ISO 24131-1:2023

(Main)Internal protection by polymeric lining for ductile iron pipes — Requirements and test methods — Part 1: Polyurethane lining

Internal protection by polymeric lining for ductile iron pipes — Requirements and test methods — Part 1: Polyurethane lining

This document specifies the requirements and test methods applicable to factory applied internal polyurethane lining for ductile iron pipes according to ISO 2531, ISO 7186 and ISO 16631. It covers internal linings for use in the conveyance of raw water, potable water and sewage water for operating temperature up to 50 °C.

Protection interne des tuyaux en fonte ductile par revêtement polymérique — Exigences et méthodes d'essai — Partie 1: Revêtement polymérique

General Information

Buy Standard

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 24131-1

First edition

2023-03

Internal protection by polymeric

lining for ductile iron pipes —

Requirements and test methods —

Part 1:

Polyurethane lining

Protection interne des tuyaux en fonte ductile par revêtement

polymérique — Exigences et méthodes d'essai —

Partie 1: Revêtement polymérique

Reference number

ISO 24131-1:2023(E)

© ISO 2023

---------------------- Page: 1 ----------------------

ISO 24131-1:2023(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

© ISO 2023 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 24131-1:2023(E)

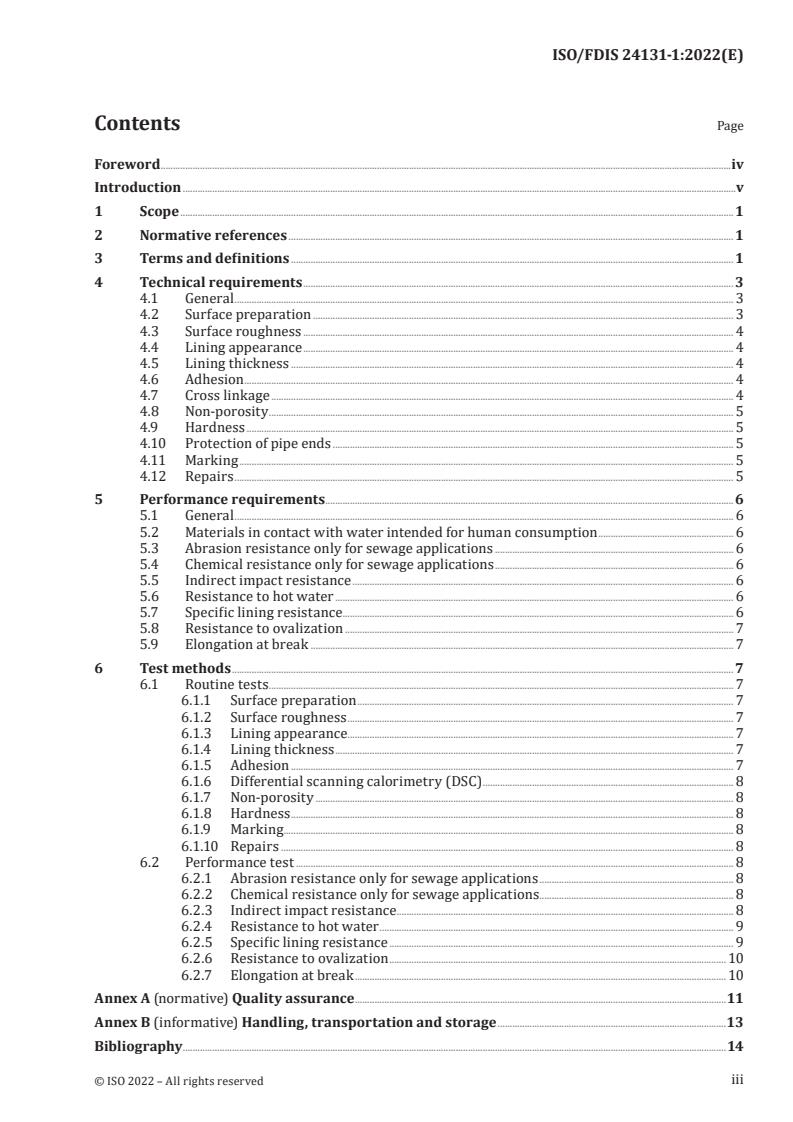

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Technical requirements . 3

4.1 General . 3

4.2 Surface preparation . 3

4.3 Surface roughness . 4

4.4 Lining appearance . 4

4.5 Lining thickness . 4

4.6 Adhesion . 4

4.7 Cross linkage . 4

4.8 Non-porosity . 5

4.9 Hardness . 5

4.10 Protection of pipe ends . 5

4.11 Marking . 5

4.12 Repairs . 5

5 Performance requirements . .6

5.1 General . 6

5.2 Materials in contact with water intended for human consumption . 6

5.3 Abrasion resistance only for sewage applications . 6

5.4 Chemical resistance only for sewage applications . 6

5.5 Indirect impact resistance . 6

5.6 Resistance to hot water . 6

5.7 Specific lining resistance . . 6

5.8 Resistance to ovalization . 7

5.9 Elongation at break . 7

6 Test methods . 7

6.1 Routine tests . . 7

6.1.1 Surface preparation . 7

6.1.2 Surface roughness . 7

6.1.3 Lining appearance . . 7

6.1.4 Lining thickness . 7

6.1.5 Adhesion . 7

6.1.6 Differential scanning calorimetry (DSC) . 8

6.1.7 Non-porosity . 8

6.1.8 Hardness . 8

6.1.9 Marking . . . 8

6.1.10 Repairs . 8

6.2 Performance test . 8

6.2.1 Abrasion resistance only for sewage applications . 8

6.2.2 Chemical resistance only for sewage applications . 8

6.2.3 Indirect impact resistance . 8

6.2.4 Resistance to hot water . 9

6.2.5 Specific lining resistance . 9

6.2.6 Resistance to ovalization . 10

6.2.7 Elongation at break . 10

Annex A (normative) Quality assurance .11

Annex B (informative) Handling, transportation and storage .13

Bibliography .14

iii

© ISO 2023 – All rights reserved

---------------------- Page: 3 ----------------------

