ISO/FDIS 27919-2

(Main)Carbon dioxide capture

Carbon dioxide capture

Captage du dioxyde de carbone

General Information

Standards Content (sample)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 27919-2

ISO/TC 265

Carbon dioxide capture —

Secretariat: SCC

Voting begins on:

Part 2:

2021-06-09

Evaluation procedure to assure and

Voting terminates on:

maintain stable performance of

2021-08-04

post-combustion CO2 capture plant

integrated with a power plant

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

ISO/FDIS 27919-2:2021(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

NATIONAL REGULATIONS. ISO 2021

---------------------- Page: 1 ----------------------

ISO/FDIS 27919-2:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/FDIS 27919-2:2021(E)

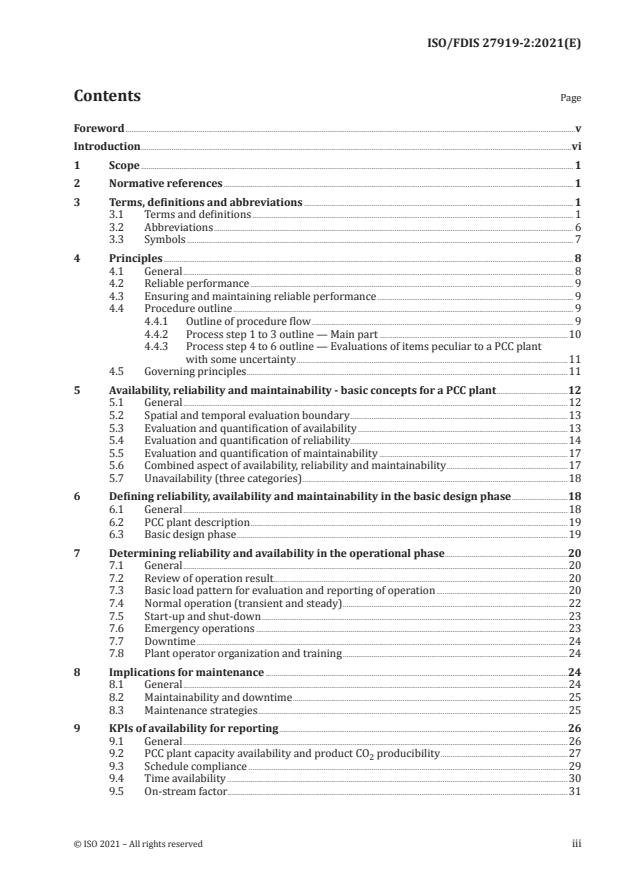

Contents Page

Foreword ..........................................................................................................................................................................................................................................v

Introduction ................................................................................................................................................................................................................................vi

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms, definitions and abbreviations ............................................................................................................................................ 1

3.1 Terms and definitions ....................................................................................................................................................................... 1

3.2 Abbreviations ........................................................................................................................................................................................... 6

3.3 Symbols ......................................................................................................................................................................................................... 7

4 Principles ..................................................................................................................................................................................................................... 8

4.1 General ........................................................................................................................................................................................................... 8

4.2 Reliable performance ........................................................................................................................................................................ 9

4.3 Ensuring and maintaining reliable performance ...................................................................................................... 9

4.4 Procedure outline ................................................................................................................................................................................. 9

4.4.1 Outline of procedure flow ........................................................................................................................................ 9

4.4.2 Process step 1 to 3 outline — Main part ..................................................................................................10

4.4.3 Process step 4 to 6 outline — Evaluations of items peculiar to a PCC plantwith some uncertainty .............................................................................................................................................11

4.5 Governing principles .......................................................................................................................................................................11

5 Availability, reliability and maintainability - basic concepts for a PCC plant .....................................12

5.1 General ........................................................................................................................................................................................................12

5.2 Spatial and temporal evaluation boundary .................................................................................................................13

5.3 Evaluation and quantification of availability .............................................................................................................13

