ISO/TS 11602-2:2010

(Main)Fire protection — Portable and wheeled fire extinguishers — Part 2: Inspection and maintenance

Fire protection — Portable and wheeled fire extinguishers — Part 2: Inspection and maintenance

ISO/TS 11602-2:2010 gives requirements for the selection and installation of portable and wheeled fire extinguishers. It is intended as a companion to ISO/TS 11602-1. It is not applicable to permanently installed systems for fire extinguishment, even though portions of such systems may be portable (such as hose and nozzles attached to a fixed supply of extinguishing media). Extinguishers for use on board aircraft, watercraft and vehicles are outside its scope.

Protection contre l'incendie — Extincteurs portatifs et extincteurs sur roues — Partie 2: Contrôle et maintenance

General Information

Relations

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 11602-2

First edition

2010-08-15

Fire protection — Portable and wheeled

fire extinguishers —

Part 2:

Inspection and maintenance

Protection contre l'incendie — Extincteurs portatifs et extincteurs sur

roues —

Partie 2: Contrôle et maintenance

Reference number

ISO/TS 11602-2:2010(E)

©

ISO 2010

---------------------- Page: 1 ----------------------

ISO/TS 11602-2:2010(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2010

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2010 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TS 11602-2:2010(E)

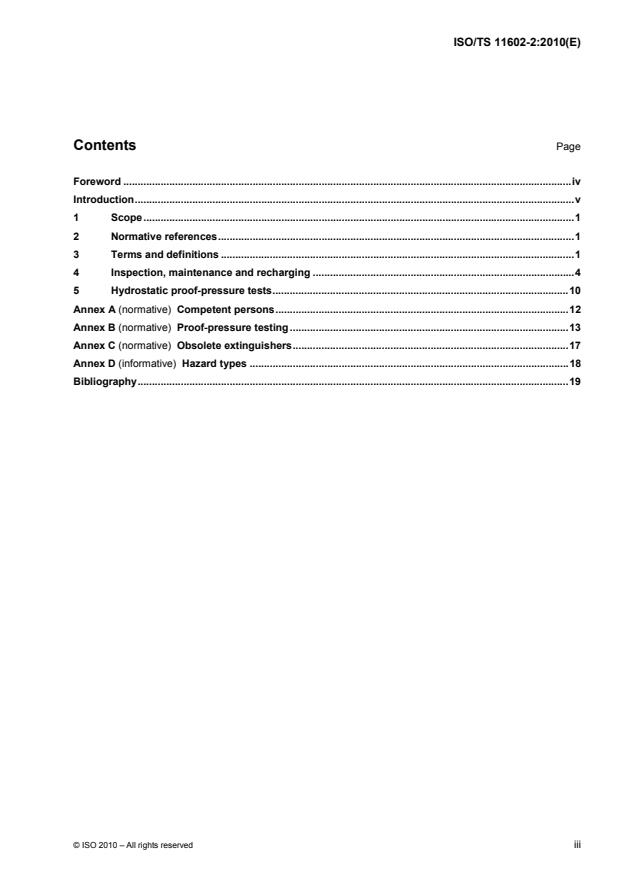

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Normative references.1

3 Terms and definitions .1

4 Inspection, maintenance and recharging .4

5 Hydrostatic proof-pressure tests.10

Annex A (normative) Competent persons.12

Annex B (normative) Proof-pressure testing.13

Annex C (normative) Obsolete extinguishers.17

Annex D (informative) Hazard types .18

Bibliography.19

© ISO 2010 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TS 11602-2:2010(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In other circumstances, particularly when there is an urgent market requirement for such documents, a

technical committee may decide to publish other types of document:

⎯ an ISO Publicly Available Specification (ISO/PAS) represents an agreement between technical experts in

an ISO working group and is accepted for publication if it is approved by more than 50 % of the members

of the parent committee casting a vote;

⎯ an ISO Technical Specification (ISO/TS) represents an agreement between the members of a technical

committee and is accepted for publication if it is approved by 2/3 of the members of the committee casting

a vote.

