ISO 3082:2009

(Main)Iron ores — Sampling and sample preparation procedures

Iron ores — Sampling and sample preparation procedures

ISO 3082:2009 gives a) the underlying theory, b) the basic principles for sampling and preparation of samples, and c) the basic requirements for the design, installation and operation of sampling systems for mechanical sampling, manual sampling and preparation of samples taken from a lot under transfer, to determine the chemical composition, moisture content, size distribution and other physical and metallurgical properties of the lot, except bulk density obtained using ISO 3852:2007 (Method 2). The methods specified in this ISO 3082:2009 are applicable to both the loading and discharging of a lot by means of belt conveyors and other ore-handling equipment to which a mechanical sampler may be installed or where manual sampling may safely be conducted. The methods are applicable to all iron ores, whether natural or processed (e.g. concentrates and agglomerates, such as pellets or sinters).

Minerais de fer — Procédures d'échantillonnage et de préparation des échantillons

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 3082

Fourth edition

2009-06-01

Iron ores — Sampling and sample

preparation procedures

Minerais de fer — Procédures d'échantillonnage et de préparation des

échantillons

Reference number

ISO 3082:2009(E)

©

ISO 2009

---------------------- Page: 1 ----------------------

ISO 3082:2009(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2009

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2009 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 3082:2009(E)

