ISO/FDIS 14053

(Main)Environmental management -- Material flow cost accounting -- Guidance for phased implementation in organizations

Environmental management -- Material flow cost accounting -- Guidance for phased implementation in organizations

Management environnemental -- Comptabilité des flux de matières -- Recommandations pour la mise en application par phases dans les organismes

General Information

Buy Standard

Standards Content (sample)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 14053

ISO/TC 207/SC 1

Environmental management —

Secretariat: BSI

Material flow cost accounting

Voting begins on:

20201019 — Guidance for practical

implementation in SMEs

Voting terminates on:

20201214

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO

ISO/FDIS 14053:2020(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN

DARDS TO WHICH REFERENCE MAY BE MADE IN

NATIONAL REGULATIONS. ISO 2020

---------------------- Page: 1 ----------------------

ISO/FDIS 14053:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/FDIS 14053:2020(E)

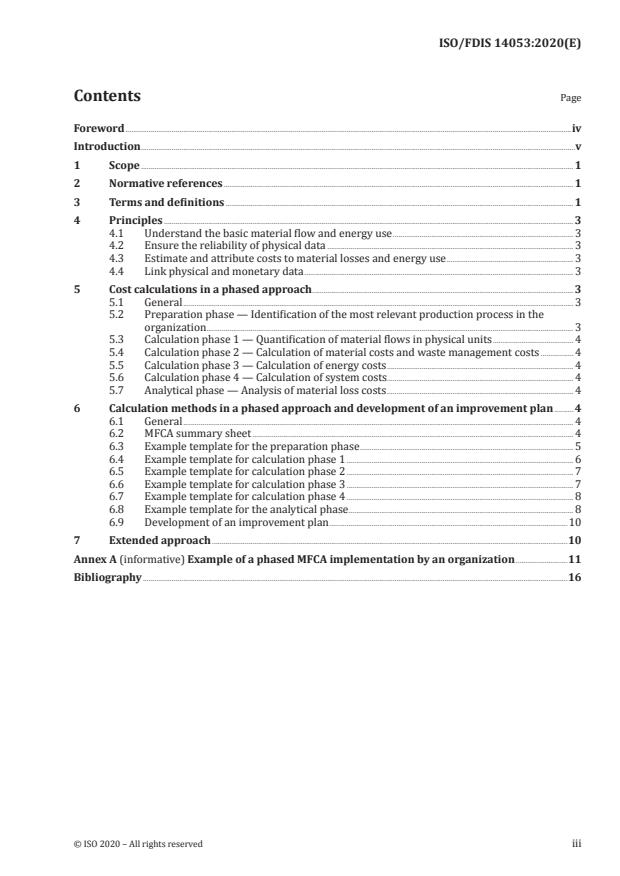

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction ..................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Principles ..................................................................................................................................................................................................................... 3

4.1 Understand the basic material flow and energy use .............................................................................................. 3

4.2 Ensure the reliability of physical data ................................................................................................................................ 3

4.3 Estimate and attribute costs to material losses and energy use .................................................................. 3

4.4 Link physical and monetary data ............................................................................................................................................ 3

5 Cost calculations in a phased approach ........................................................................................................................................ 3

5.1 General ........................................................................................................................................................................................................... 3

5.2 Preparation phase — Identification of the most relevant production process in the

organization............................................................................................................................................................................................... 3

5.3 Calculation phase 1 — Quantification of material flows in physical units .......................................... 4

5.4 Calculation phase 2 — Calculation of material costs and waste management costs ................. 4

5.5 Calculation phase 3 — Calculation of energy costs ................................................................................................. 4

5.6 Calculation phase 4 — Calculation of system costs................................................................................................. 4

5.7 Analytical phase — Analysis of material loss costs ................................................................................................. 4

6 Calculation methods in a phased approach and development of an improvement plan ..........4

6.1 General ........................................................................................................................................................................................................... 4

6.2 MFCA summary sheet ....................................................................................................................................................................... 4

6.3 Example template for the preparation phase ............................................................................................................... 5