ISO 24131-1:2023(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 5, Ferrous metal pipes and metallic fittings,

Subcommittee SC 2, Cast iron pipes, fittings and their joints.

A list of all parts in the ISO 24131 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

© ISO 2023 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 24131-1:2023(E)

Introduction

The ISO 24131 series specifies the requirements and test methods applicable to factory applied

polymeric linings for ductile iron pipes according to ISO 2531, ISO 7186 and ISO 16631. The ISO 24131

series is intended to include several types of polymeric linings.

v

© ISO 2023 – All rights reserved

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 24131-1:2023(E)

Internal protection by polymeric lining for ductile iron

pipes — Requirements and test methods —

Part 1:

Polyurethane lining

1 Scope

This document specifies the requirements and test methods applicable to factory applied internal

polyurethane lining for ductile iron pipes according to ISO 2531, ISO 7186 and ISO 16631.

It covers internal linings for use in the conveyance of raw water, potable water and sewage water for

operating temperature up to 50 °C.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 62, Plastics — Determination of water absorption

ISO 527-3, Plastics — Determination of tensile properties — Part 3: Test conditions for films and sheets

ISO 868, Plastics and ebonite — Determination of indentation hardness by means of a durometer (Shore

hardness)

ISO 2531, Ductile iron pipes, fittings, accessories and their joints for water applications

ISO 4624, Paints and varnishes — Pull-off test for adhesion

ISO 7186:2011, Ductile iron products for sewerage applications

ISO 8503-1, Preparation of steel substrates before application of paints and related products — Surface

roughness characteristics of blast-cleaned steel substrates — Part 1: Specifications and definitions for ISO

surface profile comparators for the assessment of abrasive blast-cleaned surfaces

ISO 16631, Ductile iron pipes, fittings, accessories and their joints compatible with plastic (PVC or PE)

piping systems, for water applications and for plastic pipeline connections, repair and replacement

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 2531 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

1

© ISO 2023 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 24131-1:2023(E)

3.1

polyurethane lining

factory applied lining which consists of polyurethane (3.2) on the inside of the pipe

Note 1 to entry: See Figure 1.

Key

1 gasket seat

2 pipe barrel

3 spigot end

4 lining

5 internal socket profile

Figure 1 — Location of the defined pipe areas

3.2

polyurethane

polymers made by combining diisocyanates and polyols

3.3

operating temperature

applicable temperatures under which the product maintains its properties

3.4

chalking

superficial reaction of polyurethane lining (3.1) due to exposure to UV-radiation

Note 1 to entry: The process is confined to the surface only and results in a dulling of the surface.

