ISO 10005:1995

(Main)Quality management — Guidelines for quality plans

Quality management — Guidelines for quality plans

Provides guidelines to assist suppliers in the preparation, review, acceptance and revision of quality plans. These guidelines are not intended to be used as a checklist for compliance with requirements. Applicable where a quality plan is to be used for a particular product, project or contract.

Management de la qualité — Lignes directrices pour les plans qualité

Vodenje kakovosti - Smernice za plane kakovosti

General Information

Relations

Buy Standard

Standards Content (Sample)

INTERNATIONAL IS0

STANDARD 10005

First edition

1995-09-15

Quality management - Guidelines for

quality plans

Management de la qua/it6 - Lignes directrices pour /es plans qua/it6

----lu/yyh__

- -

-

-

-

-

-

tISOi

~~~

Reference number

IS0 10005:1995(E)

---------------------- Page: 1 ----------------------

PSO 10005:1995(E)

Contents

Page

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Scope

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .~.~.

2 Normative reference

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Definitions

2

4 Preparation, review, acceptance and revision of the quality plan

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Preparation

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Review and acceptance

3

4.3 Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Contents of the quality plan

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Management responsibilities

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5.2 Quality plan and quality system

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Contract review

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Design control

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Document and data control

4

5.6 Purchasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Control of customer-supplied product

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.8 Product identification and traceability

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.9 Process control

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.10 Inspection and testing

. . . . . . . . . 5

5.11 Control of inspection, measuring and test equipment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.12 Inspection and test status

6

5.13 Control of nonconforming product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.14 Corrective and preventive action

. . . . . 6

5.15 Handling, storage, packaging, preservation and delivery

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.16 Control of quality records

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.17 Quality audits

0 IS0 1995

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced

or utilized in any form or by any means, electronic or mechanical, including photocopying and

microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case Postale 56 l CH-1211 Geneve 20 l Switzerland

Printed in Switzerland

---------------------- Page: 2 ----------------------

0 IS0

IS0 10005:1995(E)

5.18 Training . 6

5.19 Servicing . 6

5.20 Statistical techniques . 7

Annexes

A Simplified examples of formats for the presentation of quality

plans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

B Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

---------------------- Page: 3 ----------------------

0 IS0

IS0 10005:1995(E)

Foreword

IS0 (the International Organization for Standardization) is a worldwide

federation of national standards bodies (IS0 member bodies). The work

of preparing International Standards is normally carried out through IS0

technical committees. Each member body interested in a subject for

which a technical committee has been established has the right to be

represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work. IS0

collaborates closely with the International Electrotechnical Commission

(IEC) on all matters of electrotechnical standardization.

Draft International Standards adopted by the technical committees are

circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting

a vote.

International Standard IS0 10005 was prepared by Technical Committee

lSO/TC 176, Quality management and quality assurance, Subcommittee

SC 2, Quality systems.

Annexes A and B of this International Standard are for information only.

IV

---------------------- Page: 4 ----------------------

0 IS0

IS0 10005:1995(E)

Introduction

This International Standard was prepared to address the need for a

mechanism to relate generic requirements on quality system elements to

the specific requirements of a particular product, project or contract.

Its provisions should be considered advisory and not requirements.

A quality plan may be used within an organization to ensure that specific

requirements for quality are being appropriately planned and addressed for

identified products during production. A quality plan may be used to indi-

cate the specific application of a quality system to a given development

project, whether for a marketable product or for an in-house facility.

A quality plan may also be used by the supplier in a contractual situation

to demonstrate to the customer how the specific requirements for quality

of a particular contract will be met. In many cases, it may be beneficial to

obtain customer input to the development of the quality plan.

The quality plan should be compatible with other plans that may be pre-

pared.

---------------------- Page: 5 ----------------------

This page intentionally left blank

---------------------- Page: 6 ----------------------

IS0 10005:1995(E)

INTERNATIONAL STANDARD 0 ISo

Quality management - Guidelines for quality plans

for compliance with requirements. A quality plan may

1 Scope

also be used where a documented quality system

does not exist, in which case procedures may need

1 .I This International Standard provides guidelines

to be developed to support the quality plan.

to assist suppliers in the preparation, review, accept-

ance and revision of quality plans.

NOTE 1 Annex B contains a bibliography of International

Standards which provide information that may prove helpful

It is intended for use in two situations:

to those involved in the preparation and review of quality

plans.

as guidance to a supplier organization in meeting

a)

the requirements of IS0 9001, IS0 9002 or

IS0 9003 relative to the preparation of a quality

plan; or

2 Normative reference

b) as guidance to a supplier organization in preparing

The following standard contains provisions which,

a quality plan when the supplier does not have

through reference in this text, constitute provisions

such a quality system.

of this International Standard. At the time of publi-

cation, the edition indicated was valid. All standards

In both situations, the quality plan is supplemental to

are subject to revision, and parties to agreements

the supplier’s generic quality system documentation

based on this International Standard are encouraged

and should not duplicate the generic documentation.

to investigate the possibility of applying the most re-

For convenience in situations of type b), this Inter-

cent edition of the standard indicated below. Mem-

national Standard includes features that are covered

bers of IEC and IS0 maintain registers of currently

in the generic requirements of IS0 9001, IS0 9002

valid International Standards.

and IS0 9003.

IS0 8402: 1994, Quality management and quality as-

Quality plans provide a mechanism to tie specific re-

surance - Vocabulary.

quirements of the product, project or contract to ex-

isting generic quality system procedures. They do not

require the development of a comprehensive set of

procedures or instructions over and above those al-

3 Definitions

ready existing, although some additional documented

procedures may be necessary.

For the purposes of this International Standard, the

definitions given in IS0 8402, together with the fol-

1.2 This International Standard is applicable where lowing definitions, apply. Terms which are repeated

a quality plan is to be used for a particular product, here for clarity but have been defined in other Inter-

project or contract. A quality plan may be applicable national Standards are identified by the placement of

to any product of the generic product categories the number of the standard after the term being de-

(hardware, software, processed materials and ser-

fined.

vices) or industry/economic sectors.

3.1 contract: Agreed requirements between a sup-

A quality plan may be used to monitor and assess

plier and customer transmitted by any’means.

adherence to the requirements for quality, but these

guidelines are not intended to be used as a checklist [ISO 90011

---------------------- Page: 7 ----------------------

0 IS0

IS0 10005:1995(E)

3.7 quality plan: Document setting out the specific

3.2 project: Unique process consisting of a set of

coordinated and controlled activities with start and quality practices, resources and sequence of activities

finish dates, undertaken to achieve an objective con- relevant to a particular product, project or contract.

forming to specific requirements, including the con-

NOTES

straints of time, cost and resources.

11 A quality plan usually makes reference to the parts of

NOTES

the quality ma nual applicable to th e specific case.

2 An in dividual p reject may form part of a larger project

12 Depending on the scope of the plan, a qualifier may be

structure

used, for example, “quality assurance plan”, “quality man-

agement plan “.

3 In some types of projects, the objectives are refined and

the project characteristics defined progressively as the pro-

[ISO 84021

ject proceeds.

3.8 quality system: Organizational structure, pro-

4 The outco ime of a p reject may be one or several

cedures, processes and resources needed to imple-

of a product.

ment quality management.

3.3 type test: Test or series of tests directed

NOTES

towards approval of a design conducted to determine

that it is capable of meeting the requirements of the

comprehensive as

13 The quality system should be as

product specification.

the quality objectives.

needed to meet

3.4 witness testing: Testing of a product in the 14 The quality system of an organization is designed pri-

marily to satisfy the internal managerial needs of the or-

presence of the customer’s representative or a third

ganization. It is broader than the requirements of a particular

party.

customer who evaluates only the relevant part of the quality

system.

.

35 procedure: Specified way to perform an activity.

15 For contractual or mandatory quality assessment pur-

NOTES

poses, demonstration of the implementation of identified

quality system elements may be required.

5 In many cases, procedure s are documented (e.g. quality

m procedures).

syste

[ISO 84021

6 When a procedure is to be documented, the term

“written procedure” or “documented procedure” is fre-

4 Preparation, review, acceptance

quently used.

and revision of the quality plan

7 A written or documented procedure usually contains the

purpose and scope of an activity; what shall be done and

4.1 Preparation

by whom; when, where and how it shall be done; what

materials, equipment and documents shall be used; and

When preparing a quality plan, quality activities appli-

how it shall be controlled and recorded.

cable to the situation should be defined and docu-

mented.

[ISO 84021

Much of the generic documentation needed may be

3.6 product: Result of activities or processes.

contained in the supplier’s quality manual and docu-

mented procedures. This documentation may need to

NOTES

be selected, adapted and/or supplemented. The qual-

8 A product may include service, hardware, processed ity plan shows how the supplier’s generic docu-

materi als, software, or a combination thereof.

mented procedures are related to and applied to any

necessary additional procedures peculiar to the prod-

9 A product can be tangible (e.g. assemblies or processed

uct, project or contract in order to attain specified

materials) or intangible (e.g. knowledge or concepts), or a

quality objectives.

combination thereof.

The quality plan should indicate, either directly or by

10 A product can be either intended (e.g. offering to cus-

reference to appropriate documented procedures or

tomers) or unintended (e.g. polluant or unwanted effects).

other documents, how the required activities are to

[ISO 84021 be carried out.

2

---------------------- Page: 8 ----------------------

0 IS0

IS0 10005:1995(E)

stages, the supplier should submit the quality plan for

The format and level of detail in the plan should be

consistent with any agreed customer requirement, each stage to the customer prior to the start of that

the supplier’s method of operation and the complexity stage.

of the activities to be performed. The plan should be

Procedures referenced in the plan should be made

as brief as possible, consistent with meeting the pro-

available to the customer, where agreed in the con-

visions of this International Standard. (Simplified

tract.

examples of alternative presentations of quality plans

are contained in annex A.)

4.3 Revision

A quality plan may be a stand-alone document when

a supplier does not have a documented quality sys- The supplier should revise the plan, when appropriate,

tem. A quality plan may also be included as part of to reflect changes that have been made to the prod-

another document or documents (e.g. product or pro-

uct, project or contract, changes to the manner in

ject plan), depending on such things as customer re-

which the product is produced or the service is pro-

quirements or the business practices of a specific

vided, or changes in quality assurance practices.

supplier. It may be necessary to develop a quality plan

Changes to the quality plan should be reviewed for

that consists of a number of parts, each of which re-

impact and adequacy by the same authorized group

presents a plan for a distinct stage, such as for de-

which conducted the review of the original quality

sign, purchasing, production, or inspection and test,

plan.

or for particular activities such as the dependability

plan.

Subject to the specific requirements of a contract,

proposed changes to the plan should be submitted to

NOTE 16 When drafting a textural quality plan, the fol-

the customer for review and acceptance before they

lowing conventions may be used:

are implemented.

- “shall ” to express a provision that is binding between

two 0

r more par-tie s;

5 Contents of the quality plan

- “will” to express a declaration of purpose or intent by

one party;

a) Structure

- “should” to express a recommendation among other

The contents of the quality plan should be based on

possibilities;

this International Standard and the supplier’s docu-

- “may” to indicate a course

of action permissible within mented quality system. It is not essential that the

the limits of the q ua lity plan

quality plan follow the structure and numbering of any

IS0 9000 standards and the alignment of the para-

graphs in this International Standard is only intended

4.2 Review and acceptance

to ease use and understanding.

The quality plan should be reviewed for adequacy and

The elements described in the following subclauses

formally approved by an authorized group that in-

should be addressed, where relevant to the require-

cludes representatives from all affected functions

ments of the product, project or contract.

within the supplier’s organization.

b) Scope of the quality plan

In contractual situations, a quality plan may be sub-

mitted to the customer by the supplier for review and

The scope of the quality plan should be defined and

acceptance, either as part of the precontract award-

should include, but not be limited to:

bidding process or after the contract has been

awarded.

- the product or project to which it is to be ap-

If the plan is submitted as part of the bidding process plied;

and a contract is subsequently awarded, the plan

- the scope of the contract to which it is to be

should be reviewed and, where appropriate, revised

applied;

to reflect any changes in requirements that may have

oc

...

SLOVENSKI STANDARD

SIST ISO 10005:1998

01-oktober-1998

Vodenje kakovosti - Smernice za plane kakovosti

Quality management -- Guidelines for quality plans

Management de la qualité -- Lignes directrices pour les plans qualité

Ta slovenski standard je istoveten z: ISO 10005:1995

ICS:

03.120.10 Vodenje in zagotavljanje Quality management and

kakovosti quality assurance

SIST ISO 10005:1998 sl,en

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

---------------------- Page: 1 ----------------------

SIST ISO 10005:1998

---------------------- Page: 2 ----------------------

SIST ISO 10005:1998

INTERNATIONAL IS0

STANDARD 10005

First edition

1995-09-15

Quality management - Guidelines for

quality plans

Management de la qua/it6 - Lignes directrices pour /es plans qua/it6

----lu/yyh__

- -

-

-

-

-

-

tISOi