6.4 Example template for calculation phase 1 ...................................................................................................................... 6

6.5 Example template for calculation phase 2 ...................................................................................................................... 7

6.6 Example template for calculation phase 3 ...................................................................................................................... 7

6.7 Example template for calculation phase 4 ...................................................................................................................... 8

6.8 Example template for the analytical phase ..................................................................................................................... 8

6.9 Development of an improvement plan ............................................................................................................................10

7 Extended approach .........................................................................................................................................................................................10

Annex A (informative) Example of a phased MFCA implementation by an organization ...........................11

Bibliography .............................................................................................................................................................................................................................16

© ISO 2020 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/FDIS 14053:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and nongovernmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 207, Environmental management.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.iv © ISO 2020 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/FDIS 14053:2020(E)

Introduction

Achieving the Sustainable Development Goals (SDGs) established by the United Nations in 2015 has

become a high priority for society. In particular, Goal 12 requires both governments and private sectors

to ensure sustainable consumption and production patterns. Companies of all sizes need to achieve

improvements in material and energy efficiency for sustainable production.A number of International Standards provide guidance on material flow cost accounting (MFCA), which

is an approach to assess material efficiency within an organization (see ISO 14051) and to enhance

material efficiency in cooperation with supply-chain partners (see ISO 14052). While organizations

are encouraged to implement MFCA based on ISO 14051, depending on levels of operations, they may

prefer a more simplified approach to MFCA. To address this need, this document provides guidance

for organizations to initiate a phased implementation of MFCA. This approach focuses on the most

relevant production process to enhance material efficiency along with cost reductions, possibly leading

to additional business opportunities (e.g. a green supply chain).This document can be used independently of ISO 14051 and ISO 14052. However, the basic philosophy

of MFCA as well as the terms and definitions are the same as in ISO 14051. In addition, this document

has been designed to help organizations to identify new business opportunities regarding material

and energy efficiency. Large organizations can also use this document as a starting point for their

implementation of MFCA in a specific department or process.This document provides:

— common terminologies;

— principles;

— a calculation approach, analysis and improvement;

— an application of the MFCA implementation result.

Annex A gives a case example of an MFCA implementation in organizations.

© ISO 2020 – All rights reserved v

---------------------- Page: 5 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 14053:2020(E)

Environmental management — Material flow cost

accounting — Guidance for practical implementation in

SMEs

1 Scope

This document gives practical guidelines for the phased implementation of material flow cost accounting

(MFCA) that organizations, including small and mediumsized enterprises (SMEs), can adopt to enhance

their environmental performance and material efficiency.The phased approach provides flexibility that allows organizations to develop their MFCA activities at

their own pace, according to their own circumstances. The resulting information can act as a motivator

for organizations to seek opportunities to simultaneously generate financial and environmental

benefits by reducing material losses and energy consumption.This document is applicable to any organization, regardless of its level of development, the nature of its

activities, or the location at which these activities occur.This document provides basic calculation procedures to analyse saving potentials by avoiding material

losses. Detailed calculation procedures or information on techniques for improving material or energy

efficiency are out of the scope of this document.2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purpose of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at http:// www .electropedia .org/

3.1

energy cost

cost for electricity, fuels, steam, heat, compressed air and other like media

Note 1 to entry: Energy cost can be either included under material cost or quantified separately, at the discretion

of the organization.[SOURCE: ISO 14051:2011, 3.4]

3.2

energy use

application of energy

EXAMPLE Ventilation; lighting; heating; cooling; transportation; data storage; production process.

Note 1 to entry: Energy use is sometimes referred to as “energy end-use”.[SOURCE: ISO 50001:2018, 3.5.4]

© ISO 2020 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/FDIS 14053:2020(E)

3.3

material

substance that enters and/or leaves a process

Note 1 to entry: Materials can be divided into two categories:

— materials that are intended to become part of products, e.g. raw materials, auxiliary materials, intermediate

products;— materials that do not become part of products, e.g. cleaning solvents and chemical catalysts, which often are

referred to as operating materials.Note 2 to entry: Some types of materials can be classified into either category, depending on their use. Water is

one such material. In some cases, water can become part of a product (e.g. bottled water), while in other cases it

can be used as an operating material (e.g. water used in an equipment washing process).