3.5

minimum lining thickness

minimum value of the lining thickness measured at the lined item

3.6

adhesion

force per unit area, applied perpendicular to the surface, which is necessary to separate the lining from

its substrate

3.7

cross linkage

chemical reaction between polyurethane (3.2) resin and hardener to form the final cured lining

3.8

non-porosity

absence of electrical puncture in a high voltage test (holiday test) under defined test conditions

3.9

hardness

resistance of the lining to the penetration of a ball under defined test conditions

2

© ISO 2023 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 24131-1:2023(E)

3.10

protection of pipe ends

factory applied coating/lining on spigot end and internal socket profile of pipes

Note 1 to entry: See Figure 1.

3.11

abrasion resistance

ability of materials and structures to withstand abrasion

3.12

indirect impact resistance

impact energy applied from outside of the pipe with deformation to which a lining can withstand

without damage under defined test conditions

3.13

specific lining resistance

surface related electric resistance of the lining perpendicular to the pipe wall

3.14

ovalization

100 times the measured vertical deflection, (caused by the applied load) divided by the measured pipe

external diameter

3.15

routine test

test carried out to control the manufacturing process

Note 1 to entry: The frequency of the test is defined by this document or the manufacturer.

3.16

performance test

test which is done once and thereafter only when there is a change in the lining material or lining

process

4 Technical requirements

4.1 General

The following technical requirements shall be demonstrated by routine tests applied in production,

on in-process and finished lined products with defined frequency. Routine tests shall be in accordance

with the overview of requirements provided in Table A.2.

Quality assurance for polyurethane lining shall be in accordance with Annex A.

4.2 Surface preparation

Prior to lining application, all surfaces to be lined shall be substantially clean and free from oil, grease

and moisture.

In cold weather, or anytime when moisture tends to condense on the surface of the pipe, it shall be

uniformly warmed for sufficient time to dry prior to cleaning. The surface temperature shall be

maintained at least 3 °C above the dew point.

Surface preparation shall be designed in order to reach the required performances specified in this

document. It is the responsibility of the manufacturer to demonstrate the fitness for purpose of surface

3

© ISO 2023 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 24131-1:2023(E)

preparation technology and to put in place a quality control procedure to ensure the stability of those

performances.

NOTE The requirements of Class Sa 2.5 of ISO 8501-1 and ≤ Rating 3 dust quantity and Class 2 for dust size of

ISO 8502-3 can be applied.

4.3 Surface roughness

The surface roughness Ra in accordance with ISO 8503-1 shall be at least 12,5 μm which is equivalent

to anchored profile Rz of 63 μm or higher if required by the lining material provider or manufacturer.

4.4 Lining appearance

The lining of the final product shall be of

— uniform colour, except for permitted marking;

— uniform appearance and smoothness, except for allowable repairs;

— free of visible defects (i.e. pinholes, bubbles, blisters, wrinkles, cracks or voids).

Slight superficial colour variations due to repairs or long exposure to sunlight (chal

...

ISO/DISFDIS 24131-1:2022(E)

ISO TC 5/SC 2/WG 24

Date: 2022-06-0812-22

Secretariat: AFNOR

Internal protection by polymeric lining for ductile iron pipes — Requirements and test methods

— Part 1: Polyurethane lining

---------------------- Page: 1 ----------------------

ISO/DIS FDIS 24131--1:2022(E)

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no

part of this publication may be reproduced or utilized otherwise in any form or by any means,

electronic or mechanical, including photocopying, or posting on the internet or an intranet, without

prior written permission. Permission can be requested from either ISO at the address below or

ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2022 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS FDIS 24131--1:2022(E)

Contents

Foreword . iv

Introduction. v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Technical requirements . 3

5 Performance requirements . 6

6 Test methods . 7

Annex A (normative) Quality assurance . 11

Annex B (informative) Handling, transportation and storage . 13

Bibliography . 14

© ISO 2022 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/DIS FDIS 24131--1:2022(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO

collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of any

patent rights identified during the development of the document will be in the Introduction and/or on

the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the World

Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 5, Ferrous metal pipes and metallic fittings,

Subcommittee SC 2, Cast iron pipes, fittings and their joints.

