ISO 11344:2016

(Main)Rubber, raw synthetic — Determination of the molecular-mass distribution of solution polymers by gel permeation chromatography

Rubber, raw synthetic — Determination of the molecular-mass distribution of solution polymers by gel permeation chromatography

ISO 11344:2016 describes a method for the determination of the molecular mass, expressed as polystyrene, and the molecular-mass distribution of polymers produced in solution which are completely soluble in tetrahydrofuran (THF) and which have a molecular-mass range from 5 × 103 to 1 × 106. It is not the purpose of this International Standard to explain the theory of gel permeation chromatography.

Caoutchouc synthétique brut — Détermination de la répartition de la masse moléculaire pour les caoutchoucs polymérisés en solution par chromatographie par perméation de gel

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11344

Second edition

2016-10-15

Rubber, raw synthetic —

Determination of the molecular-mass

distribution of solution polymers by

gel permeation chromatography

Caoutchouc synthétique brut — Détermination de la répartition de la

masse moléculaire pour les caoutchoucs polymérisés en solution par

chromatographie par perméation de gel

Reference number

ISO 11344:2016(E)

©

ISO 2016

---------------------- Page: 1 ----------------------

ISO 11344:2016(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 11344:2016(E)

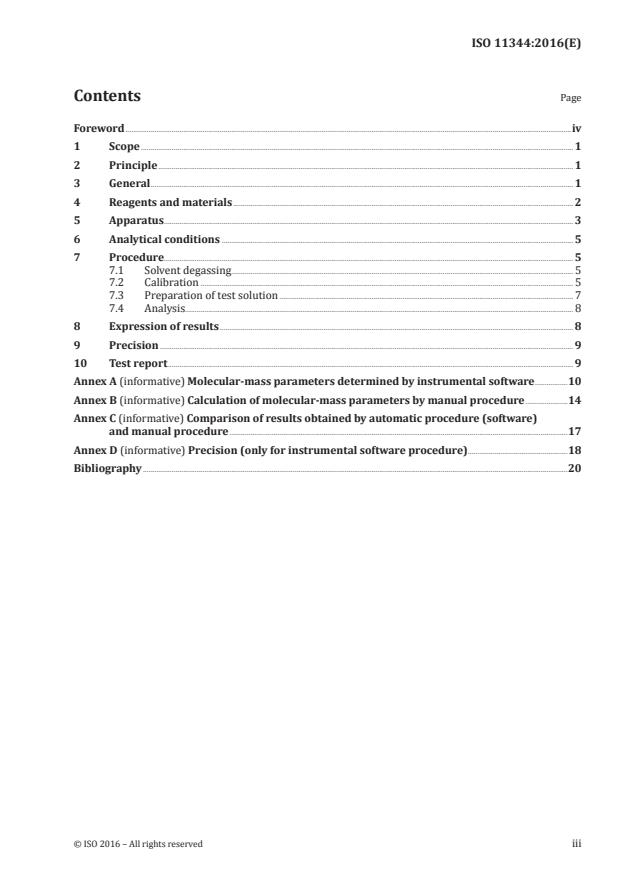

Contents Page

Foreword .iv

1 Scope . 1

2 Principle . 1

3 General . 1

4 Reagents and materials . 2

5 Apparatus . 3

6 Analytical conditions . 5

7 Procedure. 5

7.1 Solvent degassing . . 5

7.2 Calibration . 5

7.3 Preparation of test solution . 7

7.4 Analysis. 8

8 Expression of results . 8

9 Precision . 9

10 Test report . 9

Annex A (informative) Molecular-mass parameters determined by instrumental software .10

Annex B (informative) Calculation of molecular-mass parameters by manual procedure .14

Annex C (informative) Comparison of results obtained by automatic procedure (software)

and manual procedure .17

Annex D (informative) Precision (only for instrumental software procedure) .18

Bibliography .20

© ISO 2016 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 11344:2016(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2. www.iso.org/directives

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received. www.iso.org/patents

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT), see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 45, Rubber and rubber products, Subcommittee

SC 2, Testing and analysis.

This second edition cancels and replaces the first edition (ISO 11344:2004), which has been technically

revised by replacing the hazardous o-dichlorobenzene with BHT (butylated hydroxy toluene) in the

procedure. It also incorporates the Technical Corrigendum ISO 11344:2004/Cor.1:2008.

iv © ISO 2016 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 11344:2016(E)

Rubber, raw synthetic — Determination of the molecular-

mass distribution of solution polymers by gel permeation

chromatography

WARNING 1 — Persons using this International Standard should be familiar with normal

laboratory practice. This International Standard does not purport to address all of the

safety problems, if any, associated with its use. It is the responsibility of the user to establish

appropriate safety and health practices and to ensure compliance with any national regulatory

conditions.