Note 3 to entry: Energy carriers like fuels or steam can be identified as materials, at the discretion of the

organization.[SOURCE: ISO 14051:2011, 3.10, modified]

3.4

material flow cost accounting summary sheet

MFCA summary sheet

spreadsheet that reflects the MFCA (3.6) information for a production process that is treated as a

single process3.5

material cost

cost for a substance that enters and/or leaves a process

Note 1 to entry: Material cost can be calculated in various ways, e.g. standard cost, average cost, and purchase

cost. The choice between cost calculation methods is at the discretion of the organization.

[SOURCE: ISO 14051:2011, 3.12, modified]3.6

material flow cost accounting

MFCA

tool for quantifying the flows and stocks of materials (3.3) in processes or production lines in both

physical and monetary units[SOURCE: ISO 14051:2011, 3.15]

3.7

material loss

all material outputs generated in a process, except for intended products

Note 1 to entry: Material losses include air emissions, wastewater and solid waste, even if these material outputs

can be reworked, recycled or reused internally, or have market value.Note 2 to entry: By-products can be considered as either material losses or products, at the discretion of the

organization.[SOURCE: ISO 14051:2011, 3.16, modified]

3.8

system cost

cost incurred in the course of inhouse handling of the material (3.3) flows, except for material cost

(3.5), energy cost (3.1) and waste management cost (3.9)EXAMPLE Cost of labour; cost of depreciation and maintenance; cost of transport.

[SOURCE: ISO 14051:2011, 3.21]

2 © ISO 2020 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/FDIS 14053:2020(E)

3.9

waste management cost

cost of handling material losses (3.6) generated in a process

[SOURCE: ISO 14051:2011, 3.22, modified — The notes to entry have been deleted.]

4 Principles

4.1 Understand the basic material flow and energy use

The material flows related to products and energy use, including material losses in the most relevant

production process, are identified and quantified as physical data.4.2 Ensure the reliability of physical data

Physical data on material flows and energy use are collected in consistent measurement units.

NOTE Refer to ISO 14033 Quantitative Environmental Information.4.3 Estimate and attribute costs to material losses and energy use

The costs associated with material losses and energy use are estimated, and these costs are attributed

to the material losses and energy use.4.4 Link physical and monetary data

Decision-making on environmental and management issues within organizations is supported by

linking physical data with associated cost.5 Cost calculations in a phased approach

5.1 General

Data on material flows and energy use should be translated into monetary units to support decision-

making according to the cost calculations. This process consists of one preparationphase, four

calculation-phases and one analytical phase. Organizations can incrementally implement MFCA as

indicated in 5.2 to 5.7.5.2 Preparation phase — Identification of the most relevant production process in the

organizationThe organization should identify its most relevant production process. If there is a single production

process in the organization, all of the material losses and energy use should be examined. If multiple

processes are present, the organization can select either the most relevant production process or

multiple processes as one single production unit for calculation.A selection approach for the most relevant production process should be divided into two steps:

a) assess the magnitude of the different material losses and energy use;b) select the process with a high raw material unit cost, large volume of material losses and defective

products, etc. as the most relevant production process.If the organization wants to assess several relevant processes, adoption of ISO 14051 is recommended.

© ISO 2020 – All rights reserved 3---------------------- Page: 8 ----------------------

ISO/FDIS 14053:2020(E)

5.3 Calculation phase 1 — Quantification of material flows in physical units

The amounts of material inputs and outputs should be quantified in physical units such as mass, length,

number of pieces or volume, depending on the type of materials. Outputs are divided into products and

material losses.5.4 Calculation phase 2 — Calculation of material costs and waste management costs

Cost calculations should be started with material costs. This includes costs related to the materials

used in the most relevant production process which may include raw materials, auxiliary materials,

operating materials and intermediate products. The costs of all material inputs are assigned to

products and material losses according to the physical quantity. In addition, waste management costs

are calculated.5.5 Calculation phase 3 — Calculation of energy costs

The calculation of energy costs is at the discretion of the organization. When it is determined to be

necessary, energy costs should be calculated and allocated to products and material losses according to

the physical data quantified in calculation phase 1.5.6 Calculation phase 4 — Calculation of system costs

The calculation of system costs is at the discretion of the organizatio

...

