, and content of reinforcing materials;

c) type, form, and content of filler or increasing-mass materials, if any;

d) description of the manufacturing process.

3.2 Chemical resistance

The material shall not be adversely affected by exposure to chemicals typically found in the railway

environment, such as diesel and grease. Chemical compatibility can be demonstrated either by test

results or it can be documented.

3.3 Physical, mechanical, and electrical characteristics

The physical, mechanical, and electrical characteristics of materials are listed in Tables 1 and 2. The

relevance of assessment on characteristics shall be agreed on between the interested parties. Some of

the tests might not be applicable for anisotropic sleepers or sleepers with specific reinforced material.

Examples of typical plastic sleeper properties are given in Annex B.

2 © ISO 2014 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 12856-1:2014(E)

Table 1 — Physical, mechanical, and electrical characteristics

Characteristic Unit Test method

Bending strength MPa

4.2

Flexural modulus MPa

2

Longitudinal compression strength N/mm 4.3

Material strength

2

Lateral compression strength N/mm 4.4

2

Shear strength N/mm 4.5

2

Adhesive shear strength N/mm 4.6

Alternating-current breakdown voltage kV 4.7

Electrical characteristic

Direct-current insulation resistance Ω 4.8

a

Water absorption % 4.9

3

Mass density g/cm 4.10

−1

Linear expansion coefficient K 4.11

a

Percentage expressed in mass fraction.

Table 2 — Temperature-dependent mechanical properties

Characteristic Unit Test conditions Test method

a

Bending strength %

4.2

a

Flexural modulus %

In air for 24 h

Material strength a

Longitudinal com- %

b

Test temperatures : −30 °C and 60 °C 4.3

pression strength

a

Shear strength % 4.5

a

Percentages indicate the strength retention in comparison with the values determined at an ambient temperature.

b

Test temperatures can vary in the conditions where sleepers are used (tunnels, extreme weather conditions, excessively

exposed locations).

3.4 Weathering resistance

The sleeper shall be designed to guarantee that at the end of its service life, the load-bearing capacities

are sufficient for service even in case of the losses of strength due to weathering.

The requirements for the weathering resistance of the materials shall be agreed on between the

interested parties.

The weathering resistance shall be demonstrated either by a documented and substantially proven

experience or by assessing the properties in accordance with 4.13.1 or 4.13.2, as applicable.

4 Test methods

4.1 General

4.1.1 Preparation of test specimens

There shall be no damage or faults on the surface of the test specimens in order to prevent notch effects.

If there are burrs, they shall be carefully removed without damaging the surface. If necessary, the edges

of the surfaces of the test specimens shall be finished using sandpaper.

© ISO 2014 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 12856-1:2014(E)

4.1.2 Test conditions

Unless otherwise specified in a separate clause, the test shall be carried out in one of the standard

atmospheres specified in ISO 291 after the test specimens are conditioned in the same atmosphere for

at least 24 h.

4.1.3 Tolerance of test specimens

For each test method, the dimensions of the test specimens should be given with tolerances. The nominal

dimension shall be ±1 mm.

4.2 Bending strength and flexural modulus

The test shall be conducted at (23 ± 5) °C using the following method.

The longitudinal direction of the test specimen shall be parallel to the supports and vertical to the load

direction. A steel plate of dimensions 3 mm × 50 mm × 50 mm shall be placed on the test specimen and

positioned in the middle between the supports.

The dimensions of the test specimen shall be:

— length: (240 ± 2) mm,

— width: (50 ± 1) mm,

— thickness: (20 ± 1) mm,

and the span between supports shall be 160 mm to 200 mm.

The concentrated load shall be applied in the middle of the span. The average loading speed (stress) shall

2

be less than 15 N/mm per minute.

The support shall be robust enough and have sufficient area to touch the test specimen. Both supports

shall be located on the same distances from the centre of the test specimen in the longitudinal direction.

The other details of test arrangements shall refer to ISO 178.

4.3 Longitudinal compressive strength

The longitudinal compressive strength test shall be conducted at (23 ± 5) °C and using the following

method.

The dimensions of the test specimen shall be:

— length: (40 ± 2) mm,

— width: (20 ± 0,5) mm,

— thickness: (20 ± 0,5) mm.

The longitudinal direction of the test specimen is corresponding to the longitudinal direction of the

sleeper. The loading direction shall be parallel to the longitudinal direction of the test specimen.

The loading pressure shall be applied to the test specimen where the specimen is located between two

2

flat steel plates. The average loading speed (stress) shall be less than 15 N/mm per minute.

