ISO 12743:2006

(Main)Copper, lead, zinc and nickel concentrates — Sampling procedures for determination of metal and moisture content

Copper, lead, zinc and nickel concentrates — Sampling procedures for determination of metal and moisture content

ISO 12743:2006 sets out the basic methods for sampling copper, lead, zinc and nickel concentrates from moving streams and stationary lots, including stopped-belt sampling, to provide samples for chemical analysis, physical testing and determination of moisture content, in accordance with the relevant International Standards.

Concentrés de cuivre, de plomb, de zinc et de nickel — Procédures d'échantillonnage pour la détermination de la teneur en métal et de l'humidité

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 12743

Second edition

2006-06-15

Copper, lead, zinc and nickel

concentrates — Sampling procedures

for determination of metal and moisture

content

Concentrés de cuivre, de plomb, de zinc et de nickel — Procédures

d'échantillonnage pour la détermination de la teneur en métal et de

l'humidité

Reference number

ISO 12743:2006(E)

©

ISO 2006

---------------------- Page: 1 ----------------------

ISO 12743:2006(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2006

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2006 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 12743:2006(E)

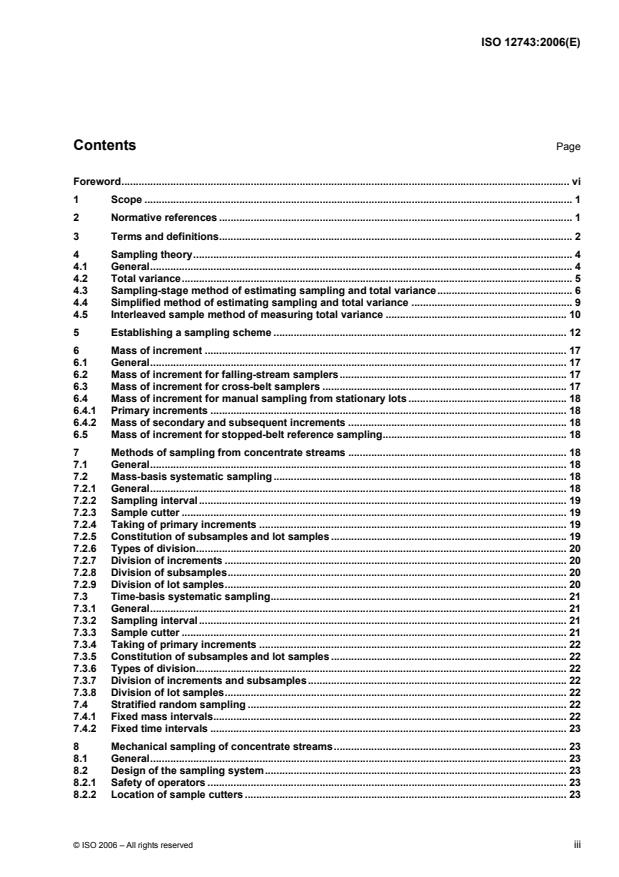

Contents Page

Foreword. vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions. 2

4 Sampling theory. 4

4.1 General. 4

4.2 Total variance. 5

4.3 Sampling-stage method of estimating sampling and total variance. 6

4.4 Simplified method of estimating sampling and total variance . 9

4.5 Interleaved sample method of measuring total variance . 10

5 Establishing a sampling scheme . 12

6 Mass of increment . 17

6.1 General. 17

6.2 Mass of increment for falling-stream samplers. 17

6.3 Mass of increment for cross-belt samplers . 17

6.4 Mass of increment for manual sampling from stationary lots . 18

6.4.1 Primary increments . 18

6.4.2 Mass of secondary and subsequent increments . 18

6.5 Mass of increment for stopped-belt reference sampling. 18

7 Methods of sampling from concentrate streams . 18

7.1 General. 18

7.2 Mass-basis systematic sampling. 18

7.2.1 General. 18

7.2.2 Sampling interval. 19

7.2.3 Sample cutter . 19

7.2.4 Taking of primary increments . 19

7.2.5 Constitution of subsamples and lot samples . 19

7.2.6 Types of division. 20

7.2.7 Division of increments . 20

7.2.8 Division of subsamples. 20

7.2.9 Division of lot samples. 20

7.3 Time-basis systematic sampling. 21

7.3.1 General. 21

7.3.2 Sampling interval. 21

7.3.3 Sample cutter . 21

7.3.4 Taking of primary increments . 22

7.3.5 Constitution of subsamples and lot samples . 22

7.3.6 Types of division. 22

7.3.7 Division of increments and subsamples. 22

7.3.8 Division of lot samples. 22

7.4 Stratified random sampling . 22

7.4.1 Fixed mass intervals. 22

7.4.2 Fixed time intervals . 23

8 Mechanical sampling of concentrate streams. 23

8.1 General. 23

8.2 Design of the sampling system. 23

8.2.1 Safety of operators . 23

8.2.2 Location of sample cutters . 23

© ISO 2006 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 12743:2006(E)