DRAFT INTERNATIONAL STANDARD

ISO/DIS 14053

ISO/TC 207 Secretariat: SCC

Voting begins on: Voting terminates on:

2019-07-16 2019-10-08

Environmental management — Material flow cost

accounting — Guidance for practical implementation in

SMEs

ICS: 13.020.20

THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 14053:2019(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2019

---------------------- Page: 1 ----------------------

ISO/DIS 14053

ISO/DIS 14053:2019(E)

Contents Page

Foreword ................................................................................................................................................... iv

Introduction ................................................................................................................................................ v

1 Scope ............................................................................................................................................. 1

2 Terms and definitions .................................................................................................................. 1

3 Principles ...................................................................................................................................... 3

3.1 Understand basic material flow and energy use ....................................................................... 3

3.2 Ensure reliability of physical data .............................................................................................. 3

3.3 Estimate and attribute costs to material losses ........................................................................ 3

3.4 Link physical and monetary data ................................................................................................ 3

4 Cost calculations in a phased manner for SMEs ...................................................................... 3

4.1 General .......................................................................................................................................... 3

4.2 Preparation phase: Identification of the most relevant production process in SMEs .......... 3

4.3 Calculation phase 1: Quantification of material flows in physical units ................................ 3

4.4 Calculation phase 2: Calculation of material costs and waste management costs .............. 3

4.5 Calculation phase 3: Calculation of energy costs .................................................................... 4

4.6 Calculation phase 4: Calculation of system costs .................................................................... 4

4.7 Analytical phase: Analysis of material loss costs .................................................................... 4

5 Calculation format in a phased manner and development of improvement plans ............... 4

5.1 General .......................................................................................................................................... 4

5.2 MFCA summary sheet .................................................................................................................. 4

5.3 Template for preparation phase .................................................................................................. 5

5.4 Template for calculation phase 1 ................................................................................................ 6

5.5 Template for calculation phase 2 ................................................................................................ 6

6 Extended approach ...................................................................................................................... 8

Annex (informative) ................................................................................................................................... 9

Bibliography ............................................................................................................................................. 14

COPYRIGHT PROTECTED DOCUMENT© ISO 2019

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

© ISO 2019 – All rights reserved iii

Published in Switzerland

ii © ISO 2019 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 14053:2019(E)

ISO/DIS 14053

Contents Page

Foreword ................................................................................................................................................... iv

Introduction ................................................................................................................................................ v

1 Scope ............................................................................................................................................. 1

2 Terms and definitions .................................................................................................................. 1

3 Principles ...................................................................................................................................... 3

3.1 Understand basic material flow and energy use ....................................................................... 3

3.2 Ensure reliability of physical data .............................................................................................. 3

3.3 Estimate and attribute costs to material losses ........................................................................ 3

3.4 Link physical and monetary data ................................................................................................ 3

4 Cost calculations in a phased manner for SMEs ...................................................................... 3

4.1 General .......................................................................................................................................... 3

4.2 Preparation phase: Identification of the most relevant production process in SMEs .......... 3

4.3 Calculation phase 1: Quantification of material flows in physical units ................................ 3

4.4 Calculation phase 2: Calculation of material costs and waste management costs .............. 3

4.5 Calculation phase 3: Calculation of energy costs .................................................................... 4

4.6 Calculation phase 4: Calculation of system costs .................................................................... 4

4.7 Analytical phase: Analysis of material loss costs .................................................................... 4

5 Calculation format in a phased manner and development of improvement plans ............... 4

5.1 General .......................................................................................................................................... 4

5.2 MFCA summary sheet .................................................................................................................. 4

5.3 Template for preparation phase .................................................................................................. 5

5.4 Template for calculation phase 1 ................................................................................................ 6

5.5 Template for calculation phase 2 ................................................................................................ 6

6 Extended approach ...................................................................................................................... 8

Annex (informative) ................................................................................................................................... 9

Bibliography ............................................................................................................................................. 14

© ISO 2019 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 14053:2019(E)

ISO/DIS 14053

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national

standards bodies (ISO member bodies). The work of preparing International Standards is normally

carried out through ISO technical committees. Each member body interested in a subject for which a

technical committee has been established has the right to be represented on that committee.