5.4 Evaluation and quantification of reliability ......... ........................................................................................................14

5.5 Evaluation and quantification of maintainability ..................................................................................................17

5.6 Combined aspect of availability, reliability and maintainability ...............................................................17

5.7 Unavailability (three categories) ..........................................................................................................................................18

6 Defining reliability, availability and maintainability in the basic design phase .............................18

6.1 General ........................................................................................................................................................................................................18

6.2 PCC plant description .....................................................................................................................................................................19

6.3 Basic design phase ............................................................................................................................................................................19

7 Determining reliability and availability in the operational phase................................................................20

7.1 General ........................................................................................................................................................................................................20

7.2 Review of operation result .........................................................................................................................................................20

7.3 Basic load pattern for evaluation and reporting of operation ....................................................................20

7.4 Normal operation (transient and steady) .....................................................................................................................22

7.5 Start-up and shut-down ...............................................................................................................................................................23

7.6 Emergency operations ..................................................................................................................................................................23

7.7 Downtime .................................................................................................................................................................................................24

7.8 Plant operator organization and training .....................................................................................................................24

8 Implications for maintenance .............................................................................................................................................................24

8.1 General ........................................................................................................................................................................................................24

8.2 Maintainability and downtime ...............................................................................................................................................25

8.3 Maintenance strategies .................................................................................................................................................................25

9 KPIs of availability for reporting ......................................................................................................................................................26

9.1 General ........................................................................................................................................................................................................26

9.2 PCC plant capacity availability and product CO producibility ..................................................................27

9.3 Schedule compliance ......................................................................................................................................................................29

9.4 Time availability .................................................................................................................................................................................30

9.5 On-stream factor .................................................................................................................................................................................31

© ISO 2021 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/FDIS 27919-2:2021(E)

Annex A (informative) Detailed evaluation procedure to assure and maintain stable

performance of a post-combustion CO capture plant ..............................................................................................33

Annex B (informative) The reference plant and its component experience ............................................................41

Annex C (informative) Technology Qualification ..................................................................................................................................47

Annex D (informative) Classification of influences for PCC plant capacity availability and

Product CO producibility in Clause 9 .........................................................................................................................................48

Annex E (informative) PCC plant achievability .......................................................................................................................................50

Annex F (informative) Calculation example of each KPI ...............................................................................................................52

Annex G (Informative) Map of key issues and items to be checked relating the performance

requirement ...........................................................................................................................................................................................................57

Bibliography .............................................................................................................................................................................................................................61

iv © ISO 2021 – All rights reserved---------------------- Page: 4 ----------------------

ISO/FDIS 27919-2:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/ iso/ foreword .html.This document was prepared by Technical Committee ISO/TC265, Carbon dioxide capture, transportation,

and geological storage.A list of all parts in the ISO 27919 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.© ISO 2021 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/FDIS 27919-2:2021(E)

Introduction

Atmospheric carbon dioxide (CO ) emissions must be reduced to meet climate change mitigation

targets. Including carbon dioxide capture and storage (CCS) in current emission reduction approaches

increases the probability of meeting these targets at the lowest cost to the global economy. CO capture

from gases produced by combustion of carbonaceous fuels is the only technology capable of dealing

directly with emissions from power plants and other industrial sectors, such as cement manufacture

and fertilizer production.This document is the second in a series of standards for post-combustion CO capture (PCC) from a

power plant using a liquid-based chemical absorption process. Building on ISO 27919-1 on evaluation

of key performance indicators (KPIs), this document provides an evaluation procedure to assure and

maintain reliable performance of a PCC plant integrated with a power plant. New or revised standards

focusing on other CO capture technologies and approaches will be developed later.