The other details of test arrangements shall be referred to ISO 604.

4.4 Lateral compressive strength

The lateral compressive strength test shall be conducted at (23 ± 5) °C using the following method.

4 © ISO 2014 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 12856-1:2014(E)

The test specimen shall be cut with a length between 500 mm and 700 mm and a width 200 mm and

thickness 100 mm. The loading direction shall be vertical to the longitudinal direction of test specimen.

The loading pressure shall be applied to the test specimen using the flat steel plates both on its top and

2

bottom sides. The average loading speed (stress) shall be less than 15 N/mm per minute.

The other details of test arrangements shall be referred to ISO 604.

4.5 Shear strength

The shear strength test shall be conducted at (23 ± 5) °C using the following method.

The loading pressure shall be parallel to the longitudinal direction of test specimen. The loading pressure

shall be applied by the method illustrated in Figure 1. The average loading speed (stress) shall be less

2

than 5,88 N/mm per minute.

The rectangular test specimen with dimensions 40 mm × 50 mm × 52 mm shall be prepared with a cut

portion of 10 mm × 10 mm × 40 mm as shown in Figure 2.

The maximum load refers to the load before the test specimen begins to break (not to deform).

The setting jig shall be robust enough and have sufficient areas to touch the test specimen. In addition,

as illustrated in Figure 1, the setting jig shall have the necessary capacity to hold the test specimen so as

not to be moved even though load is given on the edge of the test specimen.

The tolerance of radius of curvature of the edge of the cut portion and the roughness of contact surface

between the loading block and the test specimen can be defined on the agreement between the interested

parties.

The shear strength shall be determined from the test results using Formula (1).

P

m

τ = (1)

A

where

2

τ is the shear strength (N/mm );

P is the maximum load (N);

m

2

A is the cross-sectional area (mm ).

NOTE Refer to ISO 604 for the definition of “maximum load”.

© ISO 2014 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 12856-1:2014(E)

Dimensions in millimetres

F

3

2

10

1

Key

1 specimen

2 setting jig

3 loading block

F load (or force)

Figure 1 — Loading method for shear strength test

6 © ISO 2014 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 12856-1:2014(E)

Dimensions in millimetres

Key

A cross-sectional area

Figure 2 — Test specimen for shear strength test

4.6 Adhesive shear strength

For testing, the adhesive material or the method of use shall not be specified.

The adhesive shear strength test shall be conducted at (23 ± 5) °C using the following method.

Alternatively, the test specimen shall be cut out from pre-prepared glued material and then finished

to the shape and dimension as illustrated in Figure 7. The loading direction shall be parallel to the

longitudinal direction of the test specimen and the surface coated with adhesive. The average loading

speed (stress) shall be adjusted to less than 9,8 kN/min. The travel speed of the crosshead shall be

adjusted to be between 0,3 mm/min and 0,5 mm/min, and the loading pressure shall be as given in the

method shown in Figure 6.

The perimeter of the glued surface shall be free from an excess of adhesive. This clause shall apply only

to laminated materials.

The maximum load shall be the load before the test specimen begins to break (not to deform).

The setting jig shall be robust enough and have sufficient areas to touch the test specimen. In addition,

as illustrated in Figure 3, the setting jig shall have the necessary capacity to hold the test specimen so as

not to be moved even though load is given on the edge of test specimen.

© ISO 2014 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO 12856-1:2014(E)

F

3

2

1

Key

1 specimen

2 setting jig

3 loading block

F load

Figure 3 — Loading method for shear strength test

8 © ISO 2014 – All rights reserved

---------------------- Page: 13 ----------------------

ISO 12856-1:2014(E)

Dimensions in millimetres

A

26 26 40

Key

A adhesion surface area

Figure 4 — Test specimen for shear strength test

The adhesive shear strength shall be determined from the test results using Formula (2).

P

m

S = (2)

A

where

2

S is the shear strength (N/mm );

P is the maximum load (N);

m

2

A is the adhesive surface area (mm ).

NOTE Refer to ISO 604 for the definition of “maximum load”.

4.7 Alternating-current breakdown voltage

The alternating-current breakdown voltage test shall be conducted using the following method.

The test specimen with the dimensions 20 mm × 80 mm × 100 mm, as shown in Figure 5, shall be

prepared. The longitudinal axis in testing shall be parallel to the longitudinal direction of test specimen.

Prior to the test, the specimen shall be conditioned at (23 ± 1) °C for 48 h. The shape of the electrode

shall be as shown in Figure 6. The electrode equipment shall be set at the central points on the top and

bottom surfaces of the test specimen.