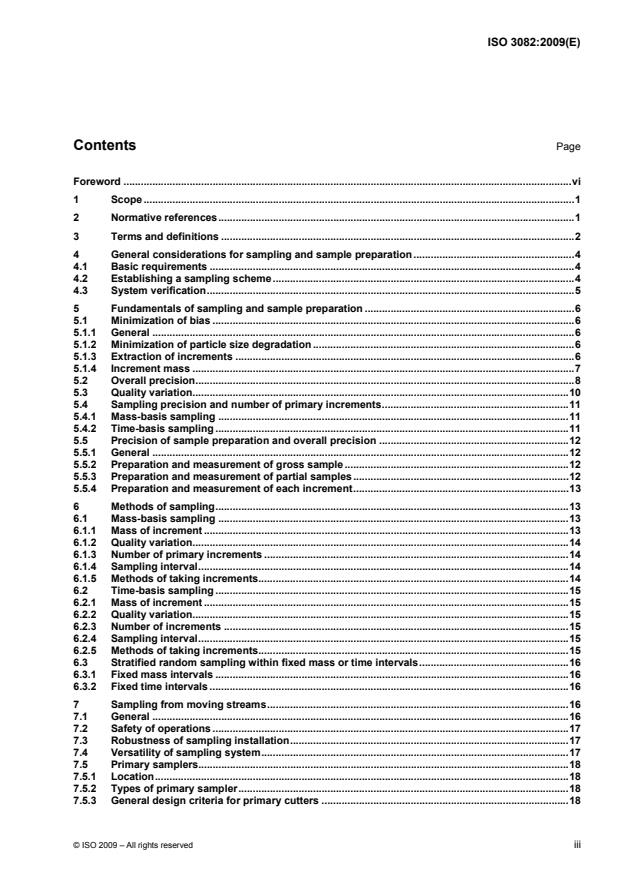

Contents Page

Foreword .vi

1 Scope .1

2 Normative references.1

3 Terms and definitions .2

4 General considerations for sampling and sample preparation .4

4.1 Basic requirements .4

4.2 Establishing a sampling scheme.4

4.3 System verification.5

5 Fundamentals of sampling and sample preparation .6

5.1 Minimization of bias .6

5.1.1 General .6

5.1.2 Minimization of particle size degradation .6

5.1.3 Extraction of increments .6

5.1.4 Increment mass .7

5.2 Overall precision.8

5.3 Quality variation.10

5.4 Sampling precision and number of primary increments.11

5.4.1 Mass-basis sampling .11

5.4.2 Time-basis sampling .11

5.5 Precision of sample preparation and overall precision .12

5.5.1 General .12

5.5.2 Preparation and measurement of gross sample.12

5.5.3 Preparation and measurement of partial samples.12

5.5.4 Preparation and measurement of each increment.13

6 Methods of sampling.13

6.1 Mass-basis sampling .13

6.1.1 Mass of increment .13

6.1.2 Quality variation.14

6.1.3 Number of primary increments .14

6.1.4 Sampling interval.14

6.1.5 Methods of taking increments.14

6.2 Time-basis sampling .15

6.2.1 Mass of increment .15

6.2.2 Quality variation.15

6.2.3 Number of increments .15

6.2.4 Sampling interval.15

6.2.5 Methods of taking increments.15

6.3 Stratified random sampling within fixed mass or time intervals.16

6.3.1 Fixed mass intervals .16

6.3.2 Fixed time intervals .16

7 Sampling from moving streams.16

7.1 General .16

7.2 Safety of operations .17

7.3 Robustness of sampling installation.17

7.4 Versatility of sampling system.17

7.5 Primary samplers.18

7.5.1 Location.18

7.5.2 Types of primary sampler.18

7.5.3 General design criteria for primary cutters .18

© ISO 2009 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 3082:2009(E)

7.5.4 Cutter aperture of primary sampler . 22

7.5.5 Cutter speed of primary sampler . 22

7.6 Secondary and subsequent samplers. 23

7.7 On-line sample preparation . 23

7.7.1 Arrangement for sample preparation . 23

7.7.2 Crushers . 23

7.7.3 Dividers. 23

7.7.4 Dryers. 27

7.8 Checking precision and bias . 27

7.9 Cleaning and maintenance . 27

7.10 Example of a flowsheet . 27

8 Sampling from stationary situations . 29

8.1 General. 29

8.2 Sampling from wagons . 29

8.2.1 Sampling devices. 29

8.2.2 Number of primary increments . 30

8.2.3 Method of sampling. 30

8.3 Sampling from ships, stockpiles and bunkers . 30

9 Stopped-belt reference sampling. 30

10 Sample preparation . 31

10.1 Fundamentals. 31

10.1.1 General. 31

10.1.2 Drying. 32

10.1.3 Crushing and grinding . 32

10.1.4 Mixing. 32

10.1.5 Sample division. 33

10.1.6 Mass of divided sample. 33

10.1.7 Split use and multiple use of sample. 36

10.2 Method of constituting partial samples or a gross sample. 36

10.2.1 General. 36

10.2.2 Method of constitution for mass-basis sampling. 36

10.2.3 Method of constitution for time-basis sampling . 38

10.2.4 Special procedure for moisture content. 38

10.3 Mechanical methods of division . 39

10.3.1 Mechanical increment division. 39

10.3.2 Other mechanical division methods. 40

10.4 Manual methods of division . 40

10.4.1 General. 40

10.4.2 Manual increment division. 40

10.4.3 Manual riffle-division method. 43

10.5 Preparation of test samples for chemical analysis . 43

10.5.1 Mass and particle size. 43

10.5.2 Preparation to − 250 µm . 46

10.5.3 Final preparation. 46

10.5.4 Grinding to −100 µm or −160 µm . 47

10.5.5 Distribution of samples for chemical analysis . 48

10.6 Preparation of test samples for moisture determination. 48

10.7 Preparation of test samples for size determination . 49

10.8 Preparation of test samples for physical testing . 49

10.8.1 Selection of sample preparation procedure. 49

10.8.2 Extraction of test samples . 49

10.8.3 Reserve samples. 58

11 Packing and marking of samples. 58

Annex A (informative) Inspection of mechanical sampling systems. 59

Annex B (normative) Equation for number of increments. 67

Annex C (informative) Alternative methods of taking the reference sample . 70

iv © ISO 2009 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 3082:2009(E)

Annex D (normative) Procedure for determining the minimum mass of divided gross sample for

size determination using other mechanical division methods.76

Annex E (normative) Riffle dividers .79

Bibliography.81

© ISO 2009 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 3082:2009(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 3082 was prepared by Technical Committee ISO/TC 102, Iron ore and direct reduced iron, Subcommittee

SC 1, Sampling.