8.2.3 Provision for interleaved sampling . 23

8.2.4 Provision for stratified random sampling. 24

8.2.5 Checking precision and bias . 24

8.2.6 Avoiding bias. 24

8.2.7 Minimizing bias . 24

8.2.8 Configuration of the sampling system . 24

8.3 Sample cutters. 24

8.3.1 General . 24

8.3.2 Design criteria . 25

8.3.3 Cutter speed . 26

8.4 Mass of increments. 27

8.5 Number of increments . 27

8.6 Sampling interval . 27

8.7 Routine checking . 27

9 Manual sampling of concentrate streams . 28

9.1 General . 28

9.2 Choosing the sampling location. 28

9.3 Sampling implements . 28

9.4 Mass of increments. 28

9.5 Number of increments . 28

9.6 Sampling interval . 28

9.7 Sampling procedures . 29

9.7.1 General . 29

9.7.2 Full stream cut from a falling stream . 29

9.7.3 Partial stream cuts from a falling stream . 29

9.7.4 Sampling from moving conveyor belts.30

10 Stopped-belt reference sampling . 30

11 Sampling from grabs . 31

11.1 General . 31

11.2 Mass of primary increments . 31

11.3 Number of primary increments. 31

11.4 Method of sampling . 31

11.5 Constitution of subsamples and lot samples . 31

12 Sampling from trucks, railway wagons and sampling hoppers. 32

12.1 General . 32

12.2 Mass of primary increments . 32

12.3 Number of primary increments. 32

12.4 Method of sampling . 32

12.5 Constitution of subsamples and lot samples . 32

13 Sampling of concentrate in bags or drums. 35

13.1 General . 35

13.2 Mass of primary increments . 35

13.3 Number of primary increments. 35

13.4 Method of sampling . 36

13.4.1 General . 36

13.4.2 Sampling during filling or emptying . 36

13.4.3 Spear sampling . 36

13.5 Constitution of subsamples and lot samples . 36

14 Sampling of stockpiles . 37

15 Methods of comminution, mixing and division. 37

15.1 General . 37

15.2 Comminution . 37

15.2.1 General . 37

15.2.2 Mills . 37

15.3 Mixing. 38

15.3.1 General . 38

iv © ISO 2006 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 12743:2006(E)

15.3.2 Methods of mixing . 38

15.4 Division . 40

15.4.1 Chemical analysis samples . 40

15.4.2 Moisture samples. 40

15.4.3 Number of increments for division . 40

15.4.4 Minimum mass of divided sample . 40

15.4.5 Rotary sample division. 41

15.4.6 Cutter-type division . 42

15.4.7 Manual increment division. 43

15.4.8 Spear division . 43

15.4.9 Fractional shovelling. 44

15.4.10 Ribbon division. 45

15.4.11 Riffle division . 47

16 Sample requirements . 49

16.1 Moisture samples. 49

16.1.1 Mass of test portion. 49

16.1.2 Processing of samples. 49

16.2 Chemical analysis samples . 49

16.3 Physical test samples. 50

17 Packing and marking of samples. 50

Annex A (normative) Sampling stage method of estimating sampling and total variance . 51

Annex B (informative) Estimation of total variance — Barge unloading using a grab . 58

Annex C (informative) Mechanical sample cutters . 62

Annex D (informative) Checklist for mechanical sampling systems . 67

Annex E (normative) Manual sampling devices. 71

Annex F (informative) Apparatus for manual sampling of concentrates from stopped belts. 73

Annex G (informative) Sampling of stockpiles. 74

Annex H (normative) Increment division scoops for conducting manual increment division . 76

Bibliography . 77

© ISO 2006 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 12743:2006(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 12743 was prepared by Technical Committee ISO/TC 183, Copper, lead, zinc and nickel ores and

concentrates.