The contact pressure between the electrode equipment shall be about 5 kN. The voltage application

method shall be as in that of a short-time breakdown test. The value of alternating-current breakdown

voltage shall be measured by applying the voltage beginning from 0 V at the speed where insulation

breakdown occurs in between 10 s and 20 s (alternating-current breakdown voltage shall be measured

here).

© ISO 2014 – All rights reserved 9

5 45

50

---------------------- Page: 14 ----------------------

ISO 12856-1:2014(E)

It is recommended that the test be conducted at (23 ± 1) °C air temperature with an application of silicon

oil to prevent an air short-circuit.

Applicability of this test can be determined by the interested parties.

Dimensions in millimetres

100

Figure 5 — Test specimen for alternating-current breakdown voltage test

10 © ISO 2014 – All rights reserved

80

20

---------------------- Page: 15 ----------------------

ISO 12856-1:2014(E)

Dimensions in millimetres

ø20

2

1

2

ø25

Key

1 specimen

2 electrode

Figure 6 — Electrode shape for alternating-current breakdown voltage test

4.8 Direct-current insulation resistance

The direct-current insulation resistance test shall be conducted at (23 ± 5) °C using the following method.

The test specimen with the dimensions 5 mm × 20 mm × 40 mm shall be prepared. The longitudinal axis

in testing shall be parallel to the longitudinal direction of the test specimen.

Prior to the test, the specimen shall be conditioned at (23 ± 1) °C in air for 48 h. Then, two holes shall be

made and finished by a taper pin reamer for insertion of the electrode as illustrated in Figure 7.

The test shall be conducted with the devices composed of electrode, power supply, galvanometer,

universal shunt, switch, etc. in order to measure the direct-current insulation resistance as shown in

Figure 8.

For the electrode, the brass taper pin with 5 mm diameter, which should be free from flaws on the

surface, shall be used. The power supply shall be equipped with a dry cell or a storage battery of 500 V

in the direct voltage.

Applicability of this test can be determined by the interested parties.

© ISO 2014 – All rights reserved 11

20

---------------------- Page: 16 ----------------------

ISO 12856-1:2014(E)

Dimensions in millimetres

40

ø5

15

Figure 7 — Test specimen for direct-current insulation resistance test

12 © ISO 2014 – All rights reserved

20

5

---------------------- Page: 17 ----------------------

ISO 12856-1:2014(E)

1

22

3

5 6

4

8

7

Key

1 guard

2 electrode

3 test specimen

4 power supply polarity change-over switch

5 universal shunt

6 reference resistance (R )

s

7 galvanometer

8 galvanometer polarity change-over switch

Figure 8 — Direct-current insulation resistance measuring device

© ISO 2014 – All rights reserved 13

---------------------- Page: 18 ----------------------

ISO 12856-1:2014(E)

The direct-current insulation resistance shall be calculated with the obtained test result using

Formula (3).

S ×θ

11

RR= (3)

s

S ×θ

22

where

R is the direct-current insulation resistance (MΩ);

R is the reference resistance (MΩ);

s

S is the magnification of universal shunt at the time of measuring using the reference resistance

1

R (mm);

s

θ is the deflection of galvanometer at the time of measuring using the reference resistance R

1 s

(mm);

S is the magnification of universal shunt at the time of connecting the test specimen (mm);

2

θ is the deflection of galvanometer at the time of connecting the test specimen (mm).

2

4.9 Water absorption

The water absorption test shall be conducted according to ISO 62, method 1.

The test specimen with the dimensions 30 mm × 30 mm × 100 mm shall be prepared and the longitudinal

axis shall be fixed in accordance with the longitudinal direction of the test specimen.

4.10 Mass density

The mass density of raw material shall be measured at (23 ± 5) °C. Based on the result of test, the

mass density shall be determined according to Formula (4). In alternative, the mass density shall be

determined according to ISO 1183-1.

m

ρ= (4)

V

where

3

ρ is the mass density (g/cm );

m is the mass (g);

3

V is the measured volume (cm ).

4.11 Linear expansion coefficient

The linear expansion test shall be conducted using the following method.

The test specimen with the dimensions 10 mm × 10 mm × 120 mm shall be prepared and heated from

temperatures of −30 °C to 60 °C in a period of 1 h, and the linear extension of the test specimen shall be

measured to an accuracy of 0,01 mm with the micrometer callipers specified in ISO 3611.