PCC is applicable to all combustion-based thermal power plants. A simplified block diagram illustrating

the PCC process is shown in Figure 1.Figure 1 — Simplified block diagram of PCC

In a typical power generation facility, carbonaceous fuel (e.g. coal, oil, gas, biomass) is combusted

with air in a boiler to raise steam. The steam drives a turbine or generator to produce power. In a gas-

turbine combined-cycle system, the combustion in the gas turbine drives power generation, while

steam generated through a heat-recovery steam generator produces additional power. Flue gas from the

boiler or gas turbine consists mostly of N , CO , H O and O , with smaller amounts of other compounds

2 2 2 2depending on the fuel used. The PCC process is located downstream of conventional pollutant controls.

Chemical-absorption-based PCC usually requires steam to be extracted from the power plant’s steam

cycle or the use of lower-grade heat sources for absorption liquid regeneration, depending on the

absorption liquid and process employed.The economic and environmental value of a PCC plant is determined by its technical performance, as

well as its ability to achieve and maintain stable operation as required by its owners/stakeholders, as

follows:— The owner of the flue gas source has an interest in sustained CO -emission reductions.

— The owner of the CO -product has an interest being able to supply CO at the desired rate regardless

2 2of external conditions.

vi © ISO 2021 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/FDIS 27919-2:2021(E)

The CO receiver has an interest in CO -product availability for its own operations.

2 2Thus, this document describes a procedure that combines technology item evaluation procedure with

reliability, availability, and in some cases maintainability evaluation methods.© ISO 2021 – All rights reserved vii

---------------------- Page: 7 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 27919-2:2021(E)

Carbon dioxide capture —

Part 2:

Evaluation procedure to assure and maintain stable

performance of post-combustion CO2 capture plant

integrated with a power plant

1 Scope

This document provides definitions, guidelines and supporting information for evaluating and

reporting (with respect to the basic design items ongoing, and the operational results of a reference

plant or unit as feedback) to ensure the (designed) performance of a PCC plant integrated with a host

power plant. The PCC plant separates CO from the power plant flue gas in preparation for subsequent

transportation and geological storage. The physical system being addressed is a single power plant,

with an optional auxiliary unit to provide thermal energy required for the PCC plant, and a single PCC

plant as described in ISO 27919-1.The formulas and methods to assure and maintain reliable performance, presented in this document,

describe issues addressed during the design and construction phases and practices that document

reliability and availability during routine operation. These practices would also guide ongoing

maintenance programs.This document does not provide guidelines for benchmark, comparison or assessment studies for PCC

plant operations using different capture technologies (i.e. absorbents), nor does it specify appropriate

operating conditions such as temperature etc.2 Normative references

There are no normative references in this document.

3 Terms, definitions and abbreviations

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at https:// www .electropedia .org/

3.1 Terms and definitions

3.1.1

administrative delay

delay to maintenance incurred for administrative reasons

[SOURCE: IEC 60050-192 (192-7-12), modified -“maintenance action” was changed to “maintenance”]

© ISO 2021 – All rights reserved 1---------------------- Page: 8 ----------------------

ISO/FDIS 27919-2:2021(E)

3.1.2

availability

ability of a PCC plant (3.1.20) integrated with the power plant to be in a state to perform as required

under given conditions at a given instant of time or over a given time interval, assuming that the

required external resources are provided3.1.3

corrective maintenance

maintenance carried out after fault detection to effect restoration

Note 1 to entry: Corrective maintenance of items disrupts the plant availability.

3.1.4derating/derated

difference between the maximum and the dependable one, or such a condition

Note 1 to entry: For derated hours, it means operating time with the rated output lowered.

3.1.5downtime

time interval for which the item (3.1.9) is in a state of being unable to perform as required due to

internal faults, or preventive maintenance (3.1.24)Note 1 to entry: unavailable time

3.1.6

emergency operation

type of sudden shut-down (3.1.36) operation to protect hardware from damage

3.1.7

external influence

critical subjects occurring outside the PCC plant (3.1.21) evaluation boundary

3.1.8

failure mechanism

process that leads to failure

Note 1 to entry: The process may be physical, chemical, logical, or a combination thereof.