WARNING 2 — Certain procedures specified in this International Standard might involve

the use or generation of substances, or the generation of waste, that could constitute a local

environmental hazard. Reference should be made to appropriate documentation on safe

handling and disposal after use.

1 Scope

This International Standard describes a method for the determination of the molecular mass, expressed

as polystyrene, and the molecular-mass distribution of polymers produced in solution which are

3

completely soluble in tetrahydrofuran (THF) and which have a molecular-mass range from 5 × 10 to

6

1 × 10 .

It is not the purpose of this International Standard to explain the theory of gel permeation

chromatography.

2 Principle

The molecular components of a polymer are separated on the basis of macromolecule size on a gel

permeation column. A known quantity of a dilute solution of the polymer is injected into a stream of

solvent, which carries it through the column at a constant rate. The concentration of the separated

molecular components in the solvent stream is measured by a suitable detector. Through the use of

a calibration curve, both the number-average molecular mass (M ) and mass-average molecular mass

n

(M ) of the material analysed can be determined from the retention time and the corresponding

w

concentration.

3 General

3.1 Gel permeation chromatography (GPC), which is also known as size exclusion chromatography

(SEC), is a particular type of liquid chromatography which allows the separation of the various

components of a polymer based on molecular size.

3.2 The molecules of a polymer do not all have the same mass, but comprise a range of different

masses. For this reason, the usual concept of molecular mass is not applicable to polymeric materials.

Instead, different average molecular masses are determined as shown in Table 1.

© ISO 2016 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO 11344:2016(E)

Table 1 — Definitions of various kinds of molecular mass

2

Mass-average molecular mass M = Σ(N M )/Σ(N M )

w i i i i

= Σ(A M )/ΣA

i i i

Number-average molecular mass M = Σ(M N )/ΣN

n i i i

= ΣA /Σ(A /M )

i i i

3 2

z-Average molecular mass M = Σ(N M )/Σ(N M )

z i i i i

2

= Σ(A M )/Σ(A M )

i i i i

Peak molecular mass M Molecular mass at peak maximum

p

where

N is the number of molecules having a molecular mass of M ;

i i

A is the area of the time-slice that corresponds to molecular mass M .

i i

The molecular-mass distribution is an important parameter in determining the properties of the

polymer. It may be represented by the polydispersity D given by

DM= M

wn

NOTE Polymers invariably consist of macromolecules with a range of molecular sizes. Even the so-called

monodisperse polystyrenes have a polydispersity of 1,1 compared to a value of 1,0 for a pure compound with

a single molecular mass. As the range of molecular sizes present within the polymer increases, so does the

polydispersity.

4 Reagents and materials

4.1 Tetrahydrofuran (THF), with or without 2,6-di-tert-butyl-4-methylphenol (BHT), solvent for

the mobile phase, analytical grade.

4.2 THF containing 2,6-di-tert-butyl-4-methylphenol, solvent for sample dissolution, analytical

grade (THF containing BHT solution).

The solution of 2,6-di-tert-butyl-4-methylphenol (also known as BHT, butylated hydroxytoluene) in

THF is commercially available. For the purpose of this International Standard, the solution is called THF

containing BHT.

When it is difficult to find this solution in the market, the alternative can be obtained by adding 100 mg

to 500 mg of BHT to 1 l of THF. Preparation of this solution is also effective when a noticeable peak is

not obtained for BHT.

4.3 Set of certified polystyrene reference standards (minimum 10), with molecular masses in the

2 7

range 5 × 10 to 1 × 10 (depending on the sample molecular-mass range) and a very narrow molecular-

mass distribution (D < 1,10) (see Table 2 for an example of such a set, available from various chemical

suppliers).

2 © ISO 2016 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 11344:2016(E)

Table 2 — Set of polystyrene standards

Standard No. Actual molecular mass M D (= M /M )

i w n

1 1 030 000 1,05

2 770 000 1,04

3 336 000 1,03

4 210 000 1,03

5 156 000 1,03

6 66 000 1,03

7 30 300 1,03

8 22 000 1,03

9 11 600 1,03

10 7 000 1,04

11 5 050 1,05

5 Apparatus

Ordinary laboratory apparatus, plus the following:

5.1 Gel permeation chromatograph, consisting of the components specified in 5.1.1 to 5.1.8.

5.1.1 Solvent reservoir, of sufficient capacity to complete the analysis without refilling.

NOTE A large stock of THF is needed to avoid frequent refills. Changes in the quantity of dissolved air or

impurities due to addition of fresh solvent cause significant variations in the refractive index and can also affect

the retention time. Air bubbles at the pump head reduce the quantity of solvent pumped (leading to errors in

retention volumes and times) and can block the pump if the volume of the air bubbles reach excessive levels.

After adding fresh solvent, it takes 2 h to 3 h to obtain a stable baseline.