This fourth edition cancels and replaces the third edition (ISO 3082:2000), of which it constitutes a technical

revision.

vi © ISO 2009 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 3082:2009(E)

Iron ores — Sampling and sample preparation procedures

WARNING — This International Standard may involve hazardous materials, operations and equipment,

and does not purport to address all the safety issues associated with its use. It is the responsibility of

the user of this International Standard to establish appropriate health and safety practices and

determine the applicability of regulatory limitations prior to use.

1 Scope

This International Standard gives

a) the underlying theory,

b) the basic principles for sampling and preparation of samples, and

c) the basic requirements for the design, installation and operation of sampling systems

for mechanical sampling, manual sampling and preparation of samples taken from a lot under transfer, to

determine the chemical composition, moisture content, size distribution and other physical and metallurgical

properties of the lot, except bulk density obtained using ISO 3852:2007 (Method 2).

The methods specified in this International Standard are applicable to both the loading and discharging of a lot

by means of belt conveyors and other ore-handling equipment to which a mechanical sampler may be

installed or where manual sampling may safely be conducted.

The methods are applicable to all iron ores, whether natural or processed (e.g. concentrates and

agglomerates, such as pellets or sinters).

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 565, Test sieves — Metal wire cloth, perforated metal plate and electroformed sheet — Nominal sizes of

openings

ISO 3084, Iron ores — Experimental methods for evaluation of quality variation

ISO 3085:2002, Iron ores — Experimental methods for checking the precision of sampling, sample

preparation and measurement

ISO 3086, Iron ores — Experimental methods for checking the bias of sampling

ISO 3087, Iron ores — Determination of moisture content of a lot

ISO 3271, Iron ores for blast furnace and direct reduction feedstocks — Determination of the tumble and

abrasion indices

ISO 3310-1, Test sieves — Technical requirements and testing — Part 1: Test sieves of metal wire cloth

© ISO 2009 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO 3082:2009(E)

ISO 3310-2, Test sieves —Technical requirements and testing — Part 2: Test sieves of perforated metal plate

ISO 3852:2007, Iron ores for blast furnace and direct reduction feedstocks — Determination of bulk density

ISO 4695, Iron ores for blast furnace feedstocks — Determination of the reducibility by the rate of reduction

index

ISO 4696-1, Iron ores for blast furnace feedstocks — Determination of low-temperature reduction-

disintegration indices by static method — Part 1: Reduction with CO, CO , H and N

2 2 2

ISO 4696-2, Iron ores for blast furnace feedstocks — Determination of low-temperature reduction-

disintegration indices by static method — Part 2: Reduction with CO and N

2

ISO 4698, Iron ore pellets for blast furnace feedstocks — Determination of the free-swelling index

ISO 4700, Iron ore pellets for blast furnace and direct reduction feedstocks — Determination of the crushing

strength

ISO 4701, Iron ore and direct reduced iron — Determination of size distribution by sieving

ISO 7215, Iron ores for blast furnace feedstocks — Determination of the reducibility by the final degree of

reduction index

ISO 7992, Iron ores for blast furnace feedstocks — Determination of reduction under load

ISO 8371, Iron ores for blast furnace feedstocks — Determination of the decrepitation index

ISO 11256, Iron ore pellets for shaft direct-reduction feedstocks — Determination of the clustering index

ISO 11257, Iron ores for shaft direct-reduction feedstocks — Determination of the low-temperature reduction-

disintegration index and degree of metallization

ISO 11258, Iron ores for shaft direct-reduction feedstocks — Determination of the reducibility index, final

degree of reduction and degree of metallization

ISO 11323, Iron ore and direct reduced iron — Vocabulary

ISO 13930, Iron ores for blast furnace feedstocks — Determination of low-temperature reduction-

disintegration indices by dynamic method

3 Terms and definitions

For the purposes of this document, the terms and definitions contained in ISO 11323, as well as those given

below, apply.

