ISO 5425:2023

(Main)Specifications for use of poly(lactic acid) based filament in additive manufacturing applications

Specifications for use of poly(lactic acid) based filament in additive manufacturing applications

This document specifies the technical requirements, test methods, detection rules, marking/labelling, packaging, transportation and storage of poly(lactic acid) (PLA) based filament for use in specific additive manufacturing technology, such as materials extrusion (MEX). The document applies to PLA based filament for MEX additive manufacturing applications.

Spécifications pour l'utilisation de filaments à base de poly(acide lactique) dans les applications de fabrication additive

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 5425

First edition

2023-08

Specifications for use of poly(lactic

acid) based filament in additive

manufacturing applications

Spécifications pour l'utilisation de filaments à base de poly(acide

lactique) dans les applications de fabrication additive

Reference number

ISO 5425:2023(E)

© ISO 2023

---------------------- Page: 1 ----------------------

ISO 5425:2023(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

© ISO 2023 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 5425:2023(E)

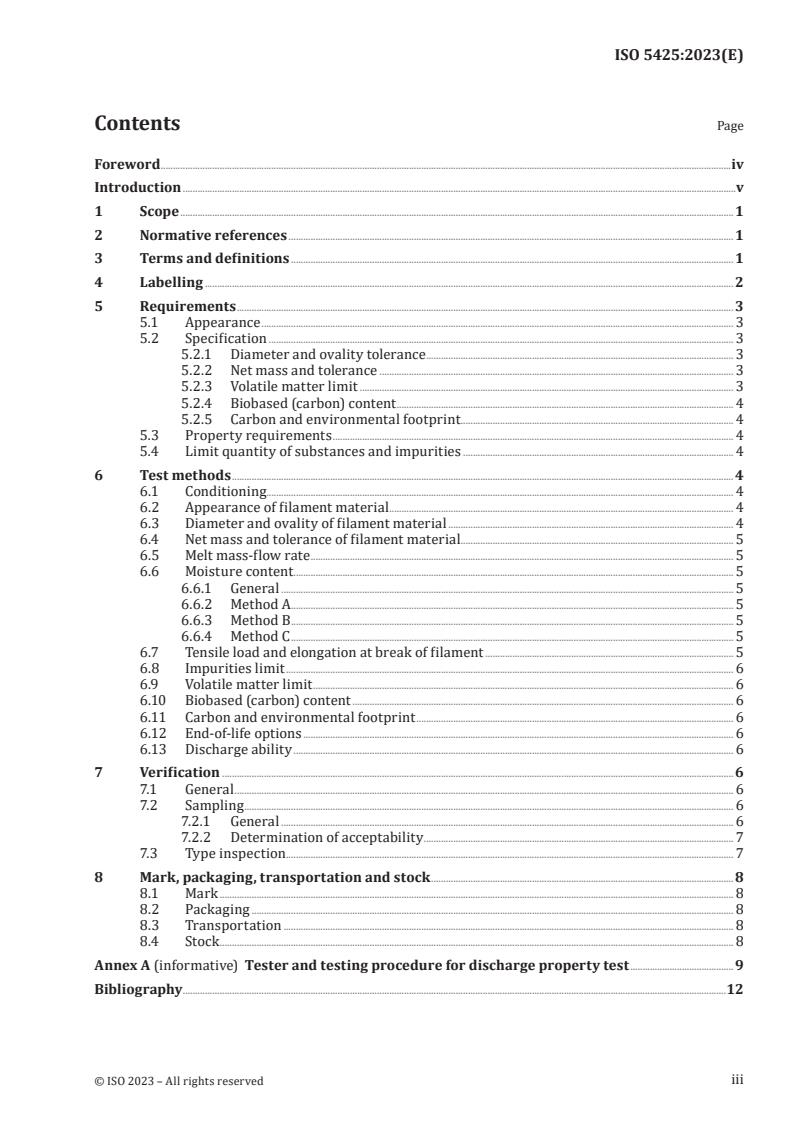

Contents Page

Foreword .iv

Introduction .v

1 Scope .1

2 Normative references .1

3 Terms and definitions .1

4 Labelling .2

5 Requirements . 3

5.1 Appearance . 3

5.2 Specification . 3

5.2.1 Diameter and ovality tolerance . 3

5.2.2 Net mass and tolerance . 3

5.2.3 Volatile matter limit . 3

5.2.4 Biobased (carbon) content . 4

5.2.5 Carbon and environmental footprint . 4

5.3 Property requirements . 4

5.4 Limit quantity of substances and impurities . 4

6 Test methods .4

6.1 Conditioning. 4

6.2 Appearance of filament material . . 4

6.3 Diameter and ovality of filament material . 4

6.4 Net mass and tolerance of filament material . 5

6.5 Melt mass-flow rate . 5

6.6 Moisture content . . 5

6.6.1 General . 5

6.6.2 Method A . . . 5

6.6.3 Method B . . 5

6.6.4 Method C . 5

6.7 Tensile load and elongation at break of filament . 5

6.8 Impurities limit . 6

6.9 Volatile matter limit . 6

6.10 Biobased (carbon) content . 6

6.11 Carbon and environmental footprint . 6

6.12 End-of-life options . 6

6.13 Discharge ability . 6

7 Verification .6

7.1 General . 6

7.2 Sampling . 6

7.2.1 General . 6

7.2.2 Determination of acceptability . 7

7.3 Type inspection . 7

8 Mark, packaging, transportation and stock .8

8.1 Mark . 8

8.2 Packaging . 8

8.3 Transportation . 8

8.4 Stock . 8

Annex A (informative) Tester and testing procedure for discharge property test .9

Bibliography .12

iii

© ISO 2023 – All rights reserved

---------------------- Page: 3 ----------------------

ISO 5425:2023(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 61, Plastics, Subcommittee SC 14,

Environmental aspects.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

© ISO 2023 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 5425:2023(E)

Introduction

Poly(lactic acid) (PLA) is a thermoplastic polymer material that is commonly used in additive

manufacturing/3D Printing. This document specifically addresses the following:

a) specify various parameters such as the appearance, dimensions, chemical and physical properties;

b) this document is expected to improve the quality management of PLA based filament for additive

