ASTM A456/A456M-24

(Specification)Standard Specification for Magnetic Particle Examination of Large Crankshaft Forgings

Standard Specification for Magnetic Particle Examination of Large Crankshaft<brk/> Forgings

ABSTRACT

This test method deals with the acceptance criteria for the magnetic particle examination of forged steel crankshafts and forgings having large main bearing journal or crankpin diameters. Covered here are three classes of forgings, which shall be evaluated under two areas of inspection, namely: major critical areas, and minor critical areas. During inspection, magnetic particle indications shall be classified as: surface indications, which include nonmetallic inclusions or stringers, open or twist cracks, flakes, or pipes; open or pinpoint indications; and non-open indications. Procedures for dimpling, depressing, inspection, and product marking are also mentioned.

SCOPE

1.1 This is an acceptance specification for the magnetic particle inspection of forged steel crankshafts having main bearing journals or crankpins 4 in. [200 mm] or larger in diameter.

1.2 There are three classes, with acceptance standards of increasing severity:

1.2.1 Class 1.

1.2.2 Class 2 (originally the sole acceptance standard of this specification).

1.2.3 Class 3 (formerly covered in Supplementary Requirement S1 of Specification A456 – 64 (1970)).

1.3 This specification is not intended to cover continuous grain flow crankshafts (see Specification A983/A983M); however, Specification A986/A986M may be used for this purpose.

Note 1: Specification A668/A668M is a product specification which may be used for slab-forged crankshaft forgings that are usually twisted in order to set the crankpin angles, or for barrel forged crankshafts where the crankpins are machined in the appropriate configuration from a cylindrical forging.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 Unless the order specifies the applicable “M” specification designation, the material shall be furnished to the inch units.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A456/A456M − 24

Standard Specification for

Magnetic Particle Examination of Large Crankshaft

1

Forgings

This standard is issued under the fixed designation A456/A456M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This is an acceptance specification for the magnetic

particle inspection of forged steel crankshafts having main

2. Referenced Documents

bearing journals or crankpins 4 in. [200 mm] or larger in

2

2.1 ASTM Standards:

diameter.

A275/A275M Practice for Magnetic Particle Examination of

1.2 There are three classes, with acceptance standards of

Steel Forgings

increasing severity:

A668/A668M Specification for Steel Forgings, Carbon and

1.2.1 Class 1.

Alloy, for General Industrial Use

1.2.2 Class 2 (originally the sole acceptance standard of this

A788/A788M Specification for Steel Forgings, General Re-

specification).

quirements

1.2.3 Class 3 (formerly covered in Supplementary Require-

A966/A966M Practice for Magnetic Particle Examination of

ment S1 of Specification A456 – 64 (1970)).

Steel Forgings Using Alternating Current

A983/A983M Specification for Continuous Grain Flow

1.3 This specification is not intended to cover continuous

grain flow crankshafts (see Specification A983/A983M); Forged Carbon and Alloy Steel Crankshafts for Medium

Speed Diesel Engines

however, Specification A986/A986M may be used for this

purpose. A986/A986M Specification for Magnetic Particle Examina-

tion of Continuous Grain Flow Crankshaft Forgings

NOTE 1—Specification A668/A668M is a product specification which

E1316 Terminology for Nondestructive Examinations

may be used for slab-forged crankshaft forgings that are usually twisted in

E1417/E1417M Practice for Liquid Penetrant Testing

order to set the crankpin angles, or for barrel forged crankshafts where the

crankpins are machined in the appropriate configuration from a cylindrical

3. Terminology

forging.

3.1 Definitions of Terms Specific to This Standard:

1.4 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in 3.1.1 For definitions of terms used in this standard, refer to

Specification A788/A788M and Terminology E1316.

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

4. Classification of Indications

values from the two systems may result in non-conformance

with the standard. 4.1 Magnetic particle indications on the surface of the

crankshaft shall be classified as follows:

1.5 Unless the order specifies the applicable “M” specifica-

4.1.1 Open cracks, flake, or pipe.

tion designation, the material shall be furnished to the inch

4.1.2 Nonmetallic inclusions or stringers occurring in a

units.

longitudinal direction.