5.1.2 Automatic online degassing system or helium sparging of solvent reservoir, to stabilize the

solvent flow, mainly to prevent formation of bubbles in the solvent.

5.1.3 Pump, to ensure that the THF solvent flows at a constant rate, programmable over the range

0,1 ml/min to 2,0 ml/min with a high degree of precision.

3

5.1.4 Injector or automatic sampler, with a 100 mm (100 µl) injection loop.

5.1.5 Columns, packed with regular, rigid, porous spheres. The pore size on the column packing

−10

material is expressed either in Angström units (1 Å = 10 m), molecular weight range or size exclusion

limit molecular weight. The packing spheres are made of cross-linked polystyrene, obtained by

polymerization of styrene with divinylbenzene. The spheres shall have a nominal diameter in the range

3 µm to 10 µm. The columns are generally 150 mm to 300 mm long. The pore size is selected depending

on the range of molecular masses to be analysed.

3 4 4 5

NOTE 1 Four columns with pore sizes 10 Å, 10 Å, 10 Å and 10 Å were used when the repeatability and

reproducibility of the method described in this International Standard were determined. The solvent first enters

the column with the lowest porosity and exits from the column with the highest porosity. Other suitable columns

can be used. These types of column are available from many suppliers.

© ISO 2016 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO 11344:2016(E)

NOTE 2 The recommended column characteristics are:

— linear range: 1 000 to 400 000 000;

— guaranteed column efficiency: > 2 400 plates for 150 mm long columns and 4 800 plates for 300 mm long

columns; this is also known as a number of theoretical plates, N, as shown in Figure 1. The following formula

is used to calculate the theoretical plate number:

2

NV=×55,(4 W )

e 12

where

V is the retention volume to the peak maximum;

e

W is the peak width at half height — using the same units for V and W.

1/2 e

Express the result as the number of theoretical plates of total column length.

— Column arrangement: two to four columns (150 mm to 300 mm long and 4,6 mm to 8,0 mm ID).

Key

1 injection

2

V

e

N =

σ

2

V

e

=×55, 4

W

12

Figure 1 — Determination of the number of theoretical plates N by the half-height method

5.1.6 Detector.

Various types of detectors may be used, such as differential refractometer or UV.

5.1.7 Integrator, capable of integrating at least 150 time-slices during the elution of the polymer being

analysed.

5.1.8 Personal computer and software, to avoid long and difficult manual calculations.

5.2 PTFE filters, having a pore size of 0,50 µm or 0,45 µm.

3 3

5.3 10 cm (10 ml) and 250 mm (250 µl) syringes.

4 © ISO 2016 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 11344:2016(E)

5.4 Autocollector (optional), with glass vials.

5.5 Mixer.

6 Analytical conditions

Flow rate: 0,2 ml/min to 1,0 ml/min.

3

Injection volume: 100 mm (100 µl) of solution, or a quantity suitable for the volume of the column used.

The injection volume shall be matched to the set of columns used. The total injection volume shall not

exceed 250 µl. The concentration of the sample solution injected shall be 0,1 g/l to 5,0 g/l.

Column temperature: 40 °C - 45 °C.

7 Procedure

7.1 Solvent degassing

3

Degass 1 dm of solvent under vacuum and/or in an ultrasonic bath for about 30 min.

To obtain a constant baseline, degassing should preferably be done 12 h before use. From time to time,

the columns should be flushed, for a period of 8 h, with THF solvent, degassed as specified in this

subclause, to remove any peroxides left in the column.

If an automatic online degassing system is available, the degassing operation given in this subclause

can be omitted.

7.2 Calibration

7.2.1 Use polystyrene standards (4.3) dissolved in THF containing BHT solution (4.2) for calibration

purposes. To ensure constant peak size, weigh out a different amount of each individual standard as

3

a function of its molecular mass, for example 1 g/l [0,025 g in 25 cm of solution (4.2)] for molecular

3

masses around 1 000 000, 5 g/l [0,125 g in 25 cm of solution (4.2)] for molecular masses lower than

30 000. The calibration plot shall cover the entire range of molecular masses present in the polymer

being analysed.

7.2.2 Shake the solutions gently.

3

7.2.3 Filter each solution through a PTFE filter (5.2) attached to a 10 cm syringe.

NOTE The reference standard solutions can be kept in a refrigerator at 6 °C to 7 °C for a maximum of

3 months.

7.2.4 The calibration procedure described in 7.2.4.1 to 7.2.4.5 is given by way of example.

7.2.4.1 Prepare 11 solutions of polystyrene in accordance with Table 3.

© ISO 2016 – All rights reserved 5

---------------------- Page: 9 ----------------------

ISO 11344:2016(E)

Table 3 — Solutions of polystyrene reference standards

Concentration

Solution No. Actual molecular mass M

3

g in 25 cm of BHT solution (4.2)

1 0,025 1 030 000

2 0,025 770 000

3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.