A list of all parts in the ISO 24131 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv © ISO 2022 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/DIS FDIS 24131--1:2022(E)

Introduction

The ISO 24131 series specifies the requirements and test methods applicable to factory applied polymeric

linings for ductile iron pipes suppliedaccording to ISO 2531, ISO 7186 and ISO 16631. The ISO 24131

series includesis intended to include several types of polymeric linings.

© ISO 2022 – All rights reserved v

---------------------- Page: 5 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/DIS FDIS 24131--1:2022(E)

Internal protection by polymeric lining for ductile iron pipes —

Requirements and test methods — Part 1: Polyurethane lining

1 Scope

This document specifies the requirements and test methods applicable to factory applied internal

polyurethane lining for ductile iron pipes according to ISO 2531, ISO 7186 and ISO 16631.

It covers internal linings for use in the conveyance of raw water, potable water and sewage water for

operating temperature up to 50 °C.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2531, Ductile iron pipes, fittings, accessories and their joints for water applications

ISO 7186:2011, Ductile iron products for sewerage applications

ISO 16631, Ductile iron pipes, fittings, accessories and their joints compatible with plastic (PVC or PE) piping

systems, for water applications and for plastic pipeline connections, repair and replacement

ISO 8503-1, Preparation of steel substrates before application of paints and related products — Surface

roughness characteristics of blast-cleaned steel substrates — Part 1: Specifications and definitions for ISO

surface profile comparators for the assessment of abrasive blast-cleaned surfaces

ISO 868, Plastics and ebonite — Determination of indentation hardness by means of a durometer (Shore

hardness)

ISO 62, Plastics — Determination of water absorption

ISO 4624, Paints and varnishes — Pull-off test for adhesion

ISO 527-3, Plastics — Determination of tensile properties — Part 3: Test conditions for films and sheets

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 2531 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

polyurethane lining

© ISO 2022 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/DISFDIS 24131-1:2022(E)

factory applied lining which consists of polyurethane (3.2) on the inside of the pipe

Note 1 to entry: See Figure 1.

Key

1 gasket seat

2 pipe barrel

3 spigot end

4 lining

5 internal socket profile

Figure 1 — Location of the defined pipe areas

3.2

polyurethane

polymers made by combining diisocyanates and polyols

3.3

operating temperature

applicable temperatures under which the product maintains its properties

3.4

chalking

superficial reaction of polyurethane lining (3.1) due to exposure to UV-radiation

Note 1 to entry: The process is confined to the surface only and results in a dulling of the surface.

3.5

minimum lining thickness

minimum value of the lining thickness measured at the lined item

3.6

adhesion

2 © ISO 2022 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS FDIS 24131--1:2022(E)

force per unit area, applied perpendicular to the surface, which is necessary to separate the lining from

its substrate

3.7

cross linkage

chemical reaction between polyurethane (3.2) resin and hardener to form the final cured lining

3.8

non-porosity

absence of electrical puncture in a high voltage test (holiday test) under defined test conditions

3.9

hardness

resistance of the lining to the penetration of a ball under defined test conditions

3.10

protection of pipe ends

factory applied coating/lining on spigot end and internal socket profile of pipes

Note 1 to entry: See Figure 1.

3.11

abrasion resistance

ability of materials and structures to withstand abrasion

3.12

indirect impact resistance

impact energy applied from outside of the pipe with deformation to which a lining can withstand without

damage under defined test conditions

3.13

specific lining resistance

surface related electric resistance of the lining perpendicular to the pipe wall

3.14

ovalization

100 times the measured vertical deflection, (caused by the applied load) divided by the measured pipe

external diameter

3.15

routine test

test carried out to control the manufacturing process

Note 1 to entry: The frequency of the test is defined by this document or the manufacturer.

3.16

performance test

test which is done once and thereafter only when there is a change in the lining material or lining process

© ISO 2022 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/DISFDIS 24131-1:2022(E)

4 Technical requirements

4.1 General

The following technical requirements shall be demonstrated by routine tests applied in production, on

in-process and finished lined products with defined frequency. Routine tests shall be in accordance with

the overview of requirements provided in Table A.2.

The information about qualityQuality assurance for polyurethane lining is givenshall be in accordance

with Annex A.

4.34.2 Surface preparation

Prior to lining application, all surfaces to be lined shall be substantially clean and free from oil, grease and

moisture.

