ISO 20421-1:2019

(Main)Cryogenic vessels — Large transportable vacuum-insulated vessels — Part 1: Design, fabrication, inspection and testing

Cryogenic vessels — Large transportable vacuum-insulated vessels — Part 1: Design, fabrication, inspection and testing

This document specifies requirements for the design, fabrication, inspection and testing of large transportable vacuum-insulated cryogenic vessels of more than 450 l volume, which are permanently (fixed tanks) or not permanently (demountable tanks and portable tanks) attached to a means of transport, for one or more modes of transport. This document applies to large transportable vacuum-insulated cryogenic vessels for fluids specified in 3.1 and does not apply to vessels designed for toxic fluids. This document does not include the general vehicle requirements, e.g. running gear, brakes, lighting, etc. NOTE 1 This document does not cover specific requirements for refillable liquid-hydrogen tanks that are primarily dedicated as fuel tanks in vehicles. For fuel tanks used in land vehicles, see ISO 13985. NOTE 2 This document does not cover specific requirements for refillable liquid hydrogen and LNG tanks that are primarily dedicated as fuel tanks in vehicles. For fuel tanks used in vehicles, see ISO 13985.

Récipients cryogéniques — Récipients transportables isolés sous vide de grande contenance — Partie 1: Conception, fabrication, inspection et essais

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 20421-1

Second edition

2019-06

Cryogenic vessels — Large

transportable vacuum-insulated

vessels —

Part 1:

Design, fabrication, inspection and

testing

Récipients cryogéniques — Récipients transportables isolés sous vide

de grande contenance —

Partie 1: Conception, fabrication, inspection et essais

Reference number

ISO 20421-1:2019(E)

©

ISO 2019

---------------------- Page: 1 ----------------------

ISO 20421-1:2019(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2019

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2019 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 20421-1:2019(E)

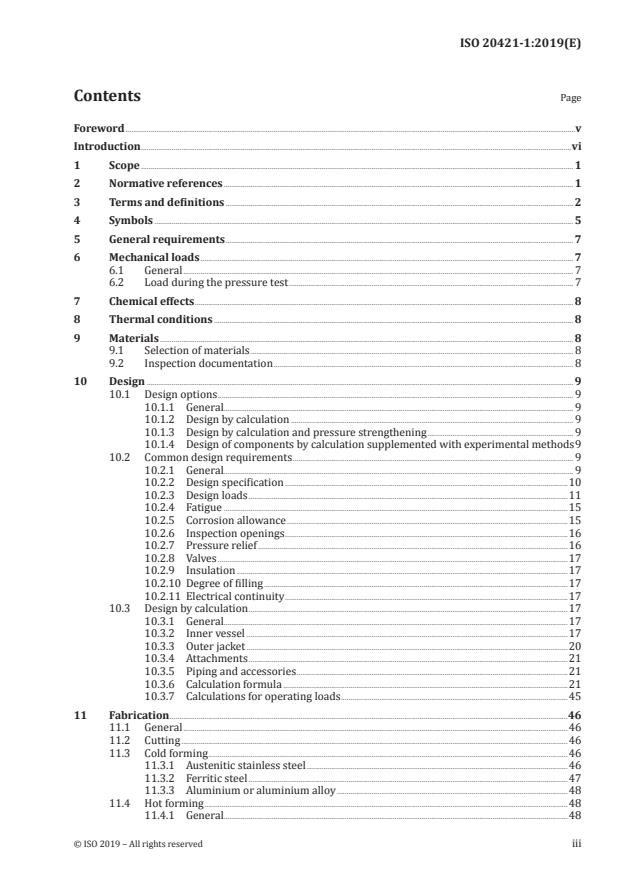

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Symbols . 5

5 General requirements . 7

6 Mechanical loads . 7

6.1 General . 7

6.2 Load during the pressure test . 7

7 Chemical effects . 8

8 Thermal conditions . 8

9 Materials . 8

9.1 Selection of materials . 8

9.2 Inspection documentation . 8

10 Design . 9

10.1 Design options . 9

10.1.1 General. 9

10.1.2 Design by calculation . 9

10.1.3 Design by calculation and pressure strengthening . 9

10.1.4 Design of components by calculation supplemented with experimental methods 9

10.2 Common design requirements . 9

10.2.1 General. 9

10.2.2 Design specification .10

10.2.3 Design loads .11

10.2.4 Fatigue .15

10.2.5 Corrosion allowance .15

10.2.6 Inspection openings .16

10.2.7 Pressure relief .16

10.2.8 Valves .17

10.2.9 Insulation .17

10.2.10 Degree of filling .17

10.2.11 Electrical continuity .17

10.3 Design by calculation .17

10.3.1 General.17

10.3.2 Inner vessel .17

10.3.3 Outer jacket .20

10.3.4 Attachments .21

10.3.5 Piping and accessories .21

10.3.6 Calculation formula .21

10.3.7 Calculations for operating loads .45

11 Fabrication .46

11.1 General .46

11.2 Cutting .46

11.3 Cold forming .46

11.3.1 Austenitic stainless steel .46

11.3.2 Ferritic steel .47

11.3.3 Aluminium or aluminium alloy .48

11.4 Hot forming .48

11.4.1 General.48

© ISO 2019 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 20421-1:2019(E)