An ISO/PAS or ISO/TS is reviewed after three years in order to decide whether it will be confirmed for a

further three years, revised to become an International Standard, or withdrawn. If the ISO/PAS or ISO/TS is

confirmed, it is reviewed again after a further three years, at which time it must either be transformed into an

International Standard or be withdrawn.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TS 11602-2 was prepared by Technical Committee ISO/TC 21, Equipment for fire protection and fire

fighting, Subcommittee SC 2, Manually transportable fire extinguishers.

This first edition of ISO/TS 11602-2 cancels and replaces ISO 11602-2:2000, of which it constitutes a

technical revision.

ISO 11602 consists of the following parts, under the general title Fire protection — Portable and wheeled fire

extinguishers:

⎯ Part 1: Selection and installation [Technical Specification]

⎯ Part 2: Inspection and maintenance [Technical Specification]

iv © ISO 2010 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/TS 11602-2:2010(E)

Introduction

This part of ISO 11602 presents a limited number of provisions for the inspection and maintenance of portable

and wheeled fire extinguishers, in the knowledge that different countries have particular environments and

climates which can affect the size, shape and occupancy of buildings.

A country's specific building configurations can affect the inspection and maintenance of fire extinguishers;

therefore, this part of ISO 11602 could be reinforced in respect of fire-extinguishing performance

characteristics in the presentation of a general-purpose standard.

It is proposed that further investigation be undertaken in light of the above for the purposes of a future revision

of this part of ISO 11602.

© ISO 2010 – All rights reserved v

---------------------- Page: 5 ----------------------

TECHNICAL SPECIFICATION ISO/TS 11602-2:2010(E)

Fire protection — Portable and wheeled fire extinguishers —

Part 2:

Inspection and maintenance

1 Scope

This part of ISO 11602 gives requirements for the selection and installation of portable and wheeled fire

extinguishers. It is intended as a companion to ISO/TS 11602-1.

Fire extinguishers are a first line of defence against fires of limited size. They are needed even if the property

is equipped with automatic sprinklers, standpipe and hose, or other fixed protection equipment.

This part of ISO 11602 is not applicable to permanently installed systems for fire extinguishment, even though

portions of such systems may be portable (such as hose and nozzles attached to a fixed supply of

extinguishing media).

Extinguishers for use on board aircraft, watercraft and vehicles are outside the scope of ISO 11602.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 5923, Fire protection — Fire extinguishing media — Carbon dioxide

ISO 7201-1, Fire protection — Fire extinguishing media — Halogenated hydrocarbons — Part 1:

Specifications for halon 1211 and halon 1301

ISO 7201-2, Fire extinguishing media — Halogenated hydrocarbons — Part 2: Code of practice for safe

handling and transfer procedures of halon 1211 and halon 1301

ISO 8421-1, Fire protection — Vocabulary — Part 1: General terms and phenomena of fire

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 8421-1 and the following apply.

3.1

clean agent

electrically non-conductive gaseous or vaporizing fire extinguishant that does not leave a residue upon

vaporization

[ISO 7165:2009, 3.5]

© ISO 2010 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/TS 11602-2:2010(E)

3.2

closed recovery system

system that provides for the transfer of media between extinguishers, supply containers, and recharge and

recovery containers so that the escape of media to the atmosphere is minimized

3.3

competent person

person with the necessary training and experience and with access to the requisite tools, equipment, parts

and information (including the manufacturer's service manual) to be capable of carrying out the inspection,

maintenance and recharging procedures of this part of ISO 11602

3.4

film-forming foam

extinguishing media comprising the aqueous film-forming foam (AFFF) and film-forming fluoroprotein (FFFP)

foam types, and including grades suitable for polar solvents (water-soluble flammable liquids) and those not

suitable for polar solvents

3.5

fire extinguisher

extinguisher

appliance containing an extinguishing medium which can be discharged and directed onto a fire by the action

of internal pressure

NOTE 1 See ISO 7165.

NOTE 2 The internal pressure may be provided by

⎯ a stored pressure (pressurization of the extinguishing medium container at the time of charging), or

⎯ a gas cartridge (pressurization at the time of use through the release of gas from a separate cylinder into the medium

container).

NOTE 3 Adapted from ISO 7165:2009, definition 3.11.