In cold weather, or anytime when moisture tends to condense on the surface of the pipe, it shall be

uniformly warmed for sufficient time to dry prior to cleaning. The surface temperature shall be

maintained at least 3 °C above the dew point.

Surface preparation shall be designed in order to reach the required performances specified in this

document. It is the responsibility of the manufacturer to demonstrate the fitness for purpose of surface

preparation technology and to put in place a quality control procedure to ensure the stability of those

performances.

NOTE The requirements of Class Sa 2.5 of ISO 8501-1 and ≤ Rating 3 dust quantity and Class 2 for dust size of

ISO 8502-3 can be applied.

4.44.3 Surface roughness

The surface roughness Ra in accordance with ISO 8503-1 shall be at least 12,5 μm which is equivalent to

anchored profile Rz of 63 μm or higher if required by the lining material provider or manufacturer.

4.54.4 Lining appearance

The lining of the final product shall be of

— uniform colour, except for permitted marking;

— uniform appearance and smoothness, except for allowable repairs;

— free of visible defects (i.e. pinholes, bubbles, blisters, wrinkles, cracks or voids).

Slight superficial colour variations due to repairs or long exposure to sunlight (chalking) are permissible.

4.64.5 Lining thickness

When measured in accordance with the method defined in 6.1.4, the lining thickness shall be as indicated

in Table 1 for water applications and in Table 2 for sewage applications.

Table 1 — Minimum lining thickness and test tension for water applications

Nominal size Minimum lining thickness Test tension

DN μm kV

80 to 2 600 800 4

4 © ISO 2022 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/DIS FDIS 24131--1:2022(E)

Table 2 — Minimum lining thickness and test tension for sewage applications

Nominal size Minimum lining thickness Test tension

DN μm kV

80 to 700 800 4

800 to 2 600 1 000 5

4.74.6 Adhesion

Adhesion shall be tested in accordance with the test method defined in 6.1.5 on production samples.

The lining adhesion shall achieve an average value of at least 8,0 MPa. The manufacturer shall determine

the test locations on the products.

4.84.7 Cross linkage

Determination of cross linkage by hardness measurement of the lining materials serves as a production

control. It is calibrated by a differential scanning calorimetry (DSC) test, see 6.1.6.

The test shall be carried out directly after production on a cured proxy sample under the same production

condition as the pipe at room temperature (23 ± 2) °C. The test method of ISO 868 shall be used.

4.94.8 Non-porosity

When tested in accordance with the test method defined in 6.1.7, the lining shall be free from porosity.

For 800 μm minimum lining thickness, the test tension shall be 4 kV. For 1 000 μm minimum lining

thickness, the test tension shall be 5 kV. The scanning electrode shall be passed over the surface of the

lining being inspected with a continuous, relative movement not exceeding 300 mm/s. This requirement

does not apply to pipe ends.

The electrode shall not be damaged and shall be in constant touch with the lining.

For thicker linings, a higher test voltage may be used by agreement between the manufacturer and the

purchaser.

4.104.9 Hardness

The different applications (e.g. drinking water, sewage) can use different hardness which are indicated

in the pipe manufacturer’s catalogue. They shall be tested in accordance with 6.1.8.

4.114.10 Protection of pipe ends

Spigot end and internal socket profile (see Figure 1) shall be coated in accordance with ISO 2531,

ISO 7186 and ISO 16631.

4.124.11 Marking

All pipes shall be marked legibly and durably according to the pipe standards, ISO 2531, ISO 7186 and

ISO 16631. Reference to this document shall be legibly and durably applied by any method upon the

external surface.

Marking shall be checked in accordance with the test method described in 6.1.9.

4.134.12 Repairs

Repairs shall be carried out when there is a fault. The fault can be

— localized damage,

© ISO 2022 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/DISFDIS 24131-1:2022(E)

— holding point,

— earthing surface for the non-porosity test, or

— other lining fault.

The lining manufacturer should establish the repair procedure. The material to be used shall satisfy two

conditions:

— be suitable for protecting pipes under the required service conditions;

— be compatible in all aspects with the previously applied lining.

The repairs shall conform to the requirements specified in 4.5, 4.7 and 4.8.

The information about handling, transportation and storage of polyurethane lined pipes is given in

Annex B.

5 Performance requirements

5.1 General

The following technical requirements shall be demonstrated by performance tests in order to verify the

lining material and process prior to production lining. Performance tests shall be in accordance with the

overview of requirements provided in Table A.1. Where there is a change of lining material or process,

the performance tests shall be undertaken on the new lining material or process.