~~~

Reference number

IS0 10005:1995(E)

---------------------- Page: 3 ----------------------

SIST ISO 10005:1998

PSO 10005:1995(E)

Contents

Page

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Scope

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .~.~.

2 Normative reference

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 Definitions

2

4 Preparation, review, acceptance and revision of the quality plan

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Preparation

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Review and acceptance

3

4.3 Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Contents of the quality plan

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Management responsibilities

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5.2 Quality plan and quality system

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Contract review

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Design control

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 Document and data control

4

5.6 Purchasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 Control of customer-supplied product

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.8 Product identification and traceability

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.9 Process control

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.10 Inspection and testing

. . . . . . . . . 5

5.11 Control of inspection, measuring and test equipment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.12 Inspection and test status

6

5.13 Control of nonconforming product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.14 Corrective and preventive action

. . . . . 6

5.15 Handling, storage, packaging, preservation and delivery

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.16 Control of quality records

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.17 Quality audits

0 IS0 1995

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced

or utilized in any form or by any means, electronic or mechanical, including photocopying and

microfilm, without permission in writing from the publisher.

International Organization for Standardization

Case Postale 56 l CH-1211 Geneve 20 l Switzerland

Printed in Switzerland

---------------------- Page: 4 ----------------------

SIST ISO 10005:1998

0 IS0

IS0 10005:1995(E)

5.18 Training . 6

5.19 Servicing . 6

5.20 Statistical techniques . 7

Annexes

A Simplified examples of formats for the presentation of quality

plans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

B Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

---------------------- Page: 5 ----------------------

SIST ISO 10005:1998

0 IS0

IS0 10005:1995(E)

Foreword

IS0 (the International Organization for Standardization) is a worldwide

federation of national standards bodies (IS0 member bodies). The work

of preparing International Standards is normally carried out through IS0

technical committees. Each member body interested in a subject for

which a technical committee has been established has the right to be

represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work. IS0

collaborates closely with the International Electrotechnical Commission

(IEC) on all matters of electrotechnical standardization.

Draft International Standards adopted by the technical committees are

circulated to the member bodies for voting. Publication as an International

Standard requires approval by at least 75 % of the member bodies casting

a vote.