3.6

high-pressure cylinder

cylinder having a service pressure higher than 2,5 MPa at 20 °C

3.7

inspection

brief examination to ensure that an extinguisher is available and will operate

NOTE This is intended to give reasonable assurance that the extinguisher is fully charged and operable. This is done

by seeing that it is in its designated place, that it has not been actuated or tampered with, and that there is no obvious

damage or condition to prevent its operation.

3.8

low-pressure cylinder

cylinder having a service pressure of 2,5 MPa or lower at 20 °C

3.9

maintenance

thorough examination of the extinguisher

NOTE This is intended to give maximum assurance that an extinguisher will operate effectively and safely. It includes

a thorough examination and any necessary repair or replacement. It will normally reveal if hydrostatic testing is required.

2 © ISO 2010 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/TS 11602-2:2010(E)

3.10

non-rechargeable extinguisher

non-refillable extinguisher

fire extinguisher that is not capable of (or intended for) undergoing complete maintenance or hydrostatic

testing, nor of being restored to its full operating capability by means of the standard practices used by fire

equipment service companies

3.11

portable fire extinguisher

fire extinguisher that is designed to be carried and operated by hand and that in working order has a mass of

not more than 20 kg

NOTE Subject to local acceptance, extinguishers having a total mass of 25 kg when fully charged are permitted.

[ISO 7165:2009, 3.15]

3.12

rating

comparative number associated with the classification assigned to an extinguisher and indicative of its

capability in the extinguishment of a standard fire

3.13

rechargeable extinguisher

refillable extinguisher

fire extinguisher that is capable of undergoing complete maintenance, including internal inspection of the

pressure vessel, replacement of all substandard parts and seals, and hydrostatic testing, and of being

recharged with media and propellant and restored to its full operating capability by means of the standard

practices used by fire equipment service companies

NOTE Rechargeable/refillable extinguishers are marked “Recharge Immediately After Any Use” or with a similar

equivalent marking.

3.14

recharging

replacement of the extinguishing medium

NOTE This also includes the propellant for certain types of extinguishers.

3.15

self-expelling-medium extinguisher

extinguisher in which the medium has sufficient vapour pressure at normal operating temperatures to expel

itself

3.16

service

servicing

process that includes maintenance, recharging or hydrostatic testing, or more than one of these

3.17

service pressure

normal operating pressure at 20 °C, as indicated on the pressure gauge or indicator and nameplate of a

stored pressure extinguisher, or the pressure developed in a cartridge-operated extinguisher upon release of

the gas from the cartridge into the medium container at a temperature of 20 °C

3.18

test pressure

pressure at which the extinguisher or its components were tested at the time of manufacture

NOTE The pressure at which the shell was tested is shown on the nameplate or the extinguisher body.

© ISO 2010 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/TS 11602-2:2010(E)

3.19

water-type extinguisher

fire extinguisher which contains a water-based medium, such as water, aqueous film-forming foam (AFFF) or

film-forming fluoroprotein (FFFP) foam and/or antifreeze

3.20

wet chemical extinguisher

fire extinguisher which contains aqueous solutions of potassium acetate, potassium carbonate, potassium

citrate, or combinations of these materials

3.21

wheeled extinguisher

fan appliance on wheels having a total mass of more than 20 kg but not greater than 450 kg, which is

designed to be transported to the fire and operated by one person

NOTE See ISO 11601.

4 Inspection, maintenance and recharging

4.1 General

4.1.1 The owner or designated agent or occupant of a property in which extinguishers are located shall be

responsible for inspection, maintenance and recharging.

4.1.2 The procedure for inspection and maintenance of extinguishers varies considerably. Minimal

knowledge is necessary to perform a monthly inspection procedure as outlined in 4.2. Only competent

persons shall service extinguishers, as outlined in 4.3 and 4.4. See Annex A.

4.1.3 Maintenance and recharging shall be performed in accordance with the appropriate manual(s), using

the proper types of tools, recharge materials, lubricants, and the manufacturer's recommended and identified

replacement parts.

4.1.4 Extinguishers out of service for maintenance or recharge shall be replaced at once by spare

extinguishers of the same type and at least equal classification and rating.