11.4.2 Austenitic stainless steel .48

11.4.3 Ferritic steel .48

11.4.4 Aluminium or aluminium alloy .48

11.5 Manufacturing tolerances .48

11.5.1 General.48

11.5.2 Plate alignment .49

11.5.3 Thickness .50

11.5.4 Dished ends .50

11.5.5 Cylinders .50

11.6 Welding .53

11.6.1 General.53

11.6.2 Qualification .53

11.6.3 Temporary attachments .53

11.6.4 Welded joints .53

11.7 Non-welded joints .54

12 Inspection and testing .54

12.1 Quality plan .54

12.1.1 General.54

12.1.2 Inspection stages during manufacture of an inner vessel .54

12.1.3 Additional inspection stages during manufacture of a large transportable

cryogenic vessel .55

12.2 Production control test plates .55

12.2.1 Requirements .55

12.2.2 Extent of testing .55

12.3 Non-destructive testing .56

12.3.1 General.56

12.3.2 Extent of examination for surface imperfections .56

12.3.3 Extent of examination for inner-vessel weld seams.57

12.3.4 Acceptance criteria for surface and volumetric imperfections as classified

in ISO 6520-1 .57

12.4 Rectification .58

12.5 Pressure testing .59

13 Marking and labelling .59

14 Final acceptance test .59

15 Periodic inspection .60

16 Documentation .60

Annex A (informative) Examples of tank plates .61

Annex B (informative) Elastic stress analysis .64

Annex C (normative) Additional requirements for 9 % Ni steel.72

Annex D (normative) Pressure strengthening of vessels from austenitic stainless steels .74

Annex E (informative) Specific weld details .87

Annex F (normative) Outer-jacket relief devices.91

Annex G (informative) Base materials .92

Annex H (informative) Components subject to external pressure (pressure on the convex

surface) — Calculation .101

Annex I (informative) Design of openings in cylinders, spheres and cones — Calculation .112

Annex J (normative) Reference material & equivalent thickness .121

Annex K (normative) Refrigerated liquefied gases .124

Bibliography .125

iv © ISO 2019 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 20421-1:2019(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 220, Cryogenic vessels.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

This second edition cancels and replaces the first edition (ISO 20421-1:2006), which has been technically

revised. It also incorporates ISO 20421-1:2006/Cor 1:2007. The main changes compared to the previous

edition are as follows:

— Subclause 12.3 has been revised;

— Annex D has been revised;

— Chinese materials have been added in Annex G.

A list of all parts in the ISO 20421 series can be found on the ISO website.

© ISO 2019 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 20421-1:2019(E)

Introduction

[1]

This document has been written so that it is suitable to be referenced in the UN Model Regulations .

This document does not include the general vehicle requirements, e.g. running gear, brakes, lighting,

etc., for which the relevant standards/regulations apply.

vi © ISO 2019 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 20421-1:2019(E)

Cryogenic vessels — Large transportable vacuum-insulated

vessels —

Part 1:

Design, fabrication, inspection and testing

1 Scope

This document specifies requirements for the design, fabrication, inspection and testing of large

transportable vacuum-insulated cryogenic vessels of more than 450 l volume, which are permanently

(fixed tanks) or not permanently (demountable tanks and portable tanks) attached to a means of

transport, for one or more modes of transport.

This document applies to large transportable vacuum-insulated cryogenic vessels for fluids specified in

3.1 and does not apply to vessels designed for toxic fluids.

This document does not include the general vehicle requirements, e.g. running gear, brakes, lighting, etc.

NOTE 1 This document does not cover specific requirements for refillable liquid-hydrogen tanks that are

primarily dedicated as fuel tanks in vehicles. For fuel tanks used in land vehicles, see ISO 13985.