3.1

lot

discrete and defined quantity of iron ore and direct reduced iron for which quality characteristics are to be

assessed

3.2

increment

quantity of iron ore and direct reduced iron collected in a single operation of a device for sampling or sample

division

3.3

sample

relatively small quantity of iron ore and direct reduced iron, so taken from a lot as to be representative in

respect of the quality characteristics to be assessed

2 © ISO 2009 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 3082:2009(E)

3.4

partial sample

sample comprising of less than the complete number of increments needed for a gross sample

3.5

gross sample

sample comprising all increments, entirely representative of all quality characteristics of a lot

3.6

test sample

sample prepared to meet all specific conditions for a test

3.7

test portion

part of a test sample that is actually and entirely subjected to the specific test

3.8

stratified sampling

sampling of a lot carried out by taking increments from systematically specified positions and in appropriate

proportions from strata

NOTE Examples of strata include production periods (e.g. 5 min), production masses (e.g. 1 000 t), holds in vessels,

wagons in a train, or containers and trucks representing a lot.

3.9

systematic sampling

sampling carried out by taking increments from a lot at regular intervals

3.10

mass-basis sampling

sampling carried out so that increments are taken at equal mass intervals, increments being as near as

possible of uniform mass

3.11

time-basis sampling

sampling carried out so that increments are taken from free falling streams, or from conveyors, at uniform time

intervals, the mass of each increment being proportional to the mass flow rate at the instant of taking the

increment

3.12

proportional mass division

division of samples or increments such that the mass of each retained divided portion is a fixed proportion of

the mass being divided

3.13

constant mass division

division of samples or increments such that the retained divided portions are of almost uniform mass,

irrespective of variations in mass of the samples or increments being divided

NOTE 1 This method is required for sampling on a mass basis.

NOTE 2 “Almost uniform” means that variations in mass are less than 20 % in terms of the coefficient of variation.

3.14

split use of sample

separate use of parts of a sample, as test samples for separate determinations of quality characteristics

© ISO 2009 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO 3082:2009(E)

3.15

multiple use of sample

use of a sample in its entirety for the determination of one quality characteristic, followed by the use of the

same sample in its entirety for the determination of one or more other quality characteristics

3.16

nominal top size

particle size expressed by the smallest aperture size of the test sieve (from a square opening complying with

the R20 or R40/3 series in ISO 565), such that no more than 5 % by mass of iron ore is retained on the sieve

4 General considerations for sampling and sample preparation

4.1 Basic requirements

The basic requirement for a correct sampling scheme is that all parts of the ore in the lot have an equal

[1]

opportunity of being selected and becoming part of the partial sample or gross sample for analysis (Gy ;

[2]

Pitard ). Any deviation from this basic requirement can result in an unacceptable loss of trueness and

precision. An incorrect sampling scheme cannot be relied on to provide representative samples.

The best sampling location to satisfy the above requirement is at a transfer point between conveyor belts.

Here the full cross-section of the ore stream can be conveniently intercepted at regular intervals, enabling

representative samples to be obtained.

In-situ sampling of ships, stockpiles, containers and bunkers is not permitted, because it is impossible to drive

the sampling device down to the bottom and extract the full column of ore. Consequently, all parts of the lot do

not have an equal opportunity of being sampled. The only effective procedure is sampling from a conveyor

belt when ore is being conveyed to or from the ship, stockpile, container or bunker.

In-situ sampling from stationary situations such as wagons is permitted only for ores with nominal top size less

than 1 mm, provided the sampling device, e.g. a spear or an auger, penetrates to the full depth of the

concentrate at the point selected for sampling and the full column of concentrate is extracted.

Sampling shall be carried out by systematic sampling either on a mass basis (see 6.1) or on a time basis (see

6.2), provided no bias is introduced by periodic variation in quality or quantity. If this is not the case, stratified

random sampling within fixed mass or time intervals shall be carried out (see 6.3).

The methods used for sampling and sample preparation depend on the final choice of the sampling scheme

and on the steps necessary to minimize possible biases and obtain acceptable overall precision.

Moisture samples shall be processed as soon as possible and test portions weighed immediately. If this is not

possible, samples shall be stored in non-absorbent airtight containers with a minimum of free air space to

minimize any change in moisture content, but should be prepared without delay.

4.2 Establishing a sampling scheme

The procedure for establishing a sampling scheme is as fol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.