4.2 Inspection

4.2.1 Extinguishers shall be checked when initially placed in service and thereafter should be checked at

approximately 30-day intervals. Extinguishers shall be checked at more frequent intervals when

circumstances require.

4.2.2 Periodic checks shall be made to ensure that

a) the extinguisher is located in the designated place,

b) the extinguisher is unobstructed and visible, with its operating instructions facing outwards,

c) operating instructions are legible,

d) seals and tamper indicators are not broken or missing,

e) the extinguisher is full (by weighing or lifting),

f) the extinguisher is not obviously damaged, corroded or leaking and does not have a clogged nozzle, and

g) where provided, the pressure gauge reading or indicator is in the operable range or position.

4 © ISO 2010 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/TS 11602-2:2010(E)

4.2.3 When a check of any extinguisher reveals a deficiency in the conditions listed as a) and b) of 4.2.2,

immediate corrective action shall be taken.

4.2.4 When a check of any rechargeable extinguisher reveals a deficiency in any of the conditions c), d), e),

f) or g) of 4.2.2, it shall be subjected to appropriate maintenance procedures.

4.2.5 When a check of any non-rechargeable powder extinguisher reveals a deficiency in any of the

conditions c), d), e), f) or g) of 4.2.2, it shall be removed from service.

4.2.6 When a check of any non-rechargeable clean agent extinguisher reveals a deficiency in any of the

conditions c), d), e), f) or g) of 4.2.2, it shall be removed from service and the medium shall be recovered or

destroyed.

4.3 Maintenance

4.3.1 General

All extinguishers, except as noted in Annex C, shall be subjected to maintenance as follows:

a) not more than once a year but not less than six months apart;

b) at the time of hydrostatic testing;

c) when specifically indicated by an inspection.

Maintenance procedures shall be performed in accordance with 4.3.2.

4.3.2 All extinguishers

4.3.2.1 At each maintenance, all extinguishers shall be subjected to the following:

a) a check of the seal and safety device to determine whether the extinguisher may have been used;

b) subsequent to maintenance, replacement of the safety device and fitting of a new seal;

c) attachment of a label to the extinguisher or marking of a label attached to the extinguisher indicating that

the required maintenance has been performed.

4.3.2.2 For the balance of the procedures to be carried out when maintaining portable fire extinguishers,

extinguisher types are categorized as follows:

⎯ Category 1: stored-pressure-type extinguishers with water, water with additives, or foam as the

extinguishing media;

⎯ Category 2: stored-pressure-type extinguishers with powder or clean agent as the extinguishing media;

⎯ Category 3: gas-cartridge-type extinguishers with water, water with additives, or foam as the

extinguishing media;

⎯ Category 4: gas-cartridge-type extinguishers with powder as the extinguishing media;

⎯ Category 5: carbon dioxide extinguishers.

4.3.2.3 In addition to the requirements of 4.3.2.1 a), b) and c), extinguishers shall be maintained in

accordance with Table 1.

4.3.2.4 Powder extinguishers shall be opened for performing maintenance procedure.

CAUTION — Before any powder extinguisher is opened, it shall be ascertained that, during inspection

and maintenance, the precautions given in 4.3.2.4.1 and 4.3.2.4.2 can and will be observed.

© ISO 2010 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/TS 11602-2:2010(E)

4.3.2.4.1 Powder extinguishers shall be opened only in the driest available conditions and for the minimum

time necessary for examination, to minimize the effect of atmospheric moisture on the powder (powder may

absorb deleterious amounts of moisture if exposed to air of high relative humidity, or if the powder is colder

than the ambient air).

4.3.2.4.2 Mixing or cross-contamination of different types of powder shall be avoided.

Some types of powder are capable of reacting with other types to produce water and carbon dioxide. This

reaction often does not become apparent until after a delay of weeks during which no apparent reaction

occurs. The water causes caking and, in a closed container, the carbon dioxide causes a pressure rise that

can be dangerous. Only extinguishers containing the same powder should be opened and examined at any

one time.