14 © ISO 2014 – All rights reserved

---------------------- Page: 19 ----------------------

ISO 12856-1:2014(E)

The linear expansion coefficient shall be determined using Formula (5). In alternative, the coefficient of

linear thermal expansion shall be determined according to ISO 11359-2.

l

α = (5)

Lt()−t

21

where

α is the linear expansion coefficient;

l is the expansion (mm);

L is the length of the test specimen before heating (mm);

t is the ambient temperature at the time of measurement of expansion, i.e. 60 °C (°C);

2

t is the ambient temperature before heat-up, i.e. −30 °C (°C).

1

The test method should be established and implemented based upon an agreement between the

interested parties.

4.12 Flame resistance

4.12.1 Option 1

The flame resistance test shall be conducted in accordance with IEC 60695-11-20:2003, 8.3. The results

shall be judged based on the occurrence of flame penetration in the test specimen. To identify non-

combustibility, the flame shall not penetrate any of the five test specimens.

4.12.2 Option 2

The f

...

DRAFT INTERNATIONAL STANDARD ISO/DIS 12856

ISO/TC 61/SC 11 Secretariat: JISC

Voting begins on Voting terminates on

2012-03-02 2012-08-02

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION • МЕЖДУНАРОДНАЯ ОРГАНИЗАЦИЯ ПО СТАНДАРТИЗАЦИИ • ORGANISATION INTERNATIONALE DE NORMALISATION

Plastic railway sleepers (railroad ties)

Traverses de chemin de fer en matières plastiques

ICS 45.080; 83.140.99

Member bodies are reminded to consult relevant national interests in each of the technical

fields concerned [Plastics (ISO/TC 61), Products (SC 11), and Plastics (ISO/TC 61), Burning

behaviour (SC 4)] before returning ballots to the ISO Central Secretariat.

To expedite distribution, this document is circulated as received from the committee

secretariat. ISO Central Secretariat work of editing and text composition will be undertaken at

publication stage.

Pour accélérer la distribution, le présent document est distribué tel qu'il est parvenu du

secrétariat du comité. Le travail de rédaction et de composition de texte sera effectué au

Secrétariat central de l'ISO au stade de publication.

THIS DOCUMENT IS A DRAFT CIRCULATED FOR COMMENT AND APPROVAL. IT IS THEREFORE SUBJECT TO CHANGE AND MAY NOT BE

REFERRED TO AS AN INTERNATIONAL STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS BEING ACCEPTABLE FOR INDUSTRIAL, TECHNOLOGICAL, COMMERCIAL AND USER PURPOSES, DRAFT

INTERNATIONAL STANDARDS MAY ON OCCASION HAVE TO BE CONSIDERED IN THE LIGHT OF THEIR POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN NATIONAL REGULATIONS.

RECIPIENTS OF THIS DRAFT ARE INVITED TO SUBMIT, WITH THEIR COMMENTS, NOTIFICATION OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPORTING DOCUMENTATION.

© International Organization for Standardization, 2012

---------------------- Page: 1 ----------------------

ISO/DIS 12856

Copyright notice

This ISO document is a Draft International Standard and is copyright-protected by ISO. Except as permitted

under the applicable laws of the user’s country, neither this ISO draft nor any extract from it may be

reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic,

photocopying, recording or otherwise, without prior written permission being secured.

Requests for permission to reproduce should be addressed to either ISO at the address below or ISO’s

member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Reproduction may be subject to royalty payments or a licensing agreement.

Violators may be prosecuted.

ii © ISO 2012 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 12856

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Normative references.1

3 Requirements.2

3.1 Dimensional tolerance .2

3.2 Bending strength and Young's modulus in flexure .3

3.3 Longitudinal compressive strength.3

3.4 Lateral compressive strength.3

3.5 Shear strength.3

3.6 Adhesive shear strength.3

3.7 Alternating-current break down voltage .3

3.8 Direct-current insulation resistance.3

3.9 Track spike pull-out strength .3

3.10 Screw spike pull-out strength .4

3.11 Water absorption.4

3.12 Unit volume mass.4

3.13 Linear expansion coefficient.4

3.14 Flame resistance.6

3.15 Fatigue resistance.6

3.16 Weather resistance.6

4 Test method .7

4.1 General.7

4.2 Dimension.7

4.3 Bending strength and Young's modulus in flexure .9

4.4 Longitudinal compressive strength.11

4.5 Lateral compressive strength.12

4.6 Shear strength.13

4.7 Adhesive shear strength.14

4.8 Alternating-current break down voltage .15

4.9 Direct-current insulation resistance.16

4.10 Track spike and screw spike pull-out strength .17

4.11 Water absorption.18

4.12 Unit volume mass.18

4.13 Linear expansion coefficient.19

4.14 Flame resistance.19

4.15 Fatigue strength.20

4.16 Weather resistance.20

5. Inspection.22

Annex A (informative) Supplementary for the Use of this Standard.23

Annex B (informative) Try (Essay) of Resistance in the Attrition of the Roadbed………………….…….24