manufacturing applications;

c) provide information on end-of-life management, use of renewable biobased carbon feedstocks

vs. fossil based feedstocks, Carbon and Environmental Footprint, and methodology of a circular

economy.

The document is expected to provide benefits to both consumers and industry. Consumers may profit

from this document by relying on standardized specification. This document is also important for the

development and growth of a new environmentally responsible polymer material industry based on

PLA.

v

© ISO 2023 – All rights reserved

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 5425:2023(E)

Specifications for use of poly(lactic acid) based filament in

additive manufacturing applications

1 Scope

This document specifies the technical requirements, test methods, detection rules, marking/labelling,

packaging, transportation and storage of poly(lactic acid) (PLA) based filament for use in specific

additive manufacturing technology, such as materials extrusion (MEX).

The document applies to PLA based filament for MEX additive manufacturing applications.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 291, Plastics — Standard atmospheres for conditioning and testing

ISO 527-2, Plastics — Determination of tensile properties — Part 2: Test conditions for moulding and

extrusion plastics

ISO 1133-1:2022, Plastics — Determination of the melt mass-flow rate (MFR) and the melt volume-flow

rate (MVR) of thermoplastics — Part 1: Standard method

ISO 2859-1, Sampling procedures for inspection by attributes — Part 1: Sampling schemes indexed by

acceptance quality limit (AQL) for lot-by-lot inspection

ISO 8124-3, Safety of toys — Part 3: Migration of certain elements

ISO 12219-2, Interior air of road vehicles — Part 2: Screening method for the determination of the emissions

of volatile organic compounds from vehicle interior parts and materials — Bag method

ISO 15512:2019, Plastics — Determination of water content

ISO 16620 (all parts), Plastics — Biobased content

ISO 22526 (all parts), Plastics — Carbon and environmental footprint of biobased plastics

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

additive manufacturing

AM

process of joining materials to make parts from 3D model data, usually layer upon layer, as opposed to

subtractive manufacturing and formative manufacturing methodologies

Note 1 to entry: This is also commonly referred to as 3D-printing.

1

© ISO 2023 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 5425:2023(E)

[SOURCE: ISO/ASTM 52900:2021, 3.1.2, modified — Note 1 to entry replaced and Note 2 to entry

removed.]

3.2

material extrusion

MEX

additive manufacturing (3.1) process, where an object is built by selectively depositing melted material

in a pre-determined path layer-by-layer

Note 1 to entry: More specifically, MEX, refers to a process in which a filament material (i.e. PLA ) is heated

to melt in a printer and extruded through a nozzle (with certain bore diameter), that moves following a preset

computer slice model to continuously deposit a layer on, and bond to a previous layer after solidification to form

the final product.

3.3

melt mass-flow rate

MFR

rate of extrusion of a molten resin through a die of specified length and diameter under prescribed

conditions of temperature, load and piston position in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.