International organizations, governmental and non-governmental, in liaison with ISO, also take part

in the work. ISO collaborates closely with the International Electrotechnical Commission (IEC) on all

matters of electrotechnical standardization.International Standards are drafted in accordance with the rules given in the ISO/IEC Directives,

Part 2.The main task of technical committees is to prepare International Standards. Draft International

Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies

casting a vote.Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all of such patent rights.

ISO 14053 was prepared by ISO/TC 207, Environmental management, Working Group 8, Material

flow cost accounting.This is the first edition of ISO 14053.

iv © ISO 2019 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/DIS 14053:2019(E)

ISO/DIS 14053

Introduction

Companies of any size face the challenge from the market, to reduce costs in order to remain

competitive or increase competitiveness. Achieving the Sustainable Development Goals (SDGs) as

set out by the United Nations in 2015 has become a high priority for society. Especially, Goal 12

requires governments as well as private sectors to ensure sustainable consumption and production

patterns. For small and medium-sized enterprises (SMEs), the need to achieve improvements in

material and energy efficiency for sustainable production is equally higher as for large organisations.

A series of international standards provide guidance on material flow cost accounting (MFCA) – an

approach to assess material efficiency within an organization (ISO 14051) and the approach and

opportunities to enhance material efficiency in cooperation with supply-chain partners (ISO 14052).

While SMEs are encouraged to implement MFCA based on ISO 14051, they may prefer more

simplified approach for MFCA. In this regard, ISO 14053 provides guidance for SMEs to initiate a

phased implementation of MFCA. This approach focuses on the most relevant production process

for their enhancement of material- efficiency along with cost-reduction, possibly leading to additional

business opportunities (e.g. a green supply-chain).The standard can be used independently of ISO 14051 and ISO 14052. However, the basic

philosophy of MFCA as well as the terms and definitions are the same as in ISO 14051. In addition ,

the standard has been designed to help SMEs to identify new business opportunities regarding

material efficiency. Large organisations can also use this standard as a starting point for their

implementation of MFCA in a specific department or process.This International Standard provides the following:

common terminologies,

principle,

calculation approach, analysis and improvement, and

application of MFCA implementation result.

In addition, the annex illustrates a case example of MFCA implementation in SMEs.

© ISO 2019 – All rights reserved v---------------------- Page: 5 ----------------------

ISO/DIS 14053:2019(E)

---------------------- Page: 6 ----------------------

ISO/DIS 14053:2019(E)

Draft International Standard ISO 14053

Environmental management – Material flow cost accounting – Guidance for practical

implementation in SMEs1 Scope

This International Standard provides practical guidance for implementation of Material Flow Cost Accounting

(MFCA) in the most relevant production process of small and medium -sized enterprises (SMEs). Under MFCA,

the flows and stocks of materials within SMEs are traced and quantified in physical units (e.g. mass, volume)

and the costs associated with those material flows are also evaluated. The resulting information can act as a

motivator for SMEs to seek opportunities to simultaneously generate financial and environmental benefits by

reducing material loss and energy consumption.This Standard is designed for an independent standard for SMEs to implement MFCA in a phased manner. This

Standard is applicable to any SMEs, regardless of its level of development, the nature of activities undertaken

or the location at which these activities occur.This Standard provides basic calculation procedures to analyse saving potentials by avoiding material losses.

Detailed calculation procedures or information on techniques for improving material or energy efficiency are out

of the scope of this Standard.2 Terms and definitions

For the purpose of this document, the following terms and definitions apply.