5.2 Materials in contact with water intended for human consumption

When used under the conditions for which it is designed, in permanent or in temporar

...

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 24131-1

ISO/TC 5/SC 2

Internal protection by polymeric

Secretariat: AFNOR

lining for ductile iron pipes —

Voting begins on:

2023-01-05 Requirements and test methods —

Voting terminates on:

Part 1:

2023-03-02

Polyurethane lining

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

ISO/FDIS 24131-1:2023(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

NATIONAL REGULATIONS. © ISO 2023

---------------------- Page: 1 ----------------------

ISO/FDIS 24131-1:2023(E)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 24131-1

ISO/TC 5/SC 2

Internal protection by polymeric

Secretariat: AFNOR

lining for ductile iron pipes —

Voting begins on:

Requirements and test methods —

Voting terminates on:

Part 1:

Polyurethane lining

COPYRIGHT PROTECTED DOCUMENT

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

RECIPIENTS OF THIS DRAFT ARE INVITED TO

ISO copyright office

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

CP 401 • Ch. de Blandonnet 8

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

CH-1214 Vernier, Geneva

DOCUMENTATION.

Phone: +41 22 749 01 11

IN ADDITION TO THEIR EVALUATION AS

Reference number

Email: copyright@iso.org

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

ISO/FDIS 24131-1:2022(E)

Website: www.iso.org

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

Published in Switzerland

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

ii

© ISO 2023 – All rights reserved

NATIONAL REGULATIONS. © ISO 2022

---------------------- Page: 2 ----------------------

ISO/FDIS 24131-1:2022(E)

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Technical requirements . 3

4.1 General . 3

4.2 Surface preparation . 3

4.3 Surface roughness . 4

4.4 Lining appearance . 4

4.5 Lining thickness . 4

4.6 Adhesion . 4

4.7 Cross linkage . 4

4.8 Non-porosity . 5

4.9 Hardness . 5

4.10 Protection of pipe ends . 5

4.11 Marking . 5

4.12 Repairs . 5

5 Performance requirements . .6

5.1 General . 6

5.2 Materials in contact with water intended for human consumption . 6

5.3 Abrasion resistance only for sewage applications . 6

5.4 Chemical resistance only for sewage applications . 6

5.5 Indirect impact resistance . 6

5.6 Resistance to hot water . 6

5.7 Specific lining resistance . . 6

5.8 Resistance to ovalization . 7

5.9 Elongation at break . 7

6 Test methods . 7

6.1 Routine tests . . 7

6.1.1 Surface preparation . 7

6.1.2 Surface roughness . 7

6.1.3 Lining appearance . . 7

6.1.4 Lining thickness . 7

6.1.5 Adhesion . 7

6.1.6 Differential scanning calorimetry (DSC) . 8

6.1.7 Non-porosity . 8

6.1.8 Hardness . 8

6.1.9 Marking . . . 8

6.1.10 Repairs . 8

6.2 Performance test . 8

6.2.1 Abrasion resistance only for sewage applications . 8

6.2.2 Chemical resistance only for sewage applications . 8

6.2.3 Indirect impact resistance . 8

6.2.4 Resistance to hot water . 9

6.2.5 Specific lining resistance . 9

6.2.6 Resistance to ovalization . 10

6.2.7 Elongation at break . 10

Annex A (normative) Quality assurance .11

Annex B (informative) Handling, transportation and storage .13

Bibliography .14

iii

© ISO 2022 – All rights reserved

---------------------- Page: 3 ----------------------

ISO/FDIS 24131-1:2022(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 5, Ferrous metal pipes and metallic fittings,

Subcommittee SC 2, Cast iron pipes, fittings and their joints.

A list of all parts in the ISO 24131 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

© ISO 2022 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/FDIS 24131-1:2022(E)

Introduction

The ISO 24131 series specifies the requirements and test methods applicable to factory applied

polymeric linings for ductile iron pipes according to ISO 2531, ISO 7186 and ISO 16631. The ISO 24131

series is intended to include several types of polymeric linings.

v

© ISO 2022 – All rights reserved

---------------------- Page: 5 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 24131-1:2022(E)

Internal protection by polymeric lining for ductile iron

pipes — Requirements and test methods —

Part 1:

Polyurethane lining

1 Scope

This document specifies the requirements and test methods applicable to factory applied internal

polyurethane lining for ductile iron pipes according to ISO 2531, ISO 7186 and ISO 16631.