This second edition cancels and replaces the first edition (ISO 12743:1998), which has been technically

revised. The principal change is the extension of the scope to cover the sampling of nickel concentrates.

vi © ISO 2006 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 12743:2006(E)

Copper, lead, zinc and nickel concentrates — Sampling

procedures for determination of metal and moisture content

WARNING — This International Standard may involve hazardous materials, operations and

equipment. It is the responsibility of the user of this International Standard to establish

appropriate health and safety practices and determine the applicability of regulatory

limitations prior to use.

1 Scope

This International Standard sets out the basic methods for sampling copper, lead, zinc and nickel

concentrates from moving streams and stationary lots, including stopped-belt sampling, to provide samples for

chemical analysis, physical testing and determination of moisture content, in accordance with the relevant

International Standards. Where the concentrates are susceptible to significant oxidation or decomposition, it is

necessary to use a common sample for moisture determination and chemical analysis to eliminate bias (see

ISO 10251). In such cases, the common sample must be sufficiently representative, i.e. unbiased and

sufficiently precise, for chemical analysis and determination of moisture content. Any large agglomerates

(> 10 mm) present in the primary sample should be crushed prior to further sample processing. Sampling of

concentrates in slurry form is specifically excluded from this International Standard.

Stopped-belt sampling is the reference method for collecting concentrate samples against which mechanical

and manual-sampling procedures may be compared. Sampling from moving streams is the preferred method.

Both falling-stream and cross-belt samplers are described.

Sampling from stationary lots is used only where sampling from moving streams is not possible. The

procedures described in this International Standard, for sampling from stationary lots, only minimize some of

the systematic sampling errors.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 10251, Copper, lead, zinc and nickel concentrates — Determination of mass loss of bulk material on

drying

ISO 12744, Copper, lead, zinc and nickel concentrates — Experimental methods for checking the precision of

sampling

ISO 13292, Copper, lead, zinc and nickel concentrates — Experimental methods for checking the bias of

sampling

© ISO 2006 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO 12743:2006(E)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

representative sample

quantity of concentrate representing a larger mass of concentrate with both precision and bias within

acceptable limits

3.2

lot

quantity of concentrate to be sampled

3.3

lot sample

quantity of concentrate representative of the lot

3.4

sub-lot

subdivided parts of a lot which are processed separately, each of them producing a subsample which is

analysed separately, e.g. for moisture determination

3.5

subsample

quantity of concentrate representative of the sub-lot

3.6

sampling

sequence of operations aimed at obtaining a sample representative of a lot

NOTE It comprises a series of sampling stages, each stage usually comprising operations of selection and

preparation

3.7

selection

operation by which a smaller quantity of concentrate is taken from a larger quantity of concentrate

3.8

increment

quantity of concentrate selected by a sampling device in one operation

3.9

increment selection

selection process that consists of extracting from the lot, or from an intermediate sample, successive

increments which can be combined to constitute a sample

3.10

division

operation of decreasing sample mass, without change of particle size, where a representative part of the

sample is retained

3.11

constant-mass division

method of division in which the retained portions from individual increments or subsamples are of uniform

mass

2 © ISO 2006 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 12743:2006(E)

3.12

proportional division

method of division in which the retained portions from individual increments or subsamples are a constant

proportion of their original mass

3.13

preparation

nonselective operation without division such as sample transfer, drying, comminution or homogenization

3.14

sample processing

whole sequence of selection and preparation operations which transforms a stage i sample into a test sample

3.15

comminution

operation of reducing particle size by crushing, grinding or pulverisation

3.16

stage i sample

sample obtained at the ith stage of the sampling scheme

3.17

moisture sample

representative quantity of concentrate from which test portions are taken for moisture determination

NOTE Alternatively, the whole moisture sample may be dried to determine its moisture content

3.18

laboratory sample

sample that is processed so that it can be sent to the laboratory and used for further processing and selection

of one or more test samples for analysis

3.19

common sample

representative quantity of concentrate which is dried to determine its mass loss and subsequently used for

further processing and selection of one or more test samples for chemical analysis

3.20

test sample

representative quantity of concentrate obtained from a laboratory sample when additional preparation, such as

drying or hygroscopic moisture determination, is needed prior to the selection of one or more test portions

3.21

test portion

representative quantity of concentrate taken from a moisture sample, a laboratory sample or a test sample

which is submitted to moisture determination or analysis in its entirety

3.22

systematic sampling

selection of increments in which the concentrate being sampled is divided into equal strata and the first

increment is taken at random within the first stratum, the interval between subsequent increments being equal

to the stratum size

3.23

stratified random sampling

selecti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.