International Standard IS0 10005 was prepared by Technical Committee

lSO/TC 176, Quality management and quality assurance, Subcommittee

SC 2, Quality systems.

Annexes A and B of this International Standard are for information only.

IV

---------------------- Page: 6 ----------------------

SIST ISO 10005:1998

0 IS0

IS0 10005:1995(E)

Introduction

This International Standard was prepared to address the need for a

mechanism to relate generic requirements on quality system elements to

the specific requirements of a particular product, project or contract.

Its provisions should be considered advisory and not requirements.

A quality plan may be used within an organization to ensure that specific

requirements for quality are being appropriately planned and addressed for

identified products during production. A quality plan may be used to indi-

cate the specific application of a quality system to a given development

project, whether for a marketable product or for an in-house facility.

A quality plan may also be used by the supplier in a contractual situation

to demonstrate to the customer how the specific requirements for quality

of a particular contract will be met. In many cases, it may be beneficial to

obtain customer input to the development of the quality plan.

The quality plan should be compatible with other plans that may be pre-

pared.

---------------------- Page: 7 ----------------------

SIST ISO 10005:1998

This page intentionally left blank

---------------------- Page: 8 ----------------------

SIST ISO 10005:1998

IS0 10005:1995(E)

INTERNATIONAL STANDARD 0 ISo

Quality management - Guidelines for quality plans

for compliance with requirements. A quality plan may

1 Scope

also be used where a documented quality system

does not exist, in which case procedures may need

1 .I This International Standard provides guidelines

to be developed to support the quality plan.

to assist suppliers in the preparation, review, accept-

ance and revision of quality plans.

NOTE 1 Annex B contains a bibliography of International

Standards which provide information that may prove helpful

It is intended for use in two situations:

to those involved in the preparation and review of quality

plans.

as guidance to a supplier organization in meeting

a)

the requirements of IS0 9001, IS0 9002 or

IS0 9003 relative to the preparation of a quality

plan; or

2 Normative reference

b) as guidance to a supplier organization in preparing

The following standard contains provisions which,

a quality plan when the supplier does not have

through reference in this text, constitute provisions

such a quality system.

of this International Standard. At the time of publi-

cation, the edition indicated was valid. All standards

In both situations, the quality plan is supplemental to

are subject to revision, and parties to agreements

the supplier’s generic quality system documentation

based on this International Standard are encouraged

and should not duplicate the generic documentation.

to investigate the possibility of applying the most re-

For convenience in situations of type b), this Inter-

cent edition of the standard indicated below. Mem-

national Standard includes features that are covered

bers of IEC and IS0 maintain registers of currently

in the generic requirements of IS0 9001, IS0 9002

valid International Standards.

and IS0 9003.

IS0 8402: 1994, Quality management and quality as-

Quality plans provide a mechanism to tie specific re-

surance - Vocabulary.

quirements of the product, project or contract to ex-

isting generic quality system procedures. They do not

require the development of a comprehensive set of

procedures or instructions over and above those al-

3 Definitions

ready existing, although some additional documented

procedures may be necessary.

For the purposes of this International Standard, the

definitions given in IS0 8402, together with the fol-

1.2 This International Standard is applicable where lowing definitions, apply. Terms which are repeated

a quality plan is to be used for a particular product, here for clarity but have been defined in other Inter-

project or contract. A quality plan may be applicable national Standards are identified by the placement of

to any product of the generic product categories the number of the standard after the term being de-

(hardware, software, processed materials and ser-

fined.

vices) or industry/economic sectors.

3.1 contract: Agreed requirements between a sup-

A quality plan may be used to monitor and assess

plier and customer transmitted by any’means.

adherence to the requirements for quality, but these

guidelines are not intended to be used as a checklist [ISO 90011

---------------------- Page: 9 ----------------------

SIST ISO 10005:1998

0 IS0

IS0 10005:1995(E)

3.7 quality plan: Document setting out the specific

3.2 project: Unique process consisting of a set of

coordinated and controlled activities with start and quality practices, resources and sequence of activities

finish dates, undertaken to achieve an objective con- relevant to a particular product, project or contract.

forming to specific requirements, including the con-

NOTES

straints of time, cost and resources.

11 A quality plan usually makes reference to the parts of

NOTES

the quality ma nual applicable to th e specific case.

2 An in dividual p reject may form part of a larger project

12 Depending on the scope of the plan, a qualifier may be

structure

used, for example, “quality assurance plan”, “quality man-

agement plan “.

3 In some types of projects, the objectives are refined and

the project characteristics defined progressively as the pro-

[ISO 84021

ject proceeds.

3.8 quality system: Organizational structure, pro-

4 The outco ime of a p reject may be one or several

cedures, processes and resources needed to imple-

of a product.

ment quality management.

3.3 type test: Test or series of tests directed

NOTES

towards approval of a design conducted to determine

that it is capable of meeting the requirements of the

comprehensive as

13 The quality system should be as

product specification.

the quality objectives.

needed to meet

3.4 witness testing: Testing of a product in the 14 The quality system of an organization is designed pri-

marily to satisfy the internal managerial needs of the or-

presence of the customer’s representative or a third

ganization. It is broader than the requirements of a particular

party.

customer who evaluates only the relevant part of the quality

system.

.

35 procedure: Specified way to perform an activity.

15 For contractual or mandatory quality assessment pur-

NOTES

poses, demonstration of the implementation of identified

quality system elements may be required.

5 In many cases, procedure s are documented (e.g. quality

m procedures).

syste

[ISO 84021

6 When a procedure is to be documented, the term

“written procedure” or “documented procedure” is fre-

4 Preparation, review, acceptance

quently used.

and revision of the quality plan

7 A written or documented procedure usually contains the

purpose and scope of an activity; what shall be done and

4.1 Preparation

by whom; when, where and how it shall be done; what

materials, equipment and documents shall be used; and

When preparing a quality plan, quality activities appli-

how it shall be controlled and recorded.

cable to the situation should be defined and docu-

mented.

[ISO 84021

Much of the generic documentation needed may be

3.6 product: Result of activities or processes.

contained in the supplier’s quality manual and docu-

mented procedures. This documentation may need to

NOTES

be selected, adapted and/or supplemented. The qual-

8 A product may include service, hardware, processed ity plan shows how the supplier’s generic docu-

materi als, software, or a combination thereof.

mented procedures are related to and applied to any

necessary additional procedures peculiar to the prod-

9 A product can be tangible (e.g. assemblies or processed

uct, project or contract in order to attain specified

materials) or intangible (e.g. knowledge or concepts), or a

quality objectives.

combination thereof.

The quality plan should indicate, either directly or by

10 A product can be either intended (e.g. offering to cus-

reference to appropriate documented procedures or

tomers) or unintended (e.g. polluant or unwanted effects).

other documents, how the required activities are to

[ISO 84021 be carried out.

2

---------------------- Page: 10 ----------------------

SIST ISO 10005:1998

0 IS0

IS0 10005:1995(E)

stages, the supplier should submit the quality plan for

The format and level of detail in the plan should be

consistent with any agreed customer requirement, each stage to the customer prior to the start of that

the supplier’s method of operation and the complexity stage.

of the activities to be performed. The plan should be

Procedures referenced in the plan should be made

as brief as possible, consistent with meeting the pro-

available to the customer, where agreed in the con-

visions of this International Standard. (Simplified

tract.

examples of alternative presentations of quality plans

are contained in annex A.)