It covers internal linings for use in the conveyance of raw water, potable water and sewage water for

operating temperature up to 50 °C.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2531, Ductile iron pipes, fittings, accessories and their joints for water applications

ISO 7186:2011, Ductile iron products for sewerage applications

ISO 16631, Ductile iron pipes, fittings, accessories and their joints compatible with plastic (PVC or PE)

piping systems, for water applications and for plastic pipeline connections, repair and replacement

ISO 8503-1, Preparation of steel substrates before application of paints and related products — Surface

roughness characteristics of blast-cleaned steel substrates — Part 1: Specifications and definitions for ISO

surface profile comparators for the assessment of abrasive blast-cleaned surfaces

ISO 868, Plastics and ebonite — Determination of indentation hardness by means of a durometer (Shore

hardness)

ISO 62, Plastics — Determination of water absorption

ISO 4624, Paints and varnishes — Pull-off test for adhesion

ISO 527-3, Plastics — Determination of tensile properties — Part 3: Test conditions for films and sheets

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 2531 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

1

© ISO 2022 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/FDIS 24131-1:2022(E)

3.1

polyurethane lining

factory applied lining which consists of polyurethane (3.2) on the inside of the pipe

Note 1 to entry: See Figure 1.

Key

1 gasket seat

2 pipe barrel

3 spigot end

4 lining

5 internal socket profile

Figure 1 — Location of the defined pipe areas

3.2

polyurethane

polymers made by combining diisocyanates and polyols

3.3

operating temperature

applicable temperatures under which the product maintains its properties

3.4

chalking

superficial reaction of polyurethane lining (3.1) due to exposure to UV-radiation

Note 1 to entry: The process is confined to the surface only and results in a dulling of the surface.

3.5

minimum lining thickness

minimum value of the lining thickness measured at the lined item

3.6

adhesion

force per unit area, applied perpendicular to the surface, which is necessary to separate the lining from

its substrate

3.7

cross linkage

chemical reaction between polyurethane (3.2) resin and hardener to form the final cured lining

3.8

non-porosity

absence of electrical puncture in a high voltage test (holiday test) under defined test conditions

3.9

hardness

resistance of the lining to the penetration of a ball under defined test conditions

2

© ISO 2022 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/FDIS 24131-1:2022(E)

3.10

protection of pipe ends

factory applied coating/lining on spigot end and internal socket profile of pipes

Note 1 to entry: See Figure 1.

3.11

abrasion resistance

ability of materials and structures to withstand abrasion

3.12

indirect impact resistance

impact energy applied from outside of the pipe with deformation to which a lining can withstand

without damage under defined test conditions

3.13

specific lining resistance

surface related electric resistance of the lining perpendicular to the pipe wall

3.14

ovalization

100 times the measured vertical deflection, (caused by the applied load) divided by the measured pipe

external diameter

3.15

routine test

test carried out to control the manufacturing process

Note 1 to entry: The frequency of the test is defined by this document or the manufacturer.

3.16

performance test

test which is done once and thereafter only when there is a change in the lining material or lining

process

4 Technical requirements

4.1 General

The following technical requirements shall be demonstrated by routine tests applied in production,

on in-process and finished lined products with defined frequency. Routine tests shall be in accordance

with the overview of requirements provided in Table A.2.

Quality assurance for polyurethane lining shall be in accordance with Annex A.

4.2 Surface preparation

Prior to lining application, all surfaces to be lined shall be substantially clean and free from oil, grease

and moisture.

In cold weather, or anytime when moisture tends to condense on the surface of the pipe, it shall be

uniformly warmed for sufficient time to dry prior to cleaning. The surface temperature shall be

maintained at least 3 °C above the dew point.

Surface preparation shall be designed in order to reach the required performances specified in this

document. It is the responsibility of the manufacturer to demonstrate the fitness for purpose of surface

3

© ISO 2022 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/FDIS 24131-1:2022(E)

preparation technology and to put in place a quality control procedure to ensure the stability of those

performances.

NOTE The requirements of Class Sa 2.5 of ISO 8501-1 and ≤ Rating 3 dust quantity and Class 2 fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.