1.6 This international standard was developed in accor-

4.1.3 Twist cracks or nonmetallic inclusions usually occur-

dance with internationally recognized principles on standard-

ring at 45° to 70° from the axis of the journal.

ization established in the Decision on Principles for the

4.2 They shall also be classified as follows:

Development of International Standards, Guides and Recom-

4.2.1 Open indications are visible after removal of the

magnetic particles or can be detected by the use of contrast dye

penetrant, as described in Type II of Practice E1417/E1417M.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys, and is the direct responsibility of Subcommittee

2

A01.06 on Steel Forgings and Billets. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2024. Published May 2024. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1999. Last previous edition approved in 2023 as A456/A456M – 08 Standards volume information, refer to the standard’s Document Summary page on

(2023). DOI: 10.1520/A0456_A0456M-24. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A456/A456M − 24

1

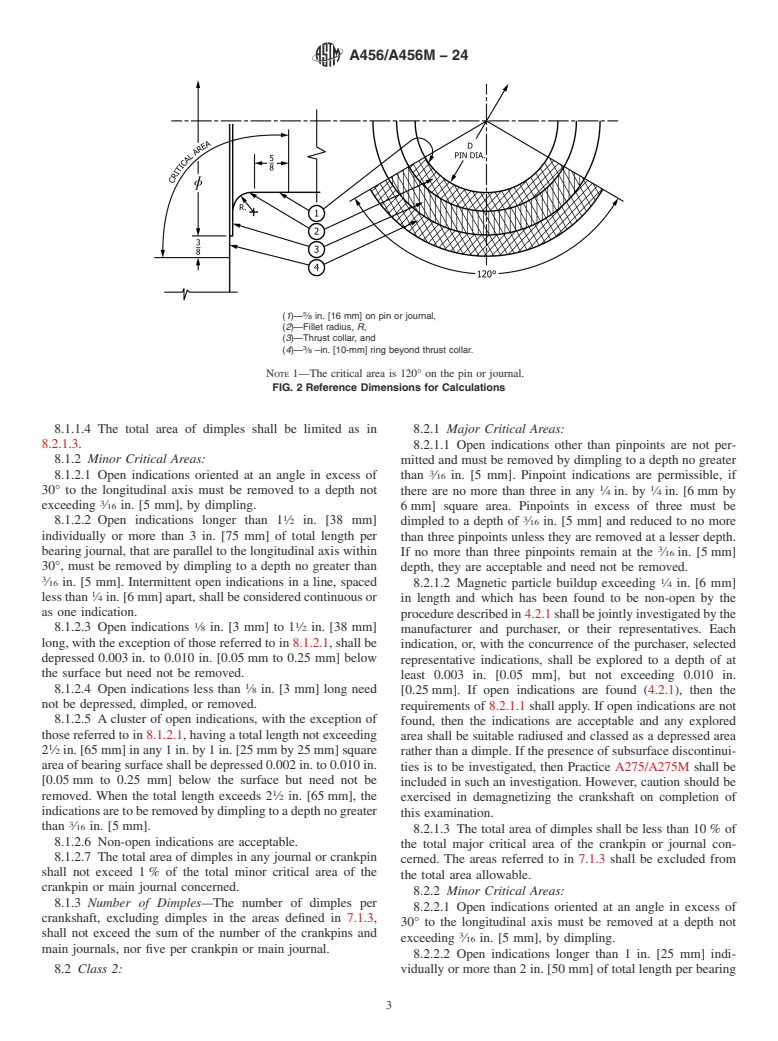

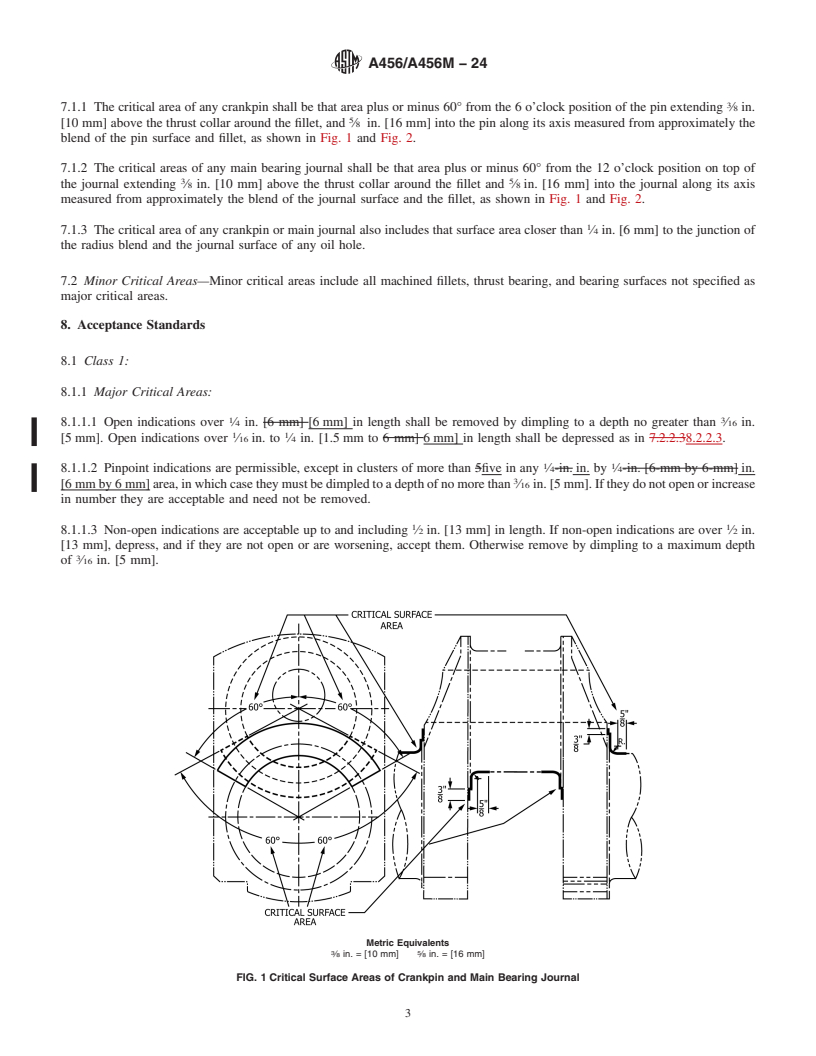

4.2.1.1 Pinpoint indications are open indications ⁄16 in. 7.1.2 The critical areas of any main bearing journal shall be

[1.5 mm] in max

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A456/A456M − 08 (Reapproved 2023) A456/A456M − 24

Standard Specification for

Magnetic Particle Examination of Large Crankshaft

1

Forgings

This standard is issued under the fixed designation A456/A456M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This is an acceptance specification for the magnetic particle inspection of forged steel crankshafts having main bearing

journals or crankpins 4 in. [200 mm] or larger in diameter.

1.2 There are three classes, with acceptance standards of increasing severity:

1.2.1 Class 1.

1.2.2 Class 2 (originally the sole acceptance standard of this specification).

1.2.3 Class 3 (formerly covered in Supplementary Requirement S1 of Specification A456 – 64 (1970)).

1.3 This specification is not intended to cover continuous grain flow crankshafts (see Specification A983/A983M); however,

Specification A986/A986M may be used for this purpose.

NOTE 1—Specification A668/A668M is a product specification which may be used for slab-forged crankshaft forgings that are usually twisted in order