4.3 Revision

A quality plan may be a stand-alone document when

a supplier does not have a documented quality sys- The supplier should revise the plan, when appropriate,

tem. A quality plan may also be included as part of to reflect changes that have been made to the prod-

another document or documents (e.g. product or pro-

uct, project or contract, changes to the manner in

ject plan), depending on such things as customer re-

which the product is produced or the service is pro-

quirements or the business practices of a specific

vided, or changes in quality assurance practices.

supplier. It may be necessary to develop a quality plan

Changes to the quality plan should be reviewed for

that consists of a number of parts, each of which re-

impact and adequacy by the same authorized group

presents a plan for a distinct stage, such as for de-

which conducted the review of the original quality

sign, purchasing, production, or inspection and test,

plan.

or for particular activities such as the dependability

plan.

Subject to the specific requirements of a contract,

proposed changes to the plan should be submitted to

NOTE 16 When drafting a textural quality plan, the fol-

the customer for review and acceptance before they

lowing conventions may be used:

are implemented.

- “shall ” to express a provision that is binding between

two 0

r more par-tie s;

5 Contents of the quality plan

- “will” to express a declaration of purpose or intent by

one party;

a) Structure

- “should” to express a recommendation among other

The contents of the quality plan should be based on

possibilities;

this International Standard and the supplier’s docu-

- “may” to indicate a course

of action permissible within mented quality system. It is not essential that the

the limits of the q ua lity plan

quality plan follow the structure and numbering of any

IS0 9000 standards and the alignment of the para-

graphs in this International Standard is only intended

4.2 Review and acceptance

to ease use and understanding.

The quality plan should be reviewed for adequacy and

The elements described in the following subclauses

formally approved by an authorized group that in-

should be addressed, where relevant to the require-

cludes representatives from all affected functions

ments of the product, project or contract.

within the supplier’s organization.

b) Scope of the quality plan

In contractual situations, a quality plan may be sub-

mitted to the customer by the supplier for review and

The scope of the quality plan should be de

...

NORME

IS0

INTERNATIONALE

10005

Premibe kdition

1995-09-I 5

Management de la qualit - Lignes

directrices pour les plans qualit

Quality management - Guidelines for quality plans

Num6ro de ri3f6rence

IS0 10005: 1995(F)

---------------------- Page: 1 ----------------------

IS0 10005:1995(F)

Sommaire

Page

1

1 Domaine d’application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Reference normative

2

3 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .*.

. . . . . . 3

4 Preparation, revue, acceptation et revision du plan qualite

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4.1 Preparation

3

4.2 Revue et acceptation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4

5 Contenu du plan qualite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Responsabilites de la direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Plan qualite et systeme qualite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5.2

4

5.3 Revue de contrat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .~. 4

5.4 Ma’itrise de la conception

MaTtrise des documents et des donnees . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5.5

5.6 Achats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.7 Ma*itrise du produit fourni par le client . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.8 Identification et tracabilite du produit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.9 Maltrise des processus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5

5.10 Controles et essais . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

5.11 MaTtrise des equipements de controle, de mesure et d’essai

6

5.12 ctat des controles et des essais . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.13 MaTtrise du produit non conforme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.14 Actions correctives et preventives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Manutention, stockage, conditionnement, preservation et

5.15

livraison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.16 MaTtrise des enregistrements relatifs a la qualite . . . . . . . . . . . . . . . . 6

0 IS0 1995

Droits de reproduction reserves. Sauf prescription differente, aucune partie de cette publi-

cation ne peut Qtre reproduite ni utilisee sous quelque forme que ce soit et par aucun pro-

cede, electronique ou mecanique, y compris la photocopie et les microfilms, sans I’accord

ecrit de I’editeur.

Organisation internationale de normalisation

Case Postale 56 l CH-1211 Geneve 20 l Suisse

Imprime en Suisse

ii

---------------------- Page: 2 ----------------------

0 IS0

IS0 10005:1995(F)

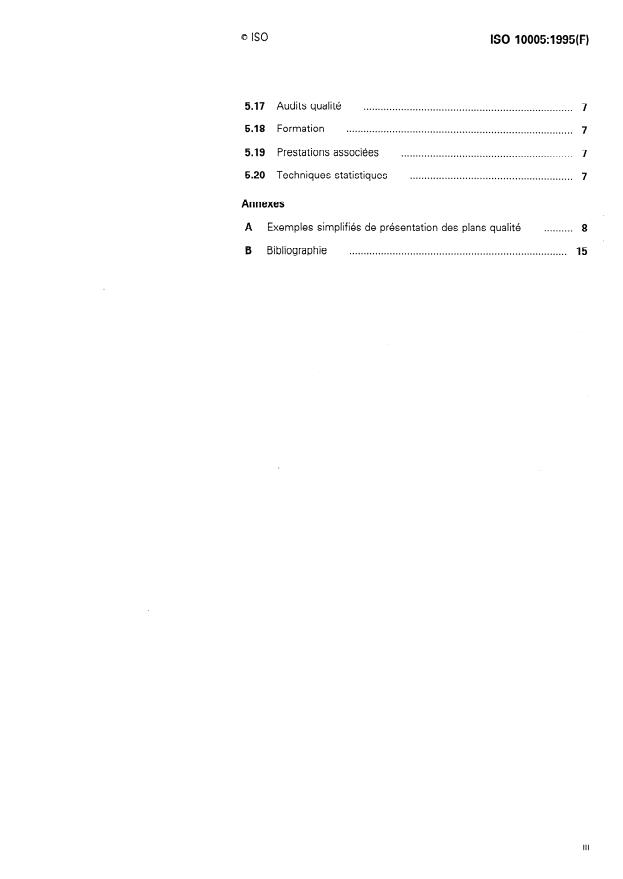

5.17 Audits qualit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .~. 7

5.18 Formation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.19 Prestations associkes 7

5.20 Techniques statistiques . .~.~. 7

Annexes

dB Exemples simplifiks de prksentation des plans qualit . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

IB Bibliographie

. . .

III

---------------------- Page: 3 ----------------------

Q IS0

IS0 10005:1995(F)

Avant-propos

L’ISO (Organisation internationale de normalisation) est une federation

mondiale d’organismes nationaux de normalisation (comites membres de

I’ISO). L’elaboration des Normes internationales est en general confiee aux

comites techniques de I’ISO. Chaque comite membre interesse par une

etude a le droit de faire par-tie du comite technique tree 8 cet effet. Les

organisations internationales, gouvernementales et non gouvernemen-

tales, en liaison avec I’ISO participent egalement aux travaux. L’ISO colla-

bore etroitement avec la Commission electrotechnique internationale (CEI)

en ce qui concerne la normalisation electrotechnique.

Les projets de Normes internationales adopt& par les comites techniques

sont soumis aux comites membres pour vote. Leur publication comme

Normes internationales requiert I’approbation de 75 % au moins des co-

mites membres votants.

La Norme internationale IS0 10005 a ete elaboree par le comite technique

lSO/TC 176, Management et assurance de /a qua/it& sous-comite SC 2,

Sys t&mes qua/it&

Le s annexes A et B de la presente Norme intern ationale sont donnees

un iquement a titre d’info rmation.

---------------------- Page: 4 ----------------------

0 IS0

IS0 10005:1995(F)

Introduction

La presente Norme internationale a ete elaboree pour repondre au besoin

d’appliquer une methode particuliere pour relier des exigences generiques

d’elements de systeme qualite aux exigences specifiques d’un produit,

projet ou contrat particulier. II convient de considerer ses dispositions

comme des conseils et non pas des exigences.

Un plan qualite peut etre utilise dans un organisme pour s’assurer que des

exigences specifiques relatives a la qualite sont convenablement planifiees

et prises en compte pour des produits identifies en tours de production.