2.1

energy cost

cost for electricity, fuels, steam, heat, compressed air and other like media

NOTE Energy cost can be either included under material cost or quantified separately, at the discretion of the

organization.[ISO 14051:2011, definition 3.4]

2.2

energy use

manner or kind of application of energy

EXAMPLE Ventilation; lighting; heating; cooling; transportation; processes; production lines.

[ISO 50001:2011, definition 3.18]2.3

material

substance that enters and/or leaves a quantity centre

NOTE 1 Materials can be divided into two categories, as follows:

materials that are intended to become part of products, e.g. raw materials, auxiliary materials, intermediate

products;materials that do not become part of products, e.g. cleaning solvents and chemical catalysts, which often are

referred to as operating materials.© ISO 2019 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO/DIS 14053:2019(E)

ISO/DIS 14053

[ISO 14051:2011, definition 3.10]

2.4

MFCA summary sheet

a spreadsheet that reflects the MFCA information for a production process that is treated as a single quantity

centre2.5

material flow cost accounting

MFCA

tool for quantifying the flows and stocks of materials in processes or production lines in both physical and

monetary units[ISO 14051:2011, definition 3.15]

2.6

material loss

all material outputs generated in a quantity centre, except for intended products

NOTE 1 Material losses include air emissions, wastewater and solid waste, even if these material outputs can

be reworked, recycled or reused internally, or have market value.NOTE 2 By-products can be considered as either material losses or products, at the discretion of the

organization.[ISO 14051:2011, definition 3.16]

2.7

quantity centre

selected part or parts of a process for which inputs and outputs are quantified in physical and monetary units

[ISO 14051:2011, definition 3.20]2.8

system cost

cost incurred in the course of in-house handling of the material flows, except for material cost, energy cost and

waste management costEXAMPLE Cost of labour; cost of depreciation and maintenance; cost of transport.

[ISO 14051:2011, definition 3.21]

2.9

waste management cost

cost of handling material losses generated in a quantity centre

[ISO 14051:2011, definition 3.22]

2 © ISO 2019 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/DIS 14053:2019(E)

ISO/DIS 14053

3 Principles

3.1 Understand basic material flow and energy use

The material flows to products and material losses and energy use in the most relevant production process

are identified and quantified as physical data.3.2 Ensure reliability of physical data

Physical data on material flows and energy use is collected in consistent measurement units, preferably mass

for material flows.3.3 Estimate and attribute costs to material losses and energy use

The costs associated with material losses and energy use are estimated, and these costs are attributed to the

material losses and energy use.3.4 Link physical and monetary data

Decision-making on environmental and management issues within SMEs are supported by linking physical data

with associated cost.4 Cost calculations in a phased manner for SMEs

4.1 General

Data on material flows and energy use should be translated into monetary units to support decision-making

according to the cost calculations. This process contains one preparation-phase, four calculation-phases and

one analytical phase. SMEs can incrementally implement MFCA as indicated in the following.

4.2 Preparation phase: Identification of the most relevant production process in SMEs

SMEs should identify the most relevant production process. In case of a single production process in SMEs, all

of the material losses and energy use should be examined. If multiple processes are present, SMEs can select

either the most relevant production process or multiple processes as one single production-unit for calculation.

A selection approach for the most relevant production process should be divided into two steps:

First step – Estimate magnitude of the different material losses and energy use, and

Second step – Select the process with high raw material unit cost, large volume of material losses and

defective products, etc. as the most relevant production process.4.3 Calculation phase 1: Quantification of material flows in physical units

Amounts of material inputs and outputs should be quantified in physical units such as mass, length, number of

pieces, or volume, depending on type of materials. Outputs are divided into products and material losses.

NOTE: Depending on the industry, further output may occur that are not related to the product, e.g. emissions,

waste water flows, and auxiliary losses. It is not always recommendable to treat those outputs as material loss.

4.4 Calculation phase 2: Calculation of material costs and waste management costs

Cost calculations should be started with material costs. This includes costs related to these m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.