to set the crankpin angles, or for barrel forged crankshafts where the crankpins are machined in the appropriate configuration from a cylindrical forging.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.5 Unless the order specifies the applicable “M” specification designation, the material shall be furnished to the inch units.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys, and is the direct responsibility of Subcommittee A01.06

on Steel Forgings and Billets.

Current edition approved March 15, 2023May 1, 2024. Published April 2023May 2024. Originally approved in 1999. Last previous edition approved in 20182023 as

A456/A456M – 08 (2018).(2023). DOI: 10.1520/A0456_A0456M-08R23.10.1520/A0456_A0456M-24.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A456/A456M − 24

2. Referenced Documents

2

2.1 ASTM Standards:

A275/A275M Practice for Magnetic Particle Examination of Steel Forgings

A668/A668M Specification for Steel Forgings, Carbon and Alloy, for General Industrial Use

A788/A788M Specification for Steel Forgings, General Requirements

A966/A966M Practice for Magnetic Particle Examination of Steel Forgings Using Alternating Current

A983/A983M Specification for Continuous Grain Flow Forged Carbon and Alloy Steel Crankshafts for Medium Speed Diesel

Engines

A986/A986M Specification for Magnetic Particle Examination of Continuous Grain Flow Crankshaft Forgings

E1316 Terminology for Nondestructive Examinations

E1417/E1417M Practice for Liquid Penetrant Testing

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 For definitions of terms used in this standard, refer to Specification A788/A788M and Terminology E1316.

4. Classification of Indications

4.1 Magnetic particle indications on the surface of the crankshaft shall be classified as follows:

4.1.1 Open cracks, flake, or pipe.

4.1.2 Nonmetallic inclusions or stringers occurring in a longitudinal direction.

4.1.3 Twist cracks or nonmetallic inclusions usually occurring at 4545° to 70° from the axis of the journal.

4.2 They shall also be classified as follows:

4.2.1 Open indications are visible after removal of the magnetic particles or can be detected by the use of contrast dye penetrant,

as described in Type II of Practice E1417/E1417M.

1

4.2.1.1 Pinpoint indications are open indications ⁄16 in. [1.5 mm] in maximum dimension, as detected by application of Type II

of Practice E1417/E1417M.

4.2.2 Non-open ind

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.