Un plan qualite peut etre utilise pour indiquer I’application specifique d’un

systeme qualite a un projet de developpement don&, soit pour un produit

commercialisable, soit pour commodite interne. Un plan qualite peut

egalement etre applique par le fournisseur dans une situation contractuelle

pour demontrer au client de quelle maniere les exigences specifiques re-

latives a la qualite d’un contrat particulier seront satisfaites. Dans un grand

nombre de cas, il peut etre avantageux d’obtenir des donnees d’entrees

du client pour le developpement de ce plan qualite.

II est souhaitable q ue le plan qualite soit compatible avec les autres plans

pouvanf etre elabo res.

---------------------- Page: 5 ----------------------

This page intentionally left blank

---------------------- Page: 6 ----------------------

NORME INTERNATIONALE 0 IS0

IS0 10005:1995(F)

Lignes directrices pour

Management de la qualit -

les plans qualit

peut etre applicable a n’importe quelle categoric ge-

1 Domaine d’application

nerique de produit (materiel, logiciel, produit issu de

processus a caractere continu et service) ou de sec-

1.1 La presente Norme internationale fournit des Ii-

teurs industriels/economiques.

gnes directrices pour aider les fournisseurs dans la

preparation, la revue, I’acceptation et la revision de

Un plan qualite peut etre utilise pour tenir sous

plans qualite.

controle et evaluer I’adhesion aux exigences de la

qualite, mais ces lignes directrices ne sont pas desti-

Elle est prevue pour etre utilisee dans deux cas:

nees a etre utilisees comme liste de controle de

conformite aux exigences. Un plan qualite peut

a) en tant que guide pour un organisme fournisseur

egalement etre utilise chaque fois qu’un systeme

pour satisfaire les exigences de I’ISO 9001,

qualite fonde sur des documents n’existe pas et, dans

I’ISO 9002 ou I’ISO 9003 relatives a I’elaboration

ce cas, il peut etre utile de developper des procedures

d’un plan qualite; ou

pour servir de base a ce plan qualite.

b) en tant que guide pour un organisme fournisseur

NOTE 1 L’annex B contient une bibliographic des Nor-

pour I’elaboration d’un plan qualite lorsque le

mes internationales qui fournissent des informations pou-

fournisseur ne possede pas un tel systeme qua-

- , vant s’avkrer utiles aux personnes chargkes de la

ljte .

prkparation et de la revue des plans qualit&

Dans les deux cas, le plan qualite vient en supplement

a la documentation du systeme qualite generique du

fournisseur, qu’il convient de ne pas dupliquer. Pour

commodite dans le cas de type b), la presente Norme

internationale comprend des caracteristiques qui sont

couvertes dans les exigences generiques de 2 Rkfbence normative

I’ISO 9001, I’ISO 9002 et I’ISO 9003.

La norme suivante contient des dispositions qui, par

Les plans qualite fournissent une methode particuliere

suite de la reference qui en est faite, constituent des

pour mettre en relation les exigences specifiques du

dispositions valables pour la presente Norme inter-

produit, projet ou contrat avec les procedures generi-

nationale. Au moment de la publication, I’edition indi-

ques de systeme qualite existantes. lls ne necessitent

quee etait en vigueur. Toute norme est sujette a

pas le developpement d’un ensemble complet de

revision et les parties prenantes des accords fond&

procedures ou d’instructions couvrant ou se

sur la presente Norme internationale sont invitees a

substitant a celles deja existantes, bien que des pro-

rechercher la possibilite d’appliquer I’edition la plus

cedures &rites supplementaires puissent s’averer

recente de la norme indiquee ci-apres. Les membres

necessaires.

de la CEI et de I’ISO possedent le registre des Nor-

mes internationales en vigueur a un moment donne.

1.2 La presente Norme internationale est applicable

IS0 8402:1994, Management de la qua/it6 et assu-

chaque fois qu’un plan qualite doit etre utilise pour un

rance de la qua126 - Vocabulaire.

produit, projet ou contrat particulier. Un plan qualite

1

---------------------- Page: 7 ----------------------

IS0 10005:1995(F) 0 IS0

quels matkriels, equipements et

documents doivent &re

3 Dbfinitions

utilisk, et comment cela doit &re

maltrisk et enregistrk

Pour les besoins de la presente Norme internationale,

[ISO 84021

les definitions donnees dans I’ISO 8402 et les dbfini-

tions suivantes s’appliquent. Les termes repris ici

36 . produit: R6sultat d’activiths ou de processus.

pour des raisons de clart6, mais d6jA definis dans

d’autres Normes internationales, sont identifih par la

NOTES

mention du num&o de la norme, aprh la dkfinition.

8 Le terme ((produit)) peut inclure les services, les mat&

riels, les produits issus de processus A caracthre continu,

3.1 contrat: Exigences ayant fait I’objet d’un accord

les logiciels, ou une combinaison de ceux-ci.

entre un fournisseur et un client, et transmises par

un moyen quelconque.

9 Un produit peut &re matkriel (par exemple, assemblage

ou produits issus de processus A caracthre continu) ou im-

[ISO 90011

matbrie (par exemple, connaissances ou concepts), ou une

combinaison des deux.

3.2 projet: Processus spkifique consistant en un

10 Un produit peut etre soit intentionnel (par exemple, une

ensemble d’activites coordonnkes et maTtrikes avec

offre aux clients), soit non intentionnel (par exemple, un

dates de d6but et de fin, entreprises pour atteindre

polluant ou des effets indhirables).

un objectif conforme aux exigences spkifiques,

comprenant les containtes de temps, cotits et

[ISO 84021

moyens.

3.7 plan qualit& Document honGant les pratiques,

NOTES

les moyens et la sequence des activitks likes 5 la

qualiti! spkcifiques 5 un produit, projet ou contrat

peut We une par-tie d’une structure

2 Un projet individuel

particulier.

de projet plus large.

NOTES

3 Pour certains types de projets, les objectifs sont affinh

et les caracthistiques du projet sont dbfinies au fur et A

11 Un plan qualitk fait g& halement rbfhence aux parties

mesure de I’avancement du projet.

du manuel q ualite applicab les sphifiquement.

4 Le ksultat d’un projet peut &re une ou plusieurs unit&

12 Selon I’objet du plan, un qualificatif peut etre utilise, par

d’un produit.

exemple ((plan assurance qualit& ((plan management de la

qualit&.

3.3 essai de type: Essai ou shie d’essais visant

I’approbation d’une conception conduite pour dkter- [ISO 84021

miner sa capacitk 8 r6pondre aux exigences de la

3.8 systkme qualit& Ensemble de I’organisation,

spkcification du produit.

des prockdures, des processus et des moyens n&

cessaires pour mettre en ceuvre le management de la

3.4 essai tbmoin: Essai d’un produit effect& en

qualit&

prhence d’un reprksentant du client ou d’une tierce

partie.

NOTES

3.5 procedure: Man&e spkifike d’accomplir une

13 II convient que le systbme qualiti! ne soit pas plus

activitk &endu qu’il n’est besoin pour atteindre les objectifs relatifs

h la qualit&

NOTES

14 Le systeme qualit d’un organisme est conCu essen-

5 Dans de nombreux cas, les procbdures sont exprimkes tiellement pour satisfaire les besoins internes de

par des documents (par exemple, prockdures d’un systhme management de I’organisme. II va au-dela des exigences

qualit@. d’un client particulier, qui n’kvalue que la partie du systeme

qualit qui le concerne.

squ’une procbdure est exprimke par un

6 Lor document, le

((proc&dure &rite)) est 15 Pour les besoins d’une &valuation qualit contractuelle

terme souvent utilisk

ou obligatoire, la dbmonstration de la mise en ceuvre d’&-

7 Une prockdure &rite comporte ghhalement I’objet et

ments identifih du systkme qualitk peut &tre exigbe.

le domaine d’application d’une activitb; ce qui doit &re fait

et qui doit le faire; quand, oh et comment cela doit Mre fait; [ISO 84021

---------------------- Page: 8 ----------------------

0 IS0

IS0 10005:1995(F)

- ((iI convient de imer une recommandatio

2) pour expr

4 IPrkparation, revue, acceptation

parmi d’autres

possibilit&;

et rbvision du plan qualit

- ((peut)) pour indiqu er une skquence d’action s permises

dans les limites du plan qualit&

4.1 Prkparation

En preparant un plan qualite, il convient de definir et

de consigner par ecrit les activites relatives a la qualite

4.2 Revue et acceptation

applicables.