Annex C (informative) The stability (immobility) of sleeper in the use of ballast track .27

Annex D (normative) Methodology for Assessing Material Aging .29

© ISO 2011 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/DIS 12856

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 12856 was prepared by Technical Committee ISO/TC 61, Plastics, Subcommittee SC 11, Products.

iv © ISO 2011 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/DIS 12856

Introduction

Railway sleepers are mainly made of pre-stressed concrete, steel or timber. Timber sleepers have been used

for many years and have the attributes of being lightweight and workable. However, they have a number of

disadvantages including being subject to decay as well as the concerns over the supply from a continuing

depletion of forest resources.

In recent years there have been increasing demands for alternative materials that can be used for making

sleepers. A sleeper made from plastic is one such alternative material. Plastic/composite sleepers offer similar

advantages as timber sleepers (lightness, workability and durability) without some of the disadvantages

(decay and environmental impact).

There are many types of plastics and manufacturing processes which could have various effects on the in

service performance. This standard has therefore been introduced in order to specify the performance for

plastic/composite sleepers.

This Standard applies to the sleepers in conventional shapes such as rectangular and to the sleepers

composed of uniform materials including those partly reinforced by filling agents or fibre. Sleepers in other

shapes or the sleepers composed of multiple materials can be included in the Standard when the full-sized

sleepers are prepared for testing.

© ISO 2011 – All rights reserved v

---------------------- Page: 5 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 12856

Plastic railway sleepers (railroad ties)

1 Scope

This International Standard specifies the requirements of plastic/composite sleepers for railway applications.

This Standard is applicable to the full-sized sleepers and the test specimens properly cut out from the full-

sized sleepers both in rectangular shapes and with the cross sections composed of uniform materials. This

International Standard is also applicable to sleepers in other shapes or with the cross sections composed of

several kinds of material, when the test specimens are cut into rectangular shapes.

This Standard deals with the following three types (categories) of plastic/composite sleepers and stipulates

each requirement for railway applications.

(Type A) Light weight sleepers with high bending-properties

(Type B) Sleepers with upper properties

(Type C) Sleepers with standard properties

In using this Standard, the railway companies or other users may select the most suitable type (category) of

requirements among the A, B and C in accordance with their schedules. The Annex A will be supplementary

information for the use of this Standard.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 62, Plastics — Determination of water absorption

ISO 75, Plastics — Determination of temperature of deflection under load (all parts)

ISO 178, Plastics — Determination of flexural properties

ISO 291, Plastics — Standard atmospheres for conditioning and testing

ISO 306, Plastics — Thermoplastic materials — Determination of Vicat softening temperature (VST)

ISO 527-2, Plastics — Determination of tensile properties — Part 2: Test conditions for moulding and

extrusion plastics

ISO 527-4, Plastics — Determination of tensile properties — Part 4: Test conditions for isotropic and

orthotropic fibre-reinforced plastic composites

ISO 877-1, Plastics — Methods of exposure to solar radiation — Part 1: General guidance

ISO 877-2, Plastics — Methods of exposure to solar radiation — Part 2: Direct weathering and exposure

behind window glass

ISO 2578, Plastics — Determination of time-temperature limits after prolonged exposure to heat

© ISO 2011 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/DIS 12856

ISO 2818, Plastics — Preparation of test specimens by machining

ISO 3611, Geometrical product specifications (GPS) – Dimensional measuring equipment:

Micrometers for external measurements – Design and metrological characteristics

ISO 4892-2, Plastics — Methods of exposure to laboratory light sources — Part 2: Xenon-arc lamps

ISO 4892-4, Plastics — Methods of exposure to laboratory light sources — Part 4: Open-flame carbon-

arc lamps

ISO 5003, Flat bottom railway rails and special rail sections for switches and crossings of non-treated steel —

Technical delivery requirements

ISO 8256, Plastics — Determination of tensile-impact strength

ISO 10640, Plastics — Methodology for assessing polymer photoageing by FTIR and UV/visible spectroscopy

ISO 11357-6, Plastics — Differential scanning calorimetry (DSC) — Part 6: Determination of oxidation

induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT)