[SOURCE: IEC 60050-192 (192-03-12)]3.1.9

item

subject being considered

Note 1 to entry: An item may be an individual part, component, device, functional or process unit, equipment,

subsystem, or system, related with technology.Note 2 to entry: An item may consist of hardware, software, people or any combination thereof.

[SOURCE: IEC 60050-192 (192-01-01), modified – “functional unit” was changed to “functional or

process unit” and “system” was changed to “related with technology” in Note1. Note3 through Note 5

were deleted.]3.1.10

logistic delay

delay, excluding administrative delay (3.1.1), incurred for the provision of resources needed for a

maintenance (3.1.12) action to proceed or continue[SOURCE: ISO 20815:2018, 3.1.24]

2 © ISO 2021 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/FDIS 27919-2:2021(E)

3.1.11

maintainability

ability to be retained in, or restored to, a state in which the required function can be performed under

given conditions3.1.12

maintenance

combination of all technical and management actions intended to retain an item (3.1.9) in, or restore it

to, a state in which it can perform as requiredNote 1 to entry: Management is assumed to include supervision activities.

[SOURCE: IEC 60050-192:2015, 192-06-01]

3.1.13

mean downtime

MDT

average of the downtime (3.1.5)

[SOURCE: IEC 60050-192:2015, 192-08-10]

3.1.14

mean time between failures

MTBF

average time between failures that initiate a forced outage (3.1.20), i.e. the quotient of attempted

operating hours to the number of forced outages (3.1.20)3.1.15

meantime between maintenance

MTBM

average time between maintenance (3.1.12), i.e. the quotient of attempted operating hours to the

number of maintenance (3.1.12)3.1.16

mission time

duration of the mission

Note 1 to entry: Mission is the state that the equipment or system is 100 % operational.

[SOURCE: ISO 10438-1:2007, 3.1.19]3.1.17

nominal product CO capacity

highest continuous flow rate of delivering captured CO under typical representative conditions defined

by the plant operator3.1.18

normal operation

operation where the product CO is exported to the transporting system maintaining the required

performance based on ISO 27919-13.1.19

on-stream factor

OSF

ratio of the summation of all on-stream time to the reference period (3.1.31), with both expressed as

hours© ISO 2021 – All rights reserved 3

---------------------- Page: 10 ----------------------

ISO/FDIS 27919-2:2021(E)

3.1.20

outage

time interval for which the item (3.1.9) is in a state of being unable to perform as required, for any

reason[SOURCE: IEC 60050-192:2015, 192-02-19, modified – “a disabled state” was changed to “a state of being

unable to perform as required, for any reason”]3.1.21

PCC plant

process and associated equipment that produces a CO stream from combustion gases

[SOURCE: ISO 27919-1:2018, 3.1.26]

3.1.22

PCC plant capacity availability

PCA

availability (3.1.2) of PCC plant (3.1.21) from a perspective of product CO2 amount (3.1.26) during a

reference period (3.1.31)Note 1 to entry: It is mathematically defined by Formula (3).

3.1.23

PCC plant load

ratio of the product CO2 capacity (3.1.27)’ in operation to the ‘nominal product CO2 capacity’ (3.1.17)

3.1.24preventive maintenance

maintenance (3.1.12) carried out in accordance with an established time schedule and performed

according to a prescribed criterionNote 1 to entry: See also condition-based maintenance (192-06-07), and scheduled maintenance (192-06-12).

[SOURCE: ISO 23815-1]3.1.25

project cycle

series of phases of which a project consists, e.g. basic design, engineering, manufacturing, commissioning

and operation3.1.26

product CO amount

volume, moles or mass of CO resulting from the PCC process

3.1.27

product CO capacity

total flow rate of the captured CO exported

Note 1 to entry: It is generally expressed as product CO amount per hour.