II convient que le plan qualite soit revu pour adequa-

Une grande partie de la documentation generique ne-

tion et formellement approuve par un groupe autorise

cessaire peut etre contenue dans le manuel qualite

qui comprend les representants de toutes les fonc-

et les procedures &rites du fournisseur. II peut etre

tions concernees au sein de I’organisme du fournis- ’

necessaire que cette documentation soit choisie,

seur.

adaptee et/au completee. Le plan qualite montre

comment les procedures &rites generiques du four-

En situations contractuelles, un plan qualite peut etre

nisseur sont reliees et appliquees a toutes procedures

soumis au client par le fournisseur pour revue et ac-

supplementaires necessaires specifiques au produit,

ceptation, soit en tant que par-tie du processus d’offre

projet ou contrat dans le but d’atteindre les objectifs

avant contrat, soit apres que le contrat a ete attribue.

specifies relatifs a la qualite.

Si le plan est presente en tant que partie du proces-

II convient que le plan qualite indique, soit direc-

sus d’offre et si un contrat est par la suite attribue, il

tement, soit en se refer-ant aux procedures &rites

convient de faire une revue de ce plan et, si neces-

appropriees ou a d’autres documents, comment les

saire, de reviser ce plan pour qu’il reflete les modifi-

activites requises doivent etre executees.

cations des exigences pouvant etre inter-venues suite

aux negotiations ayant precede le contrat.

II convient que la forme et le niveau de detail du plan

soient compatibles avec toute exigence convenue du

Lorsqu’un plan qualite est exige par un contrat, il

client, le mode de fonctionnement du fournisseur et

convient normalement qu’il soit presente avec le

la complexite des activites 21 accomplir. II convient que

commencement des activites requises. Chaque fois

le plan soit aussi bref que possible, et compatible

que le contrat se deroule en plusieurs phases, il

avec la satisfaction aux dispositions de la pr&ente

convient que le fournisseur soumette le plan qualite

Norme internationale. (L’annexe A comporte des

au client avant le commencement de chacune des

exemples simplifies de plusieurs presentations possi-

phases.

bles de plans qualite.)

II convient que les procedures auxquelles on se refer-e

Un plan qualite peut etre un document autonome,

dans un plan soient a la disposition du client, si cela

lorsqu’un fournisseur ne dispose pas d’un systeme

a ete convenu dans le contrat.

qualite documente par ecrit. Un plan qualite peut aussi

faire par-tie d’un autre document ou de documents

(comme un plan pour un produit ou pour un projet)

4.3 Rhision

dependant d’elements tels que les exigences d’un

client ou les pratiques professionnelles d’un fournis-

II convient que le fournisseur revise le plan, chaque

seur specifique. II peut etre necessaire de developper

fois que cela est necessaire, pour tenir compte des

un plan qualite qui consiste en un nombre de parties,

modifications apportees au produit, projet ou contrat,

chacune d’entre elles representant un plan pour une

des modifications sur la man&-e dont le produit est

phase distincte telle que conception, achat, produc-

fabrique, le service fourni ou des modifications dans

tion, ou controle et essais, ou activites particulieres

les pratiques de I’assurance de la qualite.

telles que le plan de skete de fonctionnement.

II convient que les modifications du plan qualite soient

NOTE 16 Lors de la rkdaction du plan qualit& les

revues pour impact et adequation par le meme groupe

conventions suivantes peuvent &re utilisbes:

autorise qui a conduit la revue du plan qualite original.

-’

((doit )) pour exprimer une disposition qui est prise entre

Suivant les exigences specifiques d’un contrat, il

deux ou plusieurs parties;

convient que des modifications du plan proposees

soient soumises a la revue et a I’acceptation du client

- le futur pour exprimer une dklaration d’objectif ou

d’ intentio n par une pat-tie avant d’etre mises en oeuvre.

---------------------- Page: 9 ----------------------

0 IS0

IS0 10005:1995(F)

e) de ma’itriser les actions correctives (voir 5.14).

5 Contenu du plan qualit

a) Structure

5.2 Plan qualit et systkme qualit

II convient que le contenu du plan qualite soit fonde

La plus grande par-tie de la documentation du plan

sur la presente Norme internationale et sur le sys-

qualite existera en principe deja en tant que par-tie de

teme qualite documente du fournisseur. II n’est pas

la documentation du systeme qualite. II est seulement

primordial que le plan qualite suive la structure et la

necessaire que le plan qualite se refere i cette docu-

num6rotation d’une norme IS0 9000 et l’alignement

mentation et demontre comment elle doit etre appli-

des paragraphes de la presente Norme internationale

quee a la situation particuliere concernee. Lorsqu’un

n’est destine qu’a faciliter son utilisation et sa

element d’une telle documentation n’existe pas en-

comprehention.

core mais est necessaire, it convient que le plan qua-

lite I’identifie ainsi que quand, comment et par qui il

II convient que les elements decrits dans les paragra-

sera prepare et approuve.

phes suivants repondent aux exigences du produit,

projet ou contrat chaque fois qu’il est pertinent de le

5.3 Revue de contrat

faire.

II

...

SLOVENSKI SIST ISO 10005

druga izdaja

STANDARD

november 1998

Vodenje kakovosti - Smernice za plane kakovosti

(enakovreden ISO 10005:1995)

Quality management - Guidelines for quality plans

Management de la qualité - Lignes directrices pour les plans qualité

Qualitätsmanagement - Leitfaden für Qualitätsmanagementpläne

Deskriptorji: vodenje kakovosti, zagotavljanje kakovosti, sistemi zagotavljanja kakovosti,

komponente, splo{ni pogoji

Referen~na {tevilka

ICS 03.120.10 SIST ISO 10005:1998 (sl,en)

Nadaljevanje na straneh od 2 do 34

© Standard je zalo`il in izdal Urad Republike Slovenije za standardizacijo in meroslovje pri Ministrstvu za znanost in tehnologijo.

Razmno`evanje ali kopiranje celote ali delov tega standarda ni dovoljeno.

---------------------- Page: 1 ----------------------

SIST ISO 10005 : 1998

UVOD

Standard SIST ISO 10005 (sl,en), Vodenje kakovosti - Smernice za plane kakovosti, druga

izdaja, 1998, ima status slovenskega standarda in je enakovreden mednarodnemu standardu

ISO 10005, Quality management - Guidelines for quality plans, prva izdaja, 1995.

NACIONALNI PREDGOVOR

Mednarodni standard ISO 10005:1995 je pripravil tehni~ni odbor Mednarodne organizacije za

standardizacijo ISO/TC 176 Vodenje in zagotavljanje kakovosti. Slovenski standard

SIST ISO 10005:1998 je prevod angle{kega besedila mednarodnega standarda

ISO 10005:1995. V primeru spora glede besedila slovenskega prevoda v tem standardu je

odlo~ilen izvirni mednarodni standard v angle{kem jeziku. Slovensko-angle{ko izdajo standarda

je pripravil in potrdil tehni~ni odbor USM/TC VZK Vodenje in zagotavljanje kakovosti.