ISO 13385-1, Geometrical product specifications (GPS) – Dimensional measuring equipment - Part 1:

Calipers; Design and metrological characteristics

ISO 13385-2, Geometrical product specifications (GPS) - Dimensional measuring equipment - Part 2: Caliper

depth gauges; Design and metrological characteristics

ISO 14125, Fibre-reinforced plastic composites — Determination of flexural properties

ISO/TR 19032, Plastics — Use of polyethylene reference specimens (PERS) for monitoring laboratory and

outdoor weathering conditions

IEC 60695-11-20, Fire hazard testing - Part 11-20. Test flames - 500 W flame-test methods

EN 13230-2, Railway applications - Track - Concrete sleepers and bearers - Part 2: Pre-stressed

monoblock sleepers

EN 13450-2002, Aggregates for railway ballast

EN 14617-2, Agglomerated stone — Test methods — Part 2: Determination of flexural strength

(bending)

EN 14617-15, Agglomerated stone — Test methods — Part 15: Determination of compressive

strength

3 Requirements

3.1 Dimensional tolerance

The dimensional tolerance shall be as specified in Table 1 when the measurement is conducted using the

method as in 4.2 of this Standard.

2 © ISO 2011 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 12856

Table 1 — Dimensional Tolerance

Item Tolerances Test Methods

Unit

Category Type A Type B Type C Type A Type B Type C

Thickness mm ± 2 ± 2 ± 3

Width mm ± 3 ± 3 ± 6 4.2 a)

Length mm ± 5 ± 10 ± 10

Camber and

⎯ ≤ 2/1000 ⎯ 4.2 b) and c) ⎯

Bend

Torsion ≤ 1/1000 4.2 d)

⎯ ⎯ ⎯

3.2 Bending strength and Young's modulus in flexure

The requirements of bending strength and Young’s modulus in flexure shall be as specified in Table 2 and 3

when the test is conducted using the methods as in 4.3 a) or b) of this Standard.

3.3 Longitudinal compressive strength

The requirement of longitudinal compressive strength shall be as specified in Table 2 and 3 when the test is

conducted using the method as in 4.4 of this Standard.

3.4 Lateral compressive strength

The requirement of lateral compressive strength shall be as specified in Table 2 when the test is conducted

using the method as in 4.5 of this Standard.

3.5 Shear strength

The requirement of shear strength shall be as specified in Table 2 and 3 when the test is conducted using the

method as in 4.6 of this Standard.

3.6 Adhesive shear strength

The requirement of adhesive shear strength shall be as specified in Table 2 when the test is conducted using

the method as in 4.7 of this Standard.

3.7 Alternating-current break down voltage

The requirement of alternating-current breakdown voltage shall be as specified in Table 2 when the test is

conducted using the method as in 4.8 of this Standard.

3.8 Direct-current insulation resistance

The requirement of direct-current insulation resistance shall be as specified in Table 2 when the test is

conducted using the method as in 4.9 of this Standard.

3.9 Track spike pull-out strength

The requirement of track spike pull-out strength shall be as specified in Table 2 when the test is conducted

using the method as in 4.10a) of this Standard.

© ISO 2011 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/DIS 12856

3.10 Screw spike pull-out strength

The requirement of screw spike pull-out strength shall be as specified in Table 2 when the test is conducted

using the method as in 4.10b) of this Standard.

3.11 Water absorption

The requirement of water absorption shall be as specified in Table 2 when the test is conducted using the

method as in 4.11 of this Standard.

3.12 Unit volume mass

The requirement of unit volume mass shall be as specified in Table 2 when the test is conducted using the

method as in 4.12 of this Standard.

3.13 Linear expansion coefficient

The requirement of linear expansion coefficient shall be as specified in Table 2 when the test is conducted

using the method as in 4.13 of this Standard.

4 © ISO 2011 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/DIS 12856

Table 2 — Physical Properties

Item Values of Physical Property Test Methods

Unit

Category A B C A B C

4.3 a)

Bending

2 1)

N/mm ≥ 28 ≥ 18 ≥ 13,8 or 4.3

Strength

b)

4.3 a) or 4.3 b)

Young's

Modulus in 2

N/mm ≥ 6 000 ≥ 2 500 ≥ 1 170 4.3 a)

Flexure

(test specimen)

Longitudinal

2 2) 2)

Compression N/mm ≥ 40 ≥ 8 ⎯ 4.4 ⎯

Material

Strength

Strength

Lateral

2 2)

Compression N/mm ≥ 8 ≥ 6,2 4.5

⎯

Strength

2

2) 2)