3.1.28

product CO producibility

PCPB

ratio of the product CO2 amount (3.1.26) produced to the nominal product CO2 capacity (3.1.17)

accumulated during the reference period (3.1.31)3.1.29

proven technology element

element with low or acceptable uncertainty levels

4 © ISO 2021 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/FDIS 27919-2:2021(E)

3.1.30

redundancy

item (3.1.9) where an equivalent unit can be put online to provide the same function if the item (3.1.9)

fail to provide the serviceNote 1 to entry: Redundancy is related to a strategy of design, where a spare system or component is provided

so that, even if one item fails, the spare system or component will operate in place of the deficient item such that

plant performance is not affected.3.1.31

reference period

period of time between an initial time and an end time over which all historical or projected performance

metrics are measured or projectedNote 1 to entry: Reference period is equivalent to period hours.

3.1.32

reliability

measure of the probability of success for an operation and, the ability of each item (3.1.9) to perform its

intended function as needed in an assembled PCC plant (3.1.20) during a given time interval within the

designed conditions without failure3.1.33

reliable performance

ability of a PCC plant (3.1.21) to function reliably as required

3.1.34

schedule compliance

ratio of the product CO2 amount (3.1.26) produced to the scheduled CO product amount requirement

met (historical) or to be met (projected) by the PCC plant (3.1.21) within a given time period

3.1.35service hours

accumulated period of time during stand-by and normal operation (3.1.18) including start-up (3.1.39)

and shut-down (3.1.36) in between[SOURCE: ISO 3977-9:1999, 3.98]

3.1.36

shut-down

event during which all required function of a PCC plant (3.1.21), and its equipment, is brought from an

operating state to a stoppage state under the control of a programmed sequence3.1.37

stand-by state

non-operating up state ready to start

3.1.38

starting reliability

probability of successful start-up (3.1.39) when the PCC plant (3.1.21) is on stream within a specified

period3.1.39

start-up

act of getting a PCC plant (3.1.21) and its equipment from a stoppage state ready to activate its items

(3.1.9) to an operating state© ISO 2021 – All rights reserved 5

---------------------- Page: 12 ----------------------

ISO/FDIS 27919-2:2021(E)

3.1.40

technical delay

accumulated time necessary to perform auxiliary technical actions associated with the maintenance

(3.1.12) action itself3.1.41

time availability

ratio of the subtraction of the summation of each element of the PCC plant (3.1.21) unavailable time

from the reference period (3.1.31) to the reference period (3.1.31)Note 1 to entry: An available time is calculated by subtraction of the unavailable time from reference period.

3.1.42time reliability

ratio of the subtraction of PCC plant (3.1.21) unavailable time from the time between preventative

maintenance (3.1.12) to the time between preventative maintenance (3.1.12)3.1.43

unavailability

PCC plant (3.1.21) is not in a state to perform as required due to an internal faults or preventive

maintenance (3.1.24)3.1.44

uptime

time interval during which a PCC plant (3.1.21) is in a state of being able to perform as required

Note 1 to entry: Absence of necessary external resources may prevent operation but does not affect.

Note 2 to entry: Available time.3.2 Abbreviations

CCS carbon dioxide capture and storage

DSS daily start-up and stop

EHS environment, health and safety

KPIs key performance indicators

MDT mean downtime

MR mission reliability

MTBF mean time between failure

MTPM mean time to preventive maintenance

MTTR mean time to repair

NC nominal product CO capacity

NPC nominal product CO

OSF on-stream factor

OST summation of each element of on-stream time

6 © ISO 2021 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/FDIS 27919-2:2021(E)

PCA PCC plant capacity availability

PCC post-combustion CO capture

PCP product CO produced

PCPB product CO producibility

PCNP product CO not produced

RAM reliability, availability and maintainability

RP reference period

SC schedule compliance

SPC scheduled product CO

SR starting reliability

TA time availability

TQ technology qualification

TR time reliability

UT unavailable time

3.3 Symbols

n number of forced outages;

n number of failures to start-up;

n number of start

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.