Ta slovenski standard je dne 1998-10-05 odobril direktor USM.

ZVEZE S STANDARDI

S prevzemom tega mednarodnega standarda velja naslednja zveza:

SIST EN ISO 8402:1997 (sl,en,de,fr) Vodenje in zagotavljanje kakovosti - Slovar (istoveten

EN ISO 8402:1995)

PREDHODNA IZDAJA

- SIST ISO 10005:1996 (en)

OSNOVA ZA IZDAJO STANDARDA

- Prevzem standarda ISO 10005:1995.

OPOMBE

- Povsod, kjer se v besedilu standarda uporablja izraz “mednarodni standard”, v

SIST ISO 10005 to pomeni “slovenski standard”.

- Uvod in nacionalni predgovor nista sestavni del standarda.

- Slovenski standard SIST ISO 10005:1998 (sl,en) je enakovreden mednarodnemu

standardu ISO 10005:1995.

2

---------------------- Page: 2 ----------------------

SIST ISO 10005 : 1998

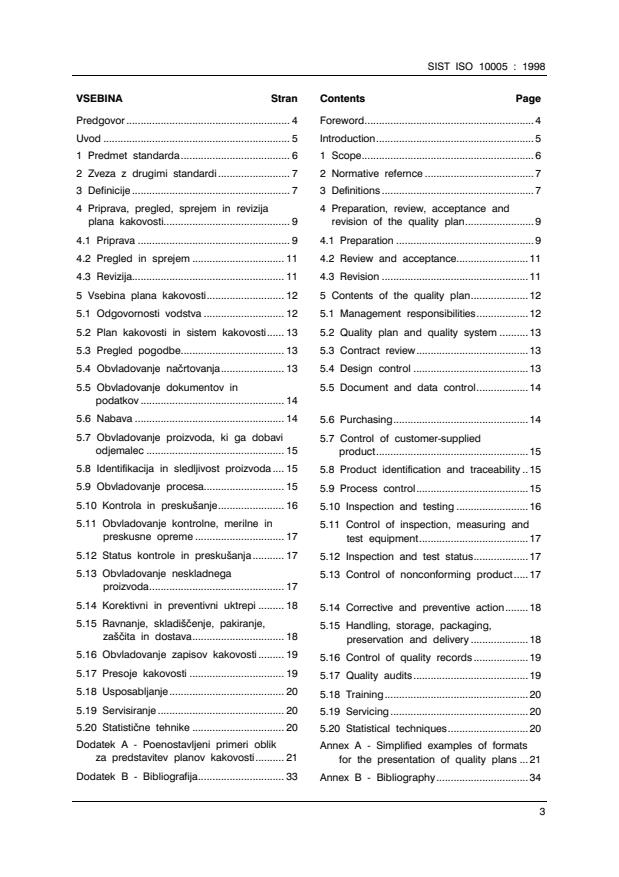

VSEBINA Stran Contents Page

Predgovor.4 Foreword.4

Uvod.5 Introduction.5

1 Predmet standarda.6 1 Scope.6

2 Zveza z drugimi standardi.7 2 Normative refernce.7

3 Definicije.7 3 Definitions.7

4 Priprava, pregled, sprejem in revizija 4 Preparation, review, acceptance and

plana kakovosti.9 revision of the quality plan.9

4.1 Priprava.9 4.1 Preparation.9

4.2 Pregled in sprejem.11 4.2 Review and acceptance.11

4.3 Revizija.11 4.3 Revision.11

5 Vsebina plana kakovosti.12 5 Contents of the quality plan.12

5.1 Odgovornosti vodstva.12 5.1 Management responsibilities.12

5.2 Plan kakovosti in sistem kakovosti.13 5.2 Quality plan and quality system.13

5.3 Pregled pogodbe.13 5.3 Contract review.13

5.4 Obvladovanje na~rtovanja.13 5.4 Design control.13

5.5 Obvladovanje dokumentov in 5.5 Document and data control.14

podatkov.14

5.6 Nabava.14

5.6 Purchasing.14

5.7 Obvladovanje proizvoda, ki ga dobavi

5.7 Control of customer-supplied

odjemalec.15

product.15

5.8 Identifikacija in sledljivost proizvoda.15

5.8 Product identification and traceability.15

5.9 Obvladovanje procesa.15

5.9 Process control.15

5.10 Kontrola in presku{anje.16

5.10 Inspection and testing.16

5.11 Obvladovanje kontrolne, merilne in

5.11 Control of inspection, measuring and

preskusne opreme.17

test equipment.17

5.12 Status kontrole in presku{anja.17

5.12 Inspection and test status.17

5.13 Obvladovanje neskladnega

5.13 Control of nonconforming product.17

proizvoda.17

5.14 Korektivni in preventivni uktrepi.18

5.14 Corrective and preventive action.18

5.15 Ravnanje, skladi{~enje, pakiranje,

5.15 Handling, storage, packaging,

za{~ita in dostava.18

preservation and delivery.18

5.16 Obvladovanje zapisov kakovosti.19

5.16 Control of quality records.19

5.17 Presoje kakovosti.19

5.17 Quality audits.19

5.18 Usposabljanje.20

5.18 Training.20

5.19 Servisiranje.20

5.19 Servicing.20

5.20 Statisti~ne tehnike.20

5.20 Statistical techniques.20

Dodatek A - Poenostavljeni primeri oblik

Annex A - Simplified examples of formats

za predstavitev planov kakovosti.21

for the presentation of quality plans.21

Dodatek B - Bibliografija.33

Annex B - Bibliography.34

3

---------------------- Page: 3 ----------------------

SIST ISO 10005 : 1998

Predgovor Foreword

ISO (Mednarodna organizacija za ISO (the International Organization for

standardizacijo) je svetovna zveza Standardization) is a worldwide federation of

nacionalnih organov za standarde (~lanov national standards bodies (ISO member

ISO). Mednarodne standarde ponavadi bodies). The work of preparing International

pripravljajo tehni~ni odbori ISO. Vsak ~lan, Standards is normally carried out through

ki `eli sodelovati na dolo~enem podro~ju, za ISO technical committees. Each member

katerega je ustanovljen tehni~ni odbor, ima body interested in a subject for which a

pravico biti zastopan v tem odboru. Pri delu technical committee has been established

sodelujejo tudi vladne in nevladne has the right to be represented on that

mednarodne organizacije, povezane z ISO. V committee. International organizations,

vseh zadevah, ki so povezane s governmental and non-governmental, in

standardizacijo na podro~ju elektrotehnike, liaison with ISO, also take part in the work.

ISO tesno sodeluje z Mednarodno ISO collaborates closely with the

elektrotehni{ko komisijo (IEC). International Electrotechnical Commission

(IEC) on all matters of electrotechnical

standardization.

Osnutki mednarodnih standardov, ki jih Draft International Standards adopted by the

sprejmejo tehni~ni odbori, se po{ljejo vsem technical committees are circulated to the

~lanicam v glasovanje. Za objavo member bodies for voting. Publication as an

mednarodnega standarda je treba pridobiti International Standard requires approval by

soglasje najmanj 75 odstotkov ~lanic, ki se at least 75 % of the member bodies casting

udele`ijo glasovanja. a vote.

Mednarodni standard ISO 10005 je pripravil International Standard was prepared by

tehni~ni odbor ISO/TC 176 Vodenje in Technical Commitee ISO/TC 176, Quality

zagotavljanje kakovosti, pododbor SC 2 management and quality assurance,

Sistemi kakovosti. Subcommitee SC 2, Quality systems.

Dodatka A in B tega mednarodnega Annexes A and B of this International

standarda sta podana samo kot informacija. Standard are for information only.