Table 1 — Maintenance procedures for each categorized extinguisher type

Category

No. Maintenance procedure

1 2 3 4 5

1 X X — — —

Examine and verify that the pressure-indicating device (if

fitted) is reading the internal pressure correctly or, where

a device is not fitted, that the internal pressure is correct.

If the extinguisher shows a loss of pressure of more than

10 %, or more than the manufacturer's recommended

maximum loss if less than 10 %, refer to the

manufacturer's instructions for appropriate action.

2 Examine the extinguisher body externally for corrosion or X X X X X

damage. If the extinguisher is slightly corroded, or has

sustained minor damage, it shall be discarded or

subjected to hydrostatic testing. If heavily corroded or

severely damaged, it shall be discarded.

3 Weigh the extinguisher (with or without the operating X X X X X

mechanism, according to the manufacturer's instructions)

or use suitable alternative means to check that it contains

the correct mass of medium. Check the mass against the

mass recorded when it was first put into service.

4 Examine the nozzle and hose (if provided) and clean if X X X X X

necessary. Replace if worn or otherwise not in good

condition.

5 Where extinguishers are designed to have the operating X X X X —

mechanism removed, check the operating mechanism

and discharge control (where fitted) for free movement.

Clean, rectify or replace if necessary. Protect the moving

parts and threads against corrosion with a lubricant as

recommended by the manufacturer.

6 Open the extinguisher or otherwise remove the head — — X X —

assembly. Remove the gas cartridge.

7 (Water with additive, or foam extinguishers only.) Pour the — — X — —

liquid into a clean container. If evidence of deterioration is

apparent (refer to manufacturer's instructions regarding

specific products), discard the liquid and refill with the

manufacturer's specified liquid. Where the foam

concentrate or additive is in a separate container, check

this for leakage. Discard leaking containers and replace

with a new container and charge.

8 Clean the inside and outside of the extinguisher and — — X — —

examine the body externally and internally for corrosion or

damage. If the extinguisher is slightly corroded, or has

sustained minor damage, it shall be discarded or

subjected to hydrostatic testing. If heavily corroded or

severely damaged, it shall be discarded.

6 © ISO 2010 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/TS 11602-2:2010(E)

Table 1 (continued)

Category

No. Maintenance procedure

1 2 3 4 5

9 — — X X —

Examine the gas cartridge externally for corrosion or

damage. If the gas cartridge is damaged or corroded,

replace the cartridge as recommended by the

manufacturer. Weigh the gas cartridge and check the

mass against that marked on the cartridge. A gas

cartridge which has a content less than the minimum as

marked, or which is found to be leaking, shall be

withdrawn from service or replaced by a cartridge as

recommended by the manufacturer.

10 Clean if necessary and pass air through the vent holes (or — — X X —

other venting device) in the cap.

11 Examine the branch pipe (where used) nozzle, strainer — — X — —

and (where fitted) the internal discharge tube and

breather valve, and clean if necessary.

12 Clean and examine the nozzle, hose and internal — — — X —

discharge tube for blockage by passing air through them;

rectify or replace if necessary.

13 Examine all washers, diaphragms and hose, and replace — — X X —

if damaged or defective. If the hose is fitted at the bottom

end of the extinguisher and a diaphragm is used, it shall

be replaced.

14 Examine the powder in the extinguisher to check that — — — X —

there are no visual signs of caking, lumps or foreign

bodies. Agitate the powder by inverting and shaking the

extinguisher, taking care to avoid spillage. If there is any

evidence of caking, lumps or foreign bodies, if it is not

free flowing, or if there is any doubt, discard all the

powder, and recharge the extinguisher with the original

manufacturer's powder.

15 Return the original charge to the extinguisher, topping up — — X — —

any loss with water, or replacing with fresh water as

necessary. For water with additives, or foam, recharge

the extinguisher in accordance with the manufacturer's

instructions.

16 Re-assemble the extinguisher in accordance with the — — X X —

manufacturer's instructions.

17 Examine the horn, hose and valve assembly, — — — — X

and clean and replace if not in good condition.