Shear Strength N/mm ≥ 7 ≥ 4,5 ⎯ 4.6 ⎯

≥ 7

Adhesive Shear Base-

2 3) 3) 3) 3)

N/mm ⎯ ⎯ 4.7 ⎯ ⎯

Strength Material

Breakage

Alternating-

2) 2)

Current Break - kV ≥ 20 ≥ 20 4.8 ⎯

⎯

Electrical down Voltage

Character-

istics

Direct-Current

10 4 4

Insulation Ω ≥ 1 × 10 ≥ 2 × 10 ≥ 2 × 10 4.9

Resistance

Track Spike

Pull-out kN ≥ 15 ≥ 10 ≥ 8,5 4.10 a)

Strength

Pull-out

Strength

Screw Spike

Pull-out kN ≥ 30 ≥ 30 ≥ 22,2 4.10 b)

Strength

4) 2) 2)

Water Absorption % ≤ 2 ≤ 2 ⎯ 4.11 ⎯

3

Mass per Unit Volume g / cm ≥ 0,64 ≥ 0,8 ≥ 0,8 4.12

-1

-5 -5 -4

Linear Expansion Coefficient K 5 × 10 ≤ 6 × 10 ≤ 1,35 × 10 ≤ 4.13

1) This is based on a minimum functional safety factor but a higher value may be required.

2) There may remain blanks in the table if the requirements should not necessarily be established. For the purpose of railway operation,

however, the requirements may be defined as a necessity through agreement between the manufacturers and purchasers.

3) This shall remain blank because there is no part to use adhesive and hence no need to establish the requirement.

4) This unit is in weight fraction.

© ISO 2011 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/DIS 12856

Table 3 — Physical Properties (dependence of temperature)

Item Unit Values of Physical Propertiy Test Methods

at -30°C (in air for 24 h) at 60°C (in air for 24 h)

Bending Strength

4.3 a)

Young's Modulus in

Flexure (test

Material

specimen) 1)

% ≥ 100 ≥ 70

Strength

Longitudinal

4.4

Compression

Strength

Shear Strength 4.6

1) The percentage indicates the strength retention against physical property values at normal temperature.

3.14 Flame resistance

For the requirement of flame resistance, non-combustibility shall be confirmed when the test is conducted

using the method as in 4.14 of this Standard.

3.15 Fatigue resistance

For the requirement of fatigue resistance, breakdown shall not take place when the test is conducted using the

method as in 4.15 of this Standard.

3.16 Weather resistance

a) Products equivalent to “Type A”

The requirement of weather resistance shall be specified in Table 4 when the test is conducted using the

method as in 4.16 a) of this Standard.

Table 4 — Physical Properties after Weathering

Value of Physical

Unit Test Method

Property

Bending Strength

Young’s Modulus in

Flexure

Material

1)

% ≥ 70

Strength 4.16 a)

Longitudinal

Compressive Strength

Adhesive Shear Strength

(base-material failure)

1) The percentage indicates the strength retention against physical property values before acceleration of

degradation in weathering resistance.

© ISO 2011 – All rights reserved 6

---------------------- Page: 11 ----------------------

ISO/DIS 12856

b) Products equivalent to “Type B and C”

The requirement of weather resistance shall be agreed between the interested parties. The resistance

capacity of material exposed to aging effects shall be assessed in accordance with 4.16 b).

4 Test method

4.1 General

4.1.1 Preparation of test specimen

Test specimens shall be prepared with reference to ISO 2818. There shall be no damage or faults on the

surface in order to prevent notch effects. If there are burrs on specimens, they shall be carefully removed

without damaging the surface. If necessary, the edges of the surfaces shall be finished using sandpaper.

4.1.2 Test condition

Unless otherwise specified in 4.16 (Weather Resistance) the test shall be carried out in one of the standard

atmospheres specified in ISO 291 after the test specimens are conditioned in the same atmosphere for at

least 24 hours.

4.2 Dimension

For measurement of the dimensions, the plastic sleeper shall be placed horizontally. The measurement shall

be conducted using a steel tape measure, metal rule or vernier caliper as specified in ISO 13385-1 and ISO

13385-2 or using micrometer calipers as specified in ISO 3611, using the following methods.

a) Measurement of dimensions For the measurement of the dimensions, the test specimen shall be

placed horizontally on a smooth surface and the dimension of each side shall be measured as shown in

Figure 1. The average values of thickness and width shall be determined by averaging the measurements at

the central point and both ends of the specimen parallel to the length. The length shall be calculated on the

average values measured at the central point and both ends parallel to the width.