NOTE 2 This document does not cover specific requirements for refillable liquid hydrogen and LNG tanks that

are primarily dedicated as fuel tanks in vehicles. For fuel tanks used in vehicles, see ISO 13985.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3834-2, Quality requirements for fusion welding of metallic materials — Part 2: Comprehensive quality

requirements

ISO 4126-2, Safety devices for protection against excessive pressure — Part 2: Bursting disc safety devices

ISO 5817, Welding — Fusion-welded joints in steel, nickel, titanium and their alloys (beam welding

excluded) — Quality levels for imperfections

ISO 9606-1, Qualification testing of welders — Fusion welding — Part 1: Steels

ISO 9606-2, Qualification test of welders — Fusion welding — Part 2: Aluminium and aluminium alloys

ISO 9712, Non-destructive testing — Qualification and certification of NDT personnel

ISO 10042, Welding — Arc-welded joints in aluminium and its alloys — Quality levels for imperfections

ISO 10474:2013, Steel and steel products — Inspection documents

ISO 10675-1, Non-destructive testing of welds — Acceptance levels for radiographic testing — Part 1: Steel,

nickel, titanium and their alloys

ISO 14732, Welding personnel — Qualification testing of welding operators and weld setters for mechanized

and automatic welding of metallic materials

© ISO 2019 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO 20421-1:2019(E)

ISO 15613, Specification and qualification of welding procedures for metallic materials — Qualification

based on pre-production welding test

ISO 15614-1, Specification and qualification of welding procedures for metallic materials — Welding

procedure test — Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

ISO 15614-2, Specification and qualification of welding procedures for metallic materials — Welding

procedure test — Part 2: Arc welding of aluminium and its alloys

ISO 17635, Non-destructive testing of welds — General rules for metallic materials

ISO 17637, Non-destructive testing of welds — Visual testing of fusion-welded joints

ISO 20421-2, Cryogenic vessels — Large transportable vacuum-insulated vessels — Part 2: Operational

requirements

ISO 21010, Cryogenic vessels — Gas/material compatibility

ISO 21011, Cryogenic vessels — Valves for cryogenic service

ISO 21028-1, Cryogenic vessels — Toughness requirements for materials at cryogenic temperature —

Part 1: Temperatures below -80 degrees C

ISO 21028-2, Cryogenic vessels — Toughness requirements for materials at cryogenic temperature —

Part 2: Temperatures between -80 degrees C and -20 degrees C

ISO 21013-3, Cryogenic vessels — Pressure-relief accessories for cryogenic service — Part 3: Sizing and

capacity determination

ISO 23208, Cryogenic vessels — Cleanliness for cryogenic service

ASME VIII-2, Rules for construction of pressure vessels, Division 2, Alternative Rules

EN 13445-3, Unfired pressure vessels — Part 3: Design

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

cryogenic fluid

refrigerated liquefied gas

gas which is partially liquid because of its low temperature (see Table K.1)

Note 1 to entry: This includes totally evaporated liquids and supercritical fluids.

Note 2 to entry: In the context of this document, the refrigerated but non-toxic gases and gas mixtures given in

Table K.1 are referred to as cryogenic fluids.

3.2

large transportable cryogenic vessel

tank

thermally insulated vessel of more than 450 l intended for the transport of one or more cryogenic fluids

(3.1), consisting of an inner vessel (3.4), an outer jacket (3.5), all of the valves and service equipment (3.9)

together with the structural parts

Note 1 to entry: The large transportable cryogenic vessel comprises a complete assembly that is ready for service.

2 © ISO 2019 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 20421-1:2019(E)

3.3

insulation

vacuum interspace between the inner vessel (3.4) and the outer jacket (3.5)

Note 1 to entry: The space may or may not be filled with material to reduce the heat transfer between the inner

vessel and the outer jacket.

3.4

inner vessel

pressure (3.16) vessel intended to contain the cryogenic fluid (3.1) to be transported

3.5

outer jacket

gas-tight enclosure which contains the inner vessel (3.4) and enables the vacuum to be established

3.6

normal operation

intended operation of the vessel at a pressure (3.16) not greater than the maximum allowable working

pressure including the handling loads (3.7)

3.7

handling load

load exerted on the transportable cryogenic vessel in all normal conditions of transport including

loading, unloading, moving and lifting

3.8

piping system

all pipes, tubes and associated components which can come in contact with cryogenic fluids (3.1)

including valves, fittings, pressure-relief devices and their supports

3.9

service equipment

measuring instruments and filling, discharge, venting, safety, heating, cooling and insulating devices

including any equipment for storing cooling fluids

3.10

manufacturer

company that carries out the final assembly, including the final

acceptance test, of the large transportable cryogenic vessel (3.2)

3.11

gross volume

internal volume of the inner vessel (3.4), excluding nozzles, pipes, etc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.