18 Perform a conductivity test on hose assemblies. — — — — X

In some countries, where it is judged by a competent authority that the quality control procedures and reliability of

manufacture of certain dry chemical internal hermetically sealed (welded seal) cartridge-type extinguishers are

considered adequate, the first internal examination only may be delayed from the date of manufacturer until required by

4.3.2.5.

4.3.2.5 In addition to the annual maintenance specified in 4.3.1 to 4.3.2.4, the maintenance procedures in

accordance with Table 2 shall be performed at intervals not exceeding five years, with the following

exceptions:

a) non-rechargeable fire extinguishers, other than clean agent types, shall be discharged and discarded not

later than five years from their date of manufacture;

b) non-rechargeable fire extinguishers of the clean agent type shall be removed from service and returned to

a recycling centre for recovery of the clean agent not later than five years from their date of manufacture.

© ISO 2010 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO/TS 11602-2:2010(E)

Table 2 — Additional maintenance procedures for extinguishers in Categories 1, 2 and 5

to be performed at intervals of not more than five years

Category

No. Maintenance procedure

1 2 5

1 Discharge the extinguisher completely. After discharge, the zero X X X

pressure gauge (where provided) shall indicate zero pressure, and

an indicator (where provided) shall show a discharged position.

2 Open the extinguisher, clean the inside and examine the body X X X

internally for corrosion or damage. If the extinguisher is slightly

corroded, or has sustained minor damage, it shall be discarded or

subjected to hydrostatic testing. If heavily corroded or severely

damaged, it shall be discarded.

3 Examine, as appropriate, the nozzle, strainer and hose, vent holes X X X

(or other venting device) in the cap or valve assembly, and the

internal discharge tube. Clean, if necessary.

4 Examine all sealing washers and hose (if fitted), and replace if X X X

defective.

5 Check the operating mechanism for free movement and clean, X X X

rectify or replace as necessary.

6 Re-assemble the extinguisher and recharge. See 4.4. X X X

4.3.2.6 Clean agent extinguishers shall not be discharged to the atmosphere but shall be emptied at

intervals not exceeding five years by a method that permits recovery of the clean agent. Following emptying,

the additional maintenance in accordance with Table 2 shall be performed. When emptied, measures should

be taken to minimize any emissions of clean agents into the atmosphere.

4.4 Recharging

4.4.1 All rechargeable-type extinguishers shall be recharged after any use or when indicated by an

inspection or maintenance deficiency.

4.4.2 When performing the recharging, the recommendations of the manufacturer shall be followed.

4.4.3 The amount of recharge medium shall be verified by weighing. The recharged gross mass shall be the

same as the gross mass that is marked on the manufacturer's label.

For those extinguishers that do not have the gross mass marked on the label, a permanent marking that

indicates the gross mass shall appear elsewhere on the extinguisher.

4.4.4 After recharging, a leak test shall be performed on stored pressure and self-expelling media

extinguishers and cartridges.

Where liquid leak detection methods are employed, caution shall be exercised to prevent contamination of the

media with the liquid.

4.4.5 Aqueous film-forming foam (AFFF), film-forming fluoroprotein (FFFP) foam and wet chemical

extinguishers shall be recharged with fresh media in accordance with the instructions on the extinguisher.

4.4.6 Only the medium specified on the nameplate shall be used.

4.4.7 One powder shall not be mixed with, or allowed to be contaminated by, another powder.

4.4.8 Extinguishers shall not be converted from one type to another, nor shall any extinguisher be

converted to use a different type of extinguishing medium.

8 © ISO 2010 – All rights reserved

---------------------- Page: 13 ----------------------

ISO/TS 11602-2:2010(E)

4.4.9 The remaining powder in a discharged extinguisher shall not be re-used.

4.4.10 Extinguishers removed for five-year maintenance or hydrostatic testing shall be emptied. The powder

shall not be re-used unless a closed recovery system is used and the media separately stored in a sealed

container to prevent contamination. Prior to re-use, the powder shall be thoroughly checked. Where doubt

exists with respect to type, contamination or condition of the powder, it shall be discarded.

4.4.11 For all non-water types of extinguishers, any moisture present in the emptied extinguisher shall be

removed before recharging.

4.4.12 Clean agent-type extinguishers

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.