Figure 1 — Measurement method of dimensions

b) Measurement of camber For the measurement of camber, the test specimen shall first be placed

horizontally on a smooth surface. A string shall be stretched horizontally between the central points on both

ends on the top-face of the specimen. The camber at the deepest position shall be measured between the

top-face of specimen and string as shown in Figure 2. The tolerance of camber shall be calculated by dividing

the measured camber by the length of the test specimen.

© ISO 2011 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO/DIS 12856

Figure 2 — Measurement method of camber

c) Measurement of bend For the measurement of bend, the test specimen shall be placed horizontally on a

smooth surface. A string shall be stretched horizontally between the central points of both ends on the side

face of specimen, and the maximum bend shall be measured as shown in Figure 3. The tolerance of bend

shall be calculated by dividing the amount of bend by the length of the test specimen.

Figure 3 — Measurement method of bend

d) Measurement of torsion For the measurement of torsion, the test specimen shall be placed on a

smooth surface. A string shall be stretched horizontally along the top face on the diagonal line. The difference

between the string and the top face at the highest position shall be measured as shown in Figure 4. The

tolerance of torsion shall be calculated by dividing the amount of torsion by the length of the specimen.

Figure 4 — Measurement method of torsion

8 © ISO 2011 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/DIS 12856

4.3 Bending strength and Young's modulus in flexure

The users of this Standard shall choose either Method A or B prescribed below in determining the test

specimen to be used. For Type A, however, the method of 4.3 a) shall be applicable in the test of Young's

modulus in flexure.

a) Test method A (to use test specimen cut out from a full-sized sleeper)

The tests for bending strength and Young's modulus in flexure shall be conducted at an ambient temperature

of 23 ± 5 °C using the following method.

The test specimen shall be cut out from a full-sized sleeper or from the material as manufactured in the same

condition as that of a full-sized sleeper. In the test, the longitudinal direction of the test specimen shall become

parallel to the supporting span and shall be vertical to the load direction in position. A steel plate of 3 mm x 50

mm x 50 mm in diameter shall be prepared and put on the central position of supporting span.

The concentrated load shall be applied at the central point of the supporting span. The average loading speed

2

(stress) shall be less than 15 N/mm per minute. The dimension and span of the test specimen shall be as

shown in Figure 5.

Figure 5 — Dimensions and span of test specimen of bending strength and Young’s modulus in

flexure

b) Test method B (to use a full-sized sleeper in actual track operation)

The values of thickness (T) and width (W) shall be identical to those of a full-sized sleeper being used in each

country. The span (l) of the test specimen shall be 8-10 times larger than the thickness. The distance of

supporting spans may be equivalent to the actual track gauge introduced in each country. The length of test

specimen shall be 12 times larger than the thickness. The test of the bending strength and Young’s modulus

in flexure shall be conducted at an ambient temperature of 23 ± 5 °C in the following method.

The concentrated load shall be applied at the central position of the test specimen between the supporting

2

spans. The average loading speed (stress) shall be less than 15 N/mm per minute. The dimension and span

of the test specimen shall be as shown in Figure 6.

© ISO 2011 – All rights reserved 9

---------------------- Page: 14 ----------------------

ISO/DIS 12856

Figure 6 — Dimensions and span of test specimen of bending strength and Young’s modulus in

flexure and fatigue strength

Steel: Minimum hardness Brinell: HBW > 240

General tolerances: ± 0,1 mm

1) Minimum Length

= Width of the sleeper at the rail seat +20 mm

2) Lubricant for High Pressure

Figure 7 — Articulated support in EN13230-2 –Annex A

10 © ISO 2011 – All rights reserved

---------------------- Page: 15 ----------------------

ISO/DIS 12856

The bending strength and Young's modulus in flexure shall be determined from the test results, using the

following formulae.

3

∆PL

E = (1)

b

48I∆Y

P l

m

σ = (2)

b

4Z

2

WT

Z = (3)

6

where

2

is the Young’s modulus in flexure (N/mm );

E

b

2

σ is the bending strength (N/mm );

b

3

Z is the section modulus (mm );

∆P is the difference between upper limit load and lower limit load in a proportional region (N);

A proportional region (N) is a load domain (= elasticity domain) where a load level is in proportion

to displacement

∆Y is the deflection of mid-span to ∆P (mm);

4

I is the geometrical moment of inertia (mm );

is the span (mm);

l

W

is the width of the test specimen (mm);

T is the height of test specimen (mm);

P is the maximum load (N)

m

NOTE: The maximum load refers to the load before th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.