4

---------------------- Page: 4 ----------------------

SIST ISO 10005 : 1998

Uvod Introduction

Mednarodni standard je bil pripravljen zaradi This International Standard was prepared to

potrebe po mehanizmu, ki bi povezal address the need for a mechanism to relate

splo{ne zahteve za elemente sistema generic requirements in quaity system

kakovosti in specifi~ne zahteve dolo~enega elements to the specific requirements of a

proizvoda, projekta ali pogodbe. Dolo~ila so particular product, project or contract. Its

samo svetovalnega zna~aja in niso zahteve. provisions should be considered advisory

and not requirements.

Plan kakovosti se lahko uporablja v A quality plan may be used within an

organizaciji, da se zagotovi ustrezno organization to ensure that specific

planiranje in naslavljanje identificiranih requirements for quality are being

proizvodov med izdelavo, v skladu s appropriately planned and addressed for

specifi~nimi zahtevami kakovosti. Plan identified products during production. A

kakovosti se lahko uporablja kot pokazatelj quality plan may be used to indicate the

specifi~ne uporabe sistema kakovosti na specific application of a quality system to a

dolo~enem razvojnem projektu za prodajni given development project, whether for a

proizvod ali za pripomo~ke, ki bodo marketable product or for an in-house

uporabljeni znotraj hi{e. Dobavitelj lahko v facility. A quality plan may also be used by

pogodbenem razmerju uporabi plan the supplier in a contractual situation to

kakovosti za prikaz, kako bo izpolnil demonstrate to the customer how the

specifi~ne zahteve za kakovost, ki so specific requirements for quality of a

dolo~ene v pogodbi. Mnogokrat je lahko particular contract will be met. In many

ugodno, ~e dobavitelj lahko pri razvoju cases, it may be beneficial to obtain

plana kakovosti pridobi odjemal~eve customer input to the development of the

pripombe. quality plan.

Plan kakovosti naj bo zdru`ljiv z drugimi The quality plan should be compatible with

plani, ki so morda `e pripravljeni. other plans that may be prepared.

5

---------------------- Page: 5 ----------------------

SIST ISO 10005 : 1998

Vodenje kakovosti - Smernice Quality management -

za plane kakovosti Guidelines for quality plans

1 Predmet standarda 1 Scope

1.1 Ta mednarodni standard dolo~a 1.1 This International Standard provides

smernice, ki bodo v pomo~ dobaviteljem pri guidelines to assist suppliers in the

pripravi, pregledu, sprejemu in reviziji planov preparation, review, acceptance and revision

kakovosti. of quality plans.

Uporablja se lahko v dveh primerih: It is intended for use in two situations:

a) kot vodilo dobaviteljevi organizaciji pri a) as guidance to a supplier organisation

izpolnjevanju zahtev ISO 9001, in meeting the requrements of ISO

ISO 9002 ali ISO 9003 za pripravo 9001, ISO 9002 or ISO 9003 relative

plana kakovosti; ali to the preparation of a quality plan;

or

b) kot vodilo dobaviteljevi organizaciji pri b) as guidance to a supplier organization

pripravi plana kakovosti, v primeru, da in preparing a quality plan when the

dobavitelj {e nima tak{nega sistema supplier does not have such a quality

kakovosti. system.

V obeh primerih je plan kakovosti le In both situations, the quality plan is

dodatek splo{ne dokumentacije supplemental to the supplier’s generic

dobaviteljevega sistema kakovosti in naj je quality system documentation and should

ne podvaja. Zaradi primernosti pri uporabi not duplicate the generic documentation. For

tipa b), vklju~uje ta mednarodni standard convenience in situations of type b), this

zna~ilnosti, ki so zajete v splo{nih zahtevah International Standard includes features that

standardov ISO 9001, ISO 9002 in are covered in the generic requirements of

ISO 9003. ISO 9001, ISO 9002 and

ISO 9003.

Plani kakovosti zagotavljajo mehanizem, ki Quality plans provide a mechanism to tie

povezuje specifi~ne zahteve proizvoda, specific requirements of the product, project

projekta ali pogodbe z obstoje~imi splo{nimi or contract to existing generic quality

postopki sistema kakovosti. Plani kakovosti system procedures. They do not require the

ne zahtevajo razvoja mno`ice dodatnih development of a comprehensive set of

postopkov ali navodil, ~eprav so lahko procedures or instructions over and above

potrebni dodatni dokumentirani postopki. those already existing, although some

additional documented procedures may be

necessary.

1.2 Ta mednarodni standard je primeren, 1.2 This International Standard is applicable

kadar se plan kakovosti uporablja za where a quality plan is to be used for a

dolo~en proizvod, projekt ali pogodbo. Plan particular product, project or contract. A

kakovosti se lahko uporablja pri vsaki izvorni quality plan may be applicable to any

vrsti proizvoda (strojna in programska product of the generic product categories

oprema, predelani materiali in storitve) ali v (hardware, software, processed materials and

industrijskih/ekonomskih sektorjih. services) or industry/economic sectors.

6

---------------------- Page: 6 ----------------------

SIST ISO 10005 : 1998

Plan kakovosti se lahko uporabi za nadzor A quality plan may be used to monitor and

in ocenjevanje skladnosti z zahtevami asses adherence to the requirements for

kakovosti, vendar te smernice niso seznam quality, but these guidelines are not

to~k za preverjanje skladnosti z zahtevami. intended to be used as a checklist for

Plan kakovosti se lahko uporabi tudi, ~e ne compliance with requirements. A quality plan

obstaja dokumentiran sistem kakovosti, may also be used where a documented

vendar so v takem primeru potrebni quality system does not exist, in which case

postopki za podporo plana kakovosti. procedures may need to be developed to

support the quality plan.

Opomba: 1. Dodatek B vsebuje seznam mednarodnih NOTE 1 Annex B contains a bibliography of

standardov, ki lahko dajo informacije in International Standards which provide

so v pomo~ vsem vklju~enim v pripravo information that may prove helpful to

in pregled planov kakovosti. those involved in the preparation and

review of quality plans.

2 Zveza z drugimi standardi 2 Normative reference

Spodaj navedeni standard vsebuje dolo~ila, The following standard contains provisions

ki v povezavi s tem besedilom tvorijo which, through reference in this text,

dolo~ila tega mednarodnega standarda. V constitute provisions of this International

~asu objave je bila veljavna spodaj Standard. At the time of publication, the

navedena izdaja. Vsi standardi se ponavadi edition indicated was valid. All standards are

revidirajo. Strankam, ki sklenejo pogodbo, subject to revision, and parties to

zasnovano na tem mednarodnem standardu, agreements based on this International

se priporo~a, naj razi{~ejo mo`nost uporabe Standard are encouraged to investigate the

najnovej{e izdaje spodaj navedenega possibility of applying the most recent

standarda. ^lani IEC in ISO vzdr`ujejo edition of the standard indicated below.

register veljavnih mednarodnih standardov. Members of IEC and ISO mantain registers

of currently valid International Standards.

ISO 8402:1994, Vodenje in zagotavljanje

kakovosti - Slovar. ISO 8402:1994, Quality management and

quality assurance - Vocabulary.

SIST EN ISO 8402:1995, Vodenje in

zagotavljanje kakovosti - Slovar.

3 Definicije 3 Definitions

V tem mednarodnem standardu so For the purposes of this International

uporabljene definicije, podane v standardu Standard, the definitions given in ISO 8402,

ISO 8402, skupaj s spodaj navedenimi together with the following definitions, apply.

definicijami. Izrazi, ki so tukaj ponovljeni Terms which are repeated here for clarity

zaradi jasnosti, definirani pa so bili v